Escolar Documentos

Profissional Documentos

Cultura Documentos

SAD PM Masterdata

Enviado por

anjitachinki0 notas0% acharam este documento útil (0 voto)

483 visualizações19 páginasSystem Appreciation document captures the Knowledge Transfer which occurred between SME and Infosys PM ADM support team on 10 th of may2011.

Descrição original:

Direitos autorais

© © All Rights Reserved

Formatos disponíveis

DOCX, PDF, TXT ou leia online no Scribd

Compartilhar este documento

Compartilhar ou incorporar documento

Você considera este documento útil?

Este conteúdo é inapropriado?

Denunciar este documentoSystem Appreciation document captures the Knowledge Transfer which occurred between SME and Infosys PM ADM support team on 10 th of may2011.

Direitos autorais:

© All Rights Reserved

Formatos disponíveis

Baixe no formato DOCX, PDF, TXT ou leia online no Scribd

0 notas0% acharam este documento útil (0 voto)

483 visualizações19 páginasSAD PM Masterdata

Enviado por

anjitachinkiSystem Appreciation document captures the Knowledge Transfer which occurred between SME and Infosys PM ADM support team on 10 th of may2011.

Direitos autorais:

© All Rights Reserved

Formatos disponíveis

Baixe no formato DOCX, PDF, TXT ou leia online no Scribd

Você está na página 1de 19

1

System Appreciation Document

ADM Support

Process Area :Plant Maintenance

System Appreciation Document

Page 2 of 19

Document control

File Naming Convention SAD_ADM-PM-001_Ver1.0

Example (One Session and One SAD):

Session No ADM-PM-001. The System Appreciation Document will be

named as SAD_ADM-PM-001_Ver1.0

Submitted By

Date Version Author (E Mail Id) Comments

05/10/2011 2.0 Krishna jois Draft

Reviewed By

Final Version

Sign Off by WFT

Name ( Email Id) Date Signature (incl electronic sign off)

System Appreciation Document

Page 3 of 19

Table of contents

1. Overview 4

2. Definitions / Abbreviations 5

3. Business Function 6

3.1 Brief Description 6

3.2 Applicable Business Unit Error! Bookmark not defined.

3.3 Business Process 6

3.4 Periodic Process Error! Bookmark not defined.

3.5 Reports 13

4. Application Design 14

4.1 Application Architecture Error! Bookmark not defined.

4.2 Configuration Elements 14

4.3 Integration with other Modules/Applications 14

5. Technical Details 15

5.1 Custom Transactions 15

5.2 Custom Reports/Queries Error! Bookmark not defined.

5.3 Custom Tables Error! Bookmark not defined.

5.4 User-Exits Error! Bookmark not defined.

5.5 Interfaces 15

5.6 Batch Processing 15

5.7 Workflows 15

5.8 Archiving Error! Bookmark not defined.

6. Application Support 16

6.1 Known Problems, Issues and Workarounds 16

6.2 Tools 16

6.3 Business Users Error! Bookmark not defined.

6.4 Third Party Support Error! Bookmark not defined.

7. Glossary of Business Terms 17

8. References 18

9. Appendix 19

System Appreciation Document

Page 4 of 19

1. Overview

This Systems Appreciation Document captures the Knowledge Transfer which occurred between SME and

Infosys PM ADM support team on 10

th

of May2011. The sessions were held on SAP PM Process.

Master data Functional location , Equipment , measuring points and class and

characteristics

Transaction data Notification and order.

This document elaborates Master data used in the Plant Maintenance.

System Appreciation Document

Page 5 of 19

2. Definitions / Abbreviations

PM Plant Maintenance

PC Profit centre

CC Cost Centre

BU Business Unit

FL Functional location

EQ Equipment

BOM Bill of Material

System Appreciation Document

Page 6 of 19

3. Business Function

3.1 Brief Description

This document gives an overview of Plant Maintenance Master Data and Process.

Functional location in the Business mainly uses the structure Z01. This has 7 Levels. Level7 is the equipment

installation. For equipment BOM will be attached.

3.2 Business Process

Maintenance Plants across the Weatherford.A planning tool used for scheduling maintenance, activities,

primarily used for regulatory Inspections

Some of the Maintenance Plants with naming conventions with respect to region as follows

System Appreciation Document

Page 7 of 19

Functional Location:

A functional location is a place where maintenance activities are completed.

Functional Location Structure Indicator determines the structure of the functional location label. It

establishes the following factors:

- Number of hierarchy levels of a technical system.

- Key length of the levels.

- Separators (hyphens).

Z01 - has defined one structure indicator to represent all functional locations. The structure with the 7 levels is

as follows:

ANN NN NNN AA AA NNN - XXXXXXXXXXXX

1 2 3 4 5 6 7

Where A = Alphabetic value allowed

N = Numeric value allowed

X = Alphanumeric value allowed

Levels are categorised as 7 Levels

Level 1: the company Z01 (Technology Services division of

Precision Drilling Corporation)

Level 2: the Product Line (Drilling Services, Testing and

Wire line)

Level 3: the Division/Service (available from that Product

Line and will be different for each Product Line)

Level 4: the Region (Canada, United States, Asia/Pacific,

Europe, Latin America and Middle East)

Level 5: the Country (within the region)

Level 6: the District (within the country, at which the plant and address data will be maintained)

Level 7: the Asset Type (Down hole Device, Lab/Shop

Equipment, Source, Surface Equipment, Surface System and

Vehicle)

System Appreciation Document

Page 8 of 19

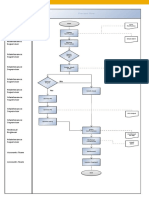

FUNCTIONAL LOCATION STRUCTURAL DIAGRAM

2005 Weatherford. All rights reserved.

Functional Location Structure

Z01 Weatherford

Level 1

Weatherford

Completions

Down Hole

Device

Brooks, AB

Canada

Level 2

Product Line

Level 3

Division

Level 4

Region

Level 5

Country

Level 6

District

Level 7

Asset Type

PDC Bits Wireline

Drilling

Services

Testing

Pumping

Services

Cased Hole

Canada

Open Hole Slick Line

Europe

Latin

America

Asia Pacific United States Middle East

Drayton

Valley, AB

Dresden, ON

Edmonton,

AB

Estevan, SK

Fort St

John, BC

Lab Shop

Equipment

Sources

Surface

Equipment

Surface

Systems

Vehicles

Casting Collar Locator Equipment

Gamma Ray Tool

Scenario:

Removing the Functional location from the structure

Delete (remove) from the main structure. This can be done using IH01

Remove the FL from

Structure

Equipment:

System Appreciation Document

Page 9 of 19

An individual physical object that is maintained independently in the system, that is, the object requiring

maintenance (tool or unit)

A piece of equipment is an individual physical (technical) object that is maintained independently in the system.

Each piece of equipment can be assigned to a technical object type for the purpose of combining into groups in

order to evaluate master data or maintenance data.

Equipment Type (and Definition)

Downhole Device (Logging tool or other equipment that is used or left downhole).

Lab or Shop Equipment (instrument or other equipment that is used to service or calibrate the

downhole device and surface system or surface equipment).

Source (radioactive emitter used in downhole equipment as well as test or calibration of equipment).

Surface Equipment (device that is located above ground, separate from the surface system. If

connected to the surface system, this device provides input to, or output from, the surface system (a

peripheral).

Surface System (uphole system providing data acquisition).

Vehicle (unit used in the field as well as company owned and leased personal vehicle).

Down hole

device

Source

Lab or

Shop

Equip

Surface

system

Surface

Equip

Vehicle

District

Functional

location-

Level-6

Functional

location

Level-7

Acoustic Tools,

Radio active

tools,Electro

magnetic tools

Oscilloscope,Callibration

equipment, Test

equipment

List of

Resources

Depth

Encoder, Gas

processor

CS400,Data

acquisition

system,LWD system

ton

truck

logging

unit

System Appreciation Document

Page 10 of 19

Senario2:

Create and installing the Material in Equipment master. Attached document will help to understand the process

Creation of

Equipment

Scenario: 3

Updating Equipment record: When a piece of equipment (or tool) is upgraded to another version, several pieces

of data need to be updated directly in the equipment record

Attached document will help to understand how up update the equipment record

Scenario: 4

Changing the Equipment: Moving Equipment from one location to another is referred to as changing the install

location. Install equipment at Functional Locations to represent their physical location

Attached document will help to understand the process

Changing the

equipment Location

Update the

Equipment record

System Appreciation Document

Page 11 of 19

Classification:

Classification in SAP allows for the creation of additional data fields in a piece of master data (in this case,

equipment records), and the ability to define and control the type of data allowed to populate those fields

TS Equipment Types and Classification:

TS functional location structure concludes with six general equipment types. The six equipment categories and their

related classes are as follows:

EQUIPMENT CATEGORY CLASSES

Downhole Device Downhole Completions (DHCP), Downhole Drilling Services (DHDS),

Downhole PDC Bits (DHPB), Downhole Pumping Services (DHPS),

Downhole Testing (DHTS) and Downhole Wireline (DHWL).

Lab/Shop Equipment Lab/Shop Completions (LSCP), Lab/Shop Drilling Services (LSDS),

Lab/Shop Pumping Services (LSPS), Lab/Shop Testing (LSTS, and

Lab/Shop Wireline (LSWL).

Source Source (same for all product lines).

Surface Equipment Surface Equipment Completions (SECP), Surface Equipment Drilling

Services (SEDS), Surface Equipment Pumping Services (SEPS), Surface

Equipment Testing (SETS) and Surface Equipment Wireline (SEWL).

Surface Systems Surface System Drilling Services (SSDS), Surface System Testing (SSTS),

And Surface System Wireline (SSWL).

Vehicle Vehicle (same for all product lines).

The following chart shows the CLASS required for each of the Product Lines:

Product Line

Downhole

Equipment

Lab/Shop

Equipment

Sources Surface

Equipment

Surface

Systems

Vehicles

Completions

(formerly Polar)

DHCP

LSCP

SECP

VEHICLE

Drilling Services

(formerly

Computalog)

DHDS

LSDS

SOURCE

SEDS

SSDS

VEHICLE

PDC Bits

(formerly United

Diamond)

DHPB

VEHICLE

Plains

(formerly Plains

Perforating)

Since Plains has merged with Wireline to become Precision Wireline, the Wireline

Classes will be used for the Plains equipment.

Pumping Services

(formerly Fleet

Cementers)

DHPS

LSPS

SEPS

SSPS

VEHICLE

Testing

(formerly Northland

Energy)

DHTS

LSTS

SETS

SSTS

VEHICLE

Wireline

(formerly

Computalog)

DHWL

LSWL

SOURCE

SEWL

SSWL

VEHICLE

System Appreciation Document

Page 12 of 19

All classes will be preceded by TS_ (e.g. TS_DHCP for Downhole Completions, TS_VEHICLE for vehicles,

etc).

Characteristic Values from the Material master will picked and updated in the equipment using the back ground

job.

ZPM_PM_Equipmentupdats.

Back ground job which runs daily and will update to equipment master data.

Measuring Points:

Measuring point: Is the Place or particular point in time, such as, run time hours or operating cycles Used to

assist in future planning and development of maintenance plans

ZPM_FE is the customized transaction, Used to update the measuring point.

Reference document for measuring point attached

Whenever the user do the order TECO, it will compare the ZPM_FE equipment measurement reading with

ZPM_MAX_HRS reading maintained , if it over the limit in the table it will pop an message that part need to

be serviced or due for service.

Max Hour Process in

SAP.doc

Task list: Task list are steps to perform against the orders. Task list are not used in details. Always it is one line

task in any order

Work centers: Work center that is responsible for carrying out assigned maintenance tasks

Work center there is no specific naming convention used but with the numeric values we can able identify the

work center belongs

Starting with 3*- Manufacturing

5*- Maintenance

Functional design

doc for reference

System Appreciation Document

Page 13 of 19

3.3 Customized Reports

ZPM_ORDER_COSTS

Order Report with Detailed Costs

ZPM_ORDPRINT

Order Print Utility

ZPM_PERFORMANCE

Analysis report - Performance-based

ZPM_PREVMAINT_RPT

Equip. Preventive Maintenance Report

ZPM_RIG

PM Rig Report

ZPM_WELL

PM Well Status Report

System Appreciation Document

Page 14 of 19

4. Application Design

4.1 Configuration Elements

NA

4.2 Integration with other Modules/Applications

Processing integrates well with all the other modules like MM, SD, PM, HR, FICO

System Appreciation Document

Page 15 of 19

5. Technical Details

5.1 Custom Transactions, Tables and User -Exits

List of Customized transactions

Customized

transaction,tables,userexit-PM

5.2 Interfaces

NA

5.3 Batch Processing

NA

5.4 Workflows

NA

System Appreciation Document

Page 16 of 19

6. Application Support

6.1 Known Problems, Issues and Workarounds

6.2 Tools

System Appreciation Document

Page 17 of 19

7. Glossary of Business Terms

System Appreciation Document

Page 18 of 19

8. References

Further reference documents available in weatherford O-drive.

Folder path:

\\sdcfile\Busapps$\TSG SAP Implementation\Team Folders\Operations Team\00-Documentation\BPP

- Business Process Procedure

System Appreciation Document

Page 19 of 19

9. Appendix

Not Applicable

Você também pode gostar

- Implementing Integrated Business Planning: A Guide Exemplified With Process Context and SAP IBP Use CasesNo EverandImplementing Integrated Business Planning: A Guide Exemplified With Process Context and SAP IBP Use CasesAinda não há avaliações

- TERP10 Unit4 Management Accounting CODocumento34 páginasTERP10 Unit4 Management Accounting CONicole LadouceurAinda não há avaliações

- FS - SM-C03-Serialized Equipment Master - Functional Specification Conversion 12Documento10 páginasFS - SM-C03-Serialized Equipment Master - Functional Specification Conversion 12darapuAinda não há avaliações

- Study Paper Sap Plant MaintananceDocumento2 páginasStudy Paper Sap Plant MaintananceInternational Journal of Innovative Science and Research TechnologyAinda não há avaliações

- QAS Calibration Process Test Case-07Documento4 páginasQAS Calibration Process Test Case-07Harshvardhan RajawatAinda não há avaliações

- Utilities Function List SAP PM English UsefulDocumento668 páginasUtilities Function List SAP PM English UsefulnileshpimpaleAinda não há avaliações

- Sap PM Work Clearance Management (WCM) : Kaushal Kumar K Eim Solutions PVT LTD 7/26/2019Documento2 páginasSap PM Work Clearance Management (WCM) : Kaushal Kumar K Eim Solutions PVT LTD 7/26/2019kumarAinda não há avaliações

- San PDFDocumento109 páginasSan PDFkalyangudluruAinda não há avaliações

- BBP For ESI Asset Supply Chain - V1.2Documento107 páginasBBP For ESI Asset Supply Chain - V1.2rupakbAinda não há avaliações

- IW32 - SAP Change PM OrderDocumento1 páginaIW32 - SAP Change PM Ordersaifrahman1234Ainda não há avaliações

- SAP MM (Material Management) Training TutorialDocumento2 páginasSAP MM (Material Management) Training TutorialSubodh KantAinda não há avaliações

- Create Equipment in SapDocumento5 páginasCreate Equipment in SapTamer FaroukAinda não há avaliações

- SAP Order To Cash Business ProcessDocumento75 páginasSAP Order To Cash Business Processrk_solomon100% (2)

- SAP PM Feature & StatusDocumento28 páginasSAP PM Feature & StatusSantrupta PandaAinda não há avaliações

- Profit Center AccountingDocumento55 páginasProfit Center AccountingMoaaz AtifAinda não há avaliações

- MEFCO - L3 - Training - Part 2 - Corrective MaintenanceDocumento19 páginasMEFCO - L3 - Training - Part 2 - Corrective MaintenanceSrinivas N GowdaAinda não há avaliações

- Book 1Documento6 páginasBook 1Dhanush S TAinda não há avaliações

- Erp - ConfiguringDocumento325 páginasErp - ConfiguringKiran KumarAinda não há avaliações

- Asset Management Part 2 Hana Cloud 2021Documento37 páginasAsset Management Part 2 Hana Cloud 2021Benbase Salim AbdelkhaderAinda não há avaliações

- SAP End User Manual Materials Management (MM)Documento17 páginasSAP End User Manual Materials Management (MM)prashant patilAinda não há avaliações

- Setup Data Requirements: Description Maintplant Abc Indic Main Work CenterDocumento4 páginasSetup Data Requirements: Description Maintplant Abc Indic Main Work CenterNeeraj GuptaAinda não há avaliações

- 04 - Materials Management - Enterprise StructureDocumento57 páginas04 - Materials Management - Enterprise StructureLaura Sofia Mendoza PovedaAinda não há avaliações

- Function Location, Equip, Work Cent CreationDocumento17 páginasFunction Location, Equip, Work Cent CreationsachinWebDAinda não há avaliações

- PM Importants TablesDocumento4 páginasPM Importants TablesMOORTHYAinda não há avaliações

- Test Script 459680Documento9 páginasTest Script 459680PawanDubeyAinda não há avaliações

- Batch03 DemoDocumento713 páginasBatch03 DemoSAP PMAinda não há avaliações

- ERP Integration (U of Warwick)Documento273 páginasERP Integration (U of Warwick)Tushar SakhalkarAinda não há avaliações

- Ready Recknor of Sap TablesDocumento9 páginasReady Recknor of Sap TablesBarryAinda não há avaliações

- Fico (New File)Documento1.071 páginasFico (New File)Taruna PAinda não há avaliações

- Sap PMDocumento2 páginasSap PMr.m.ram2340% (1)

- Programmer Competency MatrixDocumento23 páginasProgrammer Competency Matrixapi-25916350Ainda não há avaliações

- L3 Training Part 5 Capital OrderDocumento10 páginasL3 Training Part 5 Capital OrderSrinivas N GowdaAinda não há avaliações

- SAP Plant Maintenance (PM) Course ContentDocumento1 páginaSAP Plant Maintenance (PM) Course ContentsudheerravulaAinda não há avaliações

- Pradeep PS & MM - 1101Documento5 páginasPradeep PS & MM - 1101Pradeep GuptaAinda não há avaliações

- Refernce IMG SettingsDocumento123 páginasRefernce IMG Settingspritesh1984Ainda não há avaliações

- SAP FM 0001 OverviewDocumento2 páginasSAP FM 0001 OverviewMerugu JalendharAinda não há avaliações

- Project Phoenix (PM) - Daily StatusDocumento65 páginasProject Phoenix (PM) - Daily StatusSantrupta PandaAinda não há avaliações

- General Maintenance: Who Will Do? Process FlowDocumento7 páginasGeneral Maintenance: Who Will Do? Process FlowSameer BagalkotAinda não há avaliações

- Overview of The ABAP Dictionary: Srinivasulu NettemDocumento172 páginasOverview of The ABAP Dictionary: Srinivasulu NettemNagesh KhandareAinda não há avaliações

- 04 Function Location Create, Change, Display - IL01 IL02 IL03Documento33 páginas04 Function Location Create, Change, Display - IL01 IL02 IL03PragneshAinda não há avaliações

- Work Clearance ManagementDocumento47 páginasWork Clearance ManagementAllan DemisterAinda não há avaliações

- Truebell - Fin - Ap - Config - Account PayableDocumento49 páginasTruebell - Fin - Ap - Config - Account PayableRajesh ChowdaryAinda não há avaliações

- Asset Management Exercise GuideDocumento15 páginasAsset Management Exercise GuideSơn BadGuyAinda não há avaliações

- SCM - 09 - Cycle Counting and Physical Inventory Process Flows - EUDocumento4 páginasSCM - 09 - Cycle Counting and Physical Inventory Process Flows - EUsuyash4uAinda não há avaliações

- JD - SAP IS-Retail Pricing and PromotionDocumento1 páginaJD - SAP IS-Retail Pricing and PromotionSri RamAinda não há avaliações

- PLM-Enterprise Asset PMDocumento23 páginasPLM-Enterprise Asset PMRohan HazratiAinda não há avaliações

- Ricef DocumentDocumento8 páginasRicef DocumentmuraliAinda não há avaliações

- PM Tcode List For UserDocumento4 páginasPM Tcode List For Userritesh shrivastavAinda não há avaliações

- Technical - Specification DEBMAS IDOCDocumento26 páginasTechnical - Specification DEBMAS IDOCArpit Badaya0% (1)

- Business Process Detail - ETMDocumento9 páginasBusiness Process Detail - ETMSarthakTripathy100% (1)

- CMT TM MM02 V1.0Documento149 páginasCMT TM MM02 V1.0wessamalexAinda não há avaliações

- Useful Tables SAP PM PDFDocumento12 páginasUseful Tables SAP PM PDFDiego MatosAinda não há avaliações

- Function List Mining Erp607 en AuDocumento366 páginasFunction List Mining Erp607 en AuRtaccaAinda não há avaliações

- Creating Equipment Master DataDocumento14 páginasCreating Equipment Master DataRomar Jose Duran Zanotty100% (1)

- Brief Overview of Outline AgreementsDocumento9 páginasBrief Overview of Outline AgreementsrakeshkAinda não há avaliações

- 0008 SAP PM - EAM With S4 HANA Syllabus UCPL TechnologiesDocumento10 páginas0008 SAP PM - EAM With S4 HANA Syllabus UCPL TechnologiesUCPL TrainingAinda não há avaliações

- Business Rules Overview PresentationDocumento9 páginasBusiness Rules Overview PresentationmvelozmanAinda não há avaliações

- 03 - ABAP - The Data DictionaryDocumento56 páginas03 - ABAP - The Data DictionaryVaraPrasad.PAinda não há avaliações

- The Journey To World-Class: Introduction To SAP Master DataDocumento40 páginasThe Journey To World-Class: Introduction To SAP Master DataSreekarReddyBannuruAinda não há avaliações

- User Manual: (BSNL - PM - UM - 01 - Preventive - Maintenance - V2.0Documento71 páginasUser Manual: (BSNL - PM - UM - 01 - Preventive - Maintenance - V2.0anjitachinkiAinda não há avaliações

- Business Ethics QuestionsDocumento2 páginasBusiness Ethics Questionsanjitachinki100% (1)

- Precot Mills LTDDocumento9 páginasPrecot Mills LTDanjitachinkiAinda não há avaliações

- LOM Parameter LengthDocumento1 páginaLOM Parameter LengthanjitachinkiAinda não há avaliações

- Refurbishment Process in Plant MaintenanceDocumento8 páginasRefurbishment Process in Plant Maintenanceanjitachinki50% (2)

- Sap PPDocumento19 páginasSap PPJegathu Singh100% (2)

- System Name: Functional SpecificationDocumento8 páginasSystem Name: Functional SpecificationanjitachinkiAinda não há avaliações

- Steps in Implementation of SAP PPDocumento12 páginasSteps in Implementation of SAP PPVelavan Arumugam100% (1)

- SFCDocumento96 páginasSFCanjitachinkiAinda não há avaliações

- TPLM30 IG Col33Documento17 páginasTPLM30 IG Col33ahmedwwwAinda não há avaliações

- Sap Workcenter-Resource ViewsDocumento20 páginasSap Workcenter-Resource ViewsanjitachinkiAinda não há avaliações

- Module: PP (Production Planning)Documento155 páginasModule: PP (Production Planning)Suryanarayana TataAinda não há avaliações

- Routing SDocumento24 páginasRouting SanjitachinkiAinda não há avaliações

- PP Material Master ViewsDocumento26 páginasPP Material Master ViewsanjitachinkiAinda não há avaliações

- Sap MRPDocumento30 páginasSap MRPanjitachinki100% (4)

- Learn Sap MRP in 11 StepsDocumento17 páginasLearn Sap MRP in 11 Stepsanjitachinki100% (2)

- Sap Batch ManagementDocumento66 páginasSap Batch ManagementanjitachinkiAinda não há avaliações

- Master Recipes in Sap PppiDocumento11 páginasMaster Recipes in Sap PppianjitachinkiAinda não há avaliações

- SAP MRP Strategy Made Easy PDFDocumento172 páginasSAP MRP Strategy Made Easy PDFraky0369100% (4)

- Material Safety Data Sheet: KOMATSU Supercoolant AF-NAC (50/50 Pre-Diluted)Documento5 páginasMaterial Safety Data Sheet: KOMATSU Supercoolant AF-NAC (50/50 Pre-Diluted)Thais Roberta CamposAinda não há avaliações

- Donali Lalich Literature ReviewDocumento4 páginasDonali Lalich Literature Reviewapi-519746057Ainda não há avaliações

- FlazasulfuronDocumento2 páginasFlazasulfuronFenologiaVinhaAinda não há avaliações

- Ilmu KhotifDocumento28 páginasIlmu KhotifAndré Martins78% (27)

- Acoustic Phonetics PDFDocumento82 páginasAcoustic Phonetics PDFAnonymous mOSDA2100% (2)

- Hot Process Liquid SoapmakingDocumento11 páginasHot Process Liquid SoapmakingPanacea PharmaAinda não há avaliações

- CJR Fisika Umum IDocumento17 páginasCJR Fisika Umum IveronikaAinda não há avaliações

- Backlash SDPDocumento11 páginasBacklash SDPPatrick Cyr GagnéAinda não há avaliações

- Homoeopathy and MigraineDocumento4 páginasHomoeopathy and MigraineEditor IJTSRDAinda não há avaliações

- ECE 374 - Part - 1c - S2017Documento37 páginasECE 374 - Part - 1c - S2017Zakaria ElwalilyAinda não há avaliações

- Danh M C AHTN 2017 - HS Code 2017 PDFDocumento564 páginasDanh M C AHTN 2017 - HS Code 2017 PDFBao Ngoc Nguyen100% (1)

- 159 SnackDocumento97 páginas159 SnackGuy PlaterAinda não há avaliações

- CSA Pre-Test QuestionnaireDocumento16 páginasCSA Pre-Test Questionnairedaniella balaquitAinda não há avaliações

- 765 p1+2+3 Guide Limta Mock 2022Documento8 páginas765 p1+2+3 Guide Limta Mock 2022Théophile MbameAinda não há avaliações

- Mits Chocolates: Let The Life Be More Sweet'Documento30 páginasMits Chocolates: Let The Life Be More Sweet'Azaz NathaniAinda não há avaliações

- Reservoir Rock PropertiesDocumento148 páginasReservoir Rock Propertiesiscribdusername100% (7)

- Electro-Mechanical SectorDocumento22 páginasElectro-Mechanical SectorKen LeeAinda não há avaliações

- Balmatech Go Ep Tds 2022-03 GBDocumento2 páginasBalmatech Go Ep Tds 2022-03 GBAnalista De CalidadAinda não há avaliações

- SmartSlope C 110 Installation Manual PDFDocumento5 páginasSmartSlope C 110 Installation Manual PDFAivan Dredd PunzalanAinda não há avaliações

- Relatório Final Do Período Experimental - Paulo Manuel Correia Da SilvaDocumento56 páginasRelatório Final Do Período Experimental - Paulo Manuel Correia Da SilvaMagda RuanoAinda não há avaliações

- The Use of Proton Pump Inhibitors in Treating and Preventing NSAID-induced Mucosal DamageDocumento6 páginasThe Use of Proton Pump Inhibitors in Treating and Preventing NSAID-induced Mucosal DamageFriska Rachmanita PrayogoAinda não há avaliações

- BFE II ScenariosDocumento25 páginasBFE II Scenarioselmitxel100% (1)

- Macedonian KavalDocumento1 páginaMacedonian Kavalmikiszekely1362Ainda não há avaliações

- Lecture2 v1Documento69 páginasLecture2 v1c.ronaldo2012777Ainda não há avaliações

- The Church of Kapnikarea in Athens - N. GkiolesDocumento13 páginasThe Church of Kapnikarea in Athens - N. GkiolesMaronasAinda não há avaliações

- Production System: BY: Mallick MD Fahad Roll No. 16Documento36 páginasProduction System: BY: Mallick MD Fahad Roll No. 16Fahad SailorAinda não há avaliações

- The Fat CatsDocumento7 páginasThe Fat CatsMarilo Jimenez AlgabaAinda não há avaliações

- DRS Rev.0 GTP-TR1!01!002 Condensate RecyclingDocumento4 páginasDRS Rev.0 GTP-TR1!01!002 Condensate RecyclingBalasubramanianAinda não há avaliações

- Stock+List 6ct8.3g2 Esn#30549237 Cpl#2218 GeneradorDocumento34 páginasStock+List 6ct8.3g2 Esn#30549237 Cpl#2218 GeneradorAlexis SanchezAinda não há avaliações

- Power - Distribution Transformers @2020V2Documento34 páginasPower - Distribution Transformers @2020V2Musfiqul AzadAinda não há avaliações