Escolar Documentos

Profissional Documentos

Cultura Documentos

Perpan

Enviado por

T Bagus Tri LusmonoDescrição original:

Título original

Direitos autorais

Formatos disponíveis

Compartilhar este documento

Compartilhar ou incorporar documento

Você considera este documento útil?

Este conteúdo é inapropriado?

Denunciar este documentoDireitos autorais:

Formatos disponíveis

Perpan

Enviado por

T Bagus Tri LusmonoDireitos autorais:

Formatos disponíveis

2.

An annular chemical reactor consists of a packed bed of catalyst between two coaxial

cylinders. The inner and outer cylinders have radii of r

0

and r

1

, respectively. It is

reasonable to assume that there is no heat transfer through the surface of the inner

cylinder, which is at a constant temperature T

0

. The catalytic reaction releases heat at a

uniform volumetric rate S throughout the reactor, whose effective thermal

conductivity k may be considered constant. eglect the temperature gradients in the

axial direction.

a! "erive a second#order differential e$uation to describe the radial temperature

distribution in the annular reactor starting with a shell thermal energy balance.

b! %stablish the radial temperature distribution by solving the differential e$uation.

c! &hat viscous flow problem is analogous to this heat conduction problem'

d! "erive an expression for the volumetric average temperature in the reactor.

e! "evelop an expression for the temperature at the outer cylindrical wall of the reactor.

&hat will be the outer wall temperature if both the inner and outer radii are tripled'

a! (tep. "ifferential e$uation from thermal energy balance

)rom a thermal energy balance over a thin cylindrical shell of thickness r in the annular

reactor, we get

*ate of +eat In # ,ut - .eneration / Accumulation

At steady#state, the accumulation term will be 0ero. (o,

(1)

where S is the rate of generation of heat by chemical reaction per unit volume and q

r

is

the heat flux in the radial direction.

"ividing by 1 r L and taking the limit as r tends to 0ero,

(2)

(3)

(ince the effective thermal conductivity k of the reactor bed may be considered

constant, on substituting )ourier2s law 3 ! we get

(4)

b!

(tep. *adial temperature profile by solving differential e$uation

,n integrating,

(5)

The integration constants are determined using the boundary conditions4

(6)

(7)

The first boundary condition suggests no heat transfer through the inner cylindrical wall

of the annulus.

,n substituting the integration constants, the temperature profile is

(8)

c!

(tep. Analogous problem in fluid mechanics

Figure. 5elocity profile in falling film on circular tube is analogous to temperature profile

in annular chemical reactor.

The velocity profile for the falling film on the outside of a circular tube 3see )igure! is

given by4

(9)

(ubstituting aR / r

0

and R / r

1

,

(10)

The maximum velocity 3which occurs at r / r

0

! is

(11)

The difference between the above two e$uations yields

(12)

%$uations 36! and 311! are identical in form. Thus, the analogous viscous flow problem

is the laminar flow of a falling film on theinside of a circular tube. The e$uivalent

$uantities are

(13)

d!

(tep. %xpression for volumetric average temperature

The volumetric average temperature in the reactor may be defined as

(14)

,n substituting the temperature profile in the above expression and integrating

7using 8, we get

(15)

e!

(tep. %xpression for outer wall temperature

The temperature at the outer cylindrical wall 3r / r

1

! of the reactor is given by

(16)

&hen both the inner and outer radii are n times their original values, the term in s$uare

brackets gets multiplied by n

1

and the outer wall temperature is thus given by

(17)

)or the case when both the radii are tripled, n / 9 in the above expression.

1. An electric wire with radius r

0

of 0.:0 mm is made of copper 7electrical

conductivity / :.1 x 10

;

ohm

#1

m

#1

and thermal conductivity / 960 &<3m =!8. It is

insulated 3see figure! to an outer radius r

1

of 1.:0 mm with plastic 7thermal

conductivity / 0.9:0 &<3m =!8.

Figure. +eating of an insulated electric wire.

The ambient air is at 96.0

o

> and the heat transfer coefficient from the outer insulated

surface to the surrounding air is 6.:00 &<3m

1

=!. "etermine the maximum current in

amperes that can flow at steady#state in the wire without any portion of the insulation

getting heated above its maximum allowable temperature of ?9.0

o

>.

(tep. Thermal resistance representation for insulation and air

In general, the heat flow is given by Q / T<R

th

, where T is the temperature driving

force 3thermal potential difference!. The thermal resistance for a cylindrical annulus

is R

th

/ ln 3r

1

<r

0

!<31 kL! and the thermal resistance for a fluid film at a solid#fluid

interface is R

th

/ 1<3hA!. +ere, k is the thermal conductivity, h is the heat transfer

coefficient and A is the surface area for convection.

The thermal resistances for the insulation and air film are in series as shown in the

figure below.

Figure. Thermal resistance representation of insulation and air film.

@ased on the above thermal resistance representation, the heat flow is

(1)

where k is the thermal conductivity of the plastic insulation.

(tep. +eat flow due to current in wire

The flow of an electric current results in some electrical energy getting converted to

thermal energy irreversibly. The heat generation by electrical dissipation per unit volume

is given by S / I

1

<k

e

where I is the current density 3in amp<m

1

! and k

e

is the electrical

conductivity 3in ohm

#1

m

#1

!.

The total heat generated within the wire is simply the product of S and the volume of the

wire. At steady#state, all this heat generated within the wire by electrical dissipation

must leave through the wire surface and therefore the heat flow is given by

(2)

(tep. %xpression for current

,n eliminating Q from the above two e$uations, the current density is

(3)

,n multiplying the current density by the cross#sectional area of the wire, the current is

obtained from

(4)

)or the maximum current, the temperature T

0

must be maximi0ed.

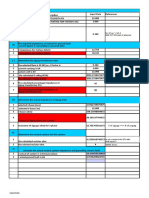

(tep. (ubstitution of numerical values

,n setting the temperature T

0

to ?9.0

o

> 3i.e., the maximum allowable temperature for

the insulation!, the maximum current that can flow through the wire may be calculated

as 19.01; amp.

The numerical values substituted in the e$uation are given below.

The values below may be changed and the problem solution recalculated with the new

values provided in consistent units.

Variable name Symbol Value Unit

electrical conductivity ke

:100000

ohm

-1

m

-1

maximum temerature T0

?9.0000

o

!

am"ient temerature T2

96.0000

o

!

outer radiu# r1

0.001:00

m

$ire radiu# r0

0.000:00

m

la#tic thermal conductivity k

0.9:000

%&(m ')

heat tran#(er coe((icient h

6.:0000

%&(m

2

')

Calculated Variable Symbol Value Unit

)aximum current 13.027 am

Você também pode gostar

- Tugas Perpindahan PanasDocumento7 páginasTugas Perpindahan PanasAnonymous DpmprYqkuAinda não há avaliações

- C and RDocumento7 páginasC and Rinba oli50% (2)

- Transport Phenomena Tutet6 Solution1Documento12 páginasTransport Phenomena Tutet6 Solution1kunu24Ainda não há avaliações

- 24th August HEAT GENERATION IN A SOLIDDocumento11 páginas24th August HEAT GENERATION IN A SOLIDSaloni.Dhawale Btech2018Ainda não há avaliações

- Tutorial 2Documento3 páginasTutorial 2Yik Vui KongAinda não há avaliações

- Home Assignment - 2Documento6 páginasHome Assignment - 2Rounak MajumdarAinda não há avaliações

- ConductionDocumento4 páginasConductionjaibalayyaAinda não há avaliações

- ProblemDocumento18 páginasProblemM Helmy AdityaAinda não há avaliações

- Heat Trandfer Mid-Term (Chapter1 4)Documento3 páginasHeat Trandfer Mid-Term (Chapter1 4)ipns109010010Ainda não há avaliações

- Home Assignment - 2Documento6 páginasHome Assignment - 2Akash FuryAinda não há avaliações

- T2 Questions and SolutionsDocumento10 páginasT2 Questions and Solutionsleroy_quekAinda não há avaliações

- Mech302hw3s PDFDocumento7 páginasMech302hw3s PDFSUMANTAinda não há avaliações

- 3 1 Last Year QueDocumento24 páginas3 1 Last Year QueSAnAinda não há avaliações

- ConductionDocumento159 páginasConductionNugi100% (1)

- Shell Energy BalancesDocumento26 páginasShell Energy BalancesSaiful Bahri100% (1)

- Transport Phenomena ProblemsDocumento10 páginasTransport Phenomena ProblemsbeningAinda não há avaliações

- Sheet 2Documento4 páginasSheet 2Yasmin RedaAinda não há avaliações

- 02 Numerical 2Documento2 páginas02 Numerical 2Aakash AgarwalAinda não há avaliações

- Ass 7Documento4 páginasAss 7Puneet MeenaAinda não há avaliações

- New Microsoft Word DocumentDocumento3 páginasNew Microsoft Word DocumentNripesh PokhrelAinda não há avaliações

- Worksheet 1 HMTDocumento5 páginasWorksheet 1 HMTmubarekjemal3279Ainda não há avaliações

- Ejercicios TransferDocumento12 páginasEjercicios TransferBryanAinda não há avaliações

- Files-5-Exams Quizzes Examples Problems Me315Documento44 páginasFiles-5-Exams Quizzes Examples Problems Me315AndrestorpAinda não há avaliações

- Files-5-Exams Quizzes Examples Problems Me315Documento44 páginasFiles-5-Exams Quizzes Examples Problems Me315TortelliniTimAinda não há avaliações

- Me 530 HW 2Documento2 páginasMe 530 HW 2nomitav119806Ainda não há avaliações

- HT QuestionsDocumento3 páginasHT QuestionsSanthoshirathnam GunjaAinda não há avaliações

- HT QuestionsDocumento3 páginasHT QuestionsSanthoshirathnam GunjaAinda não há avaliações

- HEAT TRANSFER - Chapter 2Documento2 páginasHEAT TRANSFER - Chapter 2ghostlenyAinda não há avaliações

- Tutorial 1Documento2 páginasTutorial 1David Ng Qing KaiAinda não há avaliações

- Transport Phenomena 3 4 2012 HeatDocumento59 páginasTransport Phenomena 3 4 2012 HeatSiti HannaAinda não há avaliações

- HTC SingleFin in Water 031506Documento5 páginasHTC SingleFin in Water 031506Anya CooperAinda não há avaliações

- Ejercicios TransferenciaDocumento5 páginasEjercicios TransferenciaPablo RuizAinda não há avaliações

- Difference Between Bi ND NuDocumento6 páginasDifference Between Bi ND NuIzuchucku JohnAinda não há avaliações

- Solution A2 CHE 312ADocumento12 páginasSolution A2 CHE 312AMukul ParasharAinda não há avaliações

- Roll No. Total No. of Questions: 091Documento3 páginasRoll No. Total No. of Questions: 091Mayank GroverAinda não há avaliações

- Tutorial - 3 Conduction With Heat Generation and Extended SurfacesDocumento1 páginaTutorial - 3 Conduction With Heat Generation and Extended SurfacesDr. Santosh BopcheAinda não há avaliações

- Some Solved Examples Related To Heat TransferDocumento8 páginasSome Solved Examples Related To Heat TransferManish MondalAinda não há avaliações

- Assignment 1 HMTDocumento7 páginasAssignment 1 HMTAnkit SharmaAinda não há avaliações

- Assignment 2Documento3 páginasAssignment 2Arjun AgarwalAinda não há avaliações

- Assignment 3Documento4 páginasAssignment 3abhijeetAinda não há avaliações

- HMT 7th Sem NIT Raipur QPaperDocumento28 páginasHMT 7th Sem NIT Raipur QPaperShashi Bhushan PatelAinda não há avaliações

- Problem Sheet 1 Basics and TemperatureDocumento4 páginasProblem Sheet 1 Basics and TemperatureS DAinda não há avaliações

- Tutorial 2-1Documento4 páginasTutorial 2-1chandan rajAinda não há avaliações

- Solution of Transient 2D Heat Conduction Problem Using Freefem++Documento4 páginasSolution of Transient 2D Heat Conduction Problem Using Freefem++Chicca PantanoAinda não há avaliações

- Heat Transfer PDFDocumento164 páginasHeat Transfer PDFNitish KrishnanAinda não há avaliações

- Heat and Mass Transfer (MCC 15102) Assignmnet - 1: A F B C D EDocumento4 páginasHeat and Mass Transfer (MCC 15102) Assignmnet - 1: A F B C D ERotten AppleAinda não há avaliações

- 2 Conduction Tutorial 1Documento11 páginas2 Conduction Tutorial 1GnazGoragod100% (1)

- Tutorial 1 (Question)Documento4 páginasTutorial 1 (Question)Muhd IlyasAinda não há avaliações

- Updated ProblemsDocumento3 páginasUpdated Problemsmahmoud koriemAinda não há avaliações

- Transient Heat Conduction (Chap# 4)Documento55 páginasTransient Heat Conduction (Chap# 4)Saif UllahAinda não há avaliações

- MEHB323 Tutorial Assignment 2Documento3 páginasMEHB323 Tutorial Assignment 2Amzar Aizad100% (1)

- Special Question BankDocumento8 páginasSpecial Question BankAKHIL HARIAinda não há avaliações

- Assignment 1Documento7 páginasAssignment 1AdarshpatankarAinda não há avaliações

- Sheet Ch.1Documento4 páginasSheet Ch.1Ahmed KingAinda não há avaliações

- Paper Ed7 16Documento12 páginasPaper Ed7 16RashaM.AtwiAinda não há avaliações

- Sheet 1Documento4 páginasSheet 1mohelg83Ainda não há avaliações

- Tugas Perpan Pak RomiDocumento4 páginasTugas Perpan Pak RomiIams MuhammadAinda não há avaliações

- Physical Electronics: Handbook of Vacuum PhysicsNo EverandPhysical Electronics: Handbook of Vacuum PhysicsA. H. BeckAinda não há avaliações

- Me 2209 Electrical Engineering Lab ManualDocumento45 páginasMe 2209 Electrical Engineering Lab ManualSai Karthi100% (1)

- Electric Charges and Fields DPP 1Documento4 páginasElectric Charges and Fields DPP 1deepbag79Ainda não há avaliações

- Power System ProtectionDocumento16 páginasPower System ProtectionIsmat Jahan NabilaAinda não há avaliações

- pdf29 PDFDocumento3 páginaspdf29 PDFAkhil TupiliAinda não há avaliações

- Answer KeyDocumento16 páginasAnswer KeyTinh Apple100% (5)

- Vectors and Scalars QuatitiesDocumento46 páginasVectors and Scalars QuatitiesJoric MagusaraAinda não há avaliações

- SGM1 - Study Guide For Module 1 PDFDocumento25 páginasSGM1 - Study Guide For Module 1 PDFEj ParañalAinda não há avaliações

- Chapter 7: Plane Electromagnetic Waves and Wave Propagation: An Historical PerspectiveDocumento23 páginasChapter 7: Plane Electromagnetic Waves and Wave Propagation: An Historical PerspectiveNiranjan DaradeAinda não há avaliações

- Flywheels - Theory of Machines PDFDocumento13 páginasFlywheels - Theory of Machines PDFSandip Ghosh100% (1)

- Lab Sheet Teknologi Elektrik No 3Documento10 páginasLab Sheet Teknologi Elektrik No 3semi2542Ainda não há avaliações

- DatasheetDocumento6 páginasDatasheetLuis Gustavo ReisAinda não há avaliações

- Chapter 13Documento52 páginasChapter 13MauricioAinda não há avaliações

- Filtered Battery Charger / DC Power Supply: Installation & Operation ManualDocumento50 páginasFiltered Battery Charger / DC Power Supply: Installation & Operation ManualQazi M Asim WasimAinda não há avaliações

- Analogue Panel MeterDocumento2 páginasAnalogue Panel MeterShuhan Mohammad Ariful HoqueAinda não há avaliações

- Quiz Contsts Questions ChemistryDocumento49 páginasQuiz Contsts Questions ChemistryNsBhasinAinda não há avaliações

- Signal and Linear System Analysis: 2.1 Problem SolutionsDocumento78 páginasSignal and Linear System Analysis: 2.1 Problem SolutionshayAinda não há avaliações

- Assigment 1Documento2 páginasAssigment 1Pankhuri Kumari0% (1)

- Giza Systems Ss Zigzag Calculation Xls SheetDocumento1 páginaGiza Systems Ss Zigzag Calculation Xls SheetMohamed ShafeyAinda não há avaliações

- Properties of Triangles Key Points:: Sine Rule: inDocumento47 páginasProperties of Triangles Key Points:: Sine Rule: insonuvuceAinda não há avaliações

- Title: Topic: Segment: Length: TV Anchor: SCRIPT WRITERS: Corazon Ma. M. Muñoz Melc: (MELC Week 4) Lesson ObjectiveDocumento7 páginasTitle: Topic: Segment: Length: TV Anchor: SCRIPT WRITERS: Corazon Ma. M. Muñoz Melc: (MELC Week 4) Lesson ObjectiveheartAinda não há avaliações

- TutorialDocumento9 páginasTutorialaravindAinda não há avaliações

- Exercise 1 PDFDocumento12 páginasExercise 1 PDFAnjali GuptaAinda não há avaliações

- Salan Ali SaadDocumento3 páginasSalan Ali SaadITAinda não há avaliações

- Fluid Mechanics - Unit 2 - Week 1 - INTRODUCTION PDFDocumento5 páginasFluid Mechanics - Unit 2 - Week 1 - INTRODUCTION PDFAkhilesh KumarAinda não há avaliações

- Hardware Manual ACS800-01 Drives (0.55 To 200 KW) ACS800-U1 Drives (0.75 To 200 HP)Documento174 páginasHardware Manual ACS800-01 Drives (0.55 To 200 KW) ACS800-U1 Drives (0.75 To 200 HP)virgil guimanAinda não há avaliações

- HNC AUTOMATION HSM Series AC 220V Servo Motor CatalogDocumento6 páginasHNC AUTOMATION HSM Series AC 220V Servo Motor CatalogTodi FindraAinda não há avaliações

- Getinge Ultrasonic Cleaner - Service ManualDocumento62 páginasGetinge Ultrasonic Cleaner - Service Manualgustavoesanchez100% (1)

- Thermodynamics Problems PDFDocumento21 páginasThermodynamics Problems PDFSubhash KorumilliAinda não há avaliações

- 11-Pump Affinity LawsDocumento13 páginas11-Pump Affinity LawspratheeshAinda não há avaliações