Escolar Documentos

Profissional Documentos

Cultura Documentos

AHU Operational Control Spreadsheet Training

Enviado por

niti8600 notas0% acharam este documento útil (0 voto)

180 visualizações17 páginasHVAC

Título original

AHU Operational Control Spreadsheet Training Doc

Direitos autorais

© © All Rights Reserved

Formatos disponíveis

PDF, TXT ou leia online no Scribd

Compartilhar este documento

Compartilhar ou incorporar documento

Você considera este documento útil?

Este conteúdo é inapropriado?

Denunciar este documentoHVAC

Direitos autorais:

© All Rights Reserved

Formatos disponíveis

Baixe no formato PDF, TXT ou leia online no Scribd

0 notas0% acharam este documento útil (0 voto)

180 visualizações17 páginasAHU Operational Control Spreadsheet Training

Enviado por

niti860HVAC

Direitos autorais:

© All Rights Reserved

Formatos disponíveis

Baixe no formato PDF, TXT ou leia online no Scribd

Você está na página 1de 17

1

HVAC Special Working Group

Spin III

Web v.1

Section Title

Air Handling Unit

Operational Control

Spreadsheet Training

Objectives

3

To provide a tool for systematic review of AHU performance

Paper based or Excel spreadsheet based

For use by operations and maintenance personnel

Applies logical checks

Illogical outcomes highlighted for investigation

Layout

Macro tools

One for RH system, one for heating systems

Determine desired AHU status from temp & RH requirements

Determine room needs from temp & RH requirements

Check sheet

Customise sheet per AHU

Include design operational control parameters

4

Macro tools

Assessment Tools- allows the

operator to determine the

desired status of the AHU

based on air temp & RH.

(i.e. should the AHU be in

dehum mode based on outside

temp and RH

Also determines the room

requirements.

5

AHU Condition Assessment Tool

Outside Air Temperature-Enter value between

-20

0

C and 35

0

C

Relative Humidity-Insert

value between 0% and

100%

Fresh Air Requirements-Insert value

between 0% and 100%

AHU Supply Air Condition-

Insert value between 5

0

C

and 25

0

C

AHU Supply Air

condition-Insert

value between 0%

and 100%

AHU Conditions Required

Red-Heating

Blue-Cooling

Green Rehumification

Blue-Dehumification

Indicates Room

Requirement

Insert Room

Temperature and

Humidity

Specifications

between 15

0

C to 25

0

C

and 0% To 100%

AHU Return Air

Requirements-

Insert value between

5

0

C and 25

0

C

AHU Return Air

Condition-Insert

value between 0%

and 100%

Check sheet

7

Enter AHU Number Insert Description of AHU

including location and

areas served by AHU

Insert Date (Format 03 Mar

10)

Insert Time (24 Hour Clock

format e.g. 16.45)

Insert Room Humidification

Requirement from Macro Tool

DeHum

Rehum

N/A (when Dehum or Rehum are

not required)

Enter Room

Heating

Requirements-

Heating

Cooling

None

Insert AHU Humidification

Status from Macro Tool

DeHum

Rehum

N/A (when Dehum or

Rehum are not required)

Enter AHU

Heating Status-

Heating

Cooling

None

AHU Set point Status & Conditions

Insert design supply air temperature and

humidity set points.

Insert the Original Supply Air

Volume and Return Air

Volume set points.

Insert Filter dP

limits.

Insert actual setpoint values

from BMS screen

Insert value for

each of the

conditions from

BMS screen

Insert commissioning

report data.

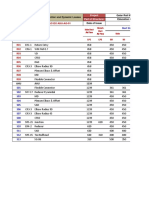

AHU Set up Check

Determine Result from Building

Management System (BMS). Enter

Yes No or N/A. Red colour indicates

incorrect result/problem on system

Determine Result from BMS.

When mixing section is fixed

enter N/A.

Determine Results from

BMS. Enter Yes, No or N/A

Determine result from BMS. View

trends for Control Valves, Speed etc

to determine if record is stable.

Enter Yes No or N/A

Confirm on BMS

room pressure

operating according

to specification.

Enter Yes, No or N/

A

AHU Operating Situation

Enter AHU pre-heating value which

can be obtained from BMS.

Enter AHU pre-cooling value which

can be obtained from BMS.

Enter cooling valve data from

BMS.

Enter heating valve data from

BMS.

Enter pre-dehumidifcation value data

from BMS.

Enter de-humidifcation

value data from BMS.

Enter heat recovery data from BMS. If heat recovery

fixed record 100% for running and enter 0% if heat

recovery is not running

Enter fresh air and

mixing air data from

BMS.

AHU Conditions

Enter AHU mode. This has already been

determined in Macro status Section.

Consult Macro Section when entering

value.

Determine if heating and cooling valves

are open at same time.

When heating is required heat recovery

should be the first stage of heating.

When cooling is required heat recovery

should be off. Enter yes, No or N/A

Free cooling from outside should be maximized when

available, and should be the first stage of cooling.

If outside air is colder than return air then100% fresh air

should be used before chilled water.

Free heating from outside should be maximized when available, and

should be the first stage of heating if outside air is hotter than return air

then in this case 100% fresh air should be used before heat recovery or

LPHW.

Determine if

the rooms

supplied by

AHU are within

specification for

temp and RH.

Using the Macro Status

information determine if

the AHU is achieving

the conditions required

for each room.

Determine if the

heating/Cooling

valves are operating

at 100% If answer is

Yes then a system is

maxed out and may

indicate a problem.

AHU Conditions

Determine DeHum mode from

Macro Status for AHU. Determine if the AHU is carrying out

DeHum and Re-Hum at the same time.

One should always be at 0%.

Determine if chilled water Pre-DeHum is

maximized when Dehum is required.

(Pre-DeHum with chilled water is cheaper than

dessicant drying, and therefore the Pre-DeHum

should be 100% before dessicant drying

commences)

Determine if Room

temperature

conditions are being

met. When in DeHum

mode or ReHum

mode verify if the

system control the

final temperature of

the rooms.

See the Macro

Status .Determine if

the AHU status match

the room status.

Determine if enthalpy

control is being used

Confirm that the

positions of the exhaust

air and mixing dampers

approximately = 100%

Determine if the fan speed is increasing/decreasing

over time and determine if this can be explained by

filter conditions

Determine if the

statis pressures is

increasing/

decreasing over time

and determine if this

cat be explained by

the filter conditions.

Determine if the fan

power is increasing/

decreasing over time

and determine if this

can be explained by

the filter conditions.

Compare the changes in filter

DP with the filter change

history. Step reductions in DP

should correspond with filter

changes

Use of check-sheet (Paper)

13

Customise worksheet per AHU

Copy insert or delete lines as required

Fill in design data

Fit one or multiple AHU spreadsheets in each page

Print workbook

Use of check-sheet (excel)

Customise worksheet per AHU

Copy insert or delete lines as required

Fill in design data

Fit one or multiple AHU spreadsheets in each page

Complete the spreadsheet

Insert new column for further data entry as per next slide

14

To Copy Cells for Adding Data

15

Highlight Column E of

Excel Sheet. Right

Click and select Copy

Right Click and

select Insert

Copied Cells

Delete Contents of

Copied Cell and add

AHU data as required

Use of check-sheet (excel)

All cells highlighted in red have potential issues causing

excessive energy usage

All issues should be fed into maintenance system on site

Spreadsheet can form part of the operational control clause of

the energy management system

AHU Operational Control

Spreadsheet Training

Você também pode gostar

- Dasco 19-26Documento8 páginasDasco 19-26Ahmed AzadAinda não há avaliações

- Hvac BasicsDocumento20 páginasHvac BasicsRommy Romanza100% (3)

- Vav BoxDocumento20 páginasVav BoxCsiszer RobertAinda não há avaliações

- Ahu DesignDocumento17 páginasAhu DesignMohamed Aboobucker Mohamed IrfanAinda não há avaliações

- Metco 16C 10-040Documento8 páginasMetco 16C 10-040JSH100Ainda não há avaliações

- Duct Leakage PPDocumento62 páginasDuct Leakage PPhbithoAinda não há avaliações

- All About AHUsDocumento24 páginasAll About AHUsrahulAinda não há avaliações

- Ahu 01 (STD)Documento5 páginasAhu 01 (STD)onspsnonsAinda não há avaliações

- Imp For As400Documento21 páginasImp For As400Dinesh ChaudhariAinda não há avaliações

- Duct Leakage Factor Workout SheetDocumento1 páginaDuct Leakage Factor Workout SheetRamakrishna AgumbeAinda não há avaliações

- Ahu SelectionDocumento28 páginasAhu SelectionkaamAinda não há avaliações

- Different Control Strategies For Chiller PlantDocumento19 páginasDifferent Control Strategies For Chiller PlantAnkit AbhinavAinda não há avaliações

- BTU MeterDocumento13 páginasBTU MeterMahesh Sadasivan NairAinda não há avaliações

- AHU Friction Loss CalculationsDocumento4 páginasAHU Friction Loss CalculationsAdnan AttishAinda não há avaliações

- Chiller System BMS PDFDocumento42 páginasChiller System BMS PDFYahya SalemAinda não há avaliações

- AHU OQ & PQ DocumentDocumento12 páginasAHU OQ & PQ DocumentAnurag KumbhareAinda não há avaliações

- Chapter 1-Introduction To Green BuildingsDocumento40 páginasChapter 1-Introduction To Green Buildingsniti860Ainda não há avaliações

- A554 D A2110 DWG A05 510Documento1 páginaA554 D A2110 DWG A05 510Non Etabas Gadnatam100% (1)

- Saiver AHUDocumento12 páginasSaiver AHUNorsyafiqah Rozi100% (1)

- FAHU SubmittalDocumento62 páginasFAHU SubmittalEngr.MmosaadAinda não há avaliações

- State of Patriot MissilesDocumento13 páginasState of Patriot MissilesTaira Mai100% (1)

- FAT HVAC Acceptance Requirements PDFDocumento120 páginasFAT HVAC Acceptance Requirements PDFshant_mAinda não há avaliações

- Air Handling Units Air Handling Units: Technical Catalogue Technical CatalogueDocumento34 páginasAir Handling Units Air Handling Units: Technical Catalogue Technical CatalogueSMBEAUTYAinda não há avaliações

- Part E - 2 - (HVAC) Engineering DesignDocumento69 páginasPart E - 2 - (HVAC) Engineering Designkeya2020Ainda não há avaliações

- Dedicated Outdoor Air Systems (Doas) : Indoor Air Quality + Energy Recovery + Humidity ControlDocumento39 páginasDedicated Outdoor Air Systems (Doas) : Indoor Air Quality + Energy Recovery + Humidity Controlhtanh100% (1)

- Oracle Exadata Technical Series: Smart ScanDocumento59 páginasOracle Exadata Technical Series: Smart ScanVishnusivathej PotukanumaAinda não há avaliações

- AHU Design GuideDocumento37 páginasAHU Design Guidesachin100% (1)

- Chap 10 HvacDocumento30 páginasChap 10 HvacVikrant HaribhaktaAinda não há avaliações

- A Hand Book For The Mechanical Designer Ventilation Duct FanDocumento107 páginasA Hand Book For The Mechanical Designer Ventilation Duct Fanrawneeh100% (6)

- A-Z in HVAC DesignDocumento94 páginasA-Z in HVAC Designniti860100% (1)

- تقرير تدريب صيفي لواء الدين مظفرDocumento23 páginasتقرير تدريب صيفي لواء الدين مظفرlalaAinda não há avaliações

- VAV Terminal UnitsDocumento15 páginasVAV Terminal Unitsckyee88Ainda não há avaliações

- Control Sequences For HVAC SystemsDocumento14 páginasControl Sequences For HVAC SystemsridwanAinda não há avaliações

- DDC Basics HogerDocumento37 páginasDDC Basics HogerharimadhavAinda não há avaliações

- Ahu Performance 2Documento29 páginasAhu Performance 2maddy1667100% (1)

- Hvac Pipe SizingDocumento1 páginaHvac Pipe SizingRaja Antony100% (1)

- Advanced Techniques in Power System Protective Relaying PDFDocumento332 páginasAdvanced Techniques in Power System Protective Relaying PDFshashikant yadavAinda não há avaliações

- Part 10. All-Air Systems - Chapter 4. Dual-Duct System: Table 1 Summarizes The Cooling Load Requirements of 2)Documento1 páginaPart 10. All-Air Systems - Chapter 4. Dual-Duct System: Table 1 Summarizes The Cooling Load Requirements of 2)Karthikeyan SankarrajanAinda não há avaliações

- Acoustic Calculation of Ventilation SystemsDocumento49 páginasAcoustic Calculation of Ventilation SystemsHari Babu DharmavarapuAinda não há avaliações

- Leed Hvac Design Leed Commissioning Jorge Mbo SmriDocumento39 páginasLeed Hvac Design Leed Commissioning Jorge Mbo Smrialmig200Ainda não há avaliações

- Shop Drawing: Welcome Air-Tech (M) SDN BHDDocumento1 páginaShop Drawing: Welcome Air-Tech (M) SDN BHDKarthi KeyanAinda não há avaliações

- Structure Maintainer, Group H (Air Conditioning & Heating): Passbooks Study GuideNo EverandStructure Maintainer, Group H (Air Conditioning & Heating): Passbooks Study GuideAinda não há avaliações

- Sumair Project Report PPT HVACDocumento37 páginasSumair Project Report PPT HVACRishabh SinghAinda não há avaliações

- Ashrae TC DDC Basics PDFDocumento11 páginasAshrae TC DDC Basics PDFDon Roseller DumayaAinda não há avaliações

- Quy Trinh T&C BMS Cho MVAC - Tham KhaoDocumento79 páginasQuy Trinh T&C BMS Cho MVAC - Tham Khaovin ssAinda não há avaliações

- Building management system Complete Self-Assessment GuideNo EverandBuilding management system Complete Self-Assessment GuideAinda não há avaliações

- The Armstrong Humidification HandbookDocumento40 páginasThe Armstrong Humidification HandbookCraig RochesterAinda não há avaliações

- Description of Useful HVAC TermsDocumento64 páginasDescription of Useful HVAC TermsShiyamraj Thamodharan100% (1)

- Need For Balancing ValvesDocumento12 páginasNeed For Balancing ValvesBubai111Ainda não há avaliações

- Chapter 1. Hvac System Analysis and SelectionDocumento20 páginasChapter 1. Hvac System Analysis and SelectionRolando Valdez GutierrezAinda não há avaliações

- 2.6.3.1 Water - Cooled.chiller - Construction.checklistDocumento4 páginas2.6.3.1 Water - Cooled.chiller - Construction.checklistdana setiawanAinda não há avaliações

- HVAC Design For Healthcare Facilities: Course No: M06-011 Credit: 6 PDHDocumento60 páginasHVAC Design For Healthcare Facilities: Course No: M06-011 Credit: 6 PDHNelson VargasAinda não há avaliações

- Daylight Sensor Design and App Guide SGDocumento24 páginasDaylight Sensor Design and App Guide SGniti860Ainda não há avaliações

- Sequence of Operation For Floor Mounted AHUDocumento1 páginaSequence of Operation For Floor Mounted AHUaneesh88Ainda não há avaliações

- General CheckListDocumento3 páginasGeneral CheckListkasandra01Ainda não há avaliações

- Pile Cap Design 4pilesDocumento6 páginasPile Cap Design 4pilesabshawAinda não há avaliações

- VRF & DX Split Type ACU Testing MethodologyDocumento1 páginaVRF & DX Split Type ACU Testing MethodologydamianAinda não há avaliações

- VAV System Air BalancingDocumento3 páginasVAV System Air BalancingShoukat Ali ShaikhAinda não há avaliações

- Air Handler Check ListDocumento3 páginasAir Handler Check Listmnt6176100% (1)

- BMS - Honeywell - R1Documento3 páginasBMS - Honeywell - R1samehAinda não há avaliações

- EAU S1 - Fan SelectionDocumento1 páginaEAU S1 - Fan SelectionMohsin ShaikhAinda não há avaliações

- Technical Overview On AHUDocumento12 páginasTechnical Overview On AHUJahidul IslamAinda não há avaliações

- Sop Hvac 01 Central Chilled Water SystemDocumento18 páginasSop Hvac 01 Central Chilled Water SystemRavi ValiyaAinda não há avaliações

- HVAC System: Fan Coil UnitsDocumento11 páginasHVAC System: Fan Coil UnitsmohamednavaviAinda não há avaliações

- HVAC Professional Heat Load SheetDocumento8 páginasHVAC Professional Heat Load Sheet45saulAinda não há avaliações

- Water-Cooled Series R (TM) RTHD Product ReportDocumento2 páginasWater-Cooled Series R (TM) RTHD Product ReporttrangocvuAinda não há avaliações

- Dq&iq (Hvac) - 2Documento38 páginasDq&iq (Hvac) - 2umair khanAinda não há avaliações

- Kitchen Exhaust/Fresh Air Fan Sequence: To BMS For MonitoringDocumento2 páginasKitchen Exhaust/Fresh Air Fan Sequence: To BMS For MonitoringShiyam SathiyajithAinda não há avaliações

- HVAC ReportDocumento5 páginasHVAC ReportrazahAinda não há avaliações

- TSI PANDA 341 User ManualDocumento38 páginasTSI PANDA 341 User ManualHernan RomeroAinda não há avaliações

- Tsi Panda 341 User ManualDocumento37 páginasTsi Panda 341 User Manuala k bAinda não há avaliações

- Wastematerials Densities DataDocumento1 páginaWastematerials Densities DataDanangMPratomoAinda não há avaliações

- Fire Detection and SuppressionDocumento33 páginasFire Detection and Suppressionniti860Ainda não há avaliações

- SyllabusDocumento16 páginasSyllabusniti860Ainda não há avaliações

- Fire Detection and Suppression: Special Extinguishing SystemsDocumento20 páginasFire Detection and Suppression: Special Extinguishing Systemsniti860Ainda não há avaliações

- 1751 Hvac R CatalogueDocumento38 páginas1751 Hvac R Catalogueniti860Ainda não há avaliações

- Create A PDF File: Exercise 1 and Exercise 2 Produce The Same Result. Choose The One That Works Best For YouDocumento6 páginasCreate A PDF File: Exercise 1 and Exercise 2 Produce The Same Result. Choose The One That Works Best For Youniti860Ainda não há avaliações

- Create A PDF File: Exercise 1 and Exercise 2 Produce The Same Result. Choose The One That Works Best For YouDocumento6 páginasCreate A PDF File: Exercise 1 and Exercise 2 Produce The Same Result. Choose The One That Works Best For Youniti860Ainda não há avaliações

- HVAC Basic NotebookDocumento85 páginasHVAC Basic NotebooksuhandywAinda não há avaliações

- EMT778Documento51 páginasEMT778niti860Ainda não há avaliações

- EMT778Documento51 páginasEMT778niti860Ainda não há avaliações

- Johnson Controls Hvac Equipments Controls Katalog 2010Documento52 páginasJohnson Controls Hvac Equipments Controls Katalog 2010niti860Ainda não há avaliações

- VLOOKUP SHARK WEEK DoawnloadableWorkbook01 StartDocumento22 páginasVLOOKUP SHARK WEEK DoawnloadableWorkbook01 Startsabah8800Ainda não há avaliações

- September 2015Documento2 páginasSeptember 2015Patriziah Marie SeldaAinda não há avaliações

- MS275 10 Inch Compound Miter Saw MB4B2ADocumento4 páginasMS275 10 Inch Compound Miter Saw MB4B2ArightoutacontrolAinda não há avaliações

- Refining Mechanical PulpingDocumento12 páginasRefining Mechanical PulpingMahdia MahmudAinda não há avaliações

- E3 - 5.5.3 - PTAct Troubleshooting Spanning Tree ProtocolDocumento2 páginasE3 - 5.5.3 - PTAct Troubleshooting Spanning Tree ProtocolIvandiAinda não há avaliações

- Grabi Al Jubail ProfileDocumento130 páginasGrabi Al Jubail ProfileSlid ISO100% (1)

- Foundation Design: Exhaust StackDocumento8 páginasFoundation Design: Exhaust Stackmdelacua2Ainda não há avaliações

- Getting Started With Java: Atul PrakashDocumento20 páginasGetting Started With Java: Atul PrakashOwsozeroAinda não há avaliações

- MC1413 D Integrated Circuit 7xdarlington Driver SO16 On SEMIDocumento8 páginasMC1413 D Integrated Circuit 7xdarlington Driver SO16 On SEMIblueword66Ainda não há avaliações

- Hazard-Identification Dec 2015Documento22 páginasHazard-Identification Dec 2015Dumitru EninAinda não há avaliações

- Hindalco Aluminium Catalogue PDFDocumento4 páginasHindalco Aluminium Catalogue PDFVansu Saini0% (1)

- Jura Subito Operating Instructions Automatic 2 Cup Espresso Coffee MachineDocumento15 páginasJura Subito Operating Instructions Automatic 2 Cup Espresso Coffee MachineyangAinda não há avaliações

- Flight DynamicsDocumento57 páginasFlight DynamicsDexto100% (2)

- On The Gaussian Error Function (1935) : Robert J. KolkerDocumento4 páginasOn The Gaussian Error Function (1935) : Robert J. KolkerSanthosh KulandaiyanAinda não há avaliações

- Manual de Instruções John Deere D170 (56 Páginas)Documento2 páginasManual de Instruções John Deere D170 (56 Páginas)Antonio CostaAinda não há avaliações

- Manual Gratis Chery Tig GoDocumento16 páginasManual Gratis Chery Tig GoPaulo Arráiz100% (1)

- While Start Drive Test Learning, You Must Know The Basic Things! These All Conotents Are at Introductory LevelDocumento15 páginasWhile Start Drive Test Learning, You Must Know The Basic Things! These All Conotents Are at Introductory LevelRakesh SolankiAinda não há avaliações

- Toshiba 42pw33q - S Ch. Pw33 SchematicsDocumento18 páginasToshiba 42pw33q - S Ch. Pw33 SchematicstodorloncarskiAinda não há avaliações

- 2014 Summer Model Answer PaperDocumento20 páginas2014 Summer Model Answer Papercivil gpkpAinda não há avaliações

- Parameters by Functional CategoryDocumento6 páginasParameters by Functional Categoryapi-3819698Ainda não há avaliações

- DNF Stand PipeDocumento3 páginasDNF Stand PipeChristopher BrownAinda não há avaliações

- Gsk980Tda Turning Machine CNC System: CharacteristicsDocumento10 páginasGsk980Tda Turning Machine CNC System: CharacteristicsPramod YadavAinda não há avaliações

- ME Harmonization Curricilum FinalDocumento307 páginasME Harmonization Curricilum Finalratchagaraja33% (3)

- Powered by QFD OnlineDocumento1 páginaPowered by QFD OnlineNiswa RochimAinda não há avaliações

- Nitrogen Purge Manifold For C2H2Documento3 páginasNitrogen Purge Manifold For C2H2Abdullah FazilAinda não há avaliações