Escolar Documentos

Profissional Documentos

Cultura Documentos

Technical Note PP 815-TN Above Grade Pipe Support

Enviado por

karuna346Título original

Direitos autorais

Formatos disponíveis

Compartilhar este documento

Compartilhar ou incorporar documento

Você considera este documento útil?

Este conteúdo é inapropriado?

Denunciar este documentoDireitos autorais:

Formatos disponíveis

Technical Note PP 815-TN Above Grade Pipe Support

Enviado por

karuna346Direitos autorais:

Formatos disponíveis

Bulletin: PP 815-TN March 2007 Supersedes all previous publications

Page 1 of 4 2007 Chevron Phillips Chemical Company LP

Performance Pipe, a division of PO Box 269006 Phone: 800-527-0662

Chevron Phillips Chemical Company LP Plano, TX 75026-9066 Fax: 972-599-7348

www.performancepipe.com

Technical Note PP 815-TN

Above Grade Pipe Support

Above grade applications frequently require non-continuous support for DriscoPlex

OD controlled

polyethylene pipe. Such applications usually involve piping in a rack or trestle, on sleepers, or

suspended from an overhead structure. In such cases, structures must provide proper pipeline support,

accommodate thermal expansion and contraction movement, and provide support spacing that limits

vertical deflection between supports.

Supports for DriscoPlex

OD controlled pipe must cradle at least the bottom 120 of the pipe, and be at

least 1/2 pipe diameter wide. Edges should be rounded or rolled to prevent cutting into the pipe.

Commercial pipe supports such as u-bolts, narrow strap-type hangers, and roller type supports are

unsuitable unless modified for width and cradling. The weight of the pipe and its contents must be

distributed over a broad surface. Narrow support surfaces can produce high concentrated stress, and

possibly lead to pipeline failure.

Figure 2 Pipeline Hanger

Figure 1 Pipeline Supports

NOTICE. This publication is for informational purposes and is intended for use as a reference guide. It should not be used in

place of the advice of a professional engineer. This publication does not contain or confer any warranty or guarantee of any kind.

Performance Pipe has made every reasonable effort towards the accuracy of the information contained in this publication, but it

may not provide all necessary information, particularl y with respect to special or unusual applications. This publication may be

changed from time to time without notice. Contact Performance Pipe to ensure that you have the most current edition.

Bulletin: PP 815-TN March 2007 Supersedes all previous publications

Page 2 of 4 2007 Chevron Phillips Chemical Company LP

Performance Pipe, a division of PO Box 269006 Phone: 800-527-0662

Chevron Phillips Chemical Company LP Plano, TX 75026-9066 Fax: 972-599-7348

www.performancepipe.com

Support Spacing

Support spacing depends upon the allowable deflection between supports, which in turn depends upon

the pipeline, the fluid within it, and the service temperature. Performance Pipe recommends that the

allowable long-term deflection between supports should not exceed 1". Recommended support spacing

may be determined from Equation 1.

( )

4

5

384

F P

S

S

W W

y I E

L

+

= (1)

where:

L

S

= distance between supports, in

E = long-term modulus for the service temperature, lb/in

2

(See PP 814-TN. Table 1)

I = moment of inertia, in

4

(See PP 814-TN, Equation 5.)

y

S

= deflection between supports, in

W

P

= weight of pipe, lb/in

W

F

= weight of fluid in pipe, lb/in

(PP 814-TN is the Technical Note for Engineering Considerations for Temperature Change)

Each support along a piping run is loaded from both sides. When run supports are equally spaced, the

load on supports along the run is:

( )

F P RUN

W W L W + = (2)

where:

W

RUN

= load on supports along the run, lb

The supports at the beginning and the end of the run are loaded from only one side, thus the load on

end supports is:

( )

2

F P

END

W W L

W

+

= (3)

where:

W

END

= load on end supports, lb

Figure 3 Deflection Between Supports

Bulletin: PP 815-TN March 2007 Supersedes all previous publications

Page 3 of 4 2007 Chevron Phillips Chemical Company LP

Performance Pipe, a division of PO Box 269006 Phone: 800-527-0662

Chevron Phillips Chemical Company LP Plano, TX 75026-9066 Fax: 972-599-7348

www.performancepipe.com

Pipe Rack Support

Pipes supported in an overhead rack require design consideration for both support spacing and thermal

length change. Support beams are spaced according to vertical deflection limits, and the rack width

accommodates the total thermal expansion offset plus the diameter of the pipe. Pipe supports should be

allowed to move along support beams, or otherwise accommodate horizontal movement as the pipe

deflects laterally with changing temperature. See PP 814-TN, Engineering Considerations for

Temperature Change, for more information.

Center anchored pipes must be allowed to pivot at the anchor point. Side anchored pipes may be rigidly

fixed to the side of the rack.

Several parallel DriscoPlex

OD controlled pipes may be accommodated in racks by spacing supports

as required for the smallest diameter pipe, and providing a rack wide enough for all of the pipes.

Thermal length change is independent of the pipe diameter, so for the same temperature variation,

length change and lateral deflection will be the same for DriscoPlex

OD controlled pipes regardless of

pipe diameter.

DriscoPlex

OD controlled pipes may be placed in racks parallel to pipes such as steel or fiberglass by

using the side anchoring approach. The rack should be widened to accommodate total horizontal

deflection, and additional support beams added as required. Non-polyethylene pipes should be located

on the anchored side to allow the DriscoPlex

OD controlled pipe to deflect horizontally to the opposite

side of the rack.

Figure 4 Pipe Rack - Side Anchored

Bulletin: PP 815-TN March 2007 Supersedes all previous publications

Page 4 of 4 2007 Chevron Phillips Chemical Company LP

Performance Pipe, a division of PO Box 269006 Phone: 800-527-0662

Chevron Phillips Chemical Company LP Plano, TX 75026-9066 Fax: 972-599-7348

www.performancepipe.com

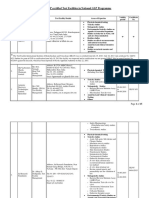

Table 1 Support Spacing at 73F (23C)

Support Spacing, ft

IPS size OD, in

DR 7.3 DR 9 DR 11 DR 13.5 DR 17 DR 21 DR 26 DR 32.5 DR 41

2 2.375 5.3 5.1 4.9

3 3.500 6.4 6.2 6.0 5.8 5.5 5.3

4 4.500 7.3 7.0 6.8 6.5 6.3 6.0 5.7 5.4

5 5.563 8.1 7.8 7.6 7.3 7.0 6.7 6.4 6.0

6 6.625 8.8 8.5 8.3 7.9 7.6 7.3 6.9 6.6

8 8.625 10.1 9.7 9.4 9.1 8.7 8.3 7.9 7.5

10 10.750 11.2 10.9 10.5 10.1 9.7 9.2 8.8 8.4

12 12.750 12.2 11.9 11.5 11.0 10.5 10.1 9.6 9.1

14 14.000 12.8 12.4 12.0 11.5 11.0 10.6 10.1 9.6

16 16.000 13.7 13.3 12.8 12.3 11.8 11.3 10.8 10.2

18 18.000 14.5 14.1 13.6 13.1 12.5 12.0 11.4 10.9

20 20.000 15.3 14.8 14.3 13.8 13.2 12.6 12.0 11.5

22 22.000 16.1 15.6 15.0 14.5 13.8 13.2 12.8 12.0

24 24.000 16.8 16.3 15.7 15.1 14.4 13.8 13.2 12.5

26 26.000 17.5 16.9 16.3 15.7 15.0 14.4 13.7 13.1

28 28.000 17.6 17.0 16.3 15.6 14.9 14.2 13.5

30 30.000 18.2 17.6 16.9 16.1 15.4 14.7 14.0 13.3

32 32.000 18.8 18.1 17.5 16.7 15.9 15.2 14.5 13.7

34 34.000 18.7 18.0 17.2 16.4 15.7 14.9 14.2

36 36.000 19.2 18.5 17.7 16.9 16.2 15.4 14.6

42 42.000 20.0 19.1 18.3 17.4 16.6 15.7

48 48.000 21.4 20.4 19.5 18.6 17.7 16.8

54 54.000 21.7 20.7 19.8 18.8 17.8

Support spacing for pipe at 73F (23C) filled with 73F (23C) water. Spacing will vary for different temperature and for

different fluids in the pipe. Calculations based on modulus value for PE 3608.

Você também pode gostar

- Hdpe Anchor Load CalcualtionDocumento14 páginasHdpe Anchor Load CalcualtionPipeline EngineerAinda não há avaliações

- Designguide 4Documento16 páginasDesignguide 4Adrian Flores GallardoAinda não há avaliações

- Pipeline Rules of Thumb Handbook: A Manual of Quick, Accurate Solutions to Everyday Pipeline Engineering ProblemsNo EverandPipeline Rules of Thumb Handbook: A Manual of Quick, Accurate Solutions to Everyday Pipeline Engineering ProblemsNota: 4.5 de 5 estrelas4.5/5 (10)

- Greenlee Dobladora de TubosDocumento16 páginasGreenlee Dobladora de TuboswilfredoAinda não há avaliações

- Dunlop Hoses and Fittings CatalogDocumento242 páginasDunlop Hoses and Fittings CatalogBrandon Troc50% (4)

- Pipe SupportsDocumento5 páginasPipe SupportsDefenceDogAinda não há avaliações

- Total Energy: International Series in Heating, Ventilation and RefrigerationNo EverandTotal Energy: International Series in Heating, Ventilation and RefrigerationAinda não há avaliações

- Process Piping Systems: Scrubber Design and Installation RequirementsDocumento6 páginasProcess Piping Systems: Scrubber Design and Installation RequirementsCamilo Andres Cardozo FajardoAinda não há avaliações

- Simple Plumbing Repairs for the Home and FarmsteadNo EverandSimple Plumbing Repairs for the Home and FarmsteadAinda não há avaliações

- Pipe Expansion and Support - International Site For Spirax SarcoDocumento8 páginasPipe Expansion and Support - International Site For Spirax SarcoSandi ApriandiAinda não há avaliações

- Scientific American Supplement, No. 388, June 9, 1883No EverandScientific American Supplement, No. 388, June 9, 1883Ainda não há avaliações

- Pipe Expansion and Support - International Site For Spirax SarcoDocumento8 páginasPipe Expansion and Support - International Site For Spirax SarcoVenkatesh NatlaAinda não há avaliações

- Prevention of Valve Fugitive Emissions in the Oil and Gas IndustryNo EverandPrevention of Valve Fugitive Emissions in the Oil and Gas IndustryAinda não há avaliações

- Sway Braces: Restoring Force For Sch.40 Pipe (Empty)Documento2 páginasSway Braces: Restoring Force For Sch.40 Pipe (Empty)azraq68Ainda não há avaliações

- Pocket Guide to Flanges, Fittings, and Piping DataNo EverandPocket Guide to Flanges, Fittings, and Piping DataNota: 3.5 de 5 estrelas3.5/5 (22)

- Support LocationsDocumento12 páginasSupport LocationsdasubhaiAinda não há avaliações

- A1200 Red Thread II PipingDocumento0 páginaA1200 Red Thread II PipingjimmycabreraAinda não há avaliações

- Heat Exchanger Handbook - Heat Exchangers PDFDocumento66 páginasHeat Exchanger Handbook - Heat Exchangers PDFhonghai_dl100% (3)

- Stripper TOT 2.50 10M DS34 TechMan1146Documento13 páginasStripper TOT 2.50 10M DS34 TechMan1146Diego OspinaAinda não há avaliações

- Sisteme de ZavorareDocumento32 páginasSisteme de ZavorareGabi CristacheAinda não há avaliações

- User Bulletin17 - Provisions For Expansion and Contraction in PlasticDocumento7 páginasUser Bulletin17 - Provisions For Expansion and Contraction in PlasticHenrique Ferreira IengoAinda não há avaliações

- Heat Exchanger PipingDocumento39 páginasHeat Exchanger PipingBhupender Sharma93% (15)

- 003 Casing & Tubing Hanger PDFDocumento4 páginas003 Casing & Tubing Hanger PDFalaliali88Ainda não há avaliações

- TH10 - Pipe Loop or Expansion JointsDocumento3 páginasTH10 - Pipe Loop or Expansion JointsloukatsAinda não há avaliações

- Seismic Restraint of Hot PipingDocumento6 páginasSeismic Restraint of Hot PipingmustafaonuronarAinda não há avaliações

- Pipe Rack 1Documento17 páginasPipe Rack 1bipin_pmkAinda não há avaliações

- Mustang Series M115-74 (Globe), M1115-74 (Angle) Specification SheetDocumento7 páginasMustang Series M115-74 (Globe), M1115-74 (Angle) Specification SheetWattsAinda não há avaliações

- Training ManualDocumento400 páginasTraining ManualJairo Peña80% (5)

- Ag Petrofac Pulsation StudyDocumento29 páginasAg Petrofac Pulsation StudyDaniel Eduardo CortezAinda não há avaliações

- Tyco - Fleksibilna CrijevaDocumento10 páginasTyco - Fleksibilna CrijevaMuhidin KozicaAinda não há avaliações

- RPS Support CatalogueDocumento49 páginasRPS Support Catalogueravivarmadatla2011Ainda não há avaliações

- Heat Transfer Handbook PDFDocumento56 páginasHeat Transfer Handbook PDFRoyer Juarez100% (1)

- Piping DesignDocumento122 páginasPiping Designfacebookshop100% (9)

- U.S. Bellows, Inc.: Examples Using Hinged or Gimbalpipe Expansion JointsDocumento2 páginasU.S. Bellows, Inc.: Examples Using Hinged or Gimbalpipe Expansion JointsMashudi FikriAinda não há avaliações

- Piping Flexibility Analysis and Supporting Guidelines Report For Dynamic Loads PDFDocumento13 páginasPiping Flexibility Analysis and Supporting Guidelines Report For Dynamic Loads PDFAnjani PrabhakarAinda não há avaliações

- United States Patent (191: Egashira (11) 4,310,281Documento12 páginasUnited States Patent (191: Egashira (11) 4,310,281rajaguru20003Ainda não há avaliações

- Plugback For Sidetrack Procedure Proposed PDFDocumento4 páginasPlugback For Sidetrack Procedure Proposed PDFPatrícia MouraAinda não há avaliações

- Tanques PDFDocumento6 páginasTanques PDFPepe PintoAinda não há avaliações

- Wellheads Xmas Trees ValvesDocumento29 páginasWellheads Xmas Trees ValvesAbdul Hameed OmarAinda não há avaliações

- Melaku Tesfaye (Parafin Oil)Documento55 páginasMelaku Tesfaye (Parafin Oil)aberAinda não há avaliações

- OTC 17815 Mitigation Measures For DeepWater Pipeline InstabilityDocumento6 páginasOTC 17815 Mitigation Measures For DeepWater Pipeline InstabilityKarun DasAinda não há avaliações

- General Catalogue AVAST Surge TankDocumento14 páginasGeneral Catalogue AVAST Surge TankNoor AnterAinda não há avaliações

- An Alternative Way To Support Horizontal Pressure Vessels Subject To To Thermal LoadingDocumento7 páginasAn Alternative Way To Support Horizontal Pressure Vessels Subject To To Thermal LoadingDavid RodriguesAinda não há avaliações

- HIGH-K Heat Exchanger Rigging and Installation InstructionsDocumento4 páginasHIGH-K Heat Exchanger Rigging and Installation InstructionsValesh MonisAinda não há avaliações

- Victaulic Piping Guide PDFDocumento8 páginasVictaulic Piping Guide PDFkumar123rajuAinda não há avaliações

- 2007 Catalog Constant SpringDocumento36 páginas2007 Catalog Constant Springinfo592Ainda não há avaliações

- Exp JinsDocumento2 páginasExp JinsAshish ParasharAinda não há avaliações

- Thermal Expansion in Piping SystemsDocumento55 páginasThermal Expansion in Piping SystemsDivyaShethAinda não há avaliações

- Parveen Well HeadDocumento25 páginasParveen Well HeadGerman PinedaAinda não há avaliações

- C StructDesign Bendapudi Feb10 (1) Part 1Documento0 páginaC StructDesign Bendapudi Feb10 (1) Part 1Rubén MenaAinda não há avaliações

- Catalogue Spring HangersDocumento57 páginasCatalogue Spring HangersVeman ReddyAinda não há avaliações

- Pipe Expansion and SupportDocumento11 páginasPipe Expansion and SupportLorenzoAinda não há avaliações

- Nexus 4in 10k 2-Door WBA Stripper Manual - REV 13Documento26 páginasNexus 4in 10k 2-Door WBA Stripper Manual - REV 13Pastor Velasquez100% (1)

- Designing Spiral Heat ExchangerDocumento10 páginasDesigning Spiral Heat Exchangerak100% (5)

- Span CalculationDocumento2 páginasSpan CalculationMohit BauskarAinda não há avaliações

- SDR 11Documento20 páginasSDR 11rupayan.baruaAinda não há avaliações

- Expansion Joint in CAESARDocumento5 páginasExpansion Joint in CAESARkaruna346Ainda não há avaliações

- If I Were You ExamplesDocumento1 páginaIf I Were You Exampleskaruna346Ainda não há avaliações

- Use of Branch Connections: Standard Practice ForDocumento5 páginasUse of Branch Connections: Standard Practice ForFelix Rodriguez LiraAinda não há avaliações

- I Have +PP ExamplesDocumento1 páginaI Have +PP Exampleskaruna346Ainda não há avaliações

- I Have To + Verb ExamplesDocumento1 páginaI Have To + Verb Exampleskaruna346Ainda não há avaliações

- How Was + (Noun)Documento1 páginaHow Was + (Noun)karuna346Ainda não há avaliações

- Iam Good at ExaplesDocumento1 páginaIam Good at Exapleskaruna346Ainda não há avaliações

- Component Material Equivalent ASTMDocumento1 páginaComponent Material Equivalent ASTMkaruna346Ainda não há avaliações

- I Have + Noun ExamplesDocumento1 páginaI Have + Noun Exampleskaruna346Ainda não há avaliações

- Plant DesignDocumento17 páginasPlant Designkaruna346Ainda não há avaliações

- CCI Power ApplicationsDocumento57 páginasCCI Power Applicationssukanya_ravichandran100% (1)

- Turbine Heat Rate CalculationDocumento2 páginasTurbine Heat Rate Calculationkaruna34650% (2)

- I Am Gonna + Verb ExeDocumento1 páginaI Am Gonna + Verb Exekaruna346Ainda não há avaliações

- Boiler Efficiency CurvesDocumento1 páginaBoiler Efficiency Curveskaruna346Ainda não há avaliações

- Design & Construction of Piping SystemsDocumento115 páginasDesign & Construction of Piping SystemsSuresh Babu100% (13)

- HRSG SimulationDocumento7 páginasHRSG Simulationkaruna346Ainda não há avaliações

- 210MW PPS SimulationDocumento11 páginas210MW PPS Simulationkaruna346Ainda não há avaliações

- Specifying Waste Heat BoilersDocumento5 páginasSpecifying Waste Heat Boilerskaruna346Ainda não há avaliações

- Stress Analysis of Piping Systems and Pipelines - Harvard - UniversityDocumento542 páginasStress Analysis of Piping Systems and Pipelines - Harvard - Universitykaruna346100% (11)

- G-ST-P/OE: Elastomerlips ProfilesDocumento1 páginaG-ST-P/OE: Elastomerlips Profileskaruna346Ainda não há avaliações

- Archery Association of IndiaDocumento17 páginasArchery Association of Indiakaruna346Ainda não há avaliações

- Measurements of Surface TensionDocumento11 páginasMeasurements of Surface TensionHema ParasuramanAinda não há avaliações

- Unit 1, 2 and 8Documento71 páginasUnit 1, 2 and 8Noor SaleemAinda não há avaliações

- HealthDocumento183 páginasHealthJonaAinda não há avaliações

- Standard Reduction PotentialsDocumento1 páginaStandard Reduction PotentialsCamiloAinda não há avaliações

- Consumer Satisfaction Towards Organic Food Products - A Study With Special Reference To Erode CityDocumento7 páginasConsumer Satisfaction Towards Organic Food Products - A Study With Special Reference To Erode Cityarcherselevators100% (1)

- Bondstrand™ LD Series: ApplicationsDocumento4 páginasBondstrand™ LD Series: ApplicationsMathan KumarAinda não há avaliações

- Forensic Assignment Muhammad Asghar Roll No. 2357Documento5 páginasForensic Assignment Muhammad Asghar Roll No. 2357Faisal AwanAinda não há avaliações

- PagesDocumento1 páginaPagesEnedis Pimentel0% (1)

- Protein Structure Function and Uses WorksheetDocumento3 páginasProtein Structure Function and Uses WorksheetAngelon UdaniAinda não há avaliações

- Inner Earth May Hold More Water Than The SeasDocumento2 páginasInner Earth May Hold More Water Than The SeasManuel TPAinda não há avaliações

- Pressure Drop Compressible FlowDocumento14 páginasPressure Drop Compressible Flowdilip matalAinda não há avaliações

- Optic Fibre Cable: Rajiv Gandhi Memorial Telecom Training CentreDocumento62 páginasOptic Fibre Cable: Rajiv Gandhi Memorial Telecom Training Centremeskb100% (1)

- Chemical Raw Material PDFDocumento4 páginasChemical Raw Material PDFA MahmoodAinda não há avaliações

- Chemistry ReviewerDocumento14 páginasChemistry ReviewerJaliesa Ann ValdezAinda não há avaliações

- Safety Data Sheet According To Regulation (EC) No 1907/2006, Annex IIDocumento10 páginasSafety Data Sheet According To Regulation (EC) No 1907/2006, Annex IIazerAinda não há avaliações

- Spark Sensor FM 1-8 - EngDocumento86 páginasSpark Sensor FM 1-8 - EngBarosz0% (1)

- LDH SLDocumento4 páginasLDH SLLUIS DANIEL VAZQUEZ RAMIREZAinda não há avaliações

- ReagentGuide 8th SynthesticOrganicChemistry MaterialsChemistryDocumento396 páginasReagentGuide 8th SynthesticOrganicChemistry MaterialsChemistryyulliarperezAinda não há avaliações

- CPVC SolventsDocumento6 páginasCPVC SolventsAhmad AnthonyAinda não há avaliações

- Applied 2 PE244 DR Mohammed Fadel PDFDocumento339 páginasApplied 2 PE244 DR Mohammed Fadel PDFعبدالحميد العرفيAinda não há avaliações

- Tarnish & CorrosionDocumento48 páginasTarnish & CorrosionmujtabaAinda não há avaliações

- New List of GLP Approved LabsDocumento15 páginasNew List of GLP Approved LabsMulayam Singh YadavAinda não há avaliações

- HDPE made via Mitsui Process: Features ﺎﻫ ﯽﮔﮋﯾو Applications ﺎﻫدﺮﺑرﺎﮐ Additives ﯽﻧدوﺰﻓا داﻮﻣDocumento1 páginaHDPE made via Mitsui Process: Features ﺎﻫ ﯽﮔﮋﯾو Applications ﺎﻫدﺮﺑرﺎﮐ Additives ﯽﻧدوﺰﻓا داﻮﻣAnonymous pmSJvwKwwLAinda não há avaliações

- Factors Affecting Enzyme ActionDocumento18 páginasFactors Affecting Enzyme Actionanon_458882066Ainda não há avaliações

- US1744693 Erythritol TetranitrateDocumento2 páginasUS1744693 Erythritol Tetranitrateteleson eliasAinda não há avaliações

- Kelebihan Kekurangan Kromatografi KolomDocumento8 páginasKelebihan Kekurangan Kromatografi KolomFendy FendyAinda não há avaliações

- Hardness Temperature in MetalsDocumento6 páginasHardness Temperature in MetalsStevenJacomeAinda não há avaliações

- Gold RecoveryDocumento21 páginasGold RecoveryAnoop Chetia100% (2)

- Tablas TermodinámicasDocumento5 páginasTablas TermodinámicasSarahí CabreraAinda não há avaliações

- Philippine Mineral DepositsDocumento9 páginasPhilippine Mineral DepositsLara CharisseAinda não há avaliações