Escolar Documentos

Profissional Documentos

Cultura Documentos

Benefits and Design Tipsfor Chillers

Enviado por

Sharon LambertDireitos autorais

Formatos disponíveis

Compartilhar este documento

Compartilhar ou incorporar documento

Você considera este documento útil?

Este conteúdo é inapropriado?

Denunciar este documentoDireitos autorais:

Formatos disponíveis

Benefits and Design Tipsfor Chillers

Enviado por

Sharon LambertDireitos autorais:

Formatos disponíveis

Optimal Air Systems

Benefits And Design Tips

While low temperature air distribution

systems are not new, their use has

generally been limited to grocery stores

and other temperature and humidity

sensitive applications. However, as

greater emphasis is placed on reducing

building construction costs and

equipment room and ceiling plenum

space, many architects and building

owners/developers are becoming

interested in the technology for offices

and other commercial buildings.

What Is Optimal Air?

Most air conditioning designs are based

on supplying 55F air to the space.

Cooling supply air to 55F generally

provides the required humidity ratio to

maintain space conditions at 75F and

50% Relative Humidity. In short,

cooling air to 55F provides reasonable

humidity control. Warmer supply air

temperatures will lead to a humid or

clammy environment when it is humid

outdoors.

Cooling supply air below 55F

offers the potential for significant

capital savings in many applications.

As the supply air temperature is

reduced, the supply air volume is

reduced proportionally. That is, a

10% increase in supply air delta T

(space setpoint minus the supply air

temperature) will result in a 10%

drop in required supply air volume.

This allows a 10% reduction in

duct and air handler face areas, and up

to a 23% reduction in supply fan

motor BHP.

The downside is that the colder supply

air temperature requires more

refrigeration work and reduces the

number of hours in a year when

economizer operation can be used. For

example, lowering the supply air

setpoint from 55F to 50F removes

the opportunity to cool the building

with outdoor air when the ambient

drybulb is between 55F and 50F.

With integrated economizers, some

cooling effect can be gained, but

supplemental mechanical cooling will

be required.

The Optimal Air or Balance Point is

the lowest supply air temperature that

can be used without increasing the

annual operating cost of the building.

While it is typically 48F to 52F, every

building is different and annual energy

analysis is required.

ENGINEERING

T

his issue of Engineering

System Solutions considers

whether one of the HVAC

industrys most valued design

parameters is truly the best

parameter for all buildings. While

the use of 55F is based on

maintaining acceptable humidity

control in a building, it does not

necessarily offer the best annual

energy performance or capital cost.

In many cases, a lower supply air

temperature is at least as efficient

and will offer significant capital

savings. This article is about finding

the best balance point and designing

the system.

McQuay also has an Application

Guide (AG 31-005) on Optimal Air

Design that can be downloaded from

www.mcquay.com or ordered from

your local McQuay Representative.

Your local McQuay Representative

has the Energy Analyzer

software

used to perform the annual energy

analyses used in this newsletter and

they are willing to assist you in any

analysis you may require on your

next building project.

Hugh Crowther

Director of Applications

McQuay North America

S Y S T E M S O L U T I O N S

Edition No. 12 July 2002

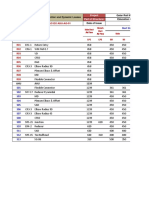

Figure 1 Annual HVAC Energy Usage

Fans

48%

Chillers

38%

Pumps

12%

Towers

2%

Continued on next page.

Optimal Air Advantages

To illustrate the benefits of Optimal

Air systems, lets consider a 10 story,

200,000 ft

2

office building in Chicago.

The HVAC system is VAV with a

chiller plant. The design supply air

temperature is 55F. In this example

the fan work actually exceeds the

chiller work on an annual basis

because the fans must operate

whenever the building is occupied.

Table 1shows the annual energy analysis

as the supply air temperature is lowered

in 1F increments down to 45F. The

following adjustments were made to

more accurately reflect changes in

equipment requirements or

performance because the supply air

temperature is being lowered:

The total static pressure is slowly

increased to offset the deeper coils

required for colder air.

The chiller plant efficiency slowly

decreases.

Reviewing the total annual work shows

the building load staying level until

49F. Beyond that point, the loss of

economizer hours causes the energy use

to increase. Comparing the 55F supply

air design to the 49F supply air design

leads to the following conclusions:

Fan Energy and Duct Sizing

The 49F supply air design shows a

23% reduction in design supply air

volume. This represents a very large

capital savings in reduced duct sizes,

air handling units and fan motors.

Refrigeration

The refrigeration work increased as

expected due to the lowered suction

pressure required by the chillers, the

increased load from the ventilation air

(which must be cooled to a lower

enthalpy than 55F supply air

systems) and the increased operating

hours to offset the reduced

economizer operation.

The design refrigeration load actually

went up slightly. This is due to

increased enthalpy load from the

ventilation air, offset slightly by the

reduced fan motor heat gain.

Space Design Temperature and

Related Comfort

The above example is based on

maintaining 75F in the occupied

space. Because the supply air has been

lowered to 49F, the space Relative

Humidity (RH) has also been lowered.

With a 90% sensible heat ratio, the

space RH is now 40%. At this RH,

the space temperature can be raised to

77F while still maintaining acceptable

conditions. ASHRAE Standard 55,

Thermal Conditions for Human

Occupancy, covers in detail the correct

temperature and humidity ranges so

that 80% of the occupants engaged in

light office work should be satisfied.

Table 2 shows an annual energy analysis

for the same 10-story office building in

Chicago based on a 49F supply air

temperature and a space temperature

ranging from 75F to 77F. Raising the

space temperature to 77F provides an

8% reduction in design supply air

volume. It also lowers the annual energy

usage by 6%. The energy savings are due

to lowered cooling loads (the indoor

versus outdoor temperature difference is

smaller) and an increase in the amount

of available economizer hours.

Sound

Because of the reduced supply air

volume in Optimal Air systems, the

fan(s) and motor(s) can be smaller,

which lowers the sound power levels of

the air handling units. Lower sound

power levels require less attenuation,

which can lower both the static

pressure drops and capital costs.

Indoor Air Quality

Using the Optimal Air approach does

not require any special requirements to

meet ASHRAE Standard 62.1. Lower

space relative humidity can actually help

reduce the possibility of mold growth.

ASHRAE Standard 90.1 Compliance

As shown in the above example, the

goal is to not increase the annual

energy usage in the building so that

Optimal Air systems comply with

Standard 90.1 requirements. Section

6.3 of ASHRAE Standard 90.1 allows

a credit for fan motor brake

horsepower when using the Optimal

Air concept.

SAT TSP Supply Air Design CWST Perfor- Room Chiller Fan Total

Volume Cooling mance Setpoint Work Work Work

F "w.c. cfm Tons F kW/ton F kWh/yr kWh/yr kWh/yr

55 3 152,686 473 44 0.55 75 219,605 202,736 422,341

54 3.02 145,415 475 43.6 0.554 75 226,594 194,061 420,655

53 3.04 138,805 477 43.2 0.558 75 236,352 186,175 422,527

52 3.06 132,770 479 42.8 0.562 75 241,228 178,975 420,203

51 3.08 127,238 481 42.4 0.566 75 248,661 172,375 421,036

50 3.1 122,149 483 42 0.57 75 255,777 166,303 422,080

49 3.12 117,451 485 41.6 0.574 75 261,285 160,698 421,983

48 3.14 113,101 486 41.2 0.578 75 269,044 155,508 424,552

47 3.16 109,061 488 40.8 0.582 75 276,512 150,689 427,201

46 3.18 105,301 490 40.4 0.586 75 286,605 146,202 432,807

45 3.2 101,791 492 40 0.59 75 292,832 142,014 434,846

Table 1 Annual Energy Analysis (55F to 45F supply air temperature range)

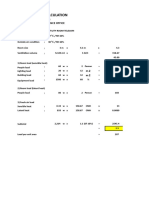

SAT TSP Supply Air Design CWST Perfor- Room Chiller Fan Total

Volume Cooling mance Setpoint Work Work Work

F "w.c. cfm Tons F kW/ton F kWh/yr kWh/yr kWh/yr

49 3.12 117,451 485 41.6 0.574 75 261,285 160,698 421,983

49 3.12 112,549 480 41.6 0.574 76 255,231 153,695 408,926

49 3.12 107,997 475 41.6 0.574 77 249,350 147,438 396,788

Table 2 Annual Energy Analysis (75F to 77F space temperature range)

Design Considerations

When Using Optimal Air

Unlike low temperature air systems,

Optimal Air requires very little changes

in design methodology versus

conventional HVAC systems. Buildings

with high sensible heat ratios are excellent

candidates for Optimal Air.

Load Calculations

The first step in designing an Optimal

Air system is to identify the supply air

balance point, which will become the

supply air temperature. This requires

some form of annual energy analysis.

McQuays Energy Analyzer can be

used to quickly find the balance point.

Most buildings can be evaluated in less

than an hour. Once the supply air

temperature is identified, the rest of the

building load analysis is the same as in a

conventional design.

Secondary System Selection

Conventional secondary system design

will work fine for Optimal Air.

Standard VAV is the most common,

but fan assisted VAV boxes are also

used. This is often predicated on the

need to address skin heat loss during

winter months.

Blowthrough Or Drawthrough

The main objective of Optimal Air is to

increase the temperature difference

between the supply air and the space

temperature to reduce the required

supply air volume. The supply air

temperature is the temperature of the

air as it leaves the air handling unit and

enters the ductwork not as it leaves

the coil.

This is a very important consideration

because a supply fan will add enough

heat to raise the supply air temperature

about 2F to3F. Because blowthrough

air handling units have the supply fan

upstream of the cooling coil, their leaving

air temperature off the cooling coil is the

same as the supply air temperature as it

enters the ductwork. On the other hand,

drawthrough units add the fan heat

downstream from the cooling coil. To

compensate, the coil leaving air

temperature must be 2F to 3F

lower than the supply air

temperature.

Both drawthrough and

blowthrough arrangements will

work in Optimal Air systems

and both have advantages. The

sensible heat ratio provided by

blowthrough equipment is a

good match for buildings with

high sensible heat ratios (such as

office buildings).

Air Distribution and Diffuser

Selection

Introducing colder air does affect

air distribution and diffuser

selection. Since Optimal Air is typically

only 5F to 8F less than conventional

systems, standard diffusers will work but

they will perform a little differently.

Linear diffusers tend to offer the best

performance since they have higher

supply air velocities than lay-in type

diffusers.

A key parameter that must be monitored

is the separation distance relative to

throw (see Figure 3). For conventional

systems, most designers treat these two

as the same. However, as the supply air

temperature is lowered and the supply

air density increases, the separation

distance will decrease from the throw.

Figure 4 shows the change in separation

distance as the supply air temperature is

lowered. The goal is to have an

acceptable separation distance at both

maximum and minimum air flow.

Primary System Selection

In an Optimal Air system, the primary

system must be capable of providing the

low supply air temperature. While this is

not a problem with chiller and air

handling systems, it can present some

unique challenges to rooftop or vertical

self-contained units. Typical unitary

equipment cannot provide the lower

supply air temperatures. However,

applied products such as McQuays

RoofPak rooftop units or the SWP

indoor vertical self-contained units have

the necessary flexibility in DX coils and

refrigeration components to meet the

lower supply air temperature

requirement.

Other Design Considerations

Duct condensation is a perceived

concern because of the colder supply air

temperature. However, because the space

RH is also lower, the difference between

the duct surface temperature and the

space dewpoint is about the same for

both conventional and Optimal Air

systems.

Infiltration is a bigger concern for

Optimal Air systems. Moist, warm air

leaking into the building is more likely

to condense on Optimal Air supply air

ductwork than a conventional design.

Duct heat gain is another issue. As a

result, many applications will require

more duct insulation.

1.20

1.00

0.80

0.60

0.40

0.20

0.00

55 54 53 52 51 50 49 48 47 46 45

Supply Air Temperature (F)

P

e

r

c

e

n

t

D

r

o

p

I

n

S

e

p

a

r

a

t

i

o

n

D

i

s

t

a

n

c

e

Separation Distance

Figure 3 Separation Distance

Figure 4 Separation Distance vs.

Supply Air Temperature

Continued on back page.

For comments or suggestions, please call or write:

Chris Sackrison, Editor

McQuay International

13600 Industrial Park Boulevard

Minneapolis, MN 55441

Phone: (763) 553-5419

E-mail: chris.sackrison@mcquay.com

For more information on McQuay products and services, or to speak with your local representative, call (800) 432-1342, or visit our web page at www.mcquay.com.

2002 McQuay International

continued from page 3.

Conclusions

While 55F supply air works well as a

design parameter, it may not be the most

efficient operating point or provide the

lowest capital cost. Lowering the design

supply air temperature until the annual

energy usage starts to climb is a good

method for optimizing an HVAC system

design.

Reviewing the design load calculations

only will not provide the answer. An

annual energy analysis must be

performed. The rest of the HVAC design

is similar to a conventional design using

standard air diffusion products. Applied

unitary products are recommended

because the lowered supply air

temperature requires more flexibility from

the HVAC equipment.

McQuay has produced an Application

Guide on Optimal Air Design (AG31-

005) which provides detailed design

considerations for Optimal Air systems.

Contact your McQuay Representative for

a copy of this and other Application

Guides or visit www.mcquay.com. In

addition, the annual energy analysis can

be performed by your local McQuay

Representative using McQuays Energy

Analyzer.

Você também pode gostar

- Geothermal HVAC: Shifting Performance Risk From Buyer To SellerDocumento5 páginasGeothermal HVAC: Shifting Performance Risk From Buyer To SellerKagitha TirumalaAinda não há avaliações

- Fluid Handling: Identifying The TRUE Cost Savings of Variable Speed Pumping SystemsDocumento2 páginasFluid Handling: Identifying The TRUE Cost Savings of Variable Speed Pumping SystemsPallab MukherjeeAinda não há avaliações

- 2.0 Design CalculationsDocumento2 páginas2.0 Design CalculationsfebousAinda não há avaliações

- ME 331 Refrigeration & Air Conditioning: M AsfandyarDocumento20 páginasME 331 Refrigeration & Air Conditioning: M AsfandyarSuaid Tariq BalghariAinda não há avaliações

- Renewable Energy: Solar Photovoltaics - ExerciseDocumento2 páginasRenewable Energy: Solar Photovoltaics - ExerciseDor MoreAinda não há avaliações

- HVAC Expansion Tanks: Plain Steel vs. Bladder-Type: Air Control or Air EliminationDocumento4 páginasHVAC Expansion Tanks: Plain Steel vs. Bladder-Type: Air Control or Air EliminationSharon LambertAinda não há avaliações

- Chiller Selection Building A+j Cooling Only Rev 2Documento7 páginasChiller Selection Building A+j Cooling Only Rev 2Anton WelgemoedAinda não há avaliações

- Sound Attenuator Selection Path Report: Source Sound Power Level Total Air Flow (M3/sec)Documento1 páginaSound Attenuator Selection Path Report: Source Sound Power Level Total Air Flow (M3/sec)mefaisal75Ainda não há avaliações

- CTDocumento3 páginasCTSundar DAACAinda não há avaliações

- Condensation On Air Distribution ProductsDocumento2 páginasCondensation On Air Distribution ProductsSonny Ramos100% (1)

- Sound Attenuator Selection Path Report: Total Air Flow (M3/sec) Source Sound Power LevelDocumento1 páginaSound Attenuator Selection Path Report: Total Air Flow (M3/sec) Source Sound Power Levelmefaisal75Ainda não há avaliações

- Generator Exhaust Pipe Diameter Calculations: Marina Towers L9959Documento4 páginasGenerator Exhaust Pipe Diameter Calculations: Marina Towers L9959febousAinda não há avaliações

- 9 571 WaterCooledChillerPlantWithEconomizerVP PDFDocumento10 páginas9 571 WaterCooledChillerPlantWithEconomizerVP PDFFirasAinda não há avaliações

- Heat Gain From PeopleDocumento1 páginaHeat Gain From Peoplehasanadel88Ainda não há avaliações

- CH2 - Heating System PDFDocumento10 páginasCH2 - Heating System PDFAaron AngAinda não há avaliações

- Ventilation Summary For Carpark & VRV System: (M /S) (M /S)Documento4 páginasVentilation Summary For Carpark & VRV System: (M /S) (M /S)sachinsaklani23Ainda não há avaliações

- Staircase Pressurization Tower ADocumento6 páginasStaircase Pressurization Tower AShanku ChakrabartyAinda não há avaliações

- Water Cooled Chiller Plant With Economiser (VP) : Data CenterDocumento10 páginasWater Cooled Chiller Plant With Economiser (VP) : Data CenterFirasAinda não há avaliações

- CalculationsDocumento5 páginasCalculationsRamarajan YogeeswaranAinda não há avaliações

- Greenhouse Ventilation and CoolingDocumento8 páginasGreenhouse Ventilation and Coolinglakshminarayanan100% (1)

- Multi Media Filters Calaculations: Input DataDocumento5 páginasMulti Media Filters Calaculations: Input DataHamdy AdelAinda não há avaliações

- BSE 3712 Intergrated System Design Report: Heating, Ventilation and Air ConditioningDocumento19 páginasBSE 3712 Intergrated System Design Report: Heating, Ventilation and Air ConditioningChan Tsz HimAinda não há avaliações

- CondensationDocumento5 páginasCondensationsswinforAinda não há avaliações

- Energy Conservation: ASHRAE Standard 90.1. Each New BuildingDocumento4 páginasEnergy Conservation: ASHRAE Standard 90.1. Each New BuildingdemuthuAinda não há avaliações

- High Performance BuildingDocumento21 páginasHigh Performance BuildingPallab MukherjeeAinda não há avaliações

- Hvac Condensate Calculator: Difference in Specific Humidity gr/ft3Documento4 páginasHvac Condensate Calculator: Difference in Specific Humidity gr/ft3Pradeep SukumaranAinda não há avaliações

- Chiller and Tower Sizing Formulas PDFDocumento2 páginasChiller and Tower Sizing Formulas PDFnagarjuna reddy mAinda não há avaliações

- Al Gharafa Sports Club Irrigation Schedule RevisedDocumento1 páginaAl Gharafa Sports Club Irrigation Schedule RevisedmansidevAinda não há avaliações

- Supersedes Bulletin # 006/2000Documento15 páginasSupersedes Bulletin # 006/2000almig200100% (2)

- AHRI Standard 885 2008 Duct Discharge Calculation SpreadsheetDocumento17 páginasAHRI Standard 885 2008 Duct Discharge Calculation SpreadsheetbinishAinda não há avaliações

- Air Cooler Size Estimation: Step CalculationDocumento1 páginaAir Cooler Size Estimation: Step CalculationmacielAinda não há avaliações

- QuickGuide Fan and PumpDocumento90 páginasQuickGuide Fan and PumppratheeshAinda não há avaliações

- Ahu Coil SelectionDocumento6 páginasAhu Coil SelectionpsjjoshiAinda não há avaliações

- Water Meter Sizing Chart: City of Gresham Department of Environmental Services-Development EngineeringDocumento1 páginaWater Meter Sizing Chart: City of Gresham Department of Environmental Services-Development EngineeringMIN GUIAinda não há avaliações

- Petrofac Case StudyDocumento2 páginasPetrofac Case StudyRalphMarrugoAinda não há avaliações

- Chilled Water System Sequence of OperationDocumento3 páginasChilled Water System Sequence of OperationdimasAinda não há avaliações

- Supertall Building Chilled Water Distribution SI May 30 2015Documento10 páginasSupertall Building Chilled Water Distribution SI May 30 2015185412Ainda não há avaliações

- Building HVAC Requirements: 4.1 OverviewDocumento55 páginasBuilding HVAC Requirements: 4.1 OverviewHaroon GhaniAinda não há avaliações

- SAFIDDocumento34 páginasSAFIDsyedahmedsabirAinda não há avaliações

- Part 10. All-Air Systems - Chapter 4. Dual-Duct System: Table 1 Summarizes The Cooling Load Requirements of 2)Documento1 páginaPart 10. All-Air Systems - Chapter 4. Dual-Duct System: Table 1 Summarizes The Cooling Load Requirements of 2)Karthikeyan SankarrajanAinda não há avaliações

- Control Valves For Ahu Chilled WaterDocumento4 páginasControl Valves For Ahu Chilled WaterHussein Akil100% (1)

- Using Waste Heat For Energy Savings: Large Commercial, Institutional, Industrial FacilitiesDocumento6 páginasUsing Waste Heat For Energy Savings: Large Commercial, Institutional, Industrial FacilitiesdomcristiniAinda não há avaliações

- Heat TransferDocumento1 páginaHeat TransferhuangjlAinda não há avaliações

- Accu FcuDocumento2 páginasAccu FcuKuzin09Ainda não há avaliações

- Thermal Storage Vessel Sizing: This Is A Free Article Provided byDocumento18 páginasThermal Storage Vessel Sizing: This Is A Free Article Provided byMokrani JaberAinda não há avaliações

- Date: Prepared By: Checked & Approved By: Client Name: Project No.: Location: Document No.: Project Name: RevisionDocumento3 páginasDate: Prepared By: Checked & Approved By: Client Name: Project No.: Location: Document No.: Project Name: RevisionMohsin ShaikhAinda não há avaliações

- ASHRAE Standards For LEED Assessment Thermal Comfort PDFDocumento60 páginasASHRAE Standards For LEED Assessment Thermal Comfort PDFAbdülhamit KayyaliAinda não há avaliações

- Sizing Heaters and Steam Requirements For HotelDocumento17 páginasSizing Heaters and Steam Requirements For HotelantonpgmAinda não há avaliações

- Combining DOAS and VRF, Part 2 of 2Documento9 páginasCombining DOAS and VRF, Part 2 of 2miniongskyAinda não há avaliações

- Coil Selection ReportDocumento1 páginaCoil Selection ReportMohsin Shaikh100% (1)

- Equations: Hvac Equations, Data, and Rules of ThumbDocumento21 páginasEquations: Hvac Equations, Data, and Rules of ThumbzodedAinda não há avaliações

- 8 Managing Data Center Heat IssuesDocumento42 páginas8 Managing Data Center Heat IssuesfabiokruseAinda não há avaliações

- Average Sheet Temperature at Drying: Gloss Efficiency (Production Time / Maximum Time Available)Documento7 páginasAverage Sheet Temperature at Drying: Gloss Efficiency (Production Time / Maximum Time Available)Alexandre HugenAinda não há avaliações

- AHU Friction Loss CalculationsDocumento4 páginasAHU Friction Loss CalculationsAdnan AttishAinda não há avaliações

- PRICE - Air Distribution GuideDocumento5 páginasPRICE - Air Distribution Guidenvenkat.narayan100% (1)

- Selection Sheet - 30XA452 Screw ChillerDocumento1 páginaSelection Sheet - 30XA452 Screw Chillercalvin.bloodaxe4478Ainda não há avaliações

- VRF SpecsDocumento6 páginasVRF SpecsAshar HassanAinda não há avaliações

- Genetics Pharma Dehumidifying Load Input Sheet: 1 BlisteringDocumento1 páginaGenetics Pharma Dehumidifying Load Input Sheet: 1 Blisteringirfanbaig36Ainda não há avaliações

- Cooling Tower CalculationeditedDocumento3 páginasCooling Tower CalculationeditedMark LouieAinda não há avaliações

- 3 Simple WaysDocumento7 páginas3 Simple WaysAruna Prasanna DewasurendraAinda não há avaliações

- Hvac BasicsDocumento73 páginasHvac BasicsSharon LambertAinda não há avaliações

- 20170706140654483Documento66 páginas20170706140654483Sharon LambertAinda não há avaliações

- Commercial Kitchen Design PDFDocumento21 páginasCommercial Kitchen Design PDFRocky WidjajaAinda não há avaliações

- HVAC Chilled Water Distribution SchemesDocumento56 páginasHVAC Chilled Water Distribution SchemesJenson Joy100% (5)

- JournalofBuildingPhysics 2012 Younes 267 302Documento37 páginasJournalofBuildingPhysics 2012 Younes 267 302Sharon LambertAinda não há avaliações

- 20170706140756729Documento36 páginas20170706140756729Sharon LambertAinda não há avaliações

- Hvac Basics 4Documento74 páginasHvac Basics 4Sharon LambertAinda não há avaliações

- HVAC Expansion Tanks: Plain Steel vs. Bladder-Type: Air Control or Air EliminationDocumento4 páginasHVAC Expansion Tanks: Plain Steel vs. Bladder-Type: Air Control or Air EliminationSharon LambertAinda não há avaliações

- Fundamentals of Water Distribution: TopicsDocumento89 páginasFundamentals of Water Distribution: TopicsRonald Kahora0% (1)

- Background Noise Rating Calculator: InstructionsDocumento29 páginasBackground Noise Rating Calculator: InstructionsSharon LambertAinda não há avaliações

- REQ 15 Sizing of Oil and Grease TrapsDocumento40 páginasREQ 15 Sizing of Oil and Grease TrapsSharon LambertAinda não há avaliações

- AHRI Standard 885 2008 Duct Discharge Calculation SpreadsheetDocumento17 páginasAHRI Standard 885 2008 Duct Discharge Calculation SpreadsheetbinishAinda não há avaliações

- Calculating Sump VolumeDocumento2 páginasCalculating Sump VolumeSharon LambertAinda não há avaliações

- How To Size and Design DuctsDocumento91 páginasHow To Size and Design DuctsPrabir Bhowmik100% (1)

- Temperature Expansion PipesDocumento2 páginasTemperature Expansion PipesSharon LambertAinda não há avaliações

- Duct SilencersDocumento125 páginasDuct SilencersesagcojrAinda não há avaliações

- MD He Tema Asme v0.1Documento31 páginasMD He Tema Asme v0.1Sharon Lambert100% (1)

- MD He Tema Asme v0.1Documento31 páginasMD He Tema Asme v0.1Sharon Lambert100% (1)

- Piping Pressure Drop Functions by Stephen Hall, PE: Pipe DataDocumento4 páginasPiping Pressure Drop Functions by Stephen Hall, PE: Pipe DataSharon LambertAinda não há avaliações

- Red Cells Contain Parameters That You Can Change To Test Different ConfigurationsDocumento3 páginasRed Cells Contain Parameters That You Can Change To Test Different ConfigurationsSharon Lambert100% (1)

- Grease Trap Calculator 03Documento2 páginasGrease Trap Calculator 03Sharon LambertAinda não há avaliações

- Pipe and Fitting Calcs MasterDocumento8 páginasPipe and Fitting Calcs MasterSharon LambertAinda não há avaliações

- Expansion LoopDocumento54 páginasExpansion Loopsteepa22Ainda não há avaliações

- The Importance of Drying Compressed Air - Paerker BalstonDocumento12 páginasThe Importance of Drying Compressed Air - Paerker Balstonppluis90Ainda não há avaliações

- Wap 3 Ventilation WksheetDocumento7 páginasWap 3 Ventilation WksheetSharon LambertAinda não há avaliações

- Equivalent Length Calculator - RevADocumento10 páginasEquivalent Length Calculator - RevArkrajan1502Ainda não há avaliações

- Pressure Drop Calculation Equations For PIPING and PIPELINEDocumento3 páginasPressure Drop Calculation Equations For PIPING and PIPELINETiano BaLajadia100% (4)

- Pertes de Charge (Fluide Compressibles) V2Documento20 páginasPertes de Charge (Fluide Compressibles) V2Sharon LambertAinda não há avaliações

- Recommended Fluid VelocitiesDocumento5 páginasRecommended Fluid Velocitiesger80100% (1)

- Emergency Vent Flam LiquidsDocumento3 páginasEmergency Vent Flam LiquidsSharon LambertAinda não há avaliações

- Selection of Water Cooled Chiller - 221 TRDocumento2 páginasSelection of Water Cooled Chiller - 221 TRcalvin.bloodaxe4478Ainda não há avaliações

- GDFGDFDocumento12 páginasGDFGDFAissa FaikAinda não há avaliações

- Energy Manager TrainingDocumento4 páginasEnergy Manager Traininghendratondang5294Ainda não há avaliações

- Menara Maybank - Preliminary Energy Walk Thru Audit by Tatasolusi PratamaDocumento37 páginasMenara Maybank - Preliminary Energy Walk Thru Audit by Tatasolusi PratamaJoe_Average100% (2)

- Humidity Control - Hospital Operating Room DehumidificationDocumento6 páginasHumidity Control - Hospital Operating Room Dehumidificationengamer80100% (1)

- Air Cooled Screw Chillers: VLHAFX Series 50HzDocumento28 páginasAir Cooled Screw Chillers: VLHAFX Series 50HzKamalMuralikumarAinda não há avaliações

- AVX A R134a 50 60Hz - MS04102B 0416 - Cs - Lo PDFDocumento40 páginasAVX A R134a 50 60Hz - MS04102B 0416 - Cs - Lo PDFEnrique EndoAinda não há avaliações

- ECBC - 2017 - Summary and ConclusionDocumento5 páginasECBC - 2017 - Summary and Conclusionharinder singhAinda não há avaliações

- Waterloo SDCH-high-capacity-swirl-diffusersDocumento8 páginasWaterloo SDCH-high-capacity-swirl-diffusersDan RotariAinda não há avaliações

- Heat Sink CalculationDocumento1 páginaHeat Sink CalculationkkbusAinda não há avaliações

- Ficha Técnica Orion RKLDocumento2 páginasFicha Técnica Orion RKLOscar MartinezAinda não há avaliações

- AC CalculationDocumento8 páginasAC CalculationFauzi RahmanAinda não há avaliações

- Evaporative Condenser PDFDocumento2 páginasEvaporative Condenser PDFDemetrius100% (1)

- Paquete Lennox - Landmark - Brochure PDFDocumento6 páginasPaquete Lennox - Landmark - Brochure PDFCamilo CotrinoAinda não há avaliações

- Desiccant Rotors International: Pvt. LTDDocumento1 páginaDesiccant Rotors International: Pvt. LTDRoger AklAinda não há avaliações

- Evaporative CoolingDocumento68 páginasEvaporative Coolingshivas34regal100% (1)

- Vw.t4.Wd.36 - Air Conditioning - ACU From Sep 94Documento6 páginasVw.t4.Wd.36 - Air Conditioning - ACU From Sep 94florinnn22Ainda não há avaliações

- Adsorption Chiller Guide SpecificationsDocumento6 páginasAdsorption Chiller Guide Specificationsmdalt9180Ainda não há avaliações

- SPD-60L Swimming Pool Dehumidifier For Humidity Control.Documento4 páginasSPD-60L Swimming Pool Dehumidifier For Humidity Control.CtrlTech DehumidifierAinda não há avaliações

- Daikin Manual LXE10E 15ADocumento161 páginasDaikin Manual LXE10E 15ALuis Sandi Rivera75% (4)

- Exp. 5 Heat Transfer Study On Plate Heat ExchangerDocumento6 páginasExp. 5 Heat Transfer Study On Plate Heat ExchangerElaine PuiAinda não há avaliações

- Refrigeration Oral SpeechDocumento2 páginasRefrigeration Oral SpeechSMAinda não há avaliações

- Rittal 3328510 Technical Details 3 2905 PDFDocumento4 páginasRittal 3328510 Technical Details 3 2905 PDFChandravadanAinda não há avaliações

- SERVICE MANUAL GeysersDocumento11 páginasSERVICE MANUAL GeysersSajal GuptaAinda não há avaliações

- Apache HvacDocumento255 páginasApache HvacJm SunAinda não há avaliações

- TECNAIR Serie P PDFDocumento28 páginasTECNAIR Serie P PDFdokundotAinda não há avaliações

- Munir Ahmad Muhammad Shafi Shad Driver License Light Vehicle (Manual)Documento3 páginasMunir Ahmad Muhammad Shafi Shad Driver License Light Vehicle (Manual)AtiqSayalAinda não há avaliações

- List Certified Refrigerator 3rd QTR 2021Documento24 páginasList Certified Refrigerator 3rd QTR 2021nikerAinda não há avaliações

- EE 451 - Kinematics & Inverse Kinematics: H.I. BozmaDocumento47 páginasEE 451 - Kinematics & Inverse Kinematics: H.I. BozmaNaeemo IraqiAinda não há avaliações

- Daikin Magnitude Magnetic Bearing ChillersDocumento27 páginasDaikin Magnitude Magnetic Bearing ChillersIbnu HanafiAinda não há avaliações

- Power of Habit: The Ultimate Guide to Forming Positive Daily Habits, Learn How to Effectively Break Your Bad Habits For Good and Start Creating Good OnesNo EverandPower of Habit: The Ultimate Guide to Forming Positive Daily Habits, Learn How to Effectively Break Your Bad Habits For Good and Start Creating Good OnesNota: 4.5 de 5 estrelas4.5/5 (21)

- Solar Power Demystified: The Beginners Guide To Solar Power, Energy Independence And Lower BillsNo EverandSolar Power Demystified: The Beginners Guide To Solar Power, Energy Independence And Lower BillsNota: 4.5 de 5 estrelas4.5/5 (2)

- Nuclear Energy in the 21st Century: World Nuclear University PressNo EverandNuclear Energy in the 21st Century: World Nuclear University PressNota: 4.5 de 5 estrelas4.5/5 (3)

- Introduction to Power System ProtectionNo EverandIntroduction to Power System ProtectionNota: 5 de 5 estrelas5/5 (1)

- The Permaculture City: Regenerative Design for Urban, Suburban, and Town ResilienceNo EverandThe Permaculture City: Regenerative Design for Urban, Suburban, and Town ResilienceAinda não há avaliações

- Fire on the Horizon: The Untold Story of the Gulf Oil DisasterNo EverandFire on the Horizon: The Untold Story of the Gulf Oil DisasterAinda não há avaliações

- Shorting the Grid: The Hidden Fragility of Our Electric GridNo EverandShorting the Grid: The Hidden Fragility of Our Electric GridNota: 4.5 de 5 estrelas4.5/5 (2)

- A Pathway to Decarbonise the Shipping Sector by 2050No EverandA Pathway to Decarbonise the Shipping Sector by 2050Ainda não há avaliações

- The Complete HVAC BIBLE for Beginners: The Most Practical & Updated Guide to Heating, Ventilation, and Air Conditioning Systems | Installation, Troubleshooting and Repair | Residential & CommercialNo EverandThe Complete HVAC BIBLE for Beginners: The Most Practical & Updated Guide to Heating, Ventilation, and Air Conditioning Systems | Installation, Troubleshooting and Repair | Residential & CommercialAinda não há avaliações

- Heat Transfer Engineering: Fundamentals and TechniquesNo EverandHeat Transfer Engineering: Fundamentals and TechniquesNota: 4 de 5 estrelas4/5 (1)

- Handbook on Battery Energy Storage SystemNo EverandHandbook on Battery Energy Storage SystemNota: 4.5 de 5 estrelas4.5/5 (2)

- Photovoltaic Solar Energy: From Fundamentals to ApplicationsNo EverandPhotovoltaic Solar Energy: From Fundamentals to ApplicationsAinda não há avaliações

- Offshore Wind Energy Generation: Control, Protection, and Integration to Electrical SystemsNo EverandOffshore Wind Energy Generation: Control, Protection, and Integration to Electrical SystemsAinda não há avaliações

- Power Electronics Diploma Interview Q&A: Career GuideNo EverandPower Electronics Diploma Interview Q&A: Career GuideAinda não há avaliações

- Practical Reservoir Engineering and CharacterizationNo EverandPractical Reservoir Engineering and CharacterizationNota: 4.5 de 5 estrelas4.5/5 (3)

- Live Off Grid: Escape The City, Learn How To Travel Intelligently Using Solar PowerNo EverandLive Off Grid: Escape The City, Learn How To Travel Intelligently Using Solar PowerAinda não há avaliações

- Fundamentals of Hydrogen Production and Utilization in Fuel Cell SystemsNo EverandFundamentals of Hydrogen Production and Utilization in Fuel Cell SystemsAinda não há avaliações

- Idaho Falls: The Untold Story of America's First Nuclear AccidentNo EverandIdaho Falls: The Untold Story of America's First Nuclear AccidentNota: 4.5 de 5 estrelas4.5/5 (21)

- VSC-FACTS-HVDC: Analysis, Modelling and Simulation in Power GridsNo EverandVSC-FACTS-HVDC: Analysis, Modelling and Simulation in Power GridsAinda não há avaliações

- Electrical Load-Curve Coverage: Proceedings of the Symposium on Load-Curve Coverage in Future Electric Power Generating Systems, Organized by the Committee on Electric Power, United Nations Economic Commission for Europe, Rome, Italy, 24 – 28 October 1977No EverandElectrical Load-Curve Coverage: Proceedings of the Symposium on Load-Curve Coverage in Future Electric Power Generating Systems, Organized by the Committee on Electric Power, United Nations Economic Commission for Europe, Rome, Italy, 24 – 28 October 1977Ainda não há avaliações

- An Introduction to Renewable Energy Sources : Environment Books for Kids | Children's Environment BooksNo EverandAn Introduction to Renewable Energy Sources : Environment Books for Kids | Children's Environment BooksAinda não há avaliações

- Introduction to Power System ProtectionNo EverandIntroduction to Power System ProtectionAinda não há avaliações

- RV Living Collection: RV living for beginners, RV travel for the whole family, RV repair and RV mobile solar power: Experience Freedom on the roads alone or with your family with this collection. Learn how to repair your motorhome while using renewable energy!No EverandRV Living Collection: RV living for beginners, RV travel for the whole family, RV repair and RV mobile solar power: Experience Freedom on the roads alone or with your family with this collection. Learn how to repair your motorhome while using renewable energy!Ainda não há avaliações

- Global Landscape of Renewable Energy FinanceNo EverandGlobal Landscape of Renewable Energy FinanceAinda não há avaliações

- Simulation of Some Power Electronics Case Studies in Matlab Simpowersystem BlocksetNo EverandSimulation of Some Power Electronics Case Studies in Matlab Simpowersystem BlocksetNota: 2 de 5 estrelas2/5 (1)