Escolar Documentos

Profissional Documentos

Cultura Documentos

UD Series

Enviado por

petergr8t10 notas0% acharam este documento útil (0 voto)

20 visualizações3 páginassffde

Direitos autorais

© © All Rights Reserved

Formatos disponíveis

PDF, TXT ou leia online no Scribd

Compartilhar este documento

Compartilhar ou incorporar documento

Você considera este documento útil?

Este conteúdo é inapropriado?

Denunciar este documentosffde

Direitos autorais:

© All Rights Reserved

Formatos disponíveis

Baixe no formato PDF, TXT ou leia online no Scribd

0 notas0% acharam este documento útil (0 voto)

20 visualizações3 páginasUD Series

Enviado por

petergr8t1sffde

Direitos autorais:

© All Rights Reserved

Formatos disponíveis

Baixe no formato PDF, TXT ou leia online no Scribd

Você está na página 1de 3

Introduction

CG Screen Protected Drip Proof Motors are specially designed to

provide continuous trouble free service. These motors are suitable for

all industrial drives, mill, pumps, etc. In SPDP motor external air is

sucked inside through a wire mesh screen by means of a shaft mounted

fan. The air traverses the length of the motor and is expelled at the

opposite end through the wire mesh screen. Crompton Greaves UDR,

UDC and VUDC series motors are continuously rated for S1 duty as per

IS: 325 / IEC 60034-7 They are suitable for 3 phase supply, 50Hz freq.

The motor enclosure is offered with Degree of protection IP 23,

providing adequate protection against dripping liquids and solid objects

as per IS: 4691/ IEC 60034-5 & the mounting dimensions are as per IS:

1231/ IEC 60072.

Stator

To minimize the iron losses, stator stack is made up of low-loss silicon

stampings. The stator winding consists of insulated coils of high

conductivity, fiber glass covered strips. Completely taped & insulated

coils are housed in the stator slots followed by insertion of tight slot

wedges & termination of the end connections.

Rotor

The rotor bars are made of Copper for carrying higher current to ensure

minimum deflection and stress concentrations, specially incorporated

strappings to make the overhang rigid to encounter stresses on account

of starting and switching for various critical applications, rotor shafts are

used of high grade steel (like EN8 or other suitable grade) with

Ultrasonic test.

Balancing

End-Shields

The end shields support the rotor on bearings & protect the winding,

with other internal parts of the machine. These are either of fabricated

Mild steel or of cast iron.

Ensuring a very low vibration level enhances the life of rotor, this is

achieved through a sturdy construction and careful three stage

balancing of rotor to very high accuracy as per ISO 1940 shafts are

subjected to stringent stage wise quality checks after fabrication &

machining. UD range comply to IEC 60034-9 for noise and IEC 60034-

14 for vibration standards.

HT/LT Squirrel Cage / Slip Ring

Induction Motors in SPDP Enclosure

Bearings

Carefully selected anti-friction bearing are used. These bearing are

regreased and located in bearing housing of adequate size. The grease used

is lithium based grade 3. All the motors irrespective of frame size have the

bearing housing insulated to prevent the flow of shaft current as a standard

practice. (Insulated bearing can also be provided for special requirements)

Terminal Box

For good mechanical strength and for good current carrying capacity the

terminal studs are made from extruded brass rods, rigid welded construction

with ample size for making connections of supply cables along with pressure

relief disk in the box in case of an arching short circuit, Cable entry position

can be changed in steps of 90 degree about the axis of terminal box. The

terminal box has been certified to withstand fault level of 43kA for 0.25 secs.

Accessories

Winding Temp. Detectors (RTD) for HT, PTC thermistor for LT.

Bearing Temp. Detectors (BTD)

Temp. Indicators Dial type thermometer (DTT)

Mounting of Vibration Probes

Phase Segregated Terminal Box (Fault withstanding type) for HT,

Star Point Terminal Box

Dial type thermometers (DTT) are used to monitor bearing temperature under

all conditions and commonly, mercury in steel type DTT is used (Non mercury

Space heater are used to

avoid any condensation of moisture inside the motor when in idle condition.

Suitably located lifting hooks of adequate strength are provided to lift the

motor for the purpose of installation, alignment, repairs and overhauling.

Earthing terminals are provided at opposite side on stator body & also on

each terminal box. Suitable sized slip ring with large creepage distances are

mounted externally to the main enclosure on the non-drive end, for ease of

maintenance, inspection windows are also provided for monitoring the

condition of the slip ring and brushes.

can also be provided for special requirements).

CGLs Motor Solutions

CG deliver variants of the UD-Series motor (with 11kV 60Hz. higher poles/low

speed). Special mounting arrangement can also be built as per customer

requirement. CG also supply configurations of UD-Series motors with sleeve

bearings, double shaft extension, low vibration, low noise levels , motors for

hazardous areas. Additional sensors (vibration sensors, speed sensor,

contact thermometer) can be provided to compliment motor monitoring and

fault protection units.

10000

8000

6000

4000

2000

0

12 Poles

RPM

2 4 6 8 10

500 3000 1500 1000 750 600

k

W

UD Series Output Chart, 3300-6600 V, 50Hz

UDC450 IP23 Drip Proof Motor

UD-Series

General Arrangement Drawing

Type A

750

850

950

950

1060

1060

1180

1180

B

1250

1250

1250

1600

1400

1800

1400

1800

C

315

315 - 570

335 - 570

335 - 355

355 - 570

355 - 570

375 - 630

375 - 630

D

85 - 125

85 - 140

100 - 140

125 - 140

125 - 160

140 - 160

160 - 180

160 - 200

E

170 - 210

170 - 250

170 - 250

210 - 250

210 - 250

210 - 250

250 - 300

300 - 350

H

450

500

560

560

630

630

710

710

HA

950

1050

1170

1170

1300

1300

1470

1470

L

2000

2050 - 2450

2075 - 2515

2475 - 2915

2350 - 2715

2750 - 3115

2450 - 2850

2850 - 3250

2 - 10

2 - 10

2 - 10

2 - 10

2 - 10

2 - 10

2 - 10

2 - 10

Poles

Overall Dimensions of Motor

Salient

Features

Robust Steel Frame

Spider type Shaft

Double Ended Radial Ventilation

Solid Deep Rotor Bars in Single Cage

End shield Mounted Bearings

Antifriction/Sleeve Bearings

Dynamically Balanced Rotors

Class 'F' Insulation with Class 'B' temp. rise

Ease of Maintenance

Space Heaters

Cane-leveller

Cane Cutter

Pump (Indoor)

Rolling Mill

Leveller

Rubber Mill

Fans

Compressors

Fibrizor

UD Series are

Specially Designed

for Applications Like

Technical Specification

Shaft Height 355 - 710 mm

Cooling IC01A1

Insulation Class H,F with VPI, RR

Frame Construction Fabricated Steel

Protection IP23

Rotor Constructions SR / SCR

Standards IEC60034 / IS:325

Voltage & Frequency 3.3 kv to 11kV, +/-10% & 50 Hz, +/-5%

Technical Specification

All dimensions are in mm

UD800 and UD900 are also available on request

Note : Due to continuous improvements and developments, the above data is likely to be changed without prior notice.

C

a

t

.

N

o

.

C

G

/

M

7

/

S

e

p

0

9

H

T

/

D

E C B

L

A

H

A

H

VUDC1700 IP23 Drip Proof Motor

UDC 450 E

UDC 500 E

UDC 560 E

UDC 560 G

UDC 630 F

UDC 630 H

UDC 710 F

UDC 710 H

UD-Series

C

a

t

.

N

o

.

C

G

/

M

7

/

S

e

p

0

9

H

T

/

Você também pode gostar

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)No EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Nota: 4.5 de 5 estrelas4.5/5 (119)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaNo EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaNota: 4.5 de 5 estrelas4.5/5 (265)

- The Little Book of Hygge: Danish Secrets to Happy LivingNo EverandThe Little Book of Hygge: Danish Secrets to Happy LivingNota: 3.5 de 5 estrelas3.5/5 (399)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryNo EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryNota: 3.5 de 5 estrelas3.5/5 (231)

- Never Split the Difference: Negotiating As If Your Life Depended On ItNo EverandNever Split the Difference: Negotiating As If Your Life Depended On ItNota: 4.5 de 5 estrelas4.5/5 (838)

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeNo EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeNota: 4 de 5 estrelas4/5 (5794)

- Team of Rivals: The Political Genius of Abraham LincolnNo EverandTeam of Rivals: The Political Genius of Abraham LincolnNota: 4.5 de 5 estrelas4.5/5 (234)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyNo EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyNota: 3.5 de 5 estrelas3.5/5 (2219)

- The Emperor of All Maladies: A Biography of CancerNo EverandThe Emperor of All Maladies: A Biography of CancerNota: 4.5 de 5 estrelas4.5/5 (271)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreNo EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreNota: 4 de 5 estrelas4/5 (1090)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersNo EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersNota: 4.5 de 5 estrelas4.5/5 (344)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceNo EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceNota: 4 de 5 estrelas4/5 (894)

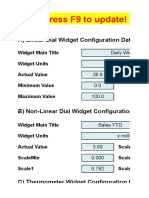

- Excel Dashboard WidgetsDocumento47 páginasExcel Dashboard WidgetskhincowAinda não há avaliações

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureNo EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureNota: 4.5 de 5 estrelas4.5/5 (474)

- The Unwinding: An Inner History of the New AmericaNo EverandThe Unwinding: An Inner History of the New AmericaNota: 4 de 5 estrelas4/5 (45)

- The Yellow House: A Memoir (2019 National Book Award Winner)No EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Nota: 4 de 5 estrelas4/5 (98)

- S-1566 PowerCommand 1.1Documento6 páginasS-1566 PowerCommand 1.1mnezami100% (2)

- BQ Mechanical (Sirim)Documento7 páginasBQ Mechanical (Sirim)mohd farhan ariff zaitonAinda não há avaliações

- Power Command Digital Generator Set Control PCC1302: Cummins (Onan) Harness-Control 327-1617-01 0338-4978Documento2 páginasPower Command Digital Generator Set Control PCC1302: Cummins (Onan) Harness-Control 327-1617-01 0338-4978Javier MongeAinda não há avaliações

- For Shunt, Arep or PMG Alternators: CharacteristicsDocumento2 páginasFor Shunt, Arep or PMG Alternators: Characteristicspetergr8t1Ainda não há avaliações

- Raft Foundations - Design & Analysis With A Practical Approach PDFDocumento140 páginasRaft Foundations - Design & Analysis With A Practical Approach PDFemmanuel83% (6)

- Innovative Mechatronics: Proforma Invoice / Quotation / Delivery ChallanDocumento1 páginaInnovative Mechatronics: Proforma Invoice / Quotation / Delivery Challanpetergr8t1Ainda não há avaliações

- Star EngineeringDocumento1 páginaStar Engineeringpetergr8t1Ainda não há avaliações

- Read MeDocumento1 páginaRead Mepetergr8t1Ainda não há avaliações

- Nagendra Singh Thekedar-100219Documento2 páginasNagendra Singh Thekedar-100219petergr8t1Ainda não há avaliações

- Hogar VDB Hikevision (Ds-Kb8113-Ime1) Google Nest Hello: Product Benchmark SheetDocumento1 páginaHogar VDB Hikevision (Ds-Kb8113-Ime1) Google Nest Hello: Product Benchmark Sheetpetergr8t1Ainda não há avaliações

- Sandeep SharmaDocumento1 páginaSandeep Sharmapetergr8t1Ainda não há avaliações

- Digital Doorlock Product Benchmark SheetDocumento1 páginaDigital Doorlock Product Benchmark Sheetpetergr8t1Ainda não há avaliações

- Dual Source Energy Meter User Friendly Cost Effective Field ProgrammableDocumento2 páginasDual Source Energy Meter User Friendly Cost Effective Field Programmablepetergr8t1Ainda não há avaliações

- Sed Man Manual For Gui 004 PDFDocumento38 páginasSed Man Manual For Gui 004 PDFpetergr8t1Ainda não há avaliações

- Enrolment Centre SearchDocumento1 páginaEnrolment Centre Searchpetergr8t1Ainda não há avaliações

- Price List FormostDocumento12 páginasPrice List Formostpetergr8t1Ainda não há avaliações

- Enrolment Centre SearchDocumento1 páginaEnrolment Centre Searchpetergr8t1Ainda não há avaliações

- F Features and D Technical Specificatio OnsDocumento1 páginaF Features and D Technical Specificatio Onspetergr8t1Ainda não há avaliações

- Release Notes BUSY 17Documento74 páginasRelease Notes BUSY 17petergr8t1Ainda não há avaliações

- AX-04 (L-T) Technical Specifications and FeaturesDocumento1 páginaAX-04 (L-T) Technical Specifications and Featurespetergr8t1Ainda não há avaliações

- Release Notes BUSY 17Documento74 páginasRelease Notes BUSY 17petergr8t1Ainda não há avaliações

- Government Receipt Portal SystemDocumento1 páginaGovernment Receipt Portal Systempetergr8t1Ainda não há avaliações

- Goods Rates Booklet 03july2017Documento176 páginasGoods Rates Booklet 03july2017Vaishnavi JayakumarAinda não há avaliações

- Combined Customs Tariff 2016-17Documento887 páginasCombined Customs Tariff 2016-17Vaishnavi JayakumarAinda não há avaliações

- HSN Product Code For GST PDFDocumento855 páginasHSN Product Code For GST PDFkashyap_ajAinda não há avaliações

- GST Rate & HSN Code For Electrical Parts & Electronics - Chapter 85Documento90 páginasGST Rate & HSN Code For Electrical Parts & Electronics - Chapter 85petergr8t10% (1)

- Standard Rectifier, Fast Recovery Diodes - Power DiodesDocumento2 páginasStandard Rectifier, Fast Recovery Diodes - Power Diodespetergr8t1Ainda não há avaliações

- Enrolment Centre SearchDocumento1 páginaEnrolment Centre Searchpetergr8t1Ainda não há avaliações

- GST Rate & HSN Code For Industrial Machinery - Chapter 84Documento9 páginasGST Rate & HSN Code For Industrial Machinery - Chapter 84petergr8t1Ainda não há avaliações

- Conveyor Chain GuideDocumento59 páginasConveyor Chain GuideajaykrishnaaAinda não há avaliações

- Ref Paper 2Documento4 páginasRef Paper 2Subhanjali MyneniAinda não há avaliações

- Gillette and The Men's Wet Shaving Market: Group 8 Section BDocumento12 páginasGillette and The Men's Wet Shaving Market: Group 8 Section BAmit Hemant JainAinda não há avaliações

- Oracle Database Question Bank 1Documento5 páginasOracle Database Question Bank 1subbaraomca2010Ainda não há avaliações

- List of Title-01Documento30 páginasList of Title-01najwaAinda não há avaliações

- Counter List HuaweiDocumento14 páginasCounter List Huaweiwedewe02Ainda não há avaliações

- Types of Commercial CellDocumento4 páginasTypes of Commercial CellDaveAinda não há avaliações

- Nazneen Wahab CVDocumento5 páginasNazneen Wahab CVRavi MittalAinda não há avaliações

- OkDocumento29 páginasOkgouthamlabsAinda não há avaliações

- The hyperwall: A multiple display wall for visualizing high-dimensional dataDocumento4 páginasThe hyperwall: A multiple display wall for visualizing high-dimensional dataMahendra PututAinda não há avaliações

- HT Series: 73-136Kw I Up To 12 Mppts Three PhaseDocumento2 páginasHT Series: 73-136Kw I Up To 12 Mppts Three PhasesyamprasadAinda não há avaliações

- Advanced Excel FormulasDocumento25 páginasAdvanced Excel Formulasskmohit singhalAinda não há avaliações

- Plett DawsonDocumento270 páginasPlett DawsonRaghu0% (1)

- Artikel Jurnal - Fundamental Differences of Transition To Industry 4.0 From Previous Industrial RevolutionsDocumento9 páginasArtikel Jurnal - Fundamental Differences of Transition To Industry 4.0 From Previous Industrial RevolutionsJohny DoelAinda não há avaliações

- Active Directory Command Line OneDocumento9 páginasActive Directory Command Line OneSreenivasan NagappanAinda não há avaliações

- INFRARED BASED VISITOR COUNTER TECHNOLOGYDocumento21 páginasINFRARED BASED VISITOR COUNTER TECHNOLOGYRahul KumarAinda não há avaliações

- POSSIBILITIES OF LOW VOLTAGE DC SYSTEMSDocumento10 páginasPOSSIBILITIES OF LOW VOLTAGE DC SYSTEMSTTaanAinda não há avaliações

- Rob Thomas Digital Booklet - Cradle SongDocumento15 páginasRob Thomas Digital Booklet - Cradle SongAgnieszka ŁukowskaAinda não há avaliações

- Reaction PaperDocumento2 páginasReaction PaperRonald CostalesAinda não há avaliações

- Paint Color Comparison ChartDocumento132 páginasPaint Color Comparison ChartCarlos Rubiños AlonsoAinda não há avaliações

- Sitsyll PDFDocumento57 páginasSitsyll PDFpreranaAinda não há avaliações

- Christianity and Online Spirituality Cybertheology As A Contribution To Theology in IndonesiaDocumento18 páginasChristianity and Online Spirituality Cybertheology As A Contribution To Theology in IndonesiaRein SiraitAinda não há avaliações

- Touch Screen TechnologyDocumento18 páginasTouch Screen TechnologySmîlērAinda não há avaliações

- Value-Instruments Cat2012 enDocumento58 páginasValue-Instruments Cat2012 enAnonymous C6Vaod9Ainda não há avaliações

- The Five Generations of Computers: AssignmentDocumento10 páginasThe Five Generations of Computers: Assignmentjismon_kjAinda não há avaliações

- Methods of Piling ExplainedDocumento3 páginasMethods of Piling ExplainedRajesh KhadkaAinda não há avaliações

- Design of A 120 In.-Diameter Steel Bifurcation With A Small Acute Angle For A High-Pressure PenstockDocumento10 páginasDesign of A 120 In.-Diameter Steel Bifurcation With A Small Acute Angle For A High-Pressure PenstockStalynMEcAinda não há avaliações