Escolar Documentos

Profissional Documentos

Cultura Documentos

Theoretical Stability Analysis of Flowing Oil Wells and Gas-Lift Wells

Enviado por

Ahmed Mamdouh0 notas0% acharam este documento útil (0 voto)

55 visualizações7 páginasThe unsteady equations of motion for flow out of naturally flowing and gas-lift wells are derived and then solved by

the Laplace transform method. This analysis produces a characteristic equation with coefficients that allow determination of the

stability of a particular well.

Direitos autorais

© © All Rights Reserved

Formatos disponíveis

PDF, TXT ou leia online no Scribd

Compartilhar este documento

Compartilhar ou incorporar documento

Você considera este documento útil?

Este conteúdo é inapropriado?

Denunciar este documentoThe unsteady equations of motion for flow out of naturally flowing and gas-lift wells are derived and then solved by

the Laplace transform method. This analysis produces a characteristic equation with coefficients that allow determination of the

stability of a particular well.

Direitos autorais:

© All Rights Reserved

Formatos disponíveis

Baixe no formato PDF, TXT ou leia online no Scribd

0 notas0% acharam este documento útil (0 voto)

55 visualizações7 páginasTheoretical Stability Analysis of Flowing Oil Wells and Gas-Lift Wells

Enviado por

Ahmed MamdouhThe unsteady equations of motion for flow out of naturally flowing and gas-lift wells are derived and then solved by

the Laplace transform method. This analysis produces a characteristic equation with coefficients that allow determination of the

stability of a particular well.

Direitos autorais:

© All Rights Reserved

Formatos disponíveis

Baixe no formato PDF, TXT ou leia online no Scribd

Você está na página 1de 7

Theoretical Stability Analysis of

Flowing Oil Wells and Gas-Lift Wells

E.F. Blick, SPE, U. of Oklahoma

P.N. Enga, * SPE, U. of Oklahoma

P.C. Lin, U. of Oklahoma

Summary. The unsteady equations of motion for flow out of naturally flowing and gas-lift wells are derived and then solved by

the Laplace transform method. This analysis produces a characteristic equation with coefficients that allow determination of the

stability of a particular well. .

Introduction

Many oil wells, naturally flowing or otherwise, reach a stage in

their flowing life when liquid rates are low. Such wells may be

candidates for flow instabilities, commonly called heading. Heading

can be defined as a flow regime characterized by regular and perhaps

irregular cyclic changes in pressure at any point in the tubing string.

Numerous studies

l

-

17

of heading have been reported since the

pioneering work of Donahue I in 1930. Among them, the first com-

prehensive discussion of the phenomenon of heading was given by

Gilbert

2

in his pioneering paper.

In this present study, a mathematical model is developed to

describe well and reservoir variables that are affected by pressure

fluctuations in the well/reservoir system. These variables include

tubing inertance, tubing capacitance, wellbore storage, and flow

perturbation from the reservoir. In the model, a series of differ-

ential equations that express the pressure-dependent variables are

Laplace transformed and combined by Cramer's rule to obtain a

characteristic equation with coefficients K I , K 2, and K 3. By using

Routh's criteria, the model predicts that a well is stable when K I,

K

2

, and K3 are all positive or all negative. However, when one

or two of the values of K!o K 2, and K 3 have a sign that is

different, the model predicts that the well is unstable.

Model for Unsteady Flow In Wells

A model for unsteady flow in gas-lift wells is developed in this

section. The model can be modified to describe the unsteady flow

in a naturally flowing oil well by changing a few terms.

It is assumed that all the physical flow variables experience only

small disturbances from steady state. These are represented by

Pw!=Pw!o+Pwj, .................................. (1)

P=Po+P', ....................................... (2)

q=qo +q', ....................................... (3)

etc. From Appendix A, Eq. A-26, the relationship between the

bottornhole-flowing-pressure (BHFP) perturbation caused by a fluc-

tuating flow out of the reservoir is

r tdqR (Bllln re/rw)

Pwj(t)=-J {l-exp[-ab(t-r)]dr}.

o dt 0.OO708kh!

..................................... (4)

The increased flow out of the annulus, qA, caused by the annulus

capacitance effect is (from Eq. A -11)

qA = - C

s

( d:;!). ................................ (5)

Now at Natl. Hydrocarbon Corp.

Copyright 1988 Society of Petroleum Engineers

508

The increased flow from the tubing, qT, caused by tubing

capacitance effect is

qT=C

T

--. .................................... (6)

dt

The total flow-rate perturbation, q: can be expressed by

q'=qR+qA +qT .................................. (7)

The change in pressure drop, in tubing section below the valve

caused by inertance effect, gas/liquid ratio change, F gLl' and flow

rate change, can be expressed as

(

I ) ( I ) aq'

-- (F

gL

)\+ -- q'+M

I

- .......... (8)

aF

gL

0 aq 0 at

Similarly, the change in pressure drop, t1pi, in the tubing section

above the valve can be expressed as

(

) ( ) aq'

-- (FgL)z+ -- q'+M

2

- . ........ (9)

aF

gL

0 aq 0 at

The difference in the BHFP and tubing-head pressure is expressed as

. ............................. (10)

The change in the tubing-head flowing pressure, Prj, can be ex-

pressed in terms of change in the gas/liquid ratio, F gL2, flow rate,

q, and choke diameter, d, as follows:

PtJ=( apt!) (FgLH+( apt!) q,+( apt!) d' . .... (11)

aFgL 0 aq 0 ad 0

In Appendix B, the above set of equations is solved by the Laplace

transform method. IS This solution shows that a well will be stable

if K I, K 2, and K 3 have like signs. Conversely, if there is a

difference in sign between K I, K 2, and K 3, the well is unstable

(it will "head up").

For a gas-lift well, assume a straight-line inflow performance,

[(

aPt!) J )

K

2

= + -- + -- -+C

s

aq 0 aq 0 aq 0 ab

[(

at1pl)

+J(M

I

+M

2

)-C

T

-- + -- , .......... (13)

aq 0 aq 0

SPE Production Engineering, November 1988

TABLE 1-NATURALLY FLOWING WELL PROPERTIES

Casing 10, in.

Casing weight, Ibmlft

J (assume straight line), bbl/(psi-O)

k, md

t/>

/1-, cp

c, psi-'

F

wv

, psi/ft

r

w

, in.

D,ft

r .Ir w

(F gdo' Mcf/bbl

qo' B/O

Po' psi

Pc' psi

7

26

0.4

17

0.30

30

10 -5

0.35

5

4,000

800

0.1

300

1,800

200

TABLE 2-COMPUTED FLOW PROPERTIES OF

NATURALLY FLOWING WELL

Tubing size, in.

Tubing weight, Ibmlft

Pwfo' psi

Plf, psi

Choke size, do, in. *

(op ffloq) 0' bbl/psi-O

(aAplaq) 0 , bbl/psi-O* *

C T, ft

3

/psi

C

s

, ft

3

/psi

M, psi-sec

2

/ft

3

K, , seconds

2

K

2

, seconds

K3

Case 1

2'l8

6.5

1,050

85

24.9/64

0.283

-0.35

0.055

0.354

958

442

-233

0.97

Case 2

1.9

2.75

1,050

220

15.1/64

0.73

-0.05

0.020

0.407

2,238

1,231

6,011

1.27

'Computed from'3 Ptto =1435(F gdO.

546

/(d

o

) ,.

69

1

Qo

psig.

"Computed from Gilbert's2 charts.

and

For a naturally flowing oil well,

[(

aPt!) (ail

p

,)]( J) (ailp)

K

2

= - + -- -+C

s

+JM-C

T

- ,

aq 0 aq 0 ab aq 0

.................................... (16)

Stability Example-Naturally Flowing Oil Well. Assume a

naturally flowing oil well with the properties listed in Table 1. Two

different tubing sizes are used: Case 1 uses a 2%-in. [7.3-cm] tubing;

Case 2 uses a 1.9-in. [4.8-cm] tubing. From the equations developed

in this paper and the well properties of Table 1, the values given

in Table 2 can be computed (see Appendix C for example calcu-

lations). Thus, it is seen that Case 1 (2%-in. [7.3-cm] tubing) was

unstable because K 2 was negative and K, and K 3 were positive.

When a smaller tubing (1.9 in. [4.8 cm]) was used (Case 2), the

well was stable (all K values were positive) with no heading. Field

experience has shown that it is not uncommon to stabilize a well

by replacing a larger tubing with a smaller one.

SPE Production Engineering, November 1988

TABLE 3-GAS-UFT-WELL PROPERTIES

D,ft

Static well pressure, psi

J, bbl/(psi-O)

(F gL) 0' Mcflbbl

Tubing size, in.

Gas-injection pressure, psi

Ap across valve, psi

8,000

2,000

0.5

1.0

3.5

600

100

TABLE 4-COMPUTED FLOW PROPERTIES

OF GAS-LIFT WELL

qo' B/O

Pw, psi

Optimum F gL' Mcf/bbl

Pff, psi

Valve depth, ft

Choke size, in. *

C T, ft

3

/psi

M, , psi-sec

2

1ft

3

M

2

, psi-sec

2

1ft3

(apfflaq)o' bbllpsi-O* *

(at:.p,/aq+aAp2Iaq)o' bbl/psi-O**

C

s

, ft

3

/psi

K, , seconds

2

K

2

, seconds

K3

Case 1

200

2,300

6.3

450

1,730

27.5/64

2.38x10-

4

481

23.2

2.25

-1.68

1.65

962

1,675

1.28

Computed '3 from Ptto =1435(F .dO.

546

/(d

o

) ,.

89

1

Qo

psig.

"Computed from Gilbert's

2

charts.

Case 2

400

2,100

4.5

341

3,530

41.8/64

3.47 x 10-

4

293

49.8

0.85

-1.24

1.93

750

-1,302

0.8

Stability Example-Continuous-Gas-Lift Well_ Assume a

continuous-gas-lift well with the properties given in Table 3. Two

different flow rates are used, 200 and 400 BID [32 and 64 m

3

/d].

The data in Table 4 can be computed for these cases. The increase

from 200 (stable flow) to 400 BID [32 to 64 m

3

/d] (Case 2) neces-

sitated opening the choke size to 41.8164 in. [0.65 cm]. This caused

the tubing-head pressure to drop from 450 to 341 psi [3.1 to 2.35

MPa]. The required optimum F gL dropped from 6.3 to 4.5

Mcf/bbl [1.1 to 0.8x10

3

m

3

/m

3

]. These changes caused

(ap 1!laq)o to drop, leaving a value too small to offset the negative

sum of (ailp,/aq+ailp2Iaq)o' Hence, the coefficient K2 was

negative for Case 2 (400 BID [64 m

3

/d]), which means that Case

2 was unstable. Thus, one cannot produce this well at 400 BID [64

m

3

/d] without flow-oscillation (heading) problems.

Conclusions

A mathematical model has been proposed for unsteady flow in

naturally flowing oil wells and continuous-gas-lift wells. This model

produces a characteristic equation that allows determination of the

stability of the well. If K" K

2

, and K3 of the characteristic

equation are oflike sign, the well is stable (small flow perturbations

from steady state damp out with time). If any of the coefficients

have a different sign, the system is unstable (small flow perturbations

increase with time). It was found that the sign of (aptflaq+

ailplaq)o strongly influenced the sign of K2 and hence the stability

of the well. If (apliaq+ailplaq)o is negative, a strong probability

exists that the well will be unstable.

Nomenclature

a = defined by Eq. A-27, hours-'

A = annulus area, ft2 [m

2

]

AI = tubing area, ft2 [m

2

]

b = defined by Eq. A-24

B = reservoir volume factor

c = compressibility, psi -, [kPa - , ]

C

s

= wellbore storage constant, ft3/psi [m

3

/kPa]

C

T

= tubing capacitance, ft3/psi [m

3

/kPa]

d = choke diameter, in X;4 in., in. [cm]

509

d' = fluctuating choke diameter, in Y.;4 in" in. [cm]

D = well depth, ft [m]

E = Young's modulus for steel, psi [kPa]

FgL = gaslliquid ratio, Mcf/bbl [m

3

/m

3

]

F;L = fluctuating gas/liquid ratio, Mcf/bbl [m

3

/m

3

]

Fwv = specific weight of liquid, psi 1ft [kPa/m]

gc = unit conversion factor, 32.17 Ibm-ftllbf-sec

2

[1 kg'm/N's2]

h = height of fluid in annulus, ft [m]

h

J

= formation thickness, ft [m]

J = productivity index, bbllD-psi [m

3

Id kPa]

k = permeability, md

K 1 ,K 2,K 3 = characteristic equation coefficients

Kbe = effective bulk modulus, psi [kPa]

KbL = bulk modulus of liquid, psi [kPa]

Kbt = bulk modulus of tubing, psi [kPa]

510

L = length of tubing, ft [m]

M = tubing inertance, (psi-sec

2

)/ft3 [(kPa' s2)/m

3

]

Mg = molecular weight of gas, g/gmol

P = pressure, psi [kPa]

jj = average pressure, psi [kPa]

Pc = annular casinghead pressure, psi [kPa]

Pg = gas pressure in annulus, psi [kPa]

Po = steady-state reservoir pressure, psi [kPa]

PtJ = flowing tubing-head pressure, psi [kPa]

Pw = BHP, psi [kPa]

PwJ = BHFP, psi [kPa]

Pwj = fluctuating BHP, psi [kPa]

PwJo = steady-state BHP, psi [kPa]

IIp = pressure drop in tubing, psi [kPa]

IIp' = fluctuating pressure drop in tubing, psi [kPa]

q = volumetric flow rate, BID [m

3

Is]

q' = perturbation flow rate out of wellhead, BID

[m

3

/s]

qA = perturbation flow rate out of annulus into

tubing, BID [m

3

/s]

qo = steady-state flow rate out of well, BID [m

3

Is]

qR = perturbation flow rate out of reservoir into

tubing, BID [m

3

/s]

qT = perturbation flow rate out of tubing because of

compressible effects, BID [m

3

Is]

re = reservoir radius, ft [m]

reD = reservoir diameter, dimensionless

r w = wellbore radius, ft [m]

R = universal gas constant, (ft-Ibt)/(lbm mol-OR)

[(m' kN)/(kmol' K)]

s = Laplace transform variable

t = time, seconds

tD = dimensionless time

T = temperature, OF [0C]

v = velocity, ft/sec [m/s]

V = volume, ft

3

[m

3

]

V = average gas volume in tube, ft3 [m

3

]

Vg = gas volume, ft3 [m

3

]

Vgs = gas volume at surface, ft3 [m

3

]

V

L

= liquid volume, ft3 [m

3

]

V

t

= tubing volume, ft3 [m

3

]

w = mass flow rate, BID [m

3

/d]

z = gas compressibility factor

'Y = specific heat ratio

p. = viscosity, cp [Pa' s]

p = density, Ibm/ft

3

[kg/m3]

Ii g = average gas density, Ibm/ft

3

[kg/m3]

PL = liquid density, Ibm/ft

3

[kg/m

3

]

T = dummy time, seconds

TD = dimensionless dummy time

cp = porosity

Subscripts

o = steady-state variable

I = variable evaluated in tubing section below

gas-lift valve

2 = variable evaluated in tubing section above

gas-lift valve

References

1. Donahue, F.P.: "Classification of Flowing Wells With Respect to Ve-

locity," Pet. Dev. and Tech. (1930) 86, 226.

2. Gilbert, W.E.: "Flowing and Gas-Lift Well Performance," Drill. &

Prod. Prac. (1954) 126-57.

3. Ros, N.C.J.: "Simultaneous Flow of Gas and Liquid as Encountered

in Well Testing," JPT(Oct. 1961) 1037-40; Trans., AIME, 222.

4. Fancher, G.H. Jr. and Brown, K.E.: "Prediction of Pressure Gradients

for Multiphase Flow in Tubing," SPEJ (March 1963) 59-62; Trans.,

AIME,228.

5. Duns, H. Jr. and Ros, N.C.J.: "Vertical Flow of Gas and Liquid

Mixtures in Wells," Proc., Sixth World Pet. Cong., Frankfurt (1963)

451.

6. Hagedorn, A.R. and Brown, K.E.: "Experimental Study of Pressure

Gradients Occurring During Continuous Two Phase Flow in Small-

Diameter Vertical Conduits," JPT(ApriI1965) 475-78; Trans., AIME,

234.

7. Marshall, R.S.: "The Later Stages of an Oil Well, Including a Dis-

cussion of Heading Phenomena," undergraduate entry, AIME Student

Paper Contest, Mid-Continent Area, Stillwater, OK (April, 1967).

8. Zarrinal, F., Brown, K.E., and Shozo, T.: "Tubing Size Determi-

nation," technical report, API Project No. 89, U. of Tulsa, Tulsa, OK

(July 1967).

9. Simmons, W.E.: "Optimizing Continuous-Flow Gas-Lift Wells," Pet.

Eng. (Aug.-Sept. 1972).

10. Grupping, A. W. et al.: "Computer Program Helps Analyze Unsteady

Flowing Oilwells," Oil & Gas J. (Sept. 8, 1980).

11. Grupping, A.W. et al.: "Computer Program Helps Analyze Unsteady

Flowing Wells," Oil & Gas J. (Sept. 1980) 55-59.

12. Grupping, A.W., M.H. Boersma, and Bos, C.F.M.: "Computer

Program Helps Predict Effect of Bean Changes on Unsteady Flowing

Oil Wells," Oil & Gas J. (June 15, 1981).

13. Nind, T.E.W.: Principles a/Oil Well Production, McGraw Hill Book

Co. Inc., New York City (1981) 159-65.

14. Tiemann, W.D. and DeMoss, E.E.: "Gas-Lift Increases High-Volume

Production from the Claymore Field," JPT (April 1982) 696-702.

15. Grupping, A.W., Luca, C.W.F., and Vermeulen, F.D.: "Heading

Action Analyzed for Stabilization," Oil & Gas J. (July 23, 1984) 47-51.

16. Grupping, A.W., Luca, C.W.F., and Vermeulen, F.D.: "These

Methods Can Eliminate or Control Annulus Heading," Oil & Gas J.

(July 30, 1984) 186-92.

17. Torre, A.J. et al.: "Casing Heading in Flowing Oil Wells," SPEPE

(Nov. 1987) 297-304; Trans., AIME, 283.

18. Hale, F.J.: Introduction to Control System Analysis and Design, Prentice-

Hall Inc., Englewood Cliffs, NJ (1973) 83-90.

19. Merritt, H.E.: Hydraulic Control Systems, John Wiley & Sons Inc.

(1967) 16-17.

20. Lee, J.: Well Testing, SPE Textbook Series, Richardson, TX (1982)

2,106,109-11.

Appendix A-UnsteadyState Flow Variables

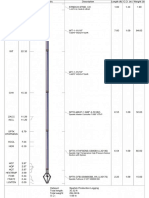

Fig. A-I is a diagram of a continuous-flow gas-lift system. As the

well flows, gas is injected into the annulus at a constant mass flow

rate, w, through a surface injection choke. This gas enters the tubing

through a valve in the tubing wall.

Tubing inertance, tubing capacitance, and annulus capacitance

are unsteady-flow parameters affected by pressure variation in the

weli/reservoir system.

Tubing Inertance, M. Tubing inertance, M, characterizes the

pressure drop caused by fluid acceleration along a pipe or tubing.

Consider the fluid in the control volume in Fig. A-2. Because

the net force on the fluid will tend to accelerate the fluid, the fol-

lowing force balance can be written:

dv

(p+llp)A

t

-pA

t

-T7f'DL=pA

t

L-. ................. (A-l)

dt

Because q=Atv, Eq. A-I can be simplified to

T7f'DL dq

IIp=--+M- . ............................. (A-2)

At dt

SPE Production Engineering, November 1988

d - choke diameter

liquid + gas

-=

00

0

0

0

0 0

0

0

0

.

..

. ...

...

..

.

..

..

. 0000

.

injected

gas

gas gas

o

...

..

...

..

valve

Fig. A-1-Continuous-flow gas-lift system.

r-----------i--------- ------------------,

I

't

I

.:

---- v

I

I

:---p

I

___________ -4.--_'t-_- __ -_-___________________ J

I

L

1

Fig. A-2-Control volume for pipe flow.

The first term on the right in Eq. A-2 is the pressure drop caused

by friction; the second term is the pressure drop owing to ac-

celeration.

The tubing inertance is defined as

pL

M=- . ....................................... (A-3)

At

For continuous-flow gas-lift system, the fluid density in the tubing

(of length L

2

) above the point of annulus gas injection (valve po-

sition), P2, is different from that below, PI. Thus, there are two

inertance terms, MI and M

2

, for the gas-lift model:

inertance for the tubing portion below the gas-injection point, and

inertance for the tubing portion above the gas-injection point.

Tubing Capacitance, CT. It has been shown 19 that the effective

bulk modulus, K

be

, of a tube containing gas and liquid can be ex-

pressed as

(

I I V I )-1

Kbe = Kbt + KbL + V: K

bg

, ................. (A-4)

SPE Production Engineering, November 1988

D

gas

pg

Vg

A=cross-sectlonal

qA= flow out of annulus

Fig. A-3-L1quld flow out of the annulus.

0.018

0.016

0.014

0.012

0.010

b

0.008

0.006

0.004

r-----Lso

0.002

0.000

100 200 300 400 500 600 700 800 900

Fig. A-4-b vs. tD'

where K

bt

, K

bL

, and K

bg

are the bulk modulus of the tube, liquid,

and gas, repectively. Because the bulk modulus is defined by

dV

then

ddV VI ddp'

dt

but -ddVldt=qt, flow out of tubing owing to elasticity of gas,

liquid, and tubing wall. Hence (Eq. 6),

d.1.p'

qT=C

T

--,

dt

511

where

C

T

=VI(_I_+_I_+ Vg _1_) ................... (A-5)

Kbl KbL VI Kbg

Wellbore Storage Constant, C

s

. The wellbore storage effect can

be derived with the aid of Fig. A-3. The volumetric flow rate of

liquid out of the annulus into the tubing is

dh

qA=-A- . ................................... (A-6)

dt

The pressure at the bottom of the annulus, neglecting gas hydro-

static pressure, is,

PWf=Pc+Fwvh . ................................. (A-7)

Solving for h from Eq. A-7 and substituting into Eq. A-6 yields

A dpwf dpc

qA =------.......................... (A-S)

Fwv dt dt

Assuming that the gas volume changes adiabatically and that P g

and Vg are the average annular gas pressure and volume, respec-

tively,

PgVg=K=constant, ............................. (A-9)

if the casinghead pressure is approximately equal to the average

gas pressure in the annulus. Hence,

dpc K dVg Pc

-=---=-qA' ...................... (A-lO)

dt V

g

2 dt Vg

With K=PgVg' dVgldt= -qA, and Vg=A(D-h), Eq. A-lO can be

substituted into Eq. A-S to obtain

dpwf

qA =-Cs-, ................................ (A-II)

dt

where

Cs=Akwv+ : ~ h ) r

1

...................... (A-12)

Reservoir Flow Fluctuations, qR' The diffusivity equation for

radial flow in a porous medium is

20

;j2p 1 ap t/>JLe ap

-+--=-- ......................... (A-13)

ar2 r ar k at

The generalized solution of Eq. A-13 is

20

O.OO70Skh

f

(po -Pwf)

P= !(tD,reD), ............. (A-I4)

qBJL

where

reD=re1rw, ................................... (A-15)

O.OOO264kt

tD= , ............................... (A-16)

t/>JLcrw

2

and t is in hours.

512

By rearranging Eq. A-I4

qBJL

Po-Pwf= !(tD,reD)' .................. (A-17)

O.OOO70Skh

If Pwfo is the steady-state BHFP and Pw/ is the fluctuating value,

then

Pwf=Pwfo +Pw/ ............................... (A-IS)

Substituting Eq. A-IS into Eq. A-I7 yields

The quasisteady-state solution is

qo

(Po-Pwfo)=-, ............................... (A-20)

J

where

J

0.OO70Skh

f

BJL In re1rw

............................... (A-2I)

Subtracting Eq. A-20 from Eq. A-I9 yields

qRBJL!(tD,reD)

Pw/ = - . . ....................... (A-22)

O.OO70Skh

f

For a finite radial-flow system with a fixed constant pressure at

the exterior boundary, r e' and consta!1t flow rate at the wellbore,

r

w

, a tabulated solution for!(tD,reD) is available. 20 However, we

have discovered by regression analysis that an approximation to

the exact tabulated solution

20

is

re

!(tD,reD)=ln-[I-exp( -brD)]' ................. (A-23)

rw

For values of b, see Fig. A-4.

The regression analysis showed that b can be approximated by

0.S92

b= ............................ (A-24)

tDo.792reDo.217

If qR is a function of time, then Eq. 22 can be replaced by a

Faltung-type integral:

Pw/(t) = - J I dqR [ BJL l!(t-r,reD)dr .. ..... (A-25)

dr O.OO70Skhf

Substituting Eqs. A-16 and A-23 into Eq. 25 yields

[ IdqR (BJL In re1rw)

Pw/(t) = - J - {I-exp[ab(t-r)]}dr,

. dr 0.OO70Skhf

.................................. (A-26)

where

O.OOO264k

a=---- ................................ (A-27)

t/>JLcrw

2

SPE Production Engineering, November 1988

Appendix B-Laplace Transform Solution

to Flow Equatlon$

Eqs. 4 through II can be Laplace-transformed to obtain

qR(S)

-Pw/(s) = , ........................... (B-I)

J (1 +s/ab)

qA(S)= -sCAPw/(s), ............................. (B-2)

qT(S)=SCTtlp'(S), ............................... (B-3)

q'(S)=qR(S)+qA(S)+qt(S), ........................ (B-4)

................................... (B-5)

(

OtlP2) (OtlP2)

tlP2'(S)= -- (FgLh'(s)+ -- q'(s)+M

2

sq'(s),

oFgL 0 oq 0

................................... (B-6)

P;"f(s)=Pt/(S) + tlpi '(s) + tlP2 '(s), .................. (B-7)

and

................................. (B-8)

where S is the Laplace transform variable.

Eqs. B-1 through B-8 are a set of eight algebraic equations with

eight unknowns: Ptf(s), Pw/(s), tlPI '(s), tlP2 '(s), qR '(s), qt '(s),

qA '(s), and q'(s). This set of equations can be solved by a number

of methods, including Cramer's rule, to obtain

................................. (B-9)

................................ (B-IO)

and

................................ (B-ll)

The denominator in each of the terms above (K

I

S2+K

2

S+K

3

)

is called the characteristic function. When the characteristic function

is set equal to zero, the resultant equation is called the character-

istic equation:

K

I

S2 +K

2

S+K

3

=0 ............................. (B-12)

SPE Production Engineering, November 1988

Control theory 18 has shown that for systems of Laplace trans-

form equations like Eqs. B-9 through B-ll to be stable (the small

fluctuations P t/, Pw/, and q' will approach zero for unit impulse

inputs on the choke diameter and/or gas/liquid ratio), the two roots

of the characteristic equation (Eq. B-12) must both be negative (if

both are real) or have negative real parts if they are complex con-

jugate.

It is possible to show by Routh's criteria 18 or by simply solving

the characteristic equation by means of the quadratic equation that

a necessary and sufficient condition to have all negative real roots

(or all negative real parts, if roots are complex conjugate) is that

the coefficients of the characteristic equation be all positive or all

negative. That is, the well is stable if

or

Therefore, a well will become unstable (head up) if a single root

or both roots are positive or have positive real parts.

Appendix C-Example Calculations of

Stability Constants

The following are calculations for Case 1 for the naturally flowing

well data of Table 1.

Areas. The tubing area is

The annulus area is

A =1(/4(6.276

2

-2.875

2

)/144=0.169 ft2.

BHFP (steady state). Pfwo is

Pfwo =po -q/J= 1 ,800-300/0.4= 1,050 psi.

Tubing-Head Pressure, Ptfo, and Pressure Drof' Ap.

From Gilbert's2 Fig. 25, for q=2oo B/D [32 m /d] andpfwo=

1,050 psi [7.2 MPa], equivalent depth =4,200 ft [1280 m]. Actual

depth=4,OOO ft [1219 m]. Equivalent depth of tubing-head

pressure=4,2oo-4,000=200 ft [61 m]. For 200 ft [61 m],

Ptfo=50 psi [345 kPa].

Similarly, from Gilbert's2 Fig. 26, for q=4oo BID [64 m

3

/d]

and Pfwo = 1,050 psi [7.2 MPa], equivalent depth=4,7oo ft [1433

m]. Actual depth=4,OOO ft [1219 m]. Equivalent depth of tubing-

head pressure =4,700-4,000 =700 ft [213 m]. For 700 ft [213 m],

Ptfo=120 psi [827 kPa].

Hence, for q=3oo B/D [48 m

3

/d], Ptfo=50+(120-50)(3OO-

200)/(400-200)=85 psi [586 kPa].

tlP=Pfwo -Ptfo = 1,050-85 =965 psi.

oPtfo Ptfo 85

-=-=-=0.2833.

oq q 300

oJ1p/oq. At q=2oo BID [32 m

3

/d], tlP=ffw

o

-Ptfo= 1,050-50=

1,000 psi. At q=400 BID [64 m /d], tlP=Pfwo-Ptfo=

1,050-120=930 psi.

Otlp 930 - 1 ,000

--= =-0.35.

oq 400-200

Tubing Capacitance, CT'

Kbt =tE/d=(0.23 in.)(30 x 10

6

psi)/(2.876 in.)=2.4x 10

6

psi.

KbL = 10

5

psi for petroleum fluid.

513

ji =(Pwo +Ptfo)/2+ 15 =(1 ,050+85)/2+ 15 =582.5 psia.

K

bg

=-yji = 1.25(582.5)=728 psi.

- -

VglV

L

= (VgslVL>(VglVgs )

VgslVL =(F

g

L>(1 ,(00)/5.61 = 178F

gL

= 178(0.1)= 17.8.

~ zRT Ps

Vgs zsRTs P

Assume constant gas temperatures and constant values of z.

~ = Ps = ____ 1_5 __ _

=0.026.

Vgs P 'h(l,050+85)+15

VglV

L

=(17.8)(0.026)=0.46.

VglV,= VgI(Vg + V

L

)=(1 + VLlVg)-1 =(1 + 110.46)-1 =0.315.

(

1 1 Vg 1 )

CT=V, -+-+--

K

b

, kbL V, K

bg

=(4,000)(0.032)(112.4 X 10

6

+ 1110

5

+0.315/728)

=0.055 ft

3

/psi.

Wellbore Storage Constant, C

s

.

h=(Pwfo -Pc)IF wv=(1 ,050-200)/(0.35) =2,429 ft.

D-h=4,000-2,429=1,571 ft.

Cs=A/[Fwv+Pcl(D-h)]

=(0.169)/(0.35 +200/1 ,571)=0.354 ft3/psi.

Inertance, M.

p g =jiIR'T=(582.5)(144)/(1 ,545/22.5)(520)=2.35 Ibm/ft3.

R'=RIM

g

.

M=D[(VglV,(p g)+(I- VglV,)pLlIA,gc

=4,000[(0.315)(2.35) +(1-0.315)50.4]/0.032(144)(32.17)

Jlab.

0.OOO264k

a=----

cpp.crw

2

514

(0.000264)(17)

--------=287 hours -I.

(0.3)(30)(10 -5)(5/12)2

For a typical heading cycle period of t=1 hour,

tD =at=(287)(I)=287.

For reD =800, from Fig. A-4, b=0.002.

Jlab=(O.4 B/D)(5.61 ft3 Ibbl)/(0.002)(287)(lIhour)(24 hourslD)

=0.163 ft3/psi.

Kl Term.

KI =M(Cs- CT+Jlab) =958(0.354-0.55 +0.163)

=442 seconds

2

[(

0Ptfo Ot.l

p

) Ot.lp]

K

2

= --+- (Jlab+Cs)-C

T

- +JM

oq oq oq

=[(0.283 -0.35)(0.163 +0.354)-0.055( -0.35)](15,388)

+(0.4)(958)115,388= -233 seconds.

(

1 bbl )(24 hOUrS)(3,600 seconds)

Note that 15,388= .

5.61 ft3 D hour

K3 Term.

(

OP'fo Ot.lp)

K3= --+- J+l=(0.28-0.35)(0.4)+1=0.97.

oq oq

SI Metric Conversion Factors

bbl x 1.589 873 E-Ol

bbl/(psi-D) x 2.305 916 E-02

cp x 1.0* E-03

ft x 3.048* E-Ol

ft3 x 2.831 685 E-02

in. x 2.54* E+oo

Ibm x 4.535 924 E-Ol

psi x 6.894 757 E+oo

scf/bbl x 1.801 175 E-Ol

* Conversion factor is exact.

m

3

m

3

/(kPa'd)

Pa's

m

m

3

cm

kg

kPa

std m

3

/m

3

SPEPE

Original SPE manuscript received for review March 13, 1986. Paper accepted for publi

cation July 6,1987. Revised manuscript received Oct. 29, 1987. Paper (SPE 15022) first

presented at the 1986 SPE Permian Basin Oil & Gas Recovery Conference held in Midland,

March 13-14.

SPE Production Engineering, November 1988

Você também pode gostar

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeNo EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeNota: 4 de 5 estrelas4/5 (5794)

- The Little Book of Hygge: Danish Secrets to Happy LivingNo EverandThe Little Book of Hygge: Danish Secrets to Happy LivingNota: 3.5 de 5 estrelas3.5/5 (399)

- Hellical Buckling of Pipe With Connectors52847 PDFDocumento15 páginasHellical Buckling of Pipe With Connectors52847 PDFAhmed MamdouhAinda não há avaliações

- Formation Characterization of Horizontal WellSPE59129 PDFDocumento6 páginasFormation Characterization of Horizontal WellSPE59129 PDFAhmed MamdouhAinda não há avaliações

- Spe Paper About Production LoggingDocumento31 páginasSpe Paper About Production LoggingAhmed MamdouhAinda não há avaliações

- API 510 PC 4sept04 Daily Exam 5 Closed PSJDocumento12 páginasAPI 510 PC 4sept04 Daily Exam 5 Closed PSJMohammed Shakil100% (1)

- Effect of Drilling Fluids & Underbalance drillingDrillingFluidDocumento18 páginasEffect of Drilling Fluids & Underbalance drillingDrillingFluidAhmed MamdouhAinda não há avaliações

- Well AbandonmentDocumento14 páginasWell AbandonmentAhmed MamdouhAinda não há avaliações

- SPE 18892 Asphaltene Deposition: A Comprehensive Description of Problem Manifestations and Modeling ApproachesDocumento15 páginasSPE 18892 Asphaltene Deposition: A Comprehensive Description of Problem Manifestations and Modeling ApproachesAhmed MamdouhAinda não há avaliações

- Detailed Casing Design For HP - HT - WellsSPE74490Documento6 páginasDetailed Casing Design For HP - HT - WellsSPE74490Ahmed MamdouhAinda não há avaliações

- Hole Problem Data PackageDocumento154 páginasHole Problem Data PackageAhmed Mamdouh100% (1)

- Spe 21588 MS PDFDocumento17 páginasSpe 21588 MS PDFAhmed MamdouhAinda não há avaliações

- 510 PC Oct04-Qar-ex5 Closed Book PSJDocumento6 páginas510 PC Oct04-Qar-ex5 Closed Book PSJCss SfaxienAinda não há avaliações

- API 510 Pressure Vessel Inspection (Training Material)Documento230 páginasAPI 510 Pressure Vessel Inspection (Training Material)Rajesh Manoharan92% (26)

- Bumper Sub 130672162Documento1 páginaBumper Sub 130672162Ahmed MamdouhAinda não há avaliações

- AHC Packer H012992 PDFDocumento2 páginasAHC Packer H012992 PDFAhmed Mamdouh100% (1)

- NG Utilization 509 Dr. Hindawi SalemDocumento90 páginasNG Utilization 509 Dr. Hindawi SalemAhmed MamdouhAinda não há avaliações

- Area Inspection - 28052019 PDFDocumento2 páginasArea Inspection - 28052019 PDFAhmed MamdouhAinda não há avaliações

- Anti-Slug Control of Gas-Lift Wells PDFDocumento6 páginasAnti-Slug Control of Gas-Lift Wells PDFAhmed MamdouhAinda não há avaliações

- PLT Spartek Tool With SpinnerDocumento1 páginaPLT Spartek Tool With SpinnerAhmed MamdouhAinda não há avaliações

- Late Life Production Boost For BP Miller With Combined Scale Squeeze and Chemical Water Shut Off TreatmentsDocumento7 páginasLate Life Production Boost For BP Miller With Combined Scale Squeeze and Chemical Water Shut Off TreatmentsAhmed MamdouhAinda não há avaliações

- Spe 123374 MSDocumento10 páginasSpe 123374 MSAhmed MamdouhAinda não há avaliações

- A Thermally Actuated Gas Lift ValveDocumento8 páginasA Thermally Actuated Gas Lift ValveAhmed MamdouhAinda não há avaliações

- Spe File About SpinnersDocumento14 páginasSpe File About SpinnersAhmed MamdouhAinda não há avaliações

- Gas-Lift Valve Performance Testing and Data CorrelationDocumento7 páginasGas-Lift Valve Performance Testing and Data CorrelationAhmed MamdouhAinda não há avaliações

- Calcium Sulphate and Barium Sulphate SPE-156013-MS-PDocumento10 páginasCalcium Sulphate and Barium Sulphate SPE-156013-MS-PAhmed MamdouhAinda não há avaliações

- Smart Gas Lift Valves Enhance Operational Efficiency of Offshore WellsDocumento5 páginasSmart Gas Lift Valves Enhance Operational Efficiency of Offshore WellsAhmed MamdouhAinda não há avaliações

- Criteria For Gas-Lift StabilityDocumento5 páginasCriteria For Gas-Lift StabilityAhmed MamdouhAinda não há avaliações

- New Gas-Lift Pilot Valve Increases Gas-Lift EfficiencyDocumento4 páginasNew Gas-Lift Pilot Valve Increases Gas-Lift EfficiencyAhmed MamdouhAinda não há avaliações

- Dynamic Model of GasLift Valve PerformanceDocumento8 páginasDynamic Model of GasLift Valve PerformanceAhmed MamdouhAinda não há avaliações

- Criteria For Operation Stability of Gas-Lift WellsDocumento27 páginasCriteria For Operation Stability of Gas-Lift WellsAhmed MamdouhAinda não há avaliações

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryNo EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryNota: 3.5 de 5 estrelas3.5/5 (231)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceNo EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceNota: 4 de 5 estrelas4/5 (894)

- The Yellow House: A Memoir (2019 National Book Award Winner)No EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Nota: 4 de 5 estrelas4/5 (98)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureNo EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureNota: 4.5 de 5 estrelas4.5/5 (474)

- Never Split the Difference: Negotiating As If Your Life Depended On ItNo EverandNever Split the Difference: Negotiating As If Your Life Depended On ItNota: 4.5 de 5 estrelas4.5/5 (838)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaNo EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaNota: 4.5 de 5 estrelas4.5/5 (265)

- The Emperor of All Maladies: A Biography of CancerNo EverandThe Emperor of All Maladies: A Biography of CancerNota: 4.5 de 5 estrelas4.5/5 (271)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersNo EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersNota: 4.5 de 5 estrelas4.5/5 (344)

- Team of Rivals: The Political Genius of Abraham LincolnNo EverandTeam of Rivals: The Political Genius of Abraham LincolnNota: 4.5 de 5 estrelas4.5/5 (234)

- The Unwinding: An Inner History of the New AmericaNo EverandThe Unwinding: An Inner History of the New AmericaNota: 4 de 5 estrelas4/5 (45)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyNo EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyNota: 3.5 de 5 estrelas3.5/5 (2219)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreNo EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreNota: 4 de 5 estrelas4/5 (1090)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)No EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Nota: 4.5 de 5 estrelas4.5/5 (119)

- Hindustan Coca ColaDocumento63 páginasHindustan Coca ColaAksMastAinda não há avaliações

- AB InBev Code of Business Conduct PDFDocumento10 páginasAB InBev Code of Business Conduct PDFcristian quelmis vilca huarachiAinda não há avaliações

- Kunci Jawaban Creative English 3BDocumento14 páginasKunci Jawaban Creative English 3BLedjab Fatima67% (3)

- De Thi Thu THPT Quoc Gia Mon Tieng Anh Truong THPT Hai An Hai Phong Nam 2015Documento10 páginasDe Thi Thu THPT Quoc Gia Mon Tieng Anh Truong THPT Hai An Hai Phong Nam 2015nguyen ngaAinda não há avaliações

- OPIM101 4 UpdatedDocumento61 páginasOPIM101 4 UpdatedJia YiAinda não há avaliações

- Factory Hygiene ProcedureDocumento5 páginasFactory Hygiene ProcedureGsr MurthyAinda não há avaliações

- GE Supplier Add Refresh FormDocumento1 páginaGE Supplier Add Refresh FormromauligouAinda não há avaliações

- Easyjet Group6Documento11 páginasEasyjet Group6Rishabh RakhechaAinda não há avaliações

- Literature Review 5Documento4 páginasLiterature Review 5api-463653994Ainda não há avaliações

- Checklist PBL 2Documento3 páginasChecklist PBL 2Hazrina AwangAinda não há avaliações

- Mint Delhi 13-12-2022Documento18 páginasMint Delhi 13-12-2022Ayush sethAinda não há avaliações

- Anthony Flagg's Complaint Against Eddie LongDocumento23 páginasAnthony Flagg's Complaint Against Eddie LongRod McCullom100% (1)

- Iqvia PDFDocumento1 páginaIqvia PDFSaksham DabasAinda não há avaliações

- UKBM 2, Bahasa InggrisDocumento10 páginasUKBM 2, Bahasa InggrisElvi SAinda não há avaliações

- UBI1Documento66 páginasUBI1Rudra SinghAinda não há avaliações

- Maths Lit 2014 ExamplarDocumento17 páginasMaths Lit 2014 ExamplarAnymore Ndlovu0% (1)

- Namal College Admissions FAQsDocumento3 páginasNamal College Admissions FAQsSauban AhmedAinda não há avaliações

- Business Advantage Pers Study Book Intermediate PDFDocumento98 páginasBusiness Advantage Pers Study Book Intermediate PDFCool Nigga100% (1)

- Wheat as an alternative to reduce corn feed costsDocumento4 páginasWheat as an alternative to reduce corn feed costsYuariza Winanda IstyanAinda não há avaliações

- Draft of The English Literature ProjectDocumento9 páginasDraft of The English Literature ProjectHarshika Verma100% (1)

- (NTA) SalaryDocumento16 páginas(NTA) SalaryHakim AndishmandAinda não há avaliações

- Introduction to Human Resource Management Functions and Their ImportanceDocumento23 páginasIntroduction to Human Resource Management Functions and Their ImportancedhrupaAinda não há avaliações

- December 2018: Russian Journal of Agricultural and Socio-Economic SciencesDocumento339 páginasDecember 2018: Russian Journal of Agricultural and Socio-Economic Sciencesnahla saviraAinda não há avaliações

- 3 0 Visual Weld InspectorDocumento74 páginas3 0 Visual Weld InspectorVincent Sofia RaphaelAinda não há avaliações

- 3000W InverterDocumento2 páginas3000W InverterSeda Armand AllaAinda não há avaliações

- Admission Checklist (Pre-) Master September 2021Documento7 páginasAdmission Checklist (Pre-) Master September 2021Máté HirschAinda não há avaliações

- DOLE AEP Rule 2017Documento2 páginasDOLE AEP Rule 2017unhoopterenceAinda não há avaliações

- KL Wellness City LIvewell 360 2023Documento32 páginasKL Wellness City LIvewell 360 2023tan sietingAinda não há avaliações

- Vallance - Sistema Do VolvoDocumento15 páginasVallance - Sistema Do VolvoNuno PachecoAinda não há avaliações

- JRC Wind Energy Status Report 2016 EditionDocumento62 páginasJRC Wind Energy Status Report 2016 EditionByambaa BattulgaAinda não há avaliações