Escolar Documentos

Profissional Documentos

Cultura Documentos

THE ROLLER FLOUR MILLING REVOLUTION - Keeping Up-To-Date

Enviado por

Milling and Grain magazine0 notas0% acharam este documento útil (0 voto)

49 visualizações7 páginasRegular readers of GFMT may recall that I am writing a series of articles which connect the 21st century flour roller-milling industry with its beginnings more than 150 years ago and its history.

Título original

THE ROLLER FLOUR MILLING REVOLUTION - Keeping up-to-date

Direitos autorais

© © All Rights Reserved

Formatos disponíveis

PDF, TXT ou leia online no Scribd

Compartilhar este documento

Compartilhar ou incorporar documento

Você considera este documento útil?

Este conteúdo é inapropriado?

Denunciar este documentoRegular readers of GFMT may recall that I am writing a series of articles which connect the 21st century flour roller-milling industry with its beginnings more than 150 years ago and its history.

Direitos autorais:

© All Rights Reserved

Formatos disponíveis

Baixe no formato PDF, TXT ou leia online no Scribd

0 notas0% acharam este documento útil (0 voto)

49 visualizações7 páginasTHE ROLLER FLOUR MILLING REVOLUTION - Keeping Up-To-Date

Enviado por

Milling and Grain magazineRegular readers of GFMT may recall that I am writing a series of articles which connect the 21st century flour roller-milling industry with its beginnings more than 150 years ago and its history.

Direitos autorais:

© All Rights Reserved

Formatos disponíveis

Baixe no formato PDF, TXT ou leia online no Scribd

Você está na página 1de 7

Digital Re-print -

September | October 2014

THE ROLLER FLOUR MILLING REVOLUTION

- Keeping up-to-date

www.gfmt.co.uk

Grain & Feed Milling Technology is published six times a year by Perendale Publishers Ltd of the United Kingdom.

All data is published in good faith, based on information received, and while every care is taken to prevent inaccuracies,

the publishers accept no liability for any errors or omissions or for the consequences of action taken on the basis of

information published.

Copyright 2014 Perendale Publishers Ltd. All rights reserved. No part of this publication may be reproduced in any form

or by any means without prior permission of the copyright owner. Printed by Perendale Publishers Ltd. ISSN: 1466-3872

A new dawn for...

In 2015, welcome to...

July 5, 1880. THE MILLER page 217

HIGH COURT OF JUSTICE Chancery Division

(Before Mr Justice Stirling)

THE GERM MILLING CASE

The Germ Milling Company v. Robinson

THE ATTORNEY-GENERAL: I appear for the Company who are, as their

name indicates, a milling company carrying on their business in Glasgow

and the defendant, Mr Robinson, is also a miller carrying on business at

Deptford.

I should like, in a few words, to give your Lordship a general idea of

the modes in which milling was carried out in this country until recent

years, and how it has been carried on in foreign countries. In this country

the system generally adopted has been what is called low grinding. The

machinery still in use in the greatest number of mills in this country is the

upper and lower millstone. Figures show that there are about 8,000 mills

in this country and that there are not more than 500 of what are called

roller mills. But although the number of roller mills is small that does not

represent their importance for in them is produced a far greater quantity

of flour and meal than in the others. The ordinary stones, made of French

burrs, consist of a nether millstone, which is fixed, and an upper millstone

which rotates, the face of each stone being marked by what are called

land and furrow marks which in the rotating action of the upper

stone the stones being so closely set that the distance between them

is not more than the thickness of a sheet of ordinary paper crushes and

also cuts and grinds the wheat berries between them.

T

his outline of traditional flour milling practice was a

reflection of the times late 19th century but a Revolution,

implies change and the increasingly successful flour mills were

within the 500 to which the Attorney-General refers.

One of the principal foot-soldiers or facilitators of the Roller

Flour Milling Revolution was Henry Gustav Simon (1835 1899), a

German-born engineer. Armed solely with an Engineering Diploma

from the Zurich Technical Polytechnical School and a surcharge of

mental energy and business initiative he moved to Manchester in

1860; by 1867 he was a naturalised British Subject with his own office

as a consulting engineer. His first

real success was in 1878 and the

introduction of a roller milling

plant for McDougall Brothers in

Manchester. (from Wikipaedia

entry, edited by Bryan McGee).

By January 1885, only 5 years

after the Attorney-General pero-

ration in the Germ Milling Case,

Simon paid for this double page

advertisement in THE MILLER

which illustrates the rapid pro-

gress of the Roller Flour Milling

Revolution (Figure 2)

The Germ Milling Case illus-

trated of the importance of the

separation of the wheat germ

from the bran and endosperm

in the roller milling process. The

Attorney-General explained to

the Court that:

... the germ should be

abstracted [because], from its

oleaginous character, if is allowed

to remain in the flour it contains

elements which by fermenting

would lead to sourness in the

flour. . . . This elimination of

the germ has commanded great

by Rob Shorland-Ball

RESEARCHING

AND REPORTING

THE ROLLER FLOUR MILLING REVOLUTION

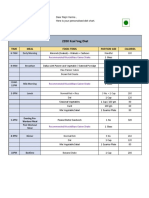

Figure 1: Intellectual framework for the research data

FRAMEWORK STRUCTURE FRAMEWORK DETAILS

u Growing wheat

Processing turning the wheat to flour

Stone milling the traditional sudden death process

Experimenting with milling processes

Globalising wheat from central Europe and North America

milling machinery from Hungary and the USA

ROLLER FLOUR MILLING REVOLUTION starts in the UK from 1850s

Designing and building new machinery and new mills

Transporting wheat [roads, canals, railways, rivers, sea-ways]

u Storing silos at the mill

u Receiving, cleaning and conditioning wheat at the mill

u Blending mixing English and overseas wheat

u Blending mixing English and overseas wheat

u Grading and packing stocks flour and other products

u Advertising marketing the stocks

u Distributing stocks to market

Transporting wheat [bulk by roads and sea-ways]

u Baking bread is the single largest market for flour

Branding HOVIS; HOMEPRIDE

TELLING THE ROLLER FLOUR MILLING STORY in the 21st CENTURY

Keeping up-to-

date

R

egular readers of GFMT may recall that I am writing a

series of articles which connect the 21st century flour

roller-milling industry with its beginnings more than 150

years ago and its history.

New readers, and perceptive regulars, may have noticed

that GFMTs title has been enhanced to become global and to

acknowledge the importance of storage. So this is No 1 in a new

volume of a journal first published in 1891 as MILLING and still

providing a valuable source of reference.

So how can my research output be as up-to-date and relevant

as GFMT? I think the fact there was a revolution in this industry is

a key factor because it was a social and a technological revolution

which had an impact that is still significant and relevant today.

My researches are discovering much data: in text, input and

output figures, pictures, map evidence, publications, memories

including some oral history from millers and mill engineers and

more memories from retired folk. The databank which will hold

this material, and make it available to enquirers and teachers, is

The Mills Archive Trust [MAT] in Reading and it illustrates the

relevance of the data that Perendale Publishers Ltd have become

a MAT Patron so we are working together.

I find it helpful to have an intellectual framework for the

research data and here is a start (Figure 1).

50 | September - October 2014

GRAIN

&

FEED MILLING TECHNOLOGY

F

September - October 2014 | 51 GRAIN

&

FEED MILLING TECHNOLOGY

MYANMARS BIGGEST INTERNATIONAL AGRICULTURE,

GRAINS, FEED & LIVESTOCK PRODUCTION EXHIBITION

9-11 DECEMBER 2014

TATMADAW HALL, YANGON

9 - 11 DECEMBER 2014

4

(+603) 4041 9889

(+603) 2770 5301

fong@ambexpo.com

09 420701651

95-1-254765

may@ambexpo.com

AMB EVENTS GROUP

Organised & Managed by:

www.ambexpo.com www.agrilivestock.net

Very successful! A show of international standards!

Mr. Jonathan Zheng

ZHENG CHANG

We have not seen before a Show of such international standard in the livestock

industry in Myanmar

Mr Win Sein

Vice Chairman

Myanmar Livestock Federation

Hosted by: Media Partners: Supporting Organisations:

Platinum Sponsors: Gold Sponsors:

Silver Sponsor:

F

Figure 2

Results and Discussion

Part 1: Sample preparation and

spectra collection

In the initial testing phase the appli-

cability of the unit to predict moisture,

protein and fat was evaluated using an ini-

tial set of materials received from Aunir.

This set consisted of 20 samples each of

ground wheat, soy and corn, covering an

appropriate range of parameters.

The parameters evaluated for wheat

and soy are indicated in Table 2 and

Table 3. For initial testing wheat was

used as an indication of the performance

of cereals (Aunir Group 10) and soy was

used as indication of the performance of

high protein-low oil (Aunir group 30)

All samples were used as received

(ground) and placed in the quartz sample

cup for NIR spectra collection. Spectra

were collected on microPHAZIR AG

analysers, each over a wavelength range

from 1595-2395nm, in diffuse reflectance

mode.

Spectra were collected over six posi-

tions of the sample cup in order to

compensate for sample inhomogeneity.

In total, this resulted in six spectra col-

lected per sample and each sample was

also tested three times, with replace-

ment, resulting in 24 spectra collected

for each sample. This sampling process

was repeated for each of the 20 samples.

Samples were scanned in a randomised

manner to compensate for any sampling

correlations.

The spectral data were then evalu-

ated and quantitative individual PLS-1 mod-

els were constructed using our internal

chemometrics software package Thermo

Method Generator

TM

software (TMG). This

software was developed for use with the

microPHAZIR analyser. An example of the

spectra collected on each microPHAZIR

analyser is shown in Figure 1.

Aside from baseline offset, all spectral

features were similar across the different

microPHAZIR analysers, with no obvi-

ous spectral non-conformities. Based on

one microPHAZIR analyzer, the resulting

spectra collected from the 20 wheat

samples are shown in Figure 2.

Figure 1: Example of wheat spectra

from 4 different instruments

Figure 2: Spectra of wheat across the

full range for protein reference values

Figure 3: Preprocessed spectra of

wheat samples

Figure 4: Correlation plot of the

reference and the predicted values for

wheat protein

September - October 2014 | 19 GRAIN

&

FEED MILLING TECHNOLOGY

Turning ideas into opportunities.

PROGRESSIVE FOOD PROCESSING

Imagine the possibilities

wenger.com

BELGIUM TAIWAN BRASIL CHINA TURKEY INDIA

Is it time to shift production to a more favorable

continuous process?

You can get higher levels of thermal energy than ever

thought possible for a more gentle cooking process

compared to high-shear cook. With Wengers Thermal

Twin Screw Extruder, products high in corn or rice

content are processed without the stickiness typically

encountered in conventional extrusion systems.

The Thermal Twin design allows ingredients to be

fully cooked without damage to the starch or

protein matrix.

Contact us now for details on the revolutionary

Thermal Twin Screw Extruder Series to learn

how it can transform your process and your

bottom line.

Excellent rms dont believe in excellence

- only in constant improvement and constant change.

Tom Peters

Wenger14.TT.Steam.Food.Ad.210x147.indd 1 9/30/14 10:31 AM

F

September - October 2014 | 51 GRAIN

&

FEED MILLING TECHNOLOGY

MYANMARS BIGGEST INTERNATIONAL AGRICULTURE,

GRAINS, FEED & LIVESTOCK PRODUCTION EXHIBITION

9-11 DECEMBER 2014

TATMADAW HALL, YANGON

9 - 11 DECEMBER 2014

4

(+603) 4041 9889

(+603) 2770 5301

fong@ambexpo.com

09 420701651

95-1-254765

may@ambexpo.com

AMB EVENTS GROUP

Organised & Managed by:

www.ambexpo.com www.agrilivestock.net

Very successful! A show of international standards!

Mr. Jonathan Zheng

ZHENG CHANG

We have not seen before a Show of such international standard in the livestock

industry in Myanmar

Mr Win Sein

Vice Chairman

Myanmar Livestock Federation

Hosted by: Media Partners: Supporting Organisations:

Platinum Sponsors: Gold Sponsors:

Silver Sponsor:

F

Figure 2

attention in the milling trade in England, on the Continent. and in

America, and by a series of experiments an operation has been

arrived at which will enable the manufacturer to get rid of the germ.

However and the survival of the HOVIS brand keeps my

historical research up-to-date not every English miller agreed with

the Attorney-General as extracts from THE MILLER March 2nd

1896 show:

BRITISH AND IRISH FLOUR MILLS.

Messrs Fitton & Sons IMPERIAL HOVIS MILLS,

WESTMINSTER, LONDON SW

JAMESON DAVIESs SYSTEM

INTRODUCTION - London has the distinction of possessing a

roller Mill devoted to the sole purpose of making Hovis" flour. At

27 MiIIbank Street, Westminster, the well-known milling engineer

Mr H Jameson Davis, of 82 Mark Lane, London EC has installed for

Messrs S Fitton & Sons of Macclesfield a roller plant on his system

his system with a capacity of 10 sacks of 280 lbs of Hovis flour

per hour.

THE MAIN WAREHOUSE - The raw, or uncooked, wheat germ,

is stored chiefly on the third floor of this warehouse. To keep this

material from fructifying, a certain proportion of salt is mixed with

it, the object being, of course, to destroy the vital principle, which

might otherwise give unequivocal, but unwelcome, manifestations of

its presence. [After the cooking process the wheat germ] . . . is then

ready to be mixed with the flour. The germ is mixed with the white

flour in the proportion of 25%, one sack of germ being shot to three

sacks of flour.

The HOVIS brand began in 1886; the HOVIS process

was patented on 6 October 1887 by Richard "Stoney" Smith

(18361900), and S. Fitton & Sons Ltd, based in Macclesfield,

developed the brand, milling the flour and selling it along with

HOVIS branded baking tins to other bakers. The name was

coined in 1890 by London student Herbert Grime in a national

competition set by S. Fitton & Sons Ltd to find a trading name

for their patent flour which was rich in wheat germ. Grime won

25 when he coined the word from the Latin phrase hominis

vis "the strength of man. HOVIS bread is still in shops today

so the brand survives!

Another element of the Framework Structure underpinning the

roller flour milling story is transport and storage, epitomised by figues

4 and 5:

The top picture contrasts the labour-intensive, horse-drawn,

sacking-and-packing milling economy in England before the Roller

Flour Milling Revolution had made such small country mills uneco-

nomic with bulk-grain storage silos in the growing areas and rail

transport to the mills in North America today.

And the Canadian picture illustrates the global nature of some

of my research. Next week I shall be in Budapest for 5 days, visiting

the MGTKSZ office (Hungarian Corn & Feed

Association) and some of the huge roller flour

mills now no longer working which made

Hungary a world-leader in roller flour milling

in the 19th century. I am also in contact with a

senior academic at the University of Minnesota,

Twin Cities, in Minneapolis and St. Paul, USA

because Minneapolis was once it claimed[!]

the worlds flour milling capital. I hope to

feed-into the roller flour milling project research

some of the ideas and influence of Cadwallader

& William Washburn and Charles A Pilsbury

whose family names were carried by huge roller

flour mills on either side of the River Mississippi

in Minneapolis.

I hope to report on these contacts and

the Budapest visit in a subsequent issue of this

journal.

I hope I have shown that historical research

on the flour milling industry need not be ret-

rogressive or irrelevant to modern needs and

interests.

Figure 4

Figure 5

( Copyright David Dixon and licensed for reuse under this Creative Commons Licence. http://

www.geograph.org.uk/photo/3164948)

Figure 3

52 | September - October 2014

GRAIN

&

FEED MILLING TECHNOLOGY

F

September - October 2014 | 53 GRAIN

&

FEED MILLING TECHNOLOGY

2

4

/

7 P

r

o

t

e

c

t

io

n

Watchdog Wrap advert.(paths).indd 1 27/03/2014 11:38

F

September - October 2014 | 53 GRAIN

&

FEED MILLING TECHNOLOGY

2

4

/

7 P

r

o

t

e

c

t

io

n

Watchdog Wrap advert.(paths).indd 1 27/03/2014 11:38

F

www.gfmt.co.uk

LINKS

See the full issue

Visit the GFMT website

Contact the GFMT Team

Subscribe to GFMT

INCORPORATING PORTS, DISTRIBUTION AND FORMULATION

S

e

p

te

m

b

e

r - O

c

to

b

e

r 2

0

1

4

first published in 1891

In this issue:

STORAGE

Silo design &

construction

Weighbridges

crucial

factors and

considerations

Irish Flour

Milling and

the German

connection

Bagging systems

chosing the right

one for your needs

Burundis

women of war

turn to rice

A new dawn for

GFMT

Our history and

our future!

This digital Re-print is part of the September | October 2014 edition of Grain & Feed

Milling Technology magazine.

Content from the magazine is available to view free-of-charge, both as a full

online magazine on our website, and as an archive of individual features on

the docstoc website.

Please click here to view our other publications on www.docstoc.com.

To purchase a paper copy of the magazine, or to subscribe to the paper edi-

tion please contact our Circulation and Subscriptions Manager on the link

adove.

INFORMATION FOR ADVERTISERS - CLICK HERE

Article reprints

All Grain & Feed Milling Tecchnology feature articles can be re-printed as a 4 or 8 page booklets (these

have been used as point of sale materials, promotional materials for shows and exhibitions etc).

If you are interested in getting this article re-printed please contact the GFMT team for more informa-

tion on - Tel: +44 1242 267707 - Email: jamest@gfmt.co.uk or visit www.gfmt.co.uk/reprints

Você também pode gostar

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeNo EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeNota: 4 de 5 estrelas4/5 (5794)

- Milling and GRain Magazine - November 2016 - FULL EDITIONDocumento116 páginasMilling and GRain Magazine - November 2016 - FULL EDITIONMilling and Grain magazine100% (2)

- The Little Book of Hygge: Danish Secrets to Happy LivingNo EverandThe Little Book of Hygge: Danish Secrets to Happy LivingNota: 3.5 de 5 estrelas3.5/5 (399)

- CASE STUDY: The Use of Posi-Flate Butterfly ValvesDocumento2 páginasCASE STUDY: The Use of Posi-Flate Butterfly ValvesMilling and Grain magazineAinda não há avaliações

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryNo EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryNota: 3.5 de 5 estrelas3.5/5 (231)

- CEREALSDocumento4 páginasCEREALSMilling and Grain magazineAinda não há avaliações

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceNo EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceNota: 4 de 5 estrelas4/5 (894)

- Combustible Dust Control - Part 2Documento4 páginasCombustible Dust Control - Part 2Milling and Grain magazineAinda não há avaliações

- The Yellow House: A Memoir (2019 National Book Award Winner)No EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Nota: 4 de 5 estrelas4/5 (98)

- Industry Profile: LambtonDocumento2 páginasIndustry Profile: LambtonMilling and Grain magazineAinda não há avaliações

- Rotary Batch Mixer - Achieving Precise Ratios For Feed SupplementsDocumento2 páginasRotary Batch Mixer - Achieving Precise Ratios For Feed SupplementsMilling and Grain magazineAinda não há avaliações

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureNo EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureNota: 4.5 de 5 estrelas4.5/5 (474)

- New Panama Canal Expansion Sees Grain Transportation Costs TumbleDocumento4 páginasNew Panama Canal Expansion Sees Grain Transportation Costs TumbleMilling and Grain magazineAinda não há avaliações

- Never Split the Difference: Negotiating As If Your Life Depended On ItNo EverandNever Split the Difference: Negotiating As If Your Life Depended On ItNota: 4.5 de 5 estrelas4.5/5 (838)

- Commodities - Grain and Feed Annual: 2016 Grain and Feed Annual MexicoDocumento4 páginasCommodities - Grain and Feed Annual: 2016 Grain and Feed Annual MexicoMilling and Grain magazineAinda não há avaliações

- STORAGE - Safe T Homes® SAVE LivesDocumento2 páginasSTORAGE - Safe T Homes® SAVE LivesMilling and Grain magazineAinda não há avaliações

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaNo EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaNota: 4.5 de 5 estrelas4.5/5 (265)

- Are Sprouted Grains The Future?Documento2 páginasAre Sprouted Grains The Future?Milling and Grain magazineAinda não há avaliações

- Preventive and Predictive Maintenance For Optimal PerformanceDocumento4 páginasPreventive and Predictive Maintenance For Optimal PerformanceMilling and Grain magazineAinda não há avaliações

- "Wheat, Flour and OCRIM's 6th Technical ConferenceDocumento6 páginas"Wheat, Flour and OCRIM's 6th Technical ConferenceMilling and Grain magazineAinda não há avaliações

- The Emperor of All Maladies: A Biography of CancerNo EverandThe Emperor of All Maladies: A Biography of CancerNota: 4.5 de 5 estrelas4.5/5 (271)

- Milling and Grain Magazine - October 2016 - FULL EDITIONDocumento116 páginasMilling and Grain Magazine - October 2016 - FULL EDITIONMilling and Grain magazine100% (1)

- How To Maximise The Life of Your Flaking RollsDocumento4 páginasHow To Maximise The Life of Your Flaking RollsMilling and Grain magazine100% (1)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersNo EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersNota: 4.5 de 5 estrelas4.5/5 (344)

- Industry Profile: GRANDS MOULINS DE PARISDocumento2 páginasIndustry Profile: GRANDS MOULINS DE PARISMilling and Grain magazineAinda não há avaliações

- Team of Rivals: The Political Genius of Abraham LincolnNo EverandTeam of Rivals: The Political Genius of Abraham LincolnNota: 4.5 de 5 estrelas4.5/5 (234)

- Commodities - MARKETS OUTLOOKDocumento6 páginasCommodities - MARKETS OUTLOOKMilling and Grain magazineAinda não há avaliações

- CASE STUDY: 20% Increase in Production CapacityDocumento2 páginasCASE STUDY: 20% Increase in Production CapacityMilling and Grain magazineAinda não há avaliações

- Enzymatic Flour StandardisationDocumento4 páginasEnzymatic Flour StandardisationMilling and Grain magazine100% (1)

- A New Protein Source For FeedDocumento4 páginasA New Protein Source For FeedMilling and Grain magazineAinda não há avaliações

- The Balance of PowerDocumento4 páginasThe Balance of PowerMilling and Grain magazineAinda não há avaliações

- The Unwinding: An Inner History of the New AmericaNo EverandThe Unwinding: An Inner History of the New AmericaNota: 4 de 5 estrelas4/5 (45)

- Milling and Grain Magazine - September 2016 - FULL EDITIONDocumento116 páginasMilling and Grain Magazine - September 2016 - FULL EDITIONMilling and Grain magazineAinda não há avaliações

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyNo EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyNota: 3.5 de 5 estrelas3.5/5 (2219)

- From Grain To BreadDocumento4 páginasFrom Grain To BreadMilling and Grain magazineAinda não há avaliações

- Commodities - The Other Side of The StoryDocumento2 páginasCommodities - The Other Side of The StoryMilling and Grain magazineAinda não há avaliações

- Combustible Dust Control - Part 1Documento4 páginasCombustible Dust Control - Part 1Milling and Grain magazineAinda não há avaliações

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreNo EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreNota: 4 de 5 estrelas4/5 (1090)

- Industry Profile: MolinoDocumento2 páginasIndustry Profile: MolinoMilling and Grain magazineAinda não há avaliações

- The Bühler Networking DaysDocumento10 páginasThe Bühler Networking DaysMilling and Grain magazineAinda não há avaliações

- STORAGE - Bentall Rowlands Storage Systems Limited Talks Grain StorageDocumento4 páginasSTORAGE - Bentall Rowlands Storage Systems Limited Talks Grain StorageMilling and Grain magazineAinda não há avaliações

- CASE STUDY: Improving Raw Material Quality For MillersDocumento6 páginasCASE STUDY: Improving Raw Material Quality For MillersMilling and Grain magazineAinda não há avaliações

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)No EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Nota: 4.5 de 5 estrelas4.5/5 (119)

- STORAGE - Dryer Tips For A More Financially Beneficial HarvestDocumento4 páginasSTORAGE - Dryer Tips For A More Financially Beneficial HarvestMilling and Grain magazineAinda não há avaliações

- Storage - Si-LowDocumento4 páginasStorage - Si-LowMilling and Grain magazineAinda não há avaliações

- Debate About CookingDocumento2 páginasDebate About CookingPavirlene Escaño NorteAinda não há avaliações

- Alibaba Cronut CafeDocumento6 páginasAlibaba Cronut CafeamadoudialloAinda não há avaliações

- Water Buffalo FAODocumento321 páginasWater Buffalo FAOAndre BroesAinda não há avaliações

- Past Continuous and Past Simple ExercisesDocumento3 páginasPast Continuous and Past Simple ExercisesAna MateusAinda não há avaliações

- Rajni Verma's Diet PlanDocumento2 páginasRajni Verma's Diet PlanPiyushAinda não há avaliações

- Sugarcane Industry: Production, Challenges and Future OutlookDocumento23 páginasSugarcane Industry: Production, Challenges and Future OutlookVivek Kr TiwariiAinda não há avaliações

- Pinggang PinoyDocumento9 páginasPinggang Pinoyjreyab100% (1)

- Trickster ReadingsDocumento47 páginasTrickster ReadingsNoemi CaladoAinda não há avaliações

- When He Comes, Close Your Eyes PDFDocumento613 páginasWhen He Comes, Close Your Eyes PDFRiza Alvarez93% (14)

- Effect of Back Massage On Lactation Amon PDFDocumento9 páginasEffect of Back Massage On Lactation Amon PDFfemyAinda não há avaliações

- Grade 6 - WITH QUESTIONS Developing Reading PowerDocumento178 páginasGrade 6 - WITH QUESTIONS Developing Reading PowerSheila Jean Dacillo93% (128)

- Gluten Free ListDocumento2 páginasGluten Free ListMiha OanaAinda não há avaliações

- Mentoring of Student - Hafiz RahmanDocumento12 páginasMentoring of Student - Hafiz RahmanReevaldo CalvinAinda não há avaliações

- Cornetto MixDocumento2 páginasCornetto Mixnitin salujaAinda não há avaliações

- Retail Store Sales Report and Order RecapDocumento3 páginasRetail Store Sales Report and Order RecapKassieAinda não há avaliações

- 5 - 1 - 2 Practice Venn DiagramsDocumento2 páginas5 - 1 - 2 Practice Venn DiagramsBRIGHTON ONYANGOAinda não há avaliações

- Agriculture in Thailand Facing CrossroadsDocumento19 páginasAgriculture in Thailand Facing CrossroadsJakgrid JainokAinda não há avaliações

- Casein ProductDocumento6 páginasCasein ProductMinh HuynhAinda não há avaliações

- Indian Monthly Grocery List (For Two People) : Item QuantityDocumento6 páginasIndian Monthly Grocery List (For Two People) : Item Quantitysurya1293Ainda não há avaliações

- Giving Directions 1. Look at The Map and Answer The QuestionsDocumento2 páginasGiving Directions 1. Look at The Map and Answer The QuestionsAnonymous Q21YDaSfAinda não há avaliações

- Science 9 Interconnectedness of The Spheres Unit Created by Brianna VissersDocumento6 páginasScience 9 Interconnectedness of The Spheres Unit Created by Brianna Vissersapi-344676223Ainda não há avaliações

- MM Assignment Group-9Documento19 páginasMM Assignment Group-9divyesh jAinda não há avaliações

- Guidance Note 18 Determination of Product Shelf Life PDFDocumento56 páginasGuidance Note 18 Determination of Product Shelf Life PDFHiếu LêAinda não há avaliações

- Macro Ebook 2Documento52 páginasMacro Ebook 2DEEPAK RAGHUVANSHI100% (2)

- 1 Plastics Give A Helpful HandDocumento10 páginas1 Plastics Give A Helpful HandNIranjanaAinda não há avaliações

- English Class 6 GulmoharDocumento6 páginasEnglish Class 6 GulmoharLokita GuptaAinda não há avaliações

- SantaDocumento1 páginaSantaRajesh VermaAinda não há avaliações

- Districtwise On ShopDocumento35 páginasDistrictwise On ShopMihir Ranjan RoutAinda não há avaliações

- NutriDocumento2 páginasNutriumer sheikhAinda não há avaliações

- Koki Chicken Q1 In-Store Activations: ChannelDocumento5 páginasKoki Chicken Q1 In-Store Activations: ChannelWasseem AtallaAinda não há avaliações