Escolar Documentos

Profissional Documentos

Cultura Documentos

Esteem Presentation

Enviado por

monugeni0 notas0% acharam este documento útil (0 voto)

126 visualizações68 páginashttp://www.esteemprojects.com

Esteem is a leading supplier and contractor for Fired Heaters (Heaters, Cracking Furnaces, Reformers, Waste Heat recovery Units, Process Furnaces) and related equipment to the Hydrocarbon and Chemical industries spanning Oil & Gas, Petrochemical, Refining, Fertilizer and related sectors.

Design, supply and construction of Fired Heaters (from Turnkey projects to revamps) designed to API 560 or other international standards form the core of our business. We have capabilities to provide furnaces based on our own design or the design supplied by clients/ consultants.

Visit us at: www.esteemprojects.com

Direitos autorais

© © All Rights Reserved

Formatos disponíveis

PDF, TXT ou leia online no Scribd

Compartilhar este documento

Compartilhar ou incorporar documento

Você considera este documento útil?

Este conteúdo é inapropriado?

Denunciar este documentohttp://www.esteemprojects.com

Esteem is a leading supplier and contractor for Fired Heaters (Heaters, Cracking Furnaces, Reformers, Waste Heat recovery Units, Process Furnaces) and related equipment to the Hydrocarbon and Chemical industries spanning Oil & Gas, Petrochemical, Refining, Fertilizer and related sectors.

Design, supply and construction of Fired Heaters (from Turnkey projects to revamps) designed to API 560 or other international standards form the core of our business. We have capabilities to provide furnaces based on our own design or the design supplied by clients/ consultants.

Visit us at: www.esteemprojects.com

Direitos autorais:

© All Rights Reserved

Formatos disponíveis

Baixe no formato PDF, TXT ou leia online no Scribd

0 notas0% acharam este documento útil (0 voto)

126 visualizações68 páginasEsteem Presentation

Enviado por

monugenihttp://www.esteemprojects.com

Esteem is a leading supplier and contractor for Fired Heaters (Heaters, Cracking Furnaces, Reformers, Waste Heat recovery Units, Process Furnaces) and related equipment to the Hydrocarbon and Chemical industries spanning Oil & Gas, Petrochemical, Refining, Fertilizer and related sectors.

Design, supply and construction of Fired Heaters (from Turnkey projects to revamps) designed to API 560 or other international standards form the core of our business. We have capabilities to provide furnaces based on our own design or the design supplied by clients/ consultants.

Visit us at: www.esteemprojects.com

Direitos autorais:

© All Rights Reserved

Formatos disponíveis

Baixe no formato PDF, TXT ou leia online no Scribd

Você está na página 1de 68

2014

Noida (Head Ofce & Works)

B-39, Sector-67,

Noida, UP 201301

Ph.: 0120 6491904/ 05/ 06

Delhi

Subhash Chowk, Laxmi Nagar,

Delhi 110092

Ph.: 011 22043491/ 92

Baddi (Workshop)

K.No. 1027-1030/369, Bhud Road,

Gullarwala, Baddi (H.P)

Ph. : 01795 657001

Email: epl@esteemprojects.com Web: www.esteemprojects.com

ESTEEM PROJECTS PVT. LTD.

Fired Heaters and related equipment

Constructive Solutions

ESTEEM

2

Track record of providing complete satisfaction to clients, always.

WE PROVIDE TURNKEY SOLUTIONS FOR FIRED HEATERS

Design, Supply and Revamp of Fired Heaters/

Crackers/ Reformers as per API-560 and other

international standards forms the core of our

business.

Esteem undertakes all activities from Detail

Engi neeri ng to Revamps & Turnarounds to

Complete Turnkey Projects.

Over the past 20 years we have built a solid

reputation for cost effective reliable and timely

services.

About Esteem

DHDT Heater & HGU Reformer by Esteem at IOCL-BGR

Introduction

Constructive Solutions

ESTEEM

3

Mechanical

Design

Procurement

& Supply

Detail

Engineering

Shop

Fabrication

Site

Fabrication

& Installation

Pre-

commissioni

ng and

commissioni

ng

Revamps &

Rebuilds

Services Provided

Our Credentials

Constructive Solutions

ESTEEM

4

Services Provided

! Structural design, detail engineering, fabrication, supply, eld

installation, instrumentation & controls, pre-commissioning and

commissioning of Fired Heaters (heaters/ crackers/ reformers in

modular/ conventional design) conforming to the latest pollution

norms.

! Supply and erection of air pre-heating/ steam super heating systems.

! Supply and erection of shop/ site fabricated equipment.

! Supply, fabrication and erection of plant/ yard piping in CS/ SS/ AS

materials.

! Erection and alignment of rotary equipment.

! Supply & eld installation of refractory lining.

! Procurement, expediting & inspection of indigenous / imported

material.

FOR NEW INSTALLATIONS QUALITY

At Esteem, Quality is the first

and foremost concern.

Over the last decade we have

built a reputation for reliability

and exceptional quality of

services.

Our repeat clients are a

testimonial to the trust we

enjoy as a result of our

painstaking attention to detail

and the drive for perfection in

whatever we do.

We would love to help you

interact with any of our past

clients to discuss about our

work.

Introduction

Constructive Solutions

ESTEEM

5

New Heaters by Esteem (partial list)

! Ketene Furnace for LOIL, Mahad

! Ketene Furnace for Jubilant Life Sciences Ltd., Nira

! 4 nos. (39 Mmkcal/hr) Naptha Cracking Furnaces for BCPL,

Lepetkata (In progress)

! Regeneration Gas Heater for BCPL, Lepetkata

! Reformer Package for 25,000 TPA Hydrogen Generation Unit at

Indian Oil Corporation Ltd. (BR Unit), India

! DHDT Heater Package (12.7 MMKcal/hr) at IOCL-BGR, India

! NG Preheater (4.48 Gcal/Hr) at SFC, Kota, India

! Dehydration Reactor feed Heater B-110B (4.59 Gcal/Hr)

! Dehydration Reactor feed Heater B-110A

! Primary Reformer for 14,500 MTPY Hydrogen Plant at HPCL,

Mumbai, India (through ITT-Kirchner Italia)

Our Credentials

Constructive Solutions

ESTEEM

6

Recent revamp jobs by Esteem

Our Credentials

Job Title Client Brief Scope Year Service

Replacement of E3203

Mixed Feed Superheat

Coil

IFFCO, Aonla, UP Replacement of entire coil including ITS, ETS 2014 Steam

Revamp of LRVPS

Heater

HPCL, Mumbai

New Convection Section, Lifting of heater by

1m. Replacement of radiant tubes and shell

2014 Crude

Revamp of Hot Oil

Heater

IOCL - Bongaigaon

Renery

Replacement of Convection Coil and Refractory 2013 Hot Oil

Revamp of Heater

B-110B

India Glycols Ltd.,

Kashipur

Replacement of leaking BFW Coils 2012

Reactor

feed

Revamp of Heater

B-110

India Glycols Ltd.,

Kashipur

Detail Engineering and Replacment of Radiant

and Convection panels and refractory, skin

thermocouples, ETSs, portion of stack

2012

Reactor

feed

APH and Duct Revamp

Numaligarh Renery

Ltd.

Revamp of Cast APH, Ducting, Expansion

joints and emergency vent of Hydrogen

reformer FG circuit incl. detail engineering

2012 HGU

Constructive Solutions

ESTEEM

7

Consulting and related jobs

Our Credentials

Job Title Client Brief Scope

Project management and Erection

Consultancy

TCI Sanmar Chemicals

S.A.E, South Port Said,

Egypt

Erection supervision and

consultancy for erection of

new Heater

Expert services Numaligarh Renery Ltd. Performance of APH

Consultancy Service for failure

analysis of BOD-2AA

Chemplast Sanmar Ltd.

Analysis of reasons of failure of

components of Heater

BOD-2AA

Consultancy services for

investigating reasons for

permature failure of RE-4C

furnace coil at Chemplast Sanmar

Ltd. Mettur Dam and suggesting

remedial measures.

Chemplast Sanmar Ltd.

Consultancy services for

investigating reasons for

permature failure of RE-4C

furnace coil at Chemplast

Sanmar Ltd. Mettur Dam and

suggesting remedial measures.

Constructive Solutions

ESTEEM

8

Details of some recently executed jobs

Job Details

Constructive Solutions

ESTEEM

9

Name of Job: LRVPS Heater

Client: HPCL, Mumbai

Consultant: EIL

Heat Duty: 27 MMkcal/hr

Tonnage: 230 MT

Supplied as: 4 nos. complete convection

modules (13m long) were

supplied from our Baddi

works

Ducting supplied in pre-

fabricated form

Job Details

Constructive Solutions

ESTEEM

10

Job Details

Constructive Solutions

ESTEEM

11

Job Details

Constructive Solutions

ESTEEM

12

Job Details

Constructive Solutions

ESTEEM

13

Name of Job: Regeneration Gas

Heater

Client: BCPL

Consultant: EIL

Heat Duty: 5.37 MMkcal/hr

Tonnage: 100MT

Supplied as: Complete Modules

Job Details

Constructive Solutions

ESTEEM

14

Modular Fabrication of Vertical Cylindrical Heater at Esteem, Baddi works

Radiant Shell (Fabricated in three petals)

Radiant Coil (Fabricated in four hairpins)

Convection Section : Fabricated in two completely

built modules including duly hydrotested coil and

dried-out refractory.

Stack: Fabricated in two modules. Dispatched duly

refractory lined and dried out.

Platforms: Fabricated in ready to install panels.

Regeneration Gas

Heater for BCPL

Job Details

Constructive Solutions

ESTEEM

15

Complete Radiant Section in

assembled condition

Radiant Shell Petals dismantled for

painting and dispatch

Job Details

Constructive Solutions

ESTEEM

16

Radiant Coil prefabricated in hairpin form

Job Details

Constructive Solutions

ESTEEM

17

Refractory lined conv. panels Prefabricated Conv. Coil

Dried-out refractory

Conv.

modules

post-dryout

Job Details

Constructive Solutions

ESTEEM

18

Convection modules ready for dispatch

Module being loaded onto trailer

Convection modules in assembled condition

Job Details

Constructive Solutions

ESTEEM

19

Stack under fabrication

Complete stack after refractory dry-out

(with damper installed)

Job Details

Constructive Solutions

ESTEEM

20

Circular Radiant Platforms

under fabrication

Convection Platforms under

fabrication

Job Details

Constructive Solutions

ESTEEM

21

Name of Job: Naptha Cracking

Furnaces

Client: BCPL

Consultant: EIL

Heat Duty: 39 Mmkcal/hr x 4

Tonnage: 1525 MT (725 MT

supplied from Baddi)

Supplied as: Panels

Job Details

Constructive Solutions

ESTEEM

22

Box Heater Fabricated at Esteem, Baddi works

Stacks Transistion Sections Radiant Arch Radiant Walls Radiant Floor

Job Details

Constructive Solutions

ESTEEM

23

Various panels for BCPL Cracker Furnaces

Job Details

Constructive Solutions

ESTEEM

24

Job Details

Erection of convection modules

Weight : 55 MT

Length : 7.6 m

Width : 2.3 m

Height : 2.5 m

Constructive Solutions

ESTEEM

25

Erection supervision and construction management for heater at TCI, Egypt

Designed by Born

Heaters, Canada

Erection supervision by

Esteem

Radiant:

L = 13 m

B = 5 m

H = 8.1 m

Constructive Solutions

ESTEEM

26

Constructive Solutions

ESTEEM

27

Modular Fabrication of VC Heater for IGL, Kashipur

Convection section fabricated and erected in three modules

Job Details

Constructive Solutions

ESTEEM

28

Modular Fabrication of VC Heater for IGL, Kashipur

Stack fabricated in two modules complete

with platforms and ladders

Job Details

Constructive Solutions

ESTEEM

29

Job Details

HGU Reformer for IOCL-BGR

Constructive Solutions

ESTEEM

30

Job Details

DHDT Heater for IOCL-BGR

Constructive Solutions

ESTEEM

31

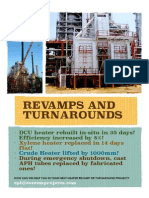

DCU-1 Revamp at IOCL-BGR Please see separate presentation specific to heater revamp

1

2

4

3

Job Details

Constructive Solutions

ESTEEM

32

Modular Fabrication of DCU Heater for IOCL-BGR

Prefabricated

convection

modules complete

with ITS and ETS

Job Details

Constructive Solutions

ESTEEM

33

Modular Fabrication of DCU Heater for IOCL-BGR

Pre-fabrication of Radiant Coils

Radiant Coil modules ready for erection

Job Details

Constructive Solutions

ESTEEM

34

Modular Fabrication of DCU Heater for IOCL-BGR

Conv. module being erected Conv. module being erected Module erected

Radiant coil erection Radiant coil erected

Job Details

Constructive Solutions

ESTEEM

35

Modular Construction

Modular Construction

" The most frequent application of modular construction is the convection section of a

fired heater or heat recovery unit. This comprises of the convection coils (bare +

finned/ studded tubes) with associated bends, fittings & flanges, end and

intermediate tube sheets, refractory and casing with structural members. Modular

construction can be executed to any level, even to complete heaters, with platforms,

burners, piping, duct work and instrumentation installed, keeping in view

transportation & handling limitations.

" Main Advantages include:

" Better quality due to controlled shop environment

" Reduced site activities

" Cost/ time advantages

Constructive Solutions

ESTEEM

36

Design for modular construction

Modular Construction

" Modular construction activity starts with design phase itself

" Points to keep in mind include:

" Structural integrity of modules

" Design for ease of transportation

" Design for ease of erection

" Design for easy interface between parts/ modules

" Ensuring completeness of module in all respects to reduce site activities

Constructive Solutions

ESTEEM

37

Specics for Fired Heater Modularization

Modular Construction

Factors to consider

" Configuration & Type

" Dimensions

" Weight

" Refractory Type

" Other Factors

" External Piping and Ducting

" Stack

Constructive Solutions

ESTEEM

38

Specics for Fired

Heater Modularization

Modular Construction

a) Box heater with arbor coiI b) CyIindricaI heater with

heIicaI coiI

c) Cabin heater with horizontaI

tube coiI

d) Box heater with verticaI tube

coiI

e) CyIindricaI heater with

verticaI coiI

f) Box heater with horizontaI

tube coiI

14

" Radiant Structure

" Box

" Double Box

" Vertical Cylindrical

" Convection

" Top mounted/ ground mounted

" Stack

" Top mounted/ ground mounted

" APH?

" Fans and other equipment?

Configuration & Type

Constructive Solutions

ESTEEM

39

Modular Construction

Horizontal

Delayed Coker

EDC Cracking

Hydrocracker

Vaccum

Hydrocracker

Hydrotreater Charge

Reboilers

Vertical Tube Box

Steam reforming

Ammonia

Hydrogen

Methanol

Ethylene Cracking

Hydrocracker

Arbor

Catalytic Reforming

Aromatics

Vertical Cylindrical

Crude

Vaccum

Atmospheric

Hot Oil

Regeneration

Most services

These are well suited for

modularization

Can be dispatched as

complete radiant, or

Petals of shell and Coil

Segments

Coils can be supplied in

arbors welded to

manifolds for shipment

and quick installation.

Entire Radiant can be

dispatched in refractory

lined condition or in

panels

Coils can be dispatched

in pre-fabricated

bundles ready for eld

installation.

For wall mounted

conguration, entire

Radiant can be sent as

a single module

Alternatively, coils can

be transported in

hairpins

R

a

d

i

a

n

t

C

o

i

l

T

y

p

e

M

o

d

u

l

a

r

i

z

a

t

i

o

n

Constructive Solutions

ESTEEM

40

Specics for Fired Heater Modularization

Modular Construction

Dimensions and Weight

" Heaters can be dispatched in single piece modules having weight around 500-600MT.

" Complete convection modules can be dispatched (refractory lined and coils hydrotested)

" Larger heater radiant sections can be dispatched in duly painted panels (with or without

refractory).

" Rough correlation with heater heat duty:

" < 10MM Kcal Complete heater can be dispatched in a single piece including platforms,

instrumentation, etc. Only items left will be stack and equipment like fans, etc.

" 10-40 MM Kcal Radiant and Convection can be dispatched in one or more modules

" > 40 MM Kcal Radiant Section can be dispatched from our works in modules / panels and

assembled at the port. Convection section can be dispatched in modules having module to

module bolted connections.

Constructive Solutions

ESTEEM

41

Specics for Fired Heater Modularization

Modular Construction

Refractory

" Ceramic Fibre blanket and module lining is most conducive for heater modularization due to its

low weight and good support arrangement.

" CF lining can be applied both in shop fabricated modules and/ or panels before dispatch.

" Sections having castable lining are also dispatched duly refractory lined from workshop. Castable

lining needs to be pre-dried out at shop before dispatch.

" Brick lining is generally not preferred to be installed and dispatched from shop.

" For site assembly in the form of panels/ modules, modularization needs to be factored-in in the

refractory design also. Joints and interfaces need to be designed for ease of installation of good

performance.

Constructive Solutions

ESTEEM

42

Facilities

PEOPLE

We are what our people are.

At Esteem, our people are of

paramount importance.

The company lays special

emphasis on training and

overall development of its

employees. They are

provided with regular training

and workshops to keep them

updated with the latest

trends in the industry.

Our rigorous recruitment

process ensures best talent

is selected.

Esteem provides equal

employment opportunity.

Overview

Noida HO

Design & Engineering

Procurement

Planning

Accounting & Finance

Noida

Workshop

Fabrication of Smaller Fired Heater

Modules & Panels

Fabrication of Dampers, Doors,

Tubesheets, Supports, etc.

Baddi

Workshop

Fabrication of Fired Heater Modules & Panels

Pre-fabricate piping of entire plant in knocked

down condition

Fabrication of Pressure Vessels

Pre-fabricated sturctures

Our Delhi ofce has been shifted to Noida. The old ofce premises shall be retained for correspondence and future requirements.

Sites Sites

Facilities

Constructive Solutions

ESTEEM

43

Facilities

Baddi Workshop

Facilities

" Fully equipped workshop specifically for Fired heaters and related components

" ~ 70,000 Sq. ft total area (6500 Sq. m)

" Two bays of 246 ft x 50 ft (75m x 15m) each

" Covered module fabrication area available : ~ 24,220 Sq. ft (2250 sq.m)

" Each bay has one EOT crane of 20MT (Additional two planned)

" Loading facility of upto 120 MT planned

" External crane available upto 300MT

" Complete gamut of fabrication facilities available in-house

" In-house surface preparation and painting facility

" Company has approved welding procedures for almost all commonly used metallurgy in Fired

heaters.

" Easy and clear access for transportation of large modules and over dimension cargo

" Currently the maximum size of single module that can be fabricated at our Baddi works is:

14.5 x 14.5 x 70 m of 100 MT (However, the supplies are limited by transportation constraints)

" Further assembly can be done near port to form larger modules as per barge size limitations

Constructive Solutions

ESTEEM

44

Facilities

Baddi Workshop

Facilities

Prefabricated plant piping and skid mounted equipment

By using 3D modeling and markup techniques, we can design the plant/ unit piping in a modular

fashion. Pre-fabricated pipe spools can be shipped from workshop complete after NDT and

hydrotest.

Pre-fabricated piping helps in achieving:

- better quality due to controlled shop atmosphere

- shorter time schedule

- reduction in site activities

- lower costs

Our workshop has facilities for fabrication and supply of equipment skids complete with all

instruments and accessories. These skids can be designed based on transportation

requirements and suitable site splices locations can be provided.

Constructive Solutions

ESTEEM

45

Facilities Baddi workshop

Constructive Solutions

ESTEEM

46

Facilities Baddi workshop

Constructive Solutions

ESTEEM

47

Facilities Baddi workshop

Constructive Solutions

ESTEEM

48

Facilities

Noida Workshop

" Fully equipped workshop specifically for smaller fired heaters modules and components

" ~ 8,611 Sq. ft total area (800 Sq. m)

" Covered fabrication area available : ~ 3,500 Sq. ft (325 sq.m)

" EOT crane of 25MT

" Max size for single piece convection module : 3.5m x 3.0m x 20m weighing upto 25MT

" Complete gamut of fabrication facilities available in-house

" In-house surface preparation and painting facility

" Easy and clear access for transportation of modules and over dimensional cargo

" Orders executed include:

" Complete Ketene Cracking furnace for Jubilant Life Sciences Ltd., Nira

" Complete Ketene Cracking furnace for Laxmi Organic Industries Ltd., Mahad

" High criticality dampers for IOCL-BGR

Facilities Noida workshop

Constructive Solutions

ESTEEM

49

Facilities Noida workshop

VC heater Shell plates being fabricated at our Noida works

Constructive Solutions

ESTEEM

50

Facilities Noida workshop

Ventillation Air dampers for HGU

Reformer at IOCL-BGR

Damper with 99.5% sealing at 900C

design temp for IOCL, BGR

Cast access doors for heater Cast peep doors for heater

Constructive Solutions

ESTEEM

51

Facilities

Noida HO

Design / Drawing Related Software

Available

Autocad 2010

Autodesk Revit Structure 2010

Autodesk Structural Detailer 2010

Graitec Advance Steel 2014

STAAD Pro

StruMIS

EasyCFD

OpenFOAM + Code Saturne

Hardware Facilities

Central File Server with ne grained

access control

Centralized hourly data snapshots

Redundant storage and power

supplies

Online Backup

In-house plotting facility

Latest Thinkcenter Workstations

Gigabit LAN

VPN connection

Data Protection

At Esteem, control of Client/

Consultants drawings and

documents are given top

priority. Employees are

informed about the usage

rights and restrictions and

same is strictly enforced.

Safeguarding of data is very

important and we have an

hourly backup system which

ensures minimum data loss

in case of unexpected

outages. Redundant disks

for storage with redundant

power supplies provide

added data safety.

Facilities

Constructive Solutions

ESTEEM

52

Facilities

Noida HO

Facilities - HO

" All design, detailing, procurement, planning and accounting related activities are

performed from our Noida office

" 7000 Sq. ft of fully equipped design office

" Latest software & hardware facilities

" Licensed software available 3D modeling, detailing, structural design, CFD, FEA

" Company owns licenses for ERP specific for Fabrication Industry. The software

provides end-to-end data integration from modelling -> procurement -> material

management -> Fabrication

" Own building with complete power backup and redundant 24 hr internet

connectivity

Constructive Solutions

ESTEEM

53

Facilities

Near Port

" We have an arrangement with a major clearing and forwarding company at Kandla

port for dispatch of modules.

" Cranes & Axles for handling of heavy modules are available on hire.

" The company has long experience of handling heavy modules at port.

" This firm has handled many ODC jobs at Kandla port

" They have handled and dispatched cargo as large as 40 x 8 x 8 m of around 550 MT

Logistics

Constructive Solutions

ESTEEM

54

Module Logistics

Location Length (m) Width (m) Height (m) Weight (MT)

Baddi Works 70 14.5 14.0 100

Inland

Transportation to

Kandla port

30 5 6 200/ 500

Handling at

Kandla port

24 15 20.5 ~ 600

Notes:

1. For inland transportation, single shipment weight above 200MT would require special permissions from

authorities.

2. These are approximate values as on date.

Logistics

Constructive Solutions

ESTEEM

55

Facilities

Near Port

Logistics

Constructive Solutions

ESTEEM

56

Facilities

Near Port

Logistics

Constructive Solutions

ESTEEM

57

Why choose Esteem?

" Dedicated to quality

Own workshop for entire heater manufacturing including coils, structure, painting and refractory.

" Knowledge

We are proud to have a team having unmatched experience in fabrication of Fired Heaters.

Due to companys sole focus on Fired Heaters, our people have been trained in the intricacies

of Fired heater fabrication.

- We know what impact an air tight firebox has on heater performance

- We know the codes (IS, ASME, IBR etc.)

- We know about welding and heat treatment like few others

- Dependent on design/service, we manufacture heaters for a run-life of approx 8 yrs

" Economical

Competent pricing. Low overheads. Quick Action.

- HGU Reformer

- DCU Revamp

- Naptha Crackers

Esteem has 100% winning rate for EIL tenders for Fired Heaters where we have bid.

" Ability to work in difficult environment

- Executed major jobs in Assam

- Recently successfully completed supervision of site erection of fired heater in Egypt

Constructive Solutions

ESTEEM

58

Our Credentials

Constructive Solutions

ESTEEM

59

Our Major Clients

Credentials

Constructive Solutions

ESTEEM

60

From: pjjr1@sanmargroup.com

Subject: Revamping

Date: 18 June 2013 12:18 pm

To: Esteem Projects Pvt. Ltd. epl@esteemprojects.com

Cc: Singh, Gurinder gurinder@esteemprojects.com, Oberoi M S msoberoi@esteemprojects.com, Singh, Tan

tanveer@esteemprojects.com

Bcc:

Mr.Gurcharan singh,

I appreciate your team has done a good job for the furnaces coil replacing.

Especially I appreciate Bhavesh Yadav who had involved the jobs in

depth,good planning and good follow up.Because of his good forecasting and

planning almost most of the jobs done in time and nally RE2C completed

with in very shortest period. He is an Good and growing knowledgeable

Engineer.

Also people who have done with out any injury is also appreciable for

taking care of safety by each and every one.

regards

P.James Johnson Rajamani

The information contained in this message is legally privileged and condential information intended only for

addressed individual or entity indicated in this message (or responsible for delivery of the message to such p

be read, copied, disclosed, distributed or used by any person other than the addressee. Unauthorised use, disclosu

strictly prohibited and may be unlawful. Opinions, conclusions and other information on this message that do not re

business of any of the constituent companies of the SANMAR GROUP shall be understood as neither given nor

Group.

If you have received this message in error, you should destroy this message and kindly notify the sender by e-ma

Thank you.

* * * * * * * * * * * * * * * * * * * * * * * * * * * * * *

RE2C completed within very

shortest period

Words of Appreciation

Credentials

Revamp of RE2C at Chemplast Sanmar

Constructive Solutions

ESTEEM

61

The entire job was meticulously planned

& executed during shutdown period of

thirty five days

Words of Appreciation

Credentials

Revamp of DCU-1 PH-II at IOCL-BGR

Constructive Solutions

ESTEEM

62

The professional approach and the technical

competence displayed by the team was

appreciable.

Words of Appreciation

Credentials

Constructive Solutions

ESTEEM

63

No major/ minor flaws in construction of heater.

Words of Appreciation

Credentials

Constructive Solutions

ESTEEM

64

Completed the job in scheduled time. The

performance is satisfactory.

Words of Appreciation

Credentials

Constructive Solutions

ESTEEM

65

The critical job has been completed ahead of

schedule. We are satisfied with the quality of

work, and also professional approach and

dedication displayed by the team.

Words of Appreciation

Credentials

Constructive Solutions

ESTEEM

66

We appreciate the professional approach and

dedication of M/s Esteem Projects towards the

job.

Words of Appreciation

Credentials

Constructive Solutions

ESTEEM

67

Reformer Package for DHDS Project

is working satisfactory since March

27, 2000. Till today we are not

having any problem.

Words of Appreciation

Credentials

Constructive Solutions

ESTEEM

68

Thanks for your attention!

Esteem Projects Pvt. Ltd.,

Address: B-39, Sector-67, Noida, UP 201301, India Ph: 0120 6491904/05/06 Email: epl@esteemprojects.com Web.: www.esteemprojects.com

Você também pode gostar

- 3s Steam BoilerDocumento13 páginas3s Steam BoilertahirAinda não há avaliações

- Penjelasan TLEsDocumento28 páginasPenjelasan TLEsFauzi IhsanAinda não há avaliações

- Esteem Brochure CombinedDocumento12 páginasEsteem Brochure CombinedmonugeniAinda não há avaliações

- Curves MLX-MLN 106-021Documento2 páginasCurves MLX-MLN 106-021Andres SanchezAinda não há avaliações

- IFC Inflow UK-Loading Arms & SkidsDocumento16 páginasIFC Inflow UK-Loading Arms & SkidslpczyfansAinda não há avaliações

- Curvas Blackmer MLX4Documento12 páginasCurvas Blackmer MLX4JulianAinda não há avaliações

- FW Utility Boiler PDFDocumento12 páginasFW Utility Boiler PDFChandan AulakhAinda não há avaliações

- Ben FieldDocumento10 páginasBen FieldashmitharajaAinda não há avaliações

- Lecore Manual PV Breather ValvesDocumento14 páginasLecore Manual PV Breather Valveskeshri roushanAinda não há avaliações

- Driving Expander TechnologyDocumento24 páginasDriving Expander TechnologysajadranjbaranAinda não há avaliações

- BS EN 14420-6 2013 Hose Fittings With Clamp UntitsDocumento54 páginasBS EN 14420-6 2013 Hose Fittings With Clamp UntitsevgenyAinda não há avaliações

- Tranfer Line Exchangers PDFDocumento28 páginasTranfer Line Exchangers PDFNaveen MeenaAinda não há avaliações

- TP PC 11 02Documento16 páginasTP PC 11 02Khoirul Walad100% (1)

- IntercambiadorDocumento2 páginasIntercambiadorIr Go JarAinda não há avaliações

- HVAC Package-3 - SITC of AHU - Section - 3Documento18 páginasHVAC Package-3 - SITC of AHU - Section - 3FarzanaShaik100% (1)

- Fired Heaters - Fired Capital Equipment Key Plant ComponentsDocumento4 páginasFired Heaters - Fired Capital Equipment Key Plant ComponentsReyes SanchezAinda não há avaliações

- Cryogel Pipe Install ManualDocumento35 páginasCryogel Pipe Install ManualDiego CarrascalAinda não há avaliações

- Callidus Low Nox Staged Gas Burner CSGL PDFDocumento3 páginasCallidus Low Nox Staged Gas Burner CSGL PDFReyes SanchezAinda não há avaliações

- ROCKWOOL© Technical InsulationDocumento36 páginasROCKWOOL© Technical InsulationHaytham ElsayedAinda não há avaliações

- Ud He TechnologyDocumento16 páginasUd He TechnologyBejavada Suresh100% (1)

- Replacement of A Secondary Reformer: Guy WillemsenDocumento15 páginasReplacement of A Secondary Reformer: Guy Willemsenvaratharajan g rAinda não há avaliações

- KSFL ReportDocumento56 páginasKSFL ReportAbhishek KumarAinda não há avaliações

- Castable-Free Fired HeaterDocumento4 páginasCastable-Free Fired HeaterchemengseliemAinda não há avaliações

- Electric Heaters For Safe Startup ofDocumento9 páginasElectric Heaters For Safe Startup ofSteve WanAinda não há avaliações

- Control TechnologiesDocumento51 páginasControl TechnologiesrajuAinda não há avaliações

- KM 111Documento12 páginasKM 111Jak AshishAinda não há avaliações

- Heaters Film and BulkDocumento24 páginasHeaters Film and BulkFathy Adel FathyAinda não há avaliações

- Process Data Sheet of Incinerator Package Unit 113X-X1: Biturox ProjectDocumento15 páginasProcess Data Sheet of Incinerator Package Unit 113X-X1: Biturox ProjecthhvgAinda não há avaliações

- High Emissivity CoatingDocumento12 páginasHigh Emissivity CoatingĐoàn TrangAinda não há avaliações

- UOP PSA Polysep Membrane Integration Case StudyDocumento1 páginaUOP PSA Polysep Membrane Integration Case StudyamitAinda não há avaliações

- Model LibraryDocumento119 páginasModel Librarydongjinzong2004Ainda não há avaliações

- EDO-PPP-ME-GNR-INT-XXX-013-107-108-Rev-A-AMMONIA STORAGE TANK DESIGN PDFDocumento33 páginasEDO-PPP-ME-GNR-INT-XXX-013-107-108-Rev-A-AMMONIA STORAGE TANK DESIGN PDFErol DAĞ100% (1)

- WSAC Alternative To CWDocumento47 páginasWSAC Alternative To CWweweqweqwAinda não há avaliações

- PSA Operation ManualDocumento83 páginasPSA Operation ManualAbassyacoubouAinda não há avaliações

- Sa 193&sa 193M PDFDocumento18 páginasSa 193&sa 193M PDFGabriel RodríguezAinda não há avaliações

- Surface CondenserDocumento7 páginasSurface Condensermhd_bashiriAinda não há avaliações

- P 3 2 e 12 150dpi19 5772 PDFDocumento12 páginasP 3 2 e 12 150dpi19 5772 PDFkeyur1109Ainda não há avaliações

- Bimetallic Steam Traps (Velan)Documento36 páginasBimetallic Steam Traps (Velan)Ebn egg100% (1)

- Replacement of Reformed Gas Waste Heat Boiler at Ammonia Plant... !!!!! X 0Documento12 páginasReplacement of Reformed Gas Waste Heat Boiler at Ammonia Plant... !!!!! X 0David PierreAinda não há avaliações

- Job Spec - Package - B224-114-80-43-SP-7204Documento11 páginasJob Spec - Package - B224-114-80-43-SP-7204Esakki muthuAinda não há avaliações

- Fired HeatersDocumento19 páginasFired HeatersCelestine OzokechiAinda não há avaliações

- PDQ Process - Process - ThyssenKrupp Industrial SolutionsDocumento2 páginasPDQ Process - Process - ThyssenKrupp Industrial SolutionsIhwan LimantoAinda não há avaliações

- Tank Heating CoilDocumento2 páginasTank Heating CoilchongchoifattAinda não há avaliações

- Dehydration Plant Twenty Years PaperDocumento5 páginasDehydration Plant Twenty Years Papersejerson07Ainda não há avaliações

- Nps 38 CFDocumento16 páginasNps 38 CFGauden Marie C. BangngayAinda não há avaliações

- Reciprocating CompressorsDocumento5 páginasReciprocating CompressorsthirumalaiAinda não há avaliações

- Instrumentation For Fired Heaters IP 15-1-1: ScopeDocumento14 páginasInstrumentation For Fired Heaters IP 15-1-1: ScopeLuis Alonso Aguirre LopezAinda não há avaliações

- XP Flare Article ReprintDocumento5 páginasXP Flare Article ReprintAnonymous cuOIjrLIAinda não há avaliações

- Ammonia Converter FailureDocumento15 páginasAmmonia Converter FailureAnonymous UoHUagAinda não há avaliações

- Fired Heater-CombustionDocumento29 páginasFired Heater-Combustionsreeau128Ainda não há avaliações

- Sa 423Documento6 páginasSa 423Widya widyaAinda não há avaliações

- Process DescriptionDocumento6 páginasProcess Descriptionافكر اشتري كورياAinda não há avaliações

- 002-BS PD 7777Documento12 páginas002-BS PD 7777Madhubalan PAinda não há avaliações

- Failure of Primary Waste Heat BoilerAiche-12-008Documento5 páginasFailure of Primary Waste Heat BoilerAiche-12-008Hsein Wang100% (1)

- Carbon CaptureDocumento13 páginasCarbon CaptureShubhalaxmi SwainAinda não há avaliações

- Steam Reforming Common ProblemsDocumento61 páginasSteam Reforming Common ProblemsBilalAinda não há avaliações

- Esteem Projects Pvt. LTD.: Noida, IndiaDocumento66 páginasEsteem Projects Pvt. LTD.: Noida, IndiamonugeniAinda não há avaliações

- Design and Fabrication of Galvanized Coated SteamDocumento4 páginasDesign and Fabrication of Galvanized Coated Steamieee4mybusinessonlyAinda não há avaliações

- AB&Co Brochure EnglishDocumento5 páginasAB&Co Brochure EnglishTony LimAinda não há avaliações

- Bwe Aph-GghDocumento20 páginasBwe Aph-GghDaniellzhangAinda não há avaliações

- Pressure Vessel FlyerDocumento1 páginaPressure Vessel FlyermonugeniAinda não há avaliações

- Winheat - Fired Heater Simulation and Rating SoftwareDocumento1 páginaWinheat - Fired Heater Simulation and Rating SoftwaremonugeniAinda não há avaliações

- Esteem Projects - The Fired Heater CompanyDocumento1 páginaEsteem Projects - The Fired Heater CompanymonugeniAinda não há avaliações

- Esteem-Brochure-Concise UpdatedDocumento20 páginasEsteem-Brochure-Concise UpdatedmonugeniAinda não há avaliações

- Esteem Projects Pvt. LTD.: Noida, IndiaDocumento66 páginasEsteem Projects Pvt. LTD.: Noida, IndiamonugeniAinda não há avaliações

- Length of Helical Pipe Coil Dia MM No. of Turns Nos. Height of Each Turn MMDocumento1 páginaLength of Helical Pipe Coil Dia MM No. of Turns Nos. Height of Each Turn MMmonugeniAinda não há avaliações

- Esteem - The Fired Heater CompanyDocumento49 páginasEsteem - The Fired Heater CompanymonugeniAinda não há avaliações

- Esteem Revamps and Turnarounds of Fired HeatersDocumento2 páginasEsteem Revamps and Turnarounds of Fired HeatersmonugeniAinda não há avaliações

- Esteem Design and Engineering For Fired HeatersDocumento2 páginasEsteem Design and Engineering For Fired HeatersmonugeniAinda não há avaliações

- Emerging Technologies in EducationDocumento345 páginasEmerging Technologies in EducationKhritish SwargiaryAinda não há avaliações

- Internet of ThingsDocumento29 páginasInternet of ThingsRochelle SiolaoAinda não há avaliações

- Project Communication PlanDocumento5 páginasProject Communication PlanCraig VanceAinda não há avaliações

- Setup Prometheus Monitoring On KubernetesDocumento6 páginasSetup Prometheus Monitoring On KubernetesAymenAinda não há avaliações

- Tiny PPT198Documento2 páginasTiny PPT198HerlinaAinda não há avaliações

- Terex Elrest SPSDocumento20 páginasTerex Elrest SPSLuis jopi50% (2)

- Visual Basic 2019 Made Easy: by DR - LiewDocumento41 páginasVisual Basic 2019 Made Easy: by DR - LiewAnup AravindakshanAinda não há avaliações

- GIGABYTE GA-H81M-DS2 Mainboard ManualDocumento32 páginasGIGABYTE GA-H81M-DS2 Mainboard Manualcr33pz1llaAinda não há avaliações

- Implementation of 1-Bit Full Adder Circuit Using Pass Transistor LogicDocumento11 páginasImplementation of 1-Bit Full Adder Circuit Using Pass Transistor LogicIJRASETPublicationsAinda não há avaliações

- Saeed Mohamed Ahmed Gooda - SEDocumento1 páginaSaeed Mohamed Ahmed Gooda - SEsaeedgooda219Ainda não há avaliações

- Readme FpgaDocumento5 páginasReadme Fpgabima saktiAinda não há avaliações

- Downloads Pqsine S 1 16 16Documento1 páginaDownloads Pqsine S 1 16 16SANDRO RAUL HUAMANI PIZARROAinda não há avaliações

- As 2282.8-1999 Methods For Testing Flexible Cellular Polyurethane Determination of Force DeflectionDocumento2 páginasAs 2282.8-1999 Methods For Testing Flexible Cellular Polyurethane Determination of Force DeflectionSAI Global - APACAinda não há avaliações

- SEO AdTech Dave ChaffeyDocumento44 páginasSEO AdTech Dave ChaffeysrinivasAinda não há avaliações

- Pandit Deendayal Energy University School of Technology: 21BCP430D Pranjal M. PatelDocumento42 páginasPandit Deendayal Energy University School of Technology: 21BCP430D Pranjal M. PatelDevasya PatelAinda não há avaliações

- 2406 Protomat s3 Serie ManualDocumento112 páginas2406 Protomat s3 Serie ManualOctavio AvendañoAinda não há avaliações

- FTire AnimationDocumento6 páginasFTire Animationhimanshuvermac3053Ainda não há avaliações

- Lexicology Coursebook (Nguyễn Mạnh Hùng)Documento33 páginasLexicology Coursebook (Nguyễn Mạnh Hùng)duongnguyen4105Ainda não há avaliações

- Vsphere Data Protection 5.5 Advanced - DatasheetDocumento2 páginasVsphere Data Protection 5.5 Advanced - DatasheetOscarAinda não há avaliações

- Indian Company List - MalaysiaDocumento21 páginasIndian Company List - MalaysiaNavajyoti DasAinda não há avaliações

- CHEAT Harvest Moon Back To Nature PSXDocumento7 páginasCHEAT Harvest Moon Back To Nature PSXSetiawan Budi NugrohoAinda não há avaliações

- Mark Scheme End of Year Exam: EDPM Paper 2 Question 1 (Copy Test) Total 10 Marks AccuracyDocumento6 páginasMark Scheme End of Year Exam: EDPM Paper 2 Question 1 (Copy Test) Total 10 Marks AccuracyJanicSmithAinda não há avaliações

- Brijesh Rai M-9811784242 E Mail: Brijeshrai1977@yahoo - Co.inDocumento3 páginasBrijesh Rai M-9811784242 E Mail: Brijeshrai1977@yahoo - Co.ininderAinda não há avaliações

- Testking - Isc.cissp - Exam.q.and.a.v31.0 DduDocumento537 páginasTestking - Isc.cissp - Exam.q.and.a.v31.0 DduSatyanarayan Bale100% (3)

- User Manual RadWin 1000Documento124 páginasUser Manual RadWin 1000Jairson Gomez BolañosAinda não há avaliações

- Elwave ManualDocumento109 páginasElwave ManualNo Name100% (1)

- Registration Form in JavaDocumento5 páginasRegistration Form in JavazubairAinda não há avaliações

- Capturing Audio Streams With Acoustic Echo Cancellation and BeamformingDocumento12 páginasCapturing Audio Streams With Acoustic Echo Cancellation and BeamformingAdam CadmonAinda não há avaliações

- Template TutorialDocumento3 páginasTemplate Tutorialcomicguy68100% (1)

- Allen Kyle ResumeDocumento2 páginasAllen Kyle ResumeJB July SantanderAinda não há avaliações