Escolar Documentos

Profissional Documentos

Cultura Documentos

10 Fluid Power Lessons

Enviado por

vietrossDireitos autorais

Formatos disponíveis

Compartilhar este documento

Compartilhar ou incorporar documento

Você considera este documento útil?

Este conteúdo é inapropriado?

Denunciar este documentoDireitos autorais:

Formatos disponíveis

10 Fluid Power Lessons

Enviado por

vietrossDireitos autorais:

Formatos disponíveis

10 fluid power lessons you don't learn in school

Completing engineering school doesn't make you an expert - at least in fluid power. Here's

some of the most common fluid power mistakes most courses never cover, and how to

avoid them.

By Charles J. Murray, Senior Technical Editor

Reprinted from DESIGN NEWS

Face it: I you !ere educated in a our"year #echanical en$ineerin$ curriculu#, you %ro&a&ly

didn't learn #uch a&out luid %o!er. (#erican uni)ersities ty%ically teach luid #echanics, luid

dyna#ics, and ther#odyna#ics. But they seldo# del)e dee%ly into the su&*ects o hydraulics or

%neu#atics as a %o!er #ediu#.

That's !hy #ost desi$n en$ineers in this country learn their luid %o!er on the *o&. (nd it's !hy

they so#eti#es #a+e #ista+es they could easily a)oid i the theoretical under%innin$s o the

su&*ect !ere #ore readily a)aila&le.

,-ou #ay ha)e let school !ith a #echanical en$ineerin$ de$ree, &ut that does not #ean you

ha)e a $ood $ras% o luid %o!er,, notes an en$ineer ro# a #a*or luid %o!er su%%ly co#%any.

Fortunately, #any hydraulic and %neu#atic co#%onent su%%liers oer trainin$ classes or desi$n

en$ineers. .ar+er /anniin, 0ic+ers, Mannes#ann 1e2roth, Festo and others teach the &asics o

hydraulics and %neu#atics. ,Most o these classes oer 345 o the #aterial that desi$n

en$ineers need,, notes Don Ca%uto, #ar+etin$ #an$er or .ar+er /anniin's /ydraulic 0al)e

Di)ision. ,We !ant to $et the !ord out to custo#ers, #any o !ho# are en$ineers, !ho ne)er

had this #aterial in school.,

For those !ho can't i##ediately attend such %ro$ra#s, Desi$n Ne!s oers a co#%ilation o

so#e o the #ost co##on #ista+es in luid %o!er desi$n. The #ista+es co)er a &road ran$e,

ro# %ro&le#s !ith %neu#atic tu&in$ to errors in hydraulic orce calculation. So#e #ay see#

ele#entary. But su%%liers a$ree on one %oint: ()oidin$ the# in your %ro*ects !ill not only cut ti#e

and sa)e #oney, it !ill eli#inate countless headaches.

H!"#$%&C'

(istake )1* Failure to recognize maximum flow

-ou're desi$nin$ a hydraulic actuator that !ill o%erate at a %rescri&ed s%eed. To acco#%lish that,

you calculate that the cylinder needs a lo! rate o 67 $allons %er #inute 8$%#9. So you si:e your

hydraulic syste# or 67 $%#, ri$ht;

Not necessarily. Many a%%lications call or the return stro+e to &e aster than the %o!er stro+e. In

the a%%lication descri&ed a&o)e, it's not unco##on or the return stro+e to need a lo! rate o <7

$%#.

I, ho!e)er, the return lines and ilters are si:ed or 67 $%#, then the user has a %ro&le#. The

syste# &uilds u% heat. =ndersi:ed ilters ail to %ro%erly clean the hydraulic luid. >ea+s result.

"emedy* Consider the return rate

1e#e#&er, the lo! rate needed or cylinder e2tension is not al!ays the syste#'s astest lo!

rate. ,Ty%ically, the user !ants to e2tend the cylinder !ith a $reat deal o control,, Ca%uto says.

,But on the !ay &ac+, they're not doin$ any !or+, so they !ant the cylinder to $et &ac+ as ast as

it can., In #ost a%%lications, Ca%uto says, the return rate is t!ice that o the e2tension lo! rate.

(istake )+* Undersized piping

(ter selectin$ a hydraulic #otor, en$ineers oten loo+ at the #otor's %ort si:es &eore choosin$

their %i%in$. I the #otor's %ort si:es are, say, three"?uarters o an inch, then they choose three"

?uarter"inch ittin$s and three"?uarter"inch outer dia#eter %i%in$.

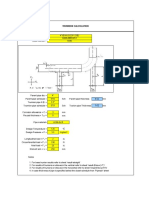

!etermining pressure drop in a length of pipe

. @

hA

6B,C77dD

Where . @ %ressure dro%Et o %i%e

h @ )iscosity 8ss)9

A @ lo!

d @ ID o %i%e

That's a #ista+e. Too oten, such sna% decisions result in undersi:ed %i%in$. (nd undersi:ed

%i%in$, in turn, causes lar$er %ressure dro%s and #ore heat $eneration than the syste# is

desi$ned or.

"emedy* Check ID, flow velocity, pressure drop

( desi$ner !ho ?uic+ly si:es %i%in$ si#%ly &y loo+in$ at the #otor's %ort ris+s #a+in$ se)eral

#ista+es. First, a three"?uarter"inch outer dia#eter is too s#all. Why; Because a three"?uarter"

inch FD #ay ha)e an inner dia#eter o as little as hal an inch. Second, selection o %i%in$

re?uires #ore thou$htul consideration. Desi$ners #ust consider )elocity o lo! throu$h the %i%e

and %ressure dro% %er oot o %i%e 8see e?uations a&o)e and &elo!9. E2%erts say that %ressure

dro% can &e i#%ortant, es%ecially in syste#s usin$ lon$ sections o %i%in$. They also reco##end

that desi$ners #aintain lo! )elocities !ith certain %ara#eters. E2ceedin$ those %ara#eters #ay

cause tur&ulence in the lo!, !hich can aect the 1eynolds nu#&er o the luid.

!etermining velocity of flow through a pipe

0 @

7.C<7B8G.M9

A

Where 0 @ lo! )elocity

G.M @ $allons %er #inute o lo! into the syste#

( @ area inside the %i%e 8in

<

9

(istake ),* Reservoir size too small

By dissi%atin$ heat, reser)oirs in any hydraulic syste# %lay an i#%ortant role. I the reser)oir is

undersi:ed, ho!e)er, it can't %ro%erly dissi%ate the heat. (s a result, %eror#ance suers and

co#%onents !ear out earlier. ,( lot o users assu#e their reser)oir is &i$ enou$h !ithout sittin$

do!n to calculate the heat dissi%ation,, Ca%uto says. ,I they !ould do so#e si#%le calculations,

they #i$ht ind that their syste# needs a &i$$er reser)oir or e)en a heat e2chan$er.,

"emedy* Calculate dissipation capailities of the reservoir in horsepower

In $eneral, a G7"$allon tan+ !ill dissi%ate hal a horse%o!er, $i)en a 47H te#%erature dierential

&et!een the oil in the reser)oir and the air outside it. Co#%are that to your syste#'s horse%o!er.

=se a &i$$er reser)oir or a heat e2chan$er, i necessary, de%endin$ on your %ac+a$in$

constraints.

!etermining heat dissipation of a reservoir

Where /. @ horse%o!er dissi%ated

( @ surace area o reser)oir 8t<9

te#%erature dierence &et!een oil in tan+ and air outside 8de$ F9

86/. @ <4DD BT=Ehr9

(istake )-* !roportional valves too ig

When selectin$ a directional )al)e, desi$ners usually chec+ their syste#'s lo! rate, o%en a

catalo$, and loo+ or a )al)e !ith a corres%ondin$ ratin$.

So !hat's !ron$ !ith that; Nothin$ I i you're %ic+in$ a directional )al)e. .ro%ortional )al)es,

ho!e)er, are dierent. ,.ro%ortional and ser)o )al)es e2hi&it their control throu$h a hi$h %ressure

dro%,, notes >arry Schrader, director o #otion control trainin$ or .ar+er /anniin. The )al)e's

lo! ratin$, he says, is usually &ased on a s%eciic %ressure dro%. Thereore, i your a%%lication's

%ressure dro% is si$niicantly dierent than the rated %ressure dro% o the )al)e, you'll %ro&a&ly

select the !ron$ )al)e. =sually, Schrader says, en$ineers end u% !ith an o)ersi:ed %ro%ortional

)al)e.

'i.ing a proportional valve /y flow rate

Where A1 @ )al)e's rated lo! or your a%%lication

AF=T @ out%ut lo! needed or a%%lication

rated %ressure dro% o %ro%ortional )al)e

actual %ressure dro% needed or a%%lication

I they do select an o)ersi:ed )al)e, users are unli+ely to $et true %ro%ortional %eror#ance. In

#ost cases, the )al)e !ill o%en all the !ay &eore it's su%%osed to, denyin$ users the resolution

that they see+.

"emedy* Use pressure drop to determine flow rate

E2%erts reco##end that desi$ners use this #ethod to chec+ the lo! ratin$ o their )al)e. In #ost

cases, they say, the lo! ratin$ they o&tain &y this #ethod !ill dier ro# the lo! ratin$s in the

catalo$.

(istake )0* "pecific gravity prolems In #any cases, users !ant to re%lace con)entional

hydraulic oil !ith %hos%hate esters o !ater $lycol luids. That's ine, say e2%erts, as lon$ as you

understand that hydraulic %u#%s can't lit those luids as easily as they lit hydraulic oil. The

reason: Con)entional hydraulic oil has a s%eciic $ra)ity o a&out 7.B4, !hile !ater $lycol ty%ically

is a&out 6.7. .hos%hate ester is e)en hea)ier at 6.6.

I desi$n en$ineers don't #a+e s%ecial acco##odations or those hea)ier luids, users soon

notice that %u#%s #a+e too #uch noise. =lti#ately, ca)itation o the %u#% occurs.

"emedy* !ut the reservoir higher than the pump

Manuacturers call this ,looded suction., The %u#% doesn't need to !or+ as hard to #o)e the

hea)ier luid. I you're not sure a&out the s%eciic $ra)ity o the luid you're usin$, call the %u#%'s

#anuacturer to see i they re?uire a looded suction or that luid.

123$(#4&C'

(istake )5* Force miscalculation

I you +no! the loads, si:in$ a cylinder is easy. =nortunately, +no!in$ the loads can so#eti#es

&e diicult. Forces caused &y riction and acceleration are #ore diicult to calculate, and are oten

o)erloo+ed. Worse, desi$ners can't al!ays oresee ho! the #achine !ill &e used. ,For the desi$n

en$ineer, it's not al!ays as easy as, 'I need to lit 47 %ounds,', says Jerry Scher:in$er, senior

su%%ort en$ineer or Bi#&a Manuacturin$. ,( lot o ti#es the desi$ner is co#in$ u% !ith a &est

esti#ate, and there are #any actors in)ol)ed in esti#ation that orce., Too oten, Scher:in$er

says, the desi$ner underesti#ates the orce re?uire#ent, rather than o)eresti#ates it. (s a result,

the syste# doesn't #o)e the load ast enou$h, or doesn't #o)e it at all.

"emedy* #versize y $%&

That's !hat Scher:in$er reco##ends to account or rictional loads. I you sus%ect that the

cylinder !ill &e su&*ected to $reater loads later on, you #i$ht e)en consider e2ceedin$ that <45

rule o thu#&. The only do!nside to doin$ that is cost: Initial costs and o%eratin$ costs can rise.

In the lon$ run, ho!e)er, users usually ind that a lar$er cylinder %ro)ides $reater &eneits. ,Don't

hesitate to o)ersi:e the cylinder,, he says. ,The ad)anta$es o o)ersi:in$ out!ei$h the

disad)anta$es.,

(istake )6* 'rong valve for ()stop

E#er$ency"sto% situations de#and that a %neu#atic syste# co#e to a co#%lete halt.

So#eti#es, ho!e)er, a %neu#atic )al)e is already shited !hen %o!er is cut o. (ter!ards, that

)al)e shits &ac+ and the associated %neu#atic cylinder #o)es. That scenario can ta+e %lace

!hen certain i)e"!ay )al)es are used !ith dou&le"actin$ cylinders. (nd the results, in so#e

cases, can &e da#a$in$ or e)en dan$erous or %ersonnel.

"emedy* Check with valve manufacturer first

In #ost cases, users notice the %ro&le# &eore da#a$e occurs. By that ti#e, ho!e)er, the )al)e

has already &een s%eciied and installed. (s a result, chan$in$ to the ri$ht )al)e can &e ti#e"

consu#in$ and costly. For that reason, e2%erts say that en$ineers #ust &e )i$ilant early in the

desi$n %rocess. ,They ha)e to understand their #achine and as+ all o the '!hat i;' ?uestions,,

notes Daniel Sando)al, didactic trainin$ #ana$er or Festo. ,What i %o!er is cut"o; What i the

.>C $oes &ad; What i so#eone hits the E"sto%; The solutions to these %ro&le#s ha)e to &e

dealt !ith in hard!are. It's not %er#issi&le to re#edy those %ro&le#s in sot!are., Because there

are #any dierent ty%es and &rands o )al)es, Sando)al says desi$ners #ust consult !ith the

)al)e #anuacturer to learn ho! the )al)e !ill &eha)e !hen %o!er is cut o.

(istake )7* *igh)speed undersizing

/i$h")elocity %neu#atic a%%lications re?uire suicient orce and hi$h lo! rates. =nortunately,

syste# desi$ners don't al!ays %ro)ide &oth o those eatures. Too oten, air cylinders are too

s#all to %ro)ide the orce needed or ?uic+ acceleration. (nd )al)es don't ha)e the necessary

lo! rates to achie)e hi$h s%eed.

"emedy* Doule the ore diameter of the chosen cylinder

For s%eeds a&o)e 6G inchesEsecond, i you're %lannin$ on selectin$ a one"inch cylinder, select a

t!o"inch #odel instead. (lso, %neu#atics #anuacturers say that desi$ners #ust loo+ careully at

the lo! ratin$s o the )al)es they %lan to use in hi$h s%eed a%%lications. Catalo$ ratin$s are

usually suicient, they say, &ut are too oten i$nored or #isinter%reted.

(istake )8* Failure to specify tough)enough construction

.neu#atic"co#%onent #anuacturers say they see the# all the ti#e: cylinders, !or+in$ in tou$h,

corrosi)e en)iron#ents, una&le to stand u% to e)ery day !ear"and"tear. Beore lon$, the cylinders

dra! in dirt, then ail to %eror# %ro%erly. In #ost cases, they say, the %ro&le# occurs &ecause

desi$ners ne)er oresee the &readth o a%%lication or their technolo$y. ,So#eti#es a desi$ner

!ill desi$n a syste# that's so $ood, three or our industries can use it,, Scher:in$er says. ,(ll o a

sudden, their e?ui%#ent is in an a%%lication !here they ne)er e2%ected it.,

"emedy* +etter materials

I you sus%ect that your #achine !ill &e used in such a%%lications as ood or %har#aceutical

%rocessin$, &e %re%ared to i#%ro)e the #aterials o construction o your cylinders. Stainless steel

or anodi:ed alu#inu# &odies resist corrosion #ore eecti)ely, %articularly in !ash do!n

en)iron#ents. (lso consider use o %lastic end ca%s, !i%ers, scra%ers or rod &oots as a #eans o

%re)entin$ in$ress o dirt into the cylinder.

(istake )10* Insufficient tuing Most desi$ners are trained to thin+ o a %neu#atic syste# as a

collection o %u#%s, cylinders, and )al)es. So#e!here in &et!een those %u#%s, cylinders, and

)al)es, ho!e)er, lies an e?ually i#%ortant co#%onent: tu&in$. I#%ro%erly desi$ned tu&in$ can

cause distur&ances in lo! and %ressure. Too oten, it &eco#es the li#itin$ actor in a %neu#atic

syste#.

"emedy* !ay attention

E2%erts say that tu&in$ #ista+es all into t!o cate$ories: too lon$ or too s+inny. >on$ sections o

tu&in$ create un!anted %ressure dro%s and s+inny tu&es cause )al)es to !or+ i#%ro%erly.

=nortunately, they say, desi$ners can only re#ind the#sel)es to &e a!are o the %ro&le#s

caused &y i#%ro%erly desi$ned tu&in$. ,When you loo+ at a dra!in$, the tu&in$ loo+s li+e a

&unch o insi$niicant lines,, Sando)al says. ,But i you don't %ay attention to it, it can cause a lot

o trou&le or you.,

'lime/usters* 1lastic end caps and stainless steel /odies, like those shown here, keep

fluid power e9uipment operating even in aggressive environment applications.

Você também pode gostar

- The Yellow House: A Memoir (2019 National Book Award Winner)No EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Nota: 4 de 5 estrelas4/5 (98)

- Flat Socket Head Cap ScrewsDocumento8 páginasFlat Socket Head Cap Screwsvietross100% (1)

- An Introduction To Air Density and Density Altitude CalculationsDocumento22 páginasAn Introduction To Air Density and Density Altitude CalculationsvietrossAinda não há avaliações

- Carbozinc 11 HS PDSDocumento2 páginasCarbozinc 11 HS PDSvietrossAinda não há avaliações

- Slide Plate ApplicationsDocumento2 páginasSlide Plate ApplicationsvietrossAinda não há avaliações

- Health InsurersDocumento2 páginasHealth InsurersvietrossAinda não há avaliações

- Simple Way To Save On EverythingDocumento2 páginasSimple Way To Save On EverythingvietrossAinda não há avaliações

- College SavingsDocumento2 páginasCollege SavingsvietrossAinda não há avaliações

- Surefire Ways To Get Taken by Identity ThievesDocumento3 páginasSurefire Ways To Get Taken by Identity ThievesvietrossAinda não há avaliações

- Sight Word SentencesDocumento52 páginasSight Word Sentencesvietross75% (4)

- Organic Foods One More Time - Jon BarronDocumento2 páginasOrganic Foods One More Time - Jon BarronvietrossAinda não há avaliações

- CombustionDocumento15 páginasCombustionvietrossAinda não há avaliações

- Matt Nesto: The Great Disconnect: Awful Earnings vs. A Hot Stock MarketDocumento1 páginaMatt Nesto: The Great Disconnect: Awful Earnings vs. A Hot Stock MarketvietrossAinda não há avaliações

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeNo EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeNota: 4 de 5 estrelas4/5 (5795)

- Never Split the Difference: Negotiating As If Your Life Depended On ItNo EverandNever Split the Difference: Negotiating As If Your Life Depended On ItNota: 4.5 de 5 estrelas4.5/5 (838)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceNo EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceNota: 4 de 5 estrelas4/5 (895)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersNo EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersNota: 4.5 de 5 estrelas4.5/5 (345)

- The Little Book of Hygge: Danish Secrets to Happy LivingNo EverandThe Little Book of Hygge: Danish Secrets to Happy LivingNota: 3.5 de 5 estrelas3.5/5 (400)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureNo EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureNota: 4.5 de 5 estrelas4.5/5 (474)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryNo EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryNota: 3.5 de 5 estrelas3.5/5 (231)

- The Emperor of All Maladies: A Biography of CancerNo EverandThe Emperor of All Maladies: A Biography of CancerNota: 4.5 de 5 estrelas4.5/5 (271)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaNo EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaNota: 4.5 de 5 estrelas4.5/5 (266)

- The Unwinding: An Inner History of the New AmericaNo EverandThe Unwinding: An Inner History of the New AmericaNota: 4 de 5 estrelas4/5 (45)

- Team of Rivals: The Political Genius of Abraham LincolnNo EverandTeam of Rivals: The Political Genius of Abraham LincolnNota: 4.5 de 5 estrelas4.5/5 (234)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyNo EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyNota: 3.5 de 5 estrelas3.5/5 (2259)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreNo EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreNota: 4 de 5 estrelas4/5 (1090)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)No EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Nota: 4.5 de 5 estrelas4.5/5 (121)

- Functions of A PumpDocumento178 páginasFunctions of A PumpKetan Sarmalkar50% (2)

- Batch 1 - 10320 Items - ConsolDocumento642 páginasBatch 1 - 10320 Items - ConsolRiyandi Achmad SyabanaAinda não há avaliações

- Methods of Wastewater TreatmentDocumento54 páginasMethods of Wastewater TreatmentPamela MendozaAinda não há avaliações

- PR 101Documento22 páginasPR 101Zohaib AlamAinda não há avaliações

- Line No. Iso. Sht. Rev. Date Drawing No. Code No. S.O No Client Project SHTDocumento5 páginasLine No. Iso. Sht. Rev. Date Drawing No. Code No. S.O No Client Project SHTAgus Umar FaruqAinda não há avaliações

- Line DiagramDocumento3 páginasLine Diagramvaranasirk1Ainda não há avaliações

- Profile PDA - PeshawarDocumento2 páginasProfile PDA - Peshawarkhan100% (1)

- System Curves Goulds Pumps PDFDocumento5 páginasSystem Curves Goulds Pumps PDFPTC Phils.Ainda não há avaliações

- Continuing Education From Plumbing Systems & DesignDocumento1 páginaContinuing Education From Plumbing Systems & Designexfireex1Ainda não há avaliações

- Experience Abba "Performance+ " Parts To Fit: Oem Model PartsDocumento5 páginasExperience Abba "Performance+ " Parts To Fit: Oem Model PartsNeil SandersAinda não há avaliações

- KS Jis (Ok)Documento26 páginasKS Jis (Ok)Tran Anh TuanAinda não há avaliações

- Peripheral Launder HydraulicsDocumento2 páginasPeripheral Launder HydraulicsahmadAinda não há avaliações

- WOLK 500 MonofasicaDocumento10 páginasWOLK 500 MonofasicaClaudio Valencia MarínAinda não há avaliações

- Trunnion Calcualtion SheetDocumento22 páginasTrunnion Calcualtion SheetAbhijit50% (2)

- Site LayoutDocumento1 páginaSite LayoutBSSBAinda não há avaliações

- 7 PeglerDocumento28 páginas7 Peglerarshad iqbalAinda não há avaliações

- Netafim Catalog 2016Documento132 páginasNetafim Catalog 2016salah najiAinda não há avaliações

- ComparativeDocumento190 páginasComparativeSatish BabuAinda não há avaliações

- Gama Completa de Vane Piese de Montaj Si InterventieiDocumento56 páginasGama Completa de Vane Piese de Montaj Si InterventieiMoHammadNashatSabbahAinda não há avaliações

- Procedure For The Design and Sizing of An Inclined Plate ClarifierDocumento10 páginasProcedure For The Design and Sizing of An Inclined Plate ClarifierKelvin Siew33% (3)

- CLASS 253086: DEP 31.38.01.12-Gen Class 253086, Rev. G Page 1 of 10Documento10 páginasCLASS 253086: DEP 31.38.01.12-Gen Class 253086, Rev. G Page 1 of 10SaguesoAinda não há avaliações

- Oxy Miser 1Documento4 páginasOxy Miser 1serlioAinda não há avaliações

- Environmental Engineering PDFDocumento2 páginasEnvironmental Engineering PDFannAinda não há avaliações

- Types of PumpsDocumento18 páginasTypes of PumpsKhoh Kai ShengAinda não há avaliações

- Experiment 3 Flow Over WeirsDocumento20 páginasExperiment 3 Flow Over Weirsfadhilahmad100% (3)

- RUJUKAN Senarai Spesifikasi JKRDocumento3 páginasRUJUKAN Senarai Spesifikasi JKREdison Lim0% (1)

- Phytorid Technology For Sewage and Waste Water TreatmentDocumento7 páginasPhytorid Technology For Sewage and Waste Water Treatmentdeerws anaparthiAinda não há avaliações

- BH-RS Products Presentation SC22Documento8 páginasBH-RS Products Presentation SC22walk111Ainda não há avaliações

- Manual Standpipes HandoutDocumento9 páginasManual Standpipes HandoutjosebolisAinda não há avaliações

- Delhi Jal Board Act - 1998Documento57 páginasDelhi Jal Board Act - 1998Vinay GargAinda não há avaliações