Escolar Documentos

Profissional Documentos

Cultura Documentos

Enviado por

GatonextDescrição original:

Título original

Direitos autorais

Formatos disponíveis

Compartilhar este documento

Compartilhar ou incorporar documento

Você considera este documento útil?

Este conteúdo é inapropriado?

Denunciar este documentoDireitos autorais:

Formatos disponíveis

Enviado por

GatonextDireitos autorais:

Formatos disponíveis

MultiDrive

English

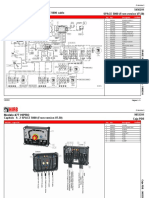

Controller 4F

Technical description

2

Controller 4F for remote control via cable

The controller 4F is a small and robust device that

communicates via CAN cable with a data transfer

rate of 50kBaud. It is designed for secure and

precise manouvering. The circuit boards in the

controller have a special treatment in order to with-

stand tough operation environment and conditions.

The controller is used for e.g. military applications.

Operator friendly user interface

All four lever/functions are exact proportional and

the different functions move according to the ang-

les of the activated levers. The controller is desig-

ned to control Olsbergs hydraulic valves.

Menus

The controller have a menu system with four dif-

ferent menus. The levers can have the same or

different functions in different menus. However one

function can only be operated by one specifc lever.

A distinct LED indicates which menu is activated.

In addition there are four push buttons for on/off

functions of which one is designated for the horn

and the rest for e.g. start, stop and rpm.

Micro control

By activating the toggle switch for micro the resolu-

tion on all levers on the controller can be changed

for operation with higher precision. It is possible to

choose 50% or 20% of normal speed. This is very

useful in narrow passages or when gentle move-

ments are required.

Function

Lever data is translated to a CAN protocol that is

transfered via CAN cables to digital amplifers, DA

modules which are connected on the positioners,

actuators, on the hydraulic valve. The DA modules

convert the data to pulse width modulated currency

that via the solenoid in each positioners controls the

valve spools and thereby the different functions.

The controller communicates also with the overall

safety system if there is one available.

Safety

The hand controller can be locked to prevent un-

authorised persons, such as children, from starting

the controller and being able to operating the applica-

tion.

The system is CE-marked and approved

in accordance with machinery directive

2006/42/EG and MIL-STD 461D.

Release-

knapp

Micro

Micro:

50%

100%

20%

M

e

n

y

O

n

/

O

f

f

k

n

a

p

p

a

r

3

Pos Part. N Description Note

1

2

3

4

5

6

7

8

9

10

11

12

13

14

15

16

17

18

19

20

21

22

1211-K

E1115-K

E0996

E0461

S0238

S2813

S2546

S2818

0499

0498

S0081

E0447

S1618

S1620

S2416

E0501

S2418

S2414

E1114-K

E1113

S2803

S1776

E1128

E1130

E1136

0020

Controller MD 4f

Controller MD 4f, top

Arch, controller

Fittings, carrier strap

Screw MC6S M5x45

Contact chassis

Screw RXK ST2.9x13

Cap, controller MD

Lever, red

Lever, black

Screw MC6S M4x12

Packing, lever

Toggle switch, tri-state

Rubber cover

Push button, red

Stop button, complete

Push button, green

Push button, black

Top box controller

Bottom box, controller

O-ring 180,0x3,0

Screw MC6S M4x20

CAN cable 15,24 m

CAN cable adaptor 1 m alternatively

CAN cable adaptor 3 m

Carrier strap

incl. arch, fittings and levers

incl. fittings

A4 black nickel

incl. screw and packing

incl. screw and packing

A4 black nickel

excluding arch, fittings and levers

70 Shore

A4 black nickel

Controller 4F

Spare parts

1

3

9

6 7

8

2

4

13 14

15

18

19

10

16

22

11

12

5

17

20

Olsbergs Hydraulics AB

Box 17

SE-575 21 EKSJ, Sweden

Phone: +46 (0)381-150 75

Fax: +46 (0)381-140 71

E-mail: hydraulics@olsbergs.se

Olsbergs Electronics AB

Box 267

SE-186 24 VALLENTUNA, Sweden

Phone: +46 (0)8-511 858 50

Fax: +46 (0)8-511 750 05

E-mail: electronics@olsbergs.se

www.olsbergs.se

U

t

g

v

a

1

,

2

0

1

2

-

1

2

-

0

8

Você também pode gostar

- 4075 ECOS ComponentsDocumento27 páginas4075 ECOS ComponentsStanislas Massengo Londe100% (1)

- 07-08, Survey, Electric Diagrams, RCL 5300Documento2 páginas07-08, Survey, Electric Diagrams, RCL 5300Ivailo ZapryanovAinda não há avaliações

- Fasteners Lecture 11-20-03Documento67 páginasFasteners Lecture 11-20-03laponggaAinda não há avaliações

- Draft ITP Pipeline Recertification Pearl OILDocumento3 páginasDraft ITP Pipeline Recertification Pearl OILIrsyad RosyidiAinda não há avaliações

- Smart Traffic Control System Using PLC ScadaDocumento14 páginasSmart Traffic Control System Using PLC ScadaSaravanan ViswakarmaAinda não há avaliações

- Ocs Manual Webb Version Eng2016Documento46 páginasOcs Manual Webb Version Eng2016Gerald Leon FloresAinda não há avaliações

- Steering Unit: EH Electro Proportional Hydraulic Valve In-Line VersionDocumento20 páginasSteering Unit: EH Electro Proportional Hydraulic Valve In-Line VersionbrunosamaeianAinda não há avaliações

- Ing F85B.0.22Documento138 páginasIng F85B.0.22HamarAinda não há avaliações

- Kabel XSDriveDocumento1 páginaKabel XSDriveDozer KamilAinda não há avaliações

- P1 e enDocumento22 páginasP1 e entsdcn100% (1)

- MD2 Relay Box PDFDocumento8 páginasMD2 Relay Box PDFtsdcnAinda não há avaliações

- HIAB 066: Capacity 5-7 TMDocumento92 páginasHIAB 066: Capacity 5-7 TMGerald Leon FloresAinda não há avaliações

- CTL 00Documento3 páginasCTL 00jose luisAinda não há avaliações

- 5000 GBDocumento401 páginas5000 GBcarlos huaya condeAinda não há avaliações

- F415a 455axp 27 PDFDocumento116 páginasF415a 455axp 27 PDFניקולאי איןAinda não há avaliações

- RCL 5300 Instruction Manual 20090219Documento71 páginasRCL 5300 Instruction Manual 20090219Marin Rebić100% (1)

- F700a 800axp 26Documento102 páginasF700a 800axp 26ניקולאי אין100% (1)

- CFJV00198BDocumento360 páginasCFJV00198BCheongAinda não há avaliações

- 7600012-011 Data 7600012-012 Op Manual HETRONIC-Tecnord GA610 03-02Documento20 páginas7600012-011 Data 7600012-012 Op Manual HETRONIC-Tecnord GA610 03-02Sorin Bode100% (1)

- Paltronic 50 EN PDFDocumento2 páginasPaltronic 50 EN PDFJhon Syalfiandy0% (1)

- Catálogo 6 F Display PDFDocumento20 páginasCatálogo 6 F Display PDFbenjaminAinda não há avaliações

- TSS - RX 22-HLDocumento1 páginaTSS - RX 22-HLMedo MedooAinda não há avaliações

- XCMG Iflex5 Operators ManualDocumento69 páginasXCMG Iflex5 Operators ManualIslam AttiaAinda não há avaliações

- Catálogo 8 F DisplayDocumento20 páginasCatálogo 8 F Displaybenjamin100% (2)

- Hetronic-IRC Instruction Manual PDFDocumento29 páginasHetronic-IRC Instruction Manual PDFOliveira eletricidadeAinda não há avaliações

- Installation: Imt Manual #Documento16 páginasInstallation: Imt Manual #Arkadiusz ArkadiuszAinda não há avaliações

- Digital Level - Display DA13Documento16 páginasDigital Level - Display DA13Sergio Belmar CrisostoAinda não há avaliações

- Danfoss - PVG32: Linear LeversDocumento2 páginasDanfoss - PVG32: Linear LeversNovakurniawanAinda não há avaliações

- The Safety System 4.12: Cylinder Pressure LED'sDocumento17 páginasThe Safety System 4.12: Cylinder Pressure LED'sMARCO HernándezAinda não há avaliações

- F1100axp 28Documento128 páginasF1100axp 28Marius Gabriel MunteanuAinda não há avaliações

- Sm0023G2B Training v104 e - ModifyDocumento65 páginasSm0023G2B Training v104 e - ModifyYosmell Fritzan Paz UrbizagasteguiAinda não há avaliações

- ScanrecoP1 2015 01 A e en PDFDocumento20 páginasScanrecoP1 2015 01 A e en PDFtsdcnAinda não há avaliações

- MParts 1055Documento212 páginasMParts 1055Andres Sanchez100% (1)

- LRT JakproDocumento21 páginasLRT JakproAzzah Auliya Ardindasari100% (1)

- d9 VolvoDocumento57 páginasd9 Volvofranklin972100% (2)

- Spare-Parts Book: C-Service 3Documento78 páginasSpare-Parts Book: C-Service 3daniloAinda não há avaliações

- OEMterexRT 130SSC Manual er22301RevDDocumento40 páginasOEMterexRT 130SSC Manual er22301RevDadan felipe romanAinda não há avaliações

- Danfoss VLT FC300 VLT Automation Drive DKDPB13C102Documento16 páginasDanfoss VLT FC300 VLT Automation Drive DKDPB13C102hoor24332Ainda não há avaliações

- Sevcon MOS90 DC Traction and Pump Controller Datasheet1-1734225600Documento41 páginasSevcon MOS90 DC Traction and Pump Controller Datasheet1-1734225600Jay Murphy100% (8)

- Dynamic Series: Instruction Manual For The Use and The Maintenance of The Cable Control UnitDocumento80 páginasDynamic Series: Instruction Manual For The Use and The Maintenance of The Cable Control UnitaaronAinda não há avaliações

- Oil and Wildlife Conservation in UgandaDocumento40 páginasOil and Wildlife Conservation in UgandaAfrican Centre for Media ExcellenceAinda não há avaliações

- Fassi Crane Use and Maintenance Manual Translation of The Original Instructions UM002Documento195 páginasFassi Crane Use and Maintenance Manual Translation of The Original Instructions UM002MANUEL CASTILLOAinda não há avaliações

- Valve pv98 EngDocumento2 páginasValve pv98 EngGerald Leon Flores100% (1)

- 38-17, Software Version 61 - 51Documento5 páginas38-17, Software Version 61 - 51nacho006Ainda não há avaliações

- Kidolgozott PeldakDocumento26 páginasKidolgozott PeldakDankos IstvanAinda não há avaliações

- Bison Lifting PlatformsDocumento8 páginasBison Lifting PlatformsAnonymous mcCJYBoAinda não há avaliações

- Englisch Allgemein Hetronic PDFDocumento32 páginasEnglisch Allgemein Hetronic PDFVerona MamaiaAinda não há avaliações

- Tabla Cargas Grua F4C-892Documento4 páginasTabla Cargas Grua F4C-892Juan Carlos Callas GarayAinda não há avaliações

- Catalog Effer 3504S Hydraulic TankDocumento1 páginaCatalog Effer 3504S Hydraulic Tankary fauzi rahmanAinda não há avaliações

- Fs9qiwltbkdf4dg8demag Ac 40 City 40-Ton All Terrain Crane NetworkDocumento13 páginasFs9qiwltbkdf4dg8demag Ac 40 City 40-Ton All Terrain Crane NetworkTornvald MAinda não há avaliações

- Yamaha RX-V2067, HTR-9063, RX-A2000 PDFDocumento190 páginasYamaha RX-V2067, HTR-9063, RX-A2000 PDFboroda24100% (1)

- Catálogo 6 F DisplayDocumento20 páginasCatálogo 6 F DisplaybenjaminAinda não há avaliações

- F900a 1000axp 24Documento76 páginasF900a 1000axp 24Krum KashavarovAinda não há avaliações

- Tecnord JHM DatasheetDocumento10 páginasTecnord JHM Datasheetfrancisco santiago gallardoAinda não há avaliações

- OpenScape Alarm Response Professional V3, Service Documentation, Issue 1Documento134 páginasOpenScape Alarm Response Professional V3, Service Documentation, Issue 1Vasile Silion0% (1)

- STC1100T6性能表Documento84 páginasSTC1100T6性能表Luciano Amâncio da SilvaAinda não há avaliações

- Powerful Performance With Low Dead Weight and High EfficiencyDocumento8 páginasPowerful Performance With Low Dead Weight and High EfficiencyYusuf JosephAinda não há avaliações

- Sany Crane-Brochure STC250C5-YR1Documento9 páginasSany Crane-Brochure STC250C5-YR1Shayan MehboobAinda não há avaliações

- Control Valve V50Documento18 páginasControl Valve V50vency100% (1)

- 8B0P0220HW00.000-1: 1 General InformationDocumento13 páginas8B0P0220HW00.000-1: 1 General InformationDiego FortunaAinda não há avaliações

- Enerpac-Solenoid Valves CatalogDocumento2 páginasEnerpac-Solenoid Valves CatalogTitanplyAinda não há avaliações

- Bronto+5th Basic Training Book USBDocumento288 páginasBronto+5th Basic Training Book USBxhdsnsxyqsAinda não há avaliações

- Datasheet M42L-AS EN 2017-07Documento2 páginasDatasheet M42L-AS EN 2017-07Benjamin Espinoza Wenzel100% (1)

- Fassi Crane: Use and MaintenanceDocumento14 páginasFassi Crane: Use and MaintenanceДенис ЧерныйAinda não há avaliações

- Manual SerDia2010 EN PDFDocumento217 páginasManual SerDia2010 EN PDFAttila EngiAinda não há avaliações

- Brochure TEC2000Documento5 páginasBrochure TEC2000maom24Ainda não há avaliações

- cjv30 Maintenance V10a PDFDocumento101 páginascjv30 Maintenance V10a PDFEdu100% (1)

- A Mesh-Free Solid-Mechanics ApproachDocumento26 páginasA Mesh-Free Solid-Mechanics ApproachMustafa YildizAinda não há avaliações

- CS 162 Memory Consistency ModelsDocumento22 páginasCS 162 Memory Consistency Modelsravikumarsid2990Ainda não há avaliações

- Technical Information: Chemical Resistance ChartDocumento7 páginasTechnical Information: Chemical Resistance ChartthessandAinda não há avaliações

- A Simplified Two-Stage Method To Estimate The Settlement and Bending Moment of Upper Tunnel Considering The Interaction of Undercrossing Twin TunnelsDocumento32 páginasA Simplified Two-Stage Method To Estimate The Settlement and Bending Moment of Upper Tunnel Considering The Interaction of Undercrossing Twin TunnelsJianfeng XueAinda não há avaliações

- tt130 Ultrasonic Wall Thickness Material Thickness Gauge Instruction Manual PDFDocumento20 páginastt130 Ultrasonic Wall Thickness Material Thickness Gauge Instruction Manual PDFelmek jayaAinda não há avaliações

- National Power Training Institute: Admission Notice: 2020-21Documento3 páginasNational Power Training Institute: Admission Notice: 2020-21a.jainAinda não há avaliações

- 360-Pungue Iwrm Strategy PresentationDocumento30 páginas360-Pungue Iwrm Strategy PresentationEdyz Piedadis PereiraAinda não há avaliações

- The Yield Stress MythDocumento5 páginasThe Yield Stress MythRavi Kiran TađaþanenǐAinda não há avaliações

- Properties of Building Materials and Their Importance in ConstructionDocumento5 páginasProperties of Building Materials and Their Importance in ConstructionDaisy Jane LulabAinda não há avaliações

- CT2000 Manual EN 20151202 PDFDocumento634 páginasCT2000 Manual EN 20151202 PDFKhang NguyenAinda não há avaliações

- Isuzu 4hk1x Sheet HRDocumento4 páginasIsuzu 4hk1x Sheet HRMuhammad Haqi Priyono100% (1)

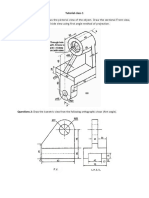

- Tutorial Class 1 Questions 1Documento2 páginasTutorial Class 1 Questions 1Bố Quỳnh ChiAinda não há avaliações

- TT2223 Week 12a Z-TransformDocumento39 páginasTT2223 Week 12a Z-TransformAjiMaulanaAinda não há avaliações

- EMI RFI Generation From LRT SystemsDocumento27 páginasEMI RFI Generation From LRT SystemsShahidan StellarAinda não há avaliações

- Viewnet Diy PricelistDocumento2 páginasViewnet Diy PricelistKhay SaadAinda não há avaliações

- Us06-106 850 01 01 02 PDFDocumento6 páginasUs06-106 850 01 01 02 PDFF2CANALESAinda não há avaliações

- Quarter-Wave Impedance TransformerDocumento4 páginasQuarter-Wave Impedance TransformerEric SkinnerAinda não há avaliações

- The Effects of Crankshaft Offset On The Engine FrictionDocumento15 páginasThe Effects of Crankshaft Offset On The Engine Frictionqingcaohe100% (1)

- Detailed Lesson Plan in Science 5Documento5 páginasDetailed Lesson Plan in Science 5hs4fptm82gAinda não há avaliações

- Data Structure Algorithm Using C PresentationDocumento245 páginasData Structure Algorithm Using C PresentationdhruvwAinda não há avaliações

- Conjoint SpssDocumento28 páginasConjoint SpssstatsoumyaAinda não há avaliações

- Department of Education: Republic of The PhilippinesDocumento14 páginasDepartment of Education: Republic of The PhilippinesRich TactaconAinda não há avaliações

- Hadron XX ManualDocumento41 páginasHadron XX ManualEverton DenardiAinda não há avaliações