Escolar Documentos

Profissional Documentos

Cultura Documentos

Adp 2

Enviado por

HariharanTítulo original

Direitos autorais

Formatos disponíveis

Compartilhar este documento

Compartilhar ou incorporar documento

Você considera este documento útil?

Este conteúdo é inapropriado?

Denunciar este documentoDireitos autorais:

Formatos disponíveis

Adp 2

Enviado por

HariharanDireitos autorais:

Formatos disponíveis

1

1. Introduction

1.1 Overview:

The structural design of an airplane actually begins with the flight

envelope or V-n diagram, which clearly limits the maximum load factors that

the airplane can withstand at any particular flight velocity. However in normal

practice the airplane might experience loads that are much higher than the

design loads. Some of the factors that lead to the structural overload of an

airplane are high gust velocities, sudden movements of the controls, fatigue load

in some cases, bird strikes or lightning strikes. So to add some inherent ability

to withstand these rare but large loads, a safety factor of 1.5 is provided during

the structural design.

The two major members that need to be considered for the structural

design of an airplane are wings and the fuselage. As far as the wing design is

concerned, the most significant load is the bending load. So the primary load

carrying member in the wing structure is the spar (the front and rear spars)

whose cross section is an I section. Apart from the spars to take the bending

loads, suitable stringers need to take the shear loads acting on the wings.

Unlike the wing, which is subjected to mainly unsymmetrical load, the

fuselage is much simpler for structural analysis due to its symmetrical crossing

and symmetrical loading. The main load in the case of fuselage is the shear load

because the load acting on the wing is transferred to the fuselage skin in the

form of shear only. The structural design of both wing and fuselage begin with

shear force and bending moment diagrams for the respective members. The

maximum bending stress produced in each of them is checked to be less than

the yield stress of the material chosen for the respective member.

2

1.2 Outline:

The Structural design involves:

Determination of loads acting on aircraft:

V-n diagram for the design study

Gust and maneuverability envelopes

Schrenks Curve

Critical loading performance and final V-n graph calculation

Determination of loads acting on individual structures

Structural design study Theory approach

Load estimation of wings

Load estimation of fuselage.

Material Selection for structural members

Detailed structural layouts

Design of some components of wings, fuselage

1.3 Parameters forwarded from ADP 1

Take off Gross Weight,

Maximum Velocity,

Cruise Velocity,

Stall Velocity,

3

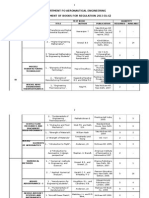

Table 1-1: Mass ratio Split up

Components Mass Fraction

Crew 0.00053146

Landing Gear 0.042516824

Payload 0.190144687

Fixed Equipment 0.002262033

Fuselage mass 0.085033649

Horizontal Stablizer 0.012597578

Vertical Stabilizer 0.006298789

Wing Structure 0.125975776

Fuel 0.4810995

Power plant 0.053539705

Total 1

Cruise Altitude = 12 km

The airfoil used her is NACA 65

3

- 418

Density at cruise altitude,

Cruise C_L @ Cruise altitude,

@ 16 aoa

@ 14 since tail angle is 15.56

@ -14 aoa

c

r

= 11.593 m

4

c

t

= 5.797 m

(

5

2. V-n Diagram

2.1 Maneuvering Envelope:

In accelerated flight, the lift becomes much more compared to the weight

of the aircraft. This implies a net force contributing to the acceleration. This

force causes stresses on the aircraft structure. The ratio of the lift experienced to

the weight at any instant is defined as the Load Factor (n).

Using the above formula, we infer that load factor has a quadratic variation

with velocity. However, this is true only up to a certain velocity.

This velocity is determined by simultaneously imposing limiting

conditions aerodynamically ((C

L

)

max

) as well as structurally (n

max

). This velocity

is called the Corner Velocity, and is determined using the following formula,

In this section, we estimate the aerodynamic limits on load factor, and

attempt to draw the variation of load factor with velocity, commonly known as

the V-n Diagram. The Vn diagram is drawn for Sea level Standard conditions.

6

Figure 2-1: Typical V-n diagram for a private airliner.

Figure 2-2: V-n diagram nomenclature

7

V-n diagram is used primarily in the determination of combination of flight

conditions and load factors to which the airplane structure must be designed. V-

n diagram precisely gives the structural (maximum load factor) and

aerodynamic (maximum CL) boundaries for a particular flight condition.

2.2 Construction of V-n diagram

2.2.1 Curve OA:

Maximum Load Factor,

Hence along the curve OA,

Using the above equation we get

Table 2-1: Velocity vs. positive load factor (n)

Velocity V (m/s) Load Factor (n)

0 0

20 0.08492371

40 0.339694842

60 0.764313394

80 1.358779368

100 2.123092762

120 3.057253578

140 4.161261814

160 5.435117472

180 6.87882055

200 8.49237105

220 10.27576897

240 12.22901431

8

At A,

2.2.2 Curve AC:

AC is a line limiting the maximum amount of load that can be withstood

by the weakest structure of the aircraft

V

C

= 408.32 m/s

n

C

=n

A

2.2.3 Along CD:

The velocity at point D is given by

V

D

=1.5V

C

= 416.66 m/s

n

D

= 0.75n

A

= 4.80864

A straight line is used to join the points C and D

This V

D

is the dive velocity or the maximum permissible EAS in which the

aircraft is at the verge of structural damage due to high dynamic pressure.

2.2.4 Along DE:

E corresponds to zero load factor point i.e

9

n= 0

For Bombers the load factor can vary from -3 to +6.5

Hence the negative load factor of aircraft is limited to -2

2.2.5 Along EF

The point F corresponds to the velocity

V

C

= V

F

= 408.32 m/s

2.2.6 Curve OG:

n

F

= -2 (for a typical bomber aircraft)

Hence along the curve OG,

Hence we get,

Table 2-2: Velocity vs. negative Load factor (n)

Velocity V (m/s) Load Factor (n)

0 0

20 -0.034356779

40 -0.137427115

60 -0.309211009

80 -0.549708461

100 -0.85891947

120 -1.236844037

140 -1.683482161

160 -2.198833843

180 -2.782899083

200 -3.43567788

220 -4.157170234

10

2.2.7 Along GF:

Also n

G

=n

F

Finally join GF by using a straight line

2.3 Nomenclature of curves:

PHAA Positive High Angle of Attack

PSL Positive Structural Limit

PLAA Positive Low Angle of Attack

HSL High Speed Limit

NHAA Negative High Angle of Attack

NSL Negative Structural Limit

NLAA Negative Low Angle of Attack

LSL Low Speed Limit

Figure 2-3: Four basic flight conditions showing how location of maximum stresses in wing depends on

angle of attack

11

2.4 Low Speed Limit:

Stall velocity is the maximum speed at which the aircraft can maintain level

flight. This implies the intersection of this line at cruise n=1 with OA curve

corresponds to stall velocity V

s

.

V

s

= 68.630 m/s

Figure 2-4: Rough V-n Diagram

From the V-n diagram, it is observed that the stall curve corresponds to

maximum value of C

Lmax

and any point beyond this curve for a particular

velocity is not achievable in flight as it enters the stall region there. The upper

horizontal line corresponds to limit load factor as well as ultimate load factor. It

-10

-5

0

5

10

0 100 200 300 400 500

L

o

a

d

F

a

c

t

o

r

Velocity (m/s)

Rough V-n Diagram

PHAA NHAA PSL HSL

NSL PLAA NLAA LSL

12

shows that there is outright structural failure when the aircraft is flown beyond

this value of load factor.

n=-2 gives the negative limit load factor and negative ultimate load

factor.

From the figure, it is clear that for a particular velocity, it is not possible

to fly at a value of C

L

higher than the C

Lmax

corresponding to that velocity. If we

wish to increase the lift of the airplane to that value of C

Lmax

, then we should

increase the flying speed of the airplane.

Figure 2-5: Maneuvering Envelope

-3

-2

-1

0

1

2

3

4

5

6

7

0 50 100 150 200 250 300 350 400 450

L

o

a

d

F

a

c

t

o

r

Velocity

Maneuvering Envelope

LSL

PIAA

NIAA

H

S

L

13

Figure 2-6: Maneuvering Envelope

Figure 2-7: Maneuvering envelope with coordinates

Hence for the strategic bomber aircraft we get,

Safety Factor = 1.5

-3

-2

-1

0

1

2

3

4

5

6

7

0 50 100 150 200 250 300 350 400 450

L

o

a

d

F

a

c

t

o

r

Velocity

Maneuvering Envelope

A

H

C

E

D

B

G F

-3

-2

-1

0

1

2

3

4

5

6

7

0 50 100 150 200 250 300 350 400 450

L

o

a

d

F

a

c

t

o

r

Velocity

Maneuvering Envelope with coordinates

68.63,

-0.4046

68.630

2,1

408.32,

6.41152

173.77,

6.41152

159.5944,-2

416.66

, 0

416.66,

4.80864

408.32,-2

14

Caution Speed = 325 m/s

Corner Velocity = 173.77 m/s

Stall speed = 59.669 m/s

Safety load factor limit i.e., indications given to pilot

n = -2/ 1.5 = -1.3333

n = 6.41152/ 1.5 = 4.2743

Dive Velocity = 416.66 m/s

15

Figure 2-8: V-n diagram with safety factor or safety limit consideration

16

3. Gust Envelope

3.1 Description:

Gust is a sudden, brief increase in the speed of the wind. Generally, winds are

least gusty over large water surfaces and most gusty over rough land and near

high buildings. With respect to aircraft turbulence, a sharp change in wind speed

relative to the aircraft; a sudden increase in airspeed due to fluctuations in the

airflow, resulting in increased structural stresses upon the aircraft.

Sharp-edged gust (u) is a wind gust that results in an instantaneous change in

direction or speed.

Derived gust velocity (U or U

max

) is the maximum velocity of a sharp-edged

gust that would produce a given acceleration on a particular airplane flown in

level flight at the design cruising speed of the aircraft and at a given air density.

As a result a 25% increase is seen in lift for a longitudinally disturbing gust.

The effect of turbulence gust is to produce a short time change in the effective

angle of attack. These changes produce a variation in lift and thereby load factor

For velocities up to V

max

, cruise, a gust velocity of 15 m/s at sea level is

assumed. For V

div

, a gust velocity of 10 m/s is assumed.

Effective gust velocity: The vertical component of the velocity of a sharp-

edged gust that would produce a given acceleration on a particular airplane

flown in level flight at the design cruising speed of the aircraft and at a given air

density.

Reference Gust Velocity (U

ref

) at sea level 15m/s.

Design Gust Velocity (U

ds

) U

ref

X K

17

Figure 3-1: Variation in Aerodynamic limits due to gust

3.2 Construction

The increase in the load factor due to the gust can be calculated by

For curve above V-axis:

Where

K Gust Alleviation Factor

U

max

Maximum derived Gust Velocity

a Lift Curve Slope for wing

For curve below V-axis:

-6

-4

-2

0

2

4

6

8

10

12

0 50 100 150 200 250

L

o

a

d

f

a

c

t

o

r

Velocity

Variation in aerodynamic limits

Normal Stall curve

Gust stall curve

Normal neg stall

curve

Gust neg stall curve

Flaps Retracted

18

Gust Alleviation Factor:

Gust Alleviation Factor (K):

Lateral Mass Ratio ():

Where

g Acceleration due to Gravity

Mean Aerodynamic Chord

)

c

t

Chord at tip

c

r

Chord at root

c

r

= 11.593 m

c

t

= 5.797 m

a= 0.1213507 /degree

19

a= 6.9528829 /radian

for a =0.15/ degree where a is lift curve slope for the chosen airfoil NACA 65-

(3) 418

a lift curve slope for airfoil

Sweep angle at leading Edge of Wing

(

Table 3-1: Equivalent air speed and corresponding Derived Gust Velocity

For Velocity at points Equivalent air speed

V (m/s)

Derived Gust Velocity

U

max

(m/s)

B,G 173.77 15

C,F 408.32 10

D,E 416.66 5

20

By using the equations and for various speeds of U

max

we get the following gust

lines

Figure 3-2: Gust Lines

-2

-1

0

1

2

3

4

0 50 100 150 200 250 300 350 400 450

L

o

a

d

f

a

c

t

o

r

Velocity

Gust Lines

U=15m/s U=10m/s U=5m/s

U=0m/s U=-5m/s U=-10./s

U=-15m/s

Level

Design speed

277.77 m/s

21

Figure 3-3: Overlapped maneuvering envelope and gust lines.

The load factors at the various points can be found using the formula using the

corresponding values of U

max

n

B

= 1.4195966

n

G

= 0.846720

n

C

= 2.5617017

n

F

= -0.5617017

n

D

= 1.796799

n

E

= 0.203200

-3

-2

-1

0

1

2

3

4

5

6

7

0 50 100 150 200 250 300 350 400 450

L

o

a

d

f

a

c

t

o

r

Velocity

Overlaped Maneuver envelope and gust lines

Gust stall curve Gust neg stall curve HSL

PLAA NLAA PIAA

NIAA U=15m/s U=10m/s

U=5m/s U=0m/s U=-5m/s

22

The positive load factor along the curve OB is given by the equation

Hence along the curve OA,

But also

Equating the above two equations we get an intersecting point B where velocity

is

V

B

= 73.1379 m/s

Since the velocities and load factors at C, D, E and F are known and straight

lines are used to join these points in sequence

3.2.1 Line FG:

It is found that negative gust line of U= -15 m/s intersects the positive high

angle of attack condition at G.

23

Equating the above equation with the OA curve equation we get the point G

where

V

G

= 51.52026m/s

Figure3-4: Gust Envelope

-2

-1.5

-1

-0.5

0

0.5

1

1.5

2

2.5

3

0 50 100 150 200 250 300 350 400 450

L

o

a

d

f

a

c

t

o

r

Velocity (m/s)

Gust Envelope

B

C

D

G

O

E

F

24

Figure 3-5: Gust Envelope with coordinates

-2

-1.5

-1

-0.5

0

0.5

1

1.5

2

2.5

3

0 50 100 150 200 250 300 350 400 450

L

o

a

d

f

a

c

t

o

r

Velocity

Gust Envelope with coordinates

416.66,

1.7968

410.9975, -1.3791

416.66, 0

416.66,

1.7968

408.32,

2.561702

73.13798, 1.419596

51.52026,

0.704426

25

4. Schrenks Curve

4.1 Description

Lift varies along the wing span due to the variation in chord length, angle of

attack and sweep along the span. Schrenks curve defines this lift distribution

over the wing span of an aircraft, also called simply as Lift Distribution Curve.

Schrenks Curve is given by

Where

y

1

is Linear Variation of lift along semi wing span also named as L

1

y

2

is Elliptic Lift Distribution along the wing span also named as L

2

a = 44.8285 m

26

Figure 4-1: Wing geometry showing sweep angle and semi span along the root.

4.2 Linear Lift Distribution:

Lift at root

L

root

= 90978.038 N/m

Lift at tip

L

tip

= 45492.942 N/m

By representing this lift at sections of root and tip we can get the equation for

the wing.

27

Figure 4-2: Linear lift distribution

Equation of linear lift distribution for starboard wing

Equation of linear lift distribution for port wing we have to replace x by x in

general,

Twice the area under y

1

= Total lift= 2491907.5 N Take off Gross Weight

Figure 4-3: Linear Variation of lift along wing semi span

0

10

20

30

40

50

60

70

80

90

100

0 10 20 30 40 50

L

i

f

t

p

e

r

m

e

t

e

r

(

N

/

m

)

T

h

o

u

s

a

n

d

s

Wing Semi Span (m)

Linear variation of Lift along wing Semi span

L1

28

For the Schrenks curve we only consider half of the linear distribution of lift

and hence we derive y

1

/2

4.3 Elliptic Lift Distribution:

Twice the area under the curve or line will give the lift which will be required to

overcome weight

Considering an elliptic lift distribution we get

Where b

1

is Actual lift at root

And a is wing semi span

Lift at tip

29

Figure 4-4: Elliptic lift distribution

Equation of elliptic lift distribution

Figure 4-5: Elliptic lift distribution

0

10

20

30

40

50

60

70

80

0 10 20 30 40 50

L

i

f

t

p

e

r

m

e

t

e

r

(

N

/

m

)

T

h

o

u

s

a

n

d

s

Wing Semi Span (m)

Elliptic variation of Lift along wing Semi span

L2

30

4.4 Construction of Schrenks Curve:

Schrenks Curve is given by

Substituting different values for x we can get the lift distribution for the wing

semi span

Table 4-1: Lift distribution table along semi

span

x L1 L2 L

0 90978.04 70776.189 80877.11

1 89963.39 70758.577 80360.98

2 88948.75 70705.716 79827.23

3 87934.1 70617.525 79275.81

4 86919.45 70493.872 78706.66

5 85904.81 70334.571 78119.69

6 84890.16 70139.378 77514.77

7 83875.52 69907.993 76891.75

8 82860.87 69640.055 76250.46

9 81846.22 69335.14 75590.68

10 80831.58 68992.759 74912.17

11 79816.93 68612.349 74214.64

12 78802.29 68193.275 73497.78

13 77787.64 67734.819 72761.23

14 76772.99 67236.175 72004.58

15 75758.35 66696.443 71227.4

16 74743.7 66114.615 70429.16

17 73729.06 65489.57 69609.31

18 72714.41 64820.058 68767.23

19 71699.76 64104.686 67902.22

20 70685.12 63341.899 67013.51

21 69670.47 62529.962 66100.22

x L1 L2 L

22 68655.83 61666.935 65161.38

23 67641.18 60750.639 64195.91

24 66626.53 59778.626 63202.58

25 65611.89 58748.129 62180.01

26 64597.24 57656.013 61126.63

27 63582.6 56498.706 60040.65

28 62567.95 55272.111 58920.03

29 61553.3 53971.505 57762.4

30 60538.66 52591.398 56565.03

31 59524.01 51125.351 55324.68

32 58509.37 49565.739 54037.55

33 57494.72 47903.426 52699.07

34 56480.07 46127.307 51303.69

35 55465.43 44223.675 49844.55

36 54450.78 42175.265 48313.02

37 53436.14 39959.82 46697.98

38 52421.49 37547.784 44984.64

39 51406.84 34898.417 43152.63

40 50392.2 31952.741 41172.47

41 49377.55 28619.406 38998.48

42 48362.91 24742.227 36552.57

43 47348.26 20007.494 33677.88

44 46333.61 13543.872 29938.74

44.8285 45492.98 0 22746.49

31

Figure 4-6: Schrenks curve with linear and elliptic lift distribution

Replacing x by x for port wing we can get lift distribution for entire span.

Figure 4-7: Schrenks curve

0

10

20

30

40

50

60

70

80

90

100

0 10 20 30 40 50

L

i

f

t

p

e

r

m

e

t

e

r

s

p

a

n

(

N

/

m

)

T

h

o

u

s

a

n

d

s

Wing span loaction (m)

Schrenk's Curve

L

L1

L2

0

10

20

30

40

50

60

70

80

90

-60 -40 -20 0 20 40 60

L

i

f

t

p

e

r

m

e

t

e

r

s

p

a

n

(

N

/

m

)

T

h

o

u

s

a

n

d

s

Wing span loaction (m)

Schrenk's Curve

L

32

5. Load Estimation on wings

5.1 Description:

The solution methods which follow Eulers beam bending theory

(/y=M/I=E/R) use the bending moment values to determine the stresses

developed at a particular section of the beam due to the combination of

aerodynamic and structural loads in the transverse direction. Most engineering

solution methods for structural mechanics problems (both exact and

approximate methods) use the shear force and bending moment equations to

determine the deflection and slope at a particular section of the beam.

Therefore, these equations are to be obtained as analytical expressions in terms

of span wise location. The bending moment produced here is about the

longitudinal (x) axis.

5.2 Loads acting on wing:

As both the wings are symmetric, let us consider the starboard wing at first.

There are three primary loads acting on a wing structure in transverse direction

which can cause considerable shear forces and bending moments on it. They

are as follows:

Lift force (given by Schrenks curve)

Self-weight of the wing

Weight of the power plant

Weight of the fuel in the wing

33

5.3 Shear force and bending moment diagrams due to

loads along transverse direction at cruise condition:

Lift Force given by Schrenks Curve:

Linear lift distribution (trapezium):

Elliptic lift distribution (quarter ellipse)

Figure 5-1: Lift distribution (linear)

0

5000

10000

15000

20000

25000

30000

35000

40000

45000

50000

0 5 10 15 20 25 30 35 40 45 50

L

i

f

t

p

e

r

u

n

i

t

l

e

n

g

t

h

(

N

/

m

)

Span wise location (m)

Linear lift distribution (y1/2)

34

Figure 5-2: Lift distribution (Elliptic)

Self-Weight (y

3

): Self-weight of the wing,

Assuming parabolic weight distribution

( (

))

Where b span

0

5000

10000

15000

20000

25000

30000

35000

40000

0 10 20 30 40 50

L

i

f

t

p

e

r

u

n

i

t

l

e

n

g

t

h

(

N

/

m

)

Span wise location (m)

Elliptic lift distribution (y2/2)

y2/2

35

When we integrate from x=0 (root location) to x=b (tip location) we get the net

weight of port wing.

( )

()

Substituting various values of x in the above equation we get the self-weight of

the wing.

Figure 5-3: Self weight of wing

Power plant weight:

Power plant is assumed to be a point load,

-25000

-20000

-15000

-10000

-5000

0

0 5 10 15 20 25 30 35 40 45 50

W

E

i

g

h

t

o

f

e

m

p

t

y

w

i

n

g

(

N

/

m

)

Span wise location (m)

Self Weight

36

Acting at x= 8 m and x= 14 m from the root.

Fuel weight:

This design has fuel in the wing so we have to consider the weight of the fuel

in the wing.

Again by using general formula for straight line y=mx + c we get,

Figure 5-4: Fuel Distribution

-20000

-18000

-16000

-14000

-12000

-10000

-8000

-6000

-4000

-2000

0

0 5 10 15 20 25 30 35 40 45 50

F

u

e

l

w

e

i

g

h

t

(

N

/

m

)

Span wise location (m)

Fuel distribution

37

Figure 5-5: Overall Load distribution

Table 5-1: Loads simplified as point loads

-80000

-60000

-40000

-20000

0

20000

40000

60000

0 5 10 15 20 25 30 35 40 45 50

L

o

a

d

a

c

t

i

n

g

o

n

w

i

n

g

(

N

/

m

)

Span wise location (m)

Load distribution

Curve / component Area enclosed / structural

weight (N)

Centroid (from wing root)

y

1

/2 1529447.31 19.923 m

y

2

/2 1245953.75 3.510534 m

Wing 313917 16.8107 m

Fuel 365752.803 16.4606 m

Power plant 66708 14 m, 8 m

38

Figure 5-6: Reaction force and Bending moment calculations

Now we know V

A

and M

A

, using this we can find out shear force and Bending

moment.

5.3.1 Shear Force:

39

)

(

By using the corresponding values of x in appropriate equations we get the plot

of shear force

Note: Shear force is a discrete function along y axis so in order to make it

continuous we introduce straight lines.

40

Figure 5-7: Shear force diagram - discrete

Figure 5-8: Shear force diagram- continuous

-3000

-2500

-2000

-1500

-1000

-500

0

500

1000

-44.8285 -34.8285 -24.8285 -14.8285 -4.8285 5.1715 15.1715 25.1715 35.1715

S

h

e

a

r

F

o

r

c

e

(

N

)

T

h

o

u

s

a

n

d

s

Location in wing (m)

Shear Force

-3000

-2500

-2000

-1500

-1000

-500

0

500

1000

-44.8285 -34.8285 -24.8285 -14.8285 -4.8285 5.1715 15.1715 25.1715 35.1715

S

h

e

a

r

F

o

r

c

e

(

N

)

T

h

o

u

s

a

n

d

s

Location in wing (m)

Shear Force (Actual)

41

5.3.2 Bending moment:

( (

))

By substituting the values of x for the above equations of bending moments

obtained we can get a continuous bending moment curve for the port wing.

Note: if we replace the x by -x in each term we get the distribution of starboard

wing

42

Figure 5-9: Bending moment diagram

5.4 Shear force and bending moment diagrams due to

loads along chordwise direction at cruise condition:

Aerodynamic center- This is a point on the chord of an airfoil section where the

bending moment due to the components of resultant aerodynamic force (Lift

and Drag) is constant irrespective of the angle of attack. Hence the forces are

transferred to this point for obtaining constant M

a.c

Shear center- This is a point on the airfoil section where if a force acts, it

produces only bending and no twisting. Hence the force is transferred to this

point and the torque is found.

Cruise C

L

=0.204908 @ V= 250 m/s

Cruise C

D

= 0.0055

Angle of attack= -0.811439 (obtained from the lift curve slope)

Angle of attack @ zero lift= -3

o

0

10

20

30

40

50

60

70

-50 -40 -30 -20 -10 0 10 20 30 40 50

B

e

n

d

i

n

g

M

o

m

e

n

t

(

N

m

)

M

i

l

l

i

o

n

s

Location in wing (m)

Bending Moment

43

Wing lift curve slope (a)= 0.1213507 /degree

Co-efficient of moment about aerodynamic centre= -0.0543

Location of aerodynamic centre:

Location of shear centre:

Lift and drag are the components of resultant aerodynamic force

acting normal to and along the direction of relative wind respectively. As a

result, components of them act in the chordwise direction also which produce a

bending moment about the normal (z) axis.

Figure 5-10: Normal and chord wise coefficients

Co-efficient of force along the normal direction,

44

Chordwise force at root

Chordwise force at tip

By using y = mx +c again we get the equation as

The above equation gives the profile of load acting chordwise, by integrating

this above equation we get a component of Shear force and again by integrating

the same we get the component of Bending Moment

45

Figure 5-11: Load along chordwise direction

To find fixing moment and the reaction force,

5.4.1 Shear Force:

0

200

400

600

800

1000

1200

1400

0 5 10 15 20 25 30 35

L

o

a

d

a

l

o

n

g

c

h

o

r

d

w

i

s

e

d

i

r

e

c

t

i

o

n

(

N

)

Spanwise location (m)

Load along Chordwise direction

46

Figure 5-12: Shear force

5.4.2 Bending Moment:

Figure 5-13: Bending moment

-35

-30

-25

-20

-15

-10

-5

0

0 5 10 15 20 25 30 35

S

h

e

a

r

F

o

r

c

e

(

N

)

T

h

o

u

s

a

n

d

s

Spanwise location (m)

Shear Force

0

100

200

300

400

500

600

0 5 10 15 20 25 30 35

B

e

n

d

i

n

g

m

o

m

e

n

t

(

N

m

)

T

h

o

u

s

a

n

d

s

Spanwise location (m)

Bending Moment

47

Torque due to normal forces and constant pitching moment at cruise condition:

Figure 5-14: Moment about aerodynamic center

The lift and drag forces produce a moment on the surface of cross-

section of the wing, otherwise called a torque, about the shear center. Moment

about the aerodynamic center gets transferred to the shear center. The

powerplant also produces a torque about the shear center on the chord under

which it is located.

Figure 5-15:Torque due to normal force and moment

48

5.5 Torque at cruise condition:

5.5.1 Torque due to normal force:

Where

c chord

the equation for chord can also be represented in terms of x by taking c= mx

+k,

Therefore torque

49

Figure 5-16: Torque due to normal force

5.5.2 Torque due to chord wise force:

5.5.3 Torque due to moment:

0

100

200

300

400

500

600

700

800

900

1000

0 5 10 15 20 25 30 35 40

T

o

r

q

u

e

(

N

m

)

T

h

o

u

s

a

n

d

s

Spanwise location (m)

Torque due to normal forces

50

Figure 5-17: Torque due to moment

5.5.4 Torque due to powerplant:

The powerplant is situated under a chord (8 m and 14 m from the

wing root; chord length 10.7504 m and 10.1184m ) from 0.1c to 0.5c at

10.7504m and from 0.1 c to 0.5249c an Uniformly Distributed Load of

15513.488 N/m is assumed to be present for this 4.3 m since the powerplant

weight is 66708N. The centroid of the applied UDL is at 0.3c for first case and

at 0.31245c at second location.

Torque produced about shear center

-8

-7

-6

-5

-4

-3

-2

-1

0

0 5 10 15 20 25 30 35 40

T

o

r

q

u

e

(

N

m

)

M

i

l

l

i

o

n

s

Spanwise location (m)

Torque due to Moment

51

Figure 5-18: Torque due to powerplant

Then the different torque components are brought together in a same graph to

make a comparison

Figure 5-19: Torque comparison

0

10

20

30

40

50

60

70

0 5 10 15 20 25 30 35 40

T

o

r

q

u

e

(

N

m

)

T

h

o

u

s

a

n

d

s

Spanwise location (m)

Torque due to Powerplant

-8000

-7000

-6000

-5000

-4000

-3000

-2000

-1000

0

1000

2000

0 10 20 30 40

T

o

r

q

u

e

(

N

m

)

T

h

o

u

s

a

n

d

s

Spanwise location (m)

Torque comparison

Torque due to Normal Forces

Torque due to moment

Torque due to powerplant

52

The net torque will be sum of all the above torques i.e. torque due to normal

force, chordwise force, powerplant and aerodynamic moment

Figure 5-20: Net torque

-7

-6

-5

-4

-3

-2

-1

0

0 5 10 15 20 25 30 35 40

T

o

r

q

u

e

(

N

m

)

M

i

l

l

i

o

n

s

Spanwise location (m)

Torque

53

5.6 Load at Critical flight condition:

Optimum Wing structural design consists of determining that stiffness

distribution which is proportional to the local load distribution. The

aerodynamic forces of lift and drag are resolved into components normal and

parallel to the wing chord. The distribution of shear force, bending moment and

torque over the aircraft wing are considered for wing structural analysis.

Identification of critical points from the maneuvering and gust envelopes:

1. Maneuvering envelope

Table 5-1: Coordinates of V-n diagram

Point Load factor E.A.S. (m/s)

A 6.41152 173.77

C 6.41152 408.32

D 4.80864 416.66

E 0 416.66

F -2 408.16

G -2 159.5944

2. Gust envelope

Table 5-2: Coordinates of gust envelope

Point Load factor E.A.S. (m/s)

B 1.41959 173.137975

C 2.5617 408.16

D 1.7968 416.66

E 0.2032 416.66

F -1.3255 408.16

G 0.5822 51.52026

54

Corner points are representative of critical flight load conditions a summary

is given below.

Table 5-3: Coordinates of critical conditions

Critical flight condition Point (n, E.A.S.)

n max point C (2.5617, 408.16)

Positive H.A.A. A (6.41152, 173.77)

Positive L.A.A D (4.80864, 416.66)

Negative H.A.A G (-2, 408.16)

Negative L.A.A E (0, 416.66)

Shear force and bending moment diagrams of a wing due to normal forces at

critical flight condition:

In the preliminary stage of structural analysis, the critical

flight loading condition of positive high angle of attack (represented by point A

in v-n diagram) will be investigated.

It is seen that lift has increased by 6.41152 times.

So we introduce a constant of proportionality for the lift alone

55

Figure 5-21: Linear Variation of lift along wing semi span

Figure 5-22: Elliptic variation of lift along wing semi span

0

100

200

300

400

500

600

700

0 10 20 30 40 50

L

i

f

t

p

e

r

m

e

t

e

r

(

N

/

m

)

T

h

o

u

s

a

n

d

s

Wing Semi Span (m)

Linear variation of Lift along wing Semi span

(critical condition)

L1

0

50

100

150

200

250

300

350

400

450

500

0 10 20 30 40 50

L

i

f

t

p

e

r

m

e

t

e

r

(

N

/

m

)

T

h

o

u

s

a

n

d

s

Wing Semi Span (m)

Elliptic variation of Lift along wing Semi span

(Critical Condition)

L2

56

The aim is to find the shear forces and bending moments due to

normal forces in critical flight condition. There are three primary loads acting

on a wing structure in transverse direction which can cause considerable shear

forces and bending moments on it. They are as follows:

Lift force (given by Schrenks curve)

Self-weight of the wing

Weight of the power plant

Weight of the fuel in the wing

Now, the proportionality constant influences the lift force alone and other

factors remain unaffected.

Table 5-4: Loads simplified as point loads at critical flight condition

Curve / component Area enclosed / structural

weight (N)

Centroid (from wing root)

y

1

/2 1529447.316.41152 19.923 m

y

2

/2 1245953.75 6.41152 3.510534 m

Wing 313917 16.8107 m

Fuel 365752.803 16.4606 m

Power plant 66708 14 m, 8 m

57

Figure 5-23: Critical schrenks curve

Figure 5-24: load distribution at critical condition

0

100

200

300

400

500

600

-60 -40 -20 0 20 40 60

L

i

f

t

p

e

r

m

e

t

e

r

s

p

a

n

(

N

/

m

)

T

h

o

u

s

a

n

d

s

Wing span loaction (m)

Schrenk's Curve (Critical Condition)

L

58

Figure 5-25: load distribution at critical condition

Now we know V

A

and M

A

, using this we can find out shear force and Bending

moment,

5.7 Shear force and bending moment diagrams due to

loads along transverse direction at critical condition:

-0.1

-0.05

0

0.05

0.1

0.15

0.2

0.25

0.3

0.35

0 5 10 15 20 25 30 35 40 45 50

L

o

a

d

(

N

)

M

i

l

l

i

o

n

s

Location in wing (m)

Load distribution (Critical Condition)

59

)))

(

By using the corresponding values of x in appropriate equations we get the plot

of shear force

60

Figure 5-26: Transverse Shear force diagram at critical condition

Figure 5-27: Transverse Shear force diagram at critical condition

5.7.1 Bending moment:

-20000

-18000

-16000

-14000

-12000

-10000

-8000

-6000

-4000

-2000

0

2000

-44.8285 -34.8285 -24.8285 -14.8285 -4.8285 5.1715 15.1715 25.1715 35.1715

S

h

e

a

r

F

o

r

c

e

(

N

)

T

h

o

u

s

a

n

d

s

Location in wing (m)

Shear Force (Critical condition)

-20000

-18000

-16000

-14000

-12000

-10000

-8000

-6000

-4000

-2000

0

2000

-44.8285 -34.8285 -24.8285 -14.8285 -4.8285 5.1715 15.1715 25.1715 35.1715

S

h

e

a

r

F

o

r

c

e

(

N

)

T

h

o

u

s

a

n

d

s

Location in wing (m)

Shear Force (Actual) (Critical Condition)

61

( (

)))

By substituting the values of x for the above equations of bending moments

obtained we can get a continuous bending moment curve for the port wing.

62

Figure 5-28: Transverse bending moment diagram at critical condition

5.8 Shear force and bending moment diagrams due to

loads along chordwise direction at critical condition:

Critical C

L

=2.71925 @ V= 250 m/s

Critical C

D

= 0.0084

Angle of attack= 16 (obtained from the lift curve slope)

Wing lift curve slope (a) = 0.1213507 /degree

Co-efficient of moment about aerodynamic centre= -0.025

Location of aerodynamic centre:

Location of shear centre:

-100

0

100

200

300

400

500

600

-50 -40 -30 -20 -10 0 10 20 30 40 50

B

e

n

d

i

n

g

M

o

m

e

n

t

(

N

m

)

M

i

l

l

i

o

n

s

Location in wing (m)

Bending Moment (Critical Condition)

63

Figure 5-29: Determination of chordwise force components at critical condition

Co-efficient of force along the normal direction,

Chordwise force at root

Chordwise force at tip

64

By using y = mx +c again we get the equation as

The above equation gives the profile of load acting chordwise, by integrating

this above equation we get a component of Shear force and again by integrating

the same we get the component of Bending Moment

Figure 5-30: Load along chord wise direction at critical condition

0

50000

100000

150000

200000

250000

300000

350000

400000

0 5 10 15 20 25 30 35

L

o

a

d

a

l

o

n

g

c

h

o

r

d

w

i

s

e

d

i

r

e

c

t

i

o

n

(

N

)

Spanwise location (m)

Load along Chordwise direction (critical

condition)

65

To find fixing moment and the reaction force,

5.8.1 Shear Force:

Figure 5-31: Chordwise Shear force diagram at critical condition

5.8.2 Bending Moment:

-12000

-10000

-8000

-6000

-4000

-2000

0

0 5 10 15 20 25 30 35

S

h

e

a

r

F

o

r

c

e

(

N

)

T

h

o

u

s

a

n

d

s

Spanwise location (m)

Shear Force

66

Figure 5-32: Chordwise Bending moment diagram at critical condition

Torque due to normal forces and constant pitching moment at cruise condition:

Figure 5-33: Determination of various components of torque

0

20000

40000

60000

80000

100000

120000

140000

160000

180000

0 5 10 15 20 25 30 35

B

e

n

d

i

n

g

m

o

m

e

n

t

(

N

m

)

T

h

o

u

s

a

n

d

s

Spanwise location (m)

Bending Moment

67

Figure 5-34: Determination of various components causing torque

5.9 Torque at critical flight condition:

5.9.1 Torque due to normal force:

Where

c chord

the equation for chord can also be represented in terms of x by taking c= mx

+k,

Therefore torque

68

Figure 5-35: Torque due to normal force at critical condition

5.9.2 Torque due to chord wise force:

5.9.3 Torque due to moment:

0

2000

4000

6000

8000

10000

12000

0 5 10 15 20 25 30 35 40

T

o

r

q

u

e

(

N

m

)

T

h

o

u

s

a

n

d

s

Spanwise location (m)

Torque due to normal forces

69

Figure 5-36: Torque due to moment at critical condition

5.9.4 Torque due to powerplant:

The powerplant is situated under a chord (8 m and 14 m from the

wing root; chord length 10.7504 m and 10.1184m ) from 0.1c to 0.5c at

10.7504m and from 0.1 c to 0.5249c an Uniformly Distributed Load of

15513.488 N/m is assumed to be present for this 4.3 m since the powerplant

weight is 66708N. The centroid of the applied UDL is at 0.3c for first case and

at 0.31245c at second location.

Torque produced about shear center

Hence tis is weight this will remain same as that of the cruise condition.

-2

-1.8

-1.6

-1.4

-1.2

-1

-0.8

-0.6

-0.4

-0.2

0

0 5 10 15 20 25 30 35 40

T

o

r

q

u

e

(

N

m

)

M

i

l

l

i

o

n

s

Spanwise location (m)

Torque due to Moment

70

Figure 5-37: Torque due to powerplant at critical condition unchanged

Then the different torque components are brought together in a same graph to

make a comparison

The net torque will be sum of all the above torques i.e. torque due to normal

force, chordwise force, powerplant and aerodynamic moment

0

10

20

30

40

50

60

70

0 5 10 15 20 25 30 35 40

T

o

r

q

u

e

(

N

m

)

T

h

o

u

s

a

n

d

s

Spanwise location (m)

Torque due to Powerplant

71

Figure 5-38: Torque comparison at critical condition

Figure 5-39: Net torque at critical condition

-4000

-2000

0

2000

4000

6000

8000

10000

12000

0 10 20 30 40

T

o

r

q

u

e

(

N

m

)

T

h

o

u

s

a

n

d

s

Spanwise location (m)

Torque comparison

Torque due to Normal Forces

Torque due to moment

Torque due to powerplant

0

1

2

3

4

5

6

7

8

9

10

0 5 10 15 20 25 30 35 40

T

o

r

q

u

e

(

N

m

)

M

i

l

l

i

o

n

s

Spanwise location (m)

Torque

72

5.10 Interim Summary:

DUE TO NORMAL FORCES:

Table 5-5: Determination of maximum values of normal force

Cruise

condition

+ve high AOA

condition

At

Max. Shear force (N)

-2461484.863

-17480623.2

Wing root

Max. Bending

moment (Nm)

65115382.95

486567918.1

Wing root

DUE TO CHORDWISE FORCES:

Table 5-6: Determination of maximum values of chordwise force

Cruise

condition

+ve high AOA

condition

At

Max. Shear force (N)

-31590.839

-10102394.13

Wing root

Max. Bending

moment (Nm)

51270.9081

163971959.1 Wing root

Max. Torque (Nm)

-6372183 8781344 Wing root

73

6. Material Selection:

6.1 Description:

Aircraft structures are basically unidirectional. This means that one dimension,

the length, is much larger than the others - width or height. For example, the

span of the wing and tail spars is much longer than their width and depth; the

ribs have a much larger chord length than height and/or width; a whole wing

has a span that is larger than its chords or thickness; and the fuselage is much

longer than it is wide or high. Even a propeller has a diameter much larger than

its blade width and thickness, etc.... For this simple reason, a designer chooses

to use unidirectional material when designing for an efficient strength to weight

structure.

Unidirectional materials are basically composed of thin, relatively flexible,

long fibers which are very strong in tension (like a thread, a rope, a stranded

steel wire cable, etc.)

An aircraft structure is also very close to a

symmetrical structure. That means the up and down

loads are almost equal to each other. The tail loads

may be down or up depending on the pilot raising or

dipping the nose of the aircraft by pulling or pushing

the pitch control; the rudder may be deflected to the

right as well as to the left (side loads on the fuselage).

The gusts hitting the wing may be positive or

negative, giving the up or down loads which the

occupant experiences by being pushed down in the

seat ... or hanging in the belt.

Because of these factors, the designer has to use a

74

structural material that can withstand both tension and compression.

Unidirectional fibers may be excellent in tension, but due to their small cross

section, they have very little inertia (we will explain inertia another time) and

cannot take much compression. They will escape the load by bucking away. As

in the illustration, you cannot load a string, or wire, or chain in compression.

In order to make thin fibers strong in compression, they are "glued together"

with some kind of an "embedding". In this way we can take advantage of their

tension strength and are no longer penalized by their individual compression

weakness because, as a whole, they become compression resistant as they help

each other to not buckle away. The embedding is usually a lighter, softer

"resin" holding the fibers together and enabling them to take the required

compression loads. This is a very good structural material.

WOOD

Historically, wood has been used as the first unidirectional structural raw

material. They have to be tall and straight and their wood must be strong and

light. The dark bands (late wood) contain many fibers, whereas the light bands

(early wood) contain much more "resin". Thus the wider the dark bands, the

stronger and heavier the wood. If the dark bands are very narrow and the light

bands quite wide, the wood is light but not very strong. To get the most

efficient strength to weight ratio for wood we need

a definite numbers of bands per inch.

Some of our aircraft structures are two-dimensional

(length and width are large with respect to

thickness). Plywood is often used for such

structures. Several thin boards (foils) are glued

together so that the fibers of the various layers cross

over at different angles (usually 90 degrees today years back you could get

75

them at 30 and 45 degrees as well). Plywood makes excellent "shear webs" if

the designer knows how to use plywood efficiently. (We will learn the basis of

stress analysis sometime later.)

Today good aircraft wood is very hard to come by. Instead of using one good

board for our spars, we have to use laminations because large pieces of wood

are practically unavailable, and we no longer can trust the wood quality. From

an availability point of view, we simply need a substitute for what nature has

supplied us with until now.

ALUMINUM ALLOYS

So, since wood may not be as available as it was before, we look at another

material which is strong, light and easily available at a reasonable price

(there's no point in discussing Titanium - it's simply too expensive). Aluminum

alloys are certainly one answer. We will discuss the properties of those alloys

which are used in light plane construction in more detail later. For the time

being we will look at aluminum as a construction material.

Extruded Aluminum Alloys: Due to the manufacturing process for aluminum

we get a unidirectional material quite a bit stronger in the lengthwise direction

than across. And even better, it is not only strong in tension but also in

compression. Comparing extrusions to wood, the tension and compression

characteristics are practically the same for aluminum alloys so that the linear

stress analysis applies. Wood, on the other hand, has a tensile strength about

twice as great as its compression strength; accordingly, special stress analysis

methods must be used and a good understanding of wood under stress is

essential if stress concentrations are to be avoided!

Aluminum alloys, in thin sheets (.016 to .125 of an inch) provide an excellent

two dimensional material used extensively as shear webs - with or without

76

stiffeners - and also as tension/compression members when suitably formed

(bent).

It is worthwhile to remember that aluminum is an artificial metal. There is no

aluminum ore in nature. Aluminum is manufactured by applying electric power

to bauxite (aluminum oxide) to obtain the metal, which is then mixed with

various strength-giving additives. (In a later article, we will see which additives

are used, and why and how we can increase aluminum's strength by cold work

hardening or by tempering.) All the commonly used aluminum alloys are

available from the shelf of dealers. When requested with the purchase, you can

obtain a "mill test report" that guarantees the chemical and physical properties

as tested to accepted specifications.

As a rule of thumb, aluminum is three times heavier, but also three times

stronger than wood. Steel is again three times heavier and stronger than

aluminum.

STEEL

The next material to be considered for aircraft structure will thus be steel,

which has the same weight-to-strength ratio of wood or aluminum.

Apart from mild steel which is used for brackets needing little strength, we are

mainly using a chrome-molybdenum alloy called AISI 413ON or 4140. The

common raw materials available are tubes and sheet metal. Steel, due to its

high density, is not used as shear webs like aluminum sheets or plywood.

Where we would need, say.100" plywood, a .032 inch aluminum sheet would

be required, but only a .010 steel sheet would be required, which is just too thin

to handle with any hope of a nice finish. That is why a steel fuselage uses tubes

also as diagonals to carry the shear in compression or tension and the whole

structure is then covered with fabric (light weight) to give it the required

77

aerodynamic shape or desired look. It must be noted that this method involves

two techniques: steel work and fabric covering.

We will be discussing tubes and welded steel structures in more detail later and

go now to "artificial wood" or composite structures.

COMPOSITE MATERIALS

The designer of composite aircraft simply uses fibers in the desired direction

exactly where and in the amount required. The fibers are embedded in resin to

hold them in place and provide the required support against buckling. Instead

of plywood or sheet metal which allows single curvature only, the composite

designer uses cloth where the fibers are laid in two directions .(the woven

thread and weft) also embedded in resin. This has the advantage of freedom of

shape in double curvature as required by optimum aerodynamic shapes and for

very appealing look (importance of esthetics).

Today's fibers (glass, nylon, Kevlar, carbon, whiskers or single crystal fibers of

various chemical compositions) are very strong, thus the structure becomes

very light. The drawback is very little stiffness. The structure needs stiffening

which is achieved either by the usual discreet stiffeners, -or more elegantly

with a sandwich structure: two layers of thin uni- or bi-directional fibers are

held apart by a lightweight core (foam or "honeycomb"). This allows the

designer to achieve the required inertia or stiffness.

From an engineering standpoint, this method is very attractive and supported

by many authorities because it allows new developments which are required in

case of war. But this method also has its drawbacks for homebuilding: A mold

is needed, and very strict quality control is a must for the right amount of fibers

and resin and for good adhesion between both to prevent too "dry" or "wet" a

structure. Also the curing of the resin is quite sensitive to temperature,

78

humidity and pressure. Finally, the resins are active chemicals which will not

only produce the well-known allergies but also the chemicals that attack our

body (especially the eyes and lungs) and they have the unfortunate property of

being cumulatively damaging and the result (in particular deterioration of the

eye) shows up only years after initial contact.

Another disadvantage of the resins is their limited shelf life, i.e., if the resin is

not used within the specified time lapse after manufacturing, the results may be

unsatisfactory and unsafe.

HEAVY AIRCRAFT RAW MATERIALS

The focus of our article is our Table which gives typical values for a variety of

raw materials.

Column 1 lists the standard materials which are easily available at a reasonable

cost. Some of the materials that fall along the borderline between practical and

impractical are:

Magnesium: An expensive material. Castings are the only readily available

forms. Special precaution must be taken when machining magnesium because

this metal burns when hot.

Titanium: A very expensive material. Very tough and difficult to machine.

Carbon Fibers: Still very expensive materials.

Kevlar Fibers: Very expensive and also critical to work with because it is hard

to "soak" in the resin. When this technique is mastered, the resulting structure

is very strong, but it also lacks in stiffness.

Columns 2 through 6:

Columns 2 through 6 list the relevant material properties in metric units.

Column 2, the density (d), is the weight divided by the volume.

79

Table 6-1: Material property table

Materials d fy fu e E/10

3

E/d Root

2

of

N/d

Root

3

of

E/d

fu/d

1 2 3 4 5 6 7 8 9 10

Wood Spruce .45 - 3.5/11 - 1.4 220

0

70 22.0 (15)

Poplar .43 - 30/12 - 1.0 220

0

70 22.0 (15)

Oregon

Pine

.56 - 4.0/13 - 1.5 220

0

70 22.0 (15)

Fiberglas

s

Matte 2.2 - 15 - 1.5 700 17 5.0 7

(70%

Glass)

Woven 2.2 - 35 - 2.0 900 20 6.0 16

Unidirectio

nal

2.2 - 60 - 3.5 150

0

27 7.0 27

Alum.

Alloy

5052-H34 2.7 16 24 4 7.1 260

0

30 7.0 11

8086-H34 2.7 22 31 5 7.1 260

0

30 7.0 11

6061 -T6 2.7 24 26 9 7.1 260

0

30 7.0 11

6351 -T6 2.7 25 28 9 7.1 260

0

30 7.0 11

6063-T6 2.7 17 21 9 7.1 260

0

30 7.0 11

7075-T3 2.8 25 41 1

2

7.2 260

0

30 7.0 14

Steel AISI 1026 7.8 25 38 1

5

21.0 270

0

18 3.5 5

4130 N

(4140)

7.8 42 63 1

0

21.0 270

0

18 3.5 7

Lead 11.3 - - - - - - - -

Magnesium Alloy 1.8 20 30 - 4.5 250

0

37 9.0 16

Titanium 4.5 50 80

-

11.0 240

0

23 5.0 18

Units for above kg/d

m

3

kg/m

m

2

kg/m

m

2

% kg/m

m

2

km kg

-

m

2

kg

2/3

m

1/3

km

to obtain: lbs/cu

3

KSI KSI % KSI

multiply by:

.0357 1420 1420 - 1420

80

Column 3, the yield stress (fy), is the stress (load per area) at which there will

be a permanent deformation after unloading (the material has yielded, given

way ... )

Column 4, the ultimate stress (fu), is the stress (load per area) at which it cannot

carry a further load increase. It is the maximum load before failure.

Column 5, the elongation at ultimate stress (e), in percentage gives an indication

of the 'Toughness" of the material.

Column 6 lists the Yongs Modular or Modulus of Elasticity (E), which is the

steepness of the stress/strain diagram as shown in Figure 1.

Important Note: For wood, the tension is much greater (2 to 3 times) than the

compression. Both values are given in the Table. For fiberglass, the same applies,

but the yield is so dependent on the manufacturing process that we cannot even

give 'Iypical values'.

Figure 6-1: Stress strain curves for different materials

Columns 7 to 10: Columns 7 to 10 are values which allow the comparison of

materials from a weight standpoint (the above referenced text by Timoshenko will

also show you why we use those "funny" looking values).

Column 7 gives the stiffness of a sandwich construction. The higher the value, the

stiffer the construction. From the Table, we see that metals are high wood comes

81

close, but fiberglass is low: which means fiberglass will be heavier for the same

stiffness.

Figure 6-2: Stress strain curve

Column 8 shows the column buckling resistance for the same geometric shapes.

This time, wood is better than the light alloys, coming before steel and fiberglass.

(Surprisingly, the usual welded steel tube fuselage is not very weight efficient.)

Column 9 gives the plate buckling stiffness, which is also a shear strength

measure. Here again, wood (plywood) is in a very good position before aluminum

and fiberglass, with steel not very good.

Column 10 provides a crude way of measuring the strength to weight ratio of

materials because it does not take into account the various ways the material is

used in "light structures". According to this primitive way of looking,

unidirectional fibers are very good, followed by high strength (2024) aluminum

and wood, then the more common aluminum alloys and finally steel.

From just this simple table, we find there is not one material that provides an

overwhelming solution to all the factors that must be considered in designing a

light aircraft. Each material has some advantage somewhere. The designer's

choice (no preconceived idea) will make a good aircraft structure ... if the choice

is good!

82

7. Detailed wing design

7.1 Spar design:

Spars are members which are basically used to carry the bending and

shear loads acting on the wing during flight. There are two spars, one located at

15-20% of the chord known as the front spar, the other located at 60-70% of

the chord known as the rear spar. Some of the functions of the spar include:

They form the boundary to the fuel tank located in the wing.

The spar flange takes up the bending loads whereas the web carries the

shear loads.

The rear spar provides a means of attaching the control surfaces on the

wing.

Considering these functions, the locations of the front and rear spar are fixed

at 0.17c and 0.65c respectively. The NACA 65 (3) 418 airfoil is drawn to scale

using any design software and the chord thickness at the front and rear spar

locations are found to be 1.9708 m and 7.5354 m respectively.

7.1.1 Geometric dimensions:

The spar design for the wing root has been taken because the maximum

bending moment and shear force are at the root. It is assumed that the flanges

take up all the bending and the web takes all the shear effect. The maximum

bending moment for high angle of attack condition is 486567918.4 Nm. the

ratio in which the spars take up the bending moment is given as

Where

83

h

1

height of front spar

h

2

height of rear spar

From the above two equations,

The yield tensile stress y for 7075 Al Alloy is 455.053962 MPa. The area of

the flanges is determined using the relation

where M is bending moment taken up by each spar,

A is the flange area of each spar,

z is the centroid distance of the area = h/2.

Using the available values,

Area of front spar,

Area of rear spar,

84

Each flange of the spar is made of two angle sections. For the front spar, the

length of the angle is 6t, angle height is 5t with angle thickness t. Area for each

angle of front spar is found to be 0.1799507 m

2

and hence value of t is found to

be

Length of the front angle section:

Height of the front angle section:

For the rear spar, the length of the angle is 8t, angle height is 3.5t with vertical

thickness t and horizontal thickness t/2. Area for each angle of rear spar is

found to be 0.164486 m

2

and hence value of t is found to be.

Length of the rear angle section:

Height of the rear angle section:

Now to determine the thickness of the web portion, the ultimate shear stress of

7075 Al Alloy is 317.1588MPa. The maximum shear force at root of the wing

85

for high angle of attack condition is 17480623.2 N. The wing chord is assumed

to be a simply supported beam supported at the two spars. The maximum shear

force acts at the centre of pressure which can be located by using the formula,

Figure 7-1: Reaction force determination at spars

Considering force and moment equilibriums for the given simply supported

configuration, the reactive shear force at the spar supports are found to be

We know that,

V shear force at the spar

86

t thickness of the web.

Thus,

FOS = 1.5

z is the centroidal distance of the area = h/2

Thus the thicknesses of the web portions are,

All dimensions are in m

It becomes necessary to check whether the shear stress due to this thickness is

less than the allowable of the material.

1.00128

0.02346

0.1251

Rear spar

0.43806

0.0763

0.13414

0.8048

0.670

Front Spar

87

For the web, the dimensions of a and b will be

a = 1.6186 m ( rib spacing) and

b = spar height.

The value of k

s

is obtained using a/b from the given plot in figure, k

s

is

obtained and thus the actual shear stress in each web

Figure 7-2: Shear buckling coefficients fro plates as a ratio of a and b for hinged and clamped edges

Both these values are less than 211.4392 GPa. Thus, the web does not fail due

to shear buckling.

88

7.1.2 Shear flow:

The shear flow can be considered for the two cells in the airfoil cross

section. The shear flow will be due to the torque as well due to the bending

moments. These are computed separately and summed up to obtain the net

shear flow pattern for the wing cross section.

Due to torque,

A area of each cell

Q shear flow due to the torque

The maximum torque experienced at the root of the wing is -25338 Nm.

Using GAMBIT software, the areas and perimeters of the cells in the airfoil

formed by the spars and the skin are found to be,

Cell1 A

1

= 2.1783 m

2

Cell2 A

2

= 10.5862 m

2

Cell3 A

3

= 2.7528 m

2

l

1

= 4.45527 m, l

2

= 1.6186 m, l

3

= 5.6214 m, l

4

= 5.5827 m, l

5

= 1.4795 m, l

6

=

4.092 m, l

7

= 4.176 m .

l1, l2 belong to cell1,l2, l3, l4, l5 belong to cell2, l5, l6 and l7 to cell3. l2 and l5

are the spars.

The equations for the two cells involving shear flow of cell1 q1 and shear flow

of cell2 q2 are

)]

)]

)]

89

The second, third and fourth equations are obtained from the condition that

the cell twist is zero.

Solving these equations, we get shear flow values due to torque alone.

The shear flow due to bending is given by the formula,

*

+ *

+

Vx = 1012394.13 N (shear force due to chordwise forces)

Vy = 17480623.2 N (shear force due to normal forces)

90

S

p

a

r

A

r

e

a

A

*

x

A

*

y

x

_

b

a

r

y

b

a

r

x

_

c

y

_

c

I

x

x

I

y

y

I

x

y

q

F

_

U

_

1

1

7

9

9

3

5

.

3

9

6

3

0

6

3

4

3

6

1

0

.

4

1

4

5

3

9

8

2

3

6

.

2

1

7

0

2

.

5

2

8

0

8

.

0

5

8

-

1

7

7

5

.

3

8

8

0

8

.

0

5

8

1

.

2

0

9

9

8

E

+

1

1

5

.

7

0

6

5

9

E

+

1

1

-

2

.

5

8

1

3

7

E

+

1

1

-

1

4

8

5

8

6

8

F

_

U

_

2

1

7

9

9

3

5

.

3

9

6

4

0

2

8

8

9

7

4

6

.

5

1

4

5

3

9

8

2

3

6

.

2

2

2

3

9

.

0

8

8

0

8

.

0

5

8

-

1

2

3

8

.

8

2

8

0

8

.

0

5

8

1

.

2

0

9

9

8

E

+

1

1

2

.

7

9

6

5

E

+

1

1

-

1

.

8

0

1

2

2

E

+

1

1

-

1

9

6

4

4

3

8

F

_

L

_

1

1

7

9

9

3

5

.

3

9

6

3

0

6

3

4

3

6

1

0

.

4

-

4

9

3

0

0

4

9

9

.

2

1

7

0

2

.

5

2

-

2

7

3

.

9

9

-

1

7

7

5

.

3

8

-

2

7

3

.

9

9

1

7

0

1

5

3

2

4

6

5

8

5

.

7

0

6

5

9

E

+

1

1

8

7

5

2

7

1

2

0

1

8

1

4

2

1

8

0

4

.

4

9

F

_

L

_

2

1

7

9

9

3

5

.

3

9

6

4

0

2

8

8

9

7

4

6

.

5

-

4

9

3

0

0

4

9

9

.

2

2

2

3

9

.

0

8

-

2

7

3

.

9

9

-

1

2

3

8

.

8

2

-

2

7

3

.

9

9

1

7

0

1

5

3

2

4

6

5

8

2

.

7

9

6

5

E

+

1

1

6

1

0

7

4

4

4

4

3

5

7

5

5

5

7

6

5

.

2

6

R

_

U

_

1

1

6

4

4

8

2

.

7

6

9

1

1

9

8

2

7

8

3

5

3

1

1

8

9

6

1

0

1

1

.

2

7

2

8

5

.

1

3

7

2

3

.

2

4

3

3

8

0

7

.

2

3

7

2

3

.

2

4

3

8

8

6

9

6

1

4

3

0

5

1

2

.

3

8

6

8

4

E

+

1

2

4

.

5

2

9

1

2

E

+

1

1

6

0

7

5

6

9

.

2

3

R

_

U

_

2

1

6

4

4

8

2

.

7

6

9

1

2

8

0

6

2

5

0

0

7

1

1

8

9

6

1

0

1

1

.

2

7

7

8

5

.

7

7

7

2

3

.

2

4

3

4

3

0

7

.

8

7

7

2

3

.

2

4

3

8

8

6

9

6

1

4

3

0

5

1

3

.

0

5

5

0

9

E

+

1

2

5

.

1

2

4

6

9

E

+

1

1

5

4

9

3

6

9

.

1

1

R

_

L

_

1

1

6

4

4

8

2

.

7

6

9

1

1

9

8

2

7

8

3

5

3

-

4

2

0

4

5

2

4

9

.

8

7

2

8

5

.

1

3

-

2

5

5

.

6

2

1

3

8

0

7

.

2

3

-

2

5

5

.

6

2

1

1

3

4

0

6

0

7