Escolar Documentos

Profissional Documentos

Cultura Documentos

Dial Gauge Calibration Procedure

Enviado por

arabcalDireitos autorais

Formatos disponíveis

Compartilhar este documento

Compartilhar ou incorporar documento

Você considera este documento útil?

Este conteúdo é inapropriado?

Denunciar este documentoDireitos autorais:

Formatos disponíveis

Dial Gauge Calibration Procedure

Enviado por

arabcalDireitos autorais:

Formatos disponíveis

UNITEDSTATES DEPARTMENTOF THE INTERIOR

BUREAU OF RECLAMATION

PROCEDUREFOR

CALIBRATINGDIAL INDICATORS

USBR 1007-89

INTRODUCTION

This procedure is under the jurisdiction of the Geotechnical Services Branch, code D-3760, Research and Laboratory Services

Division, Denver Office, Denver, Colorado. The procedure is issued under the fixed designation USBR 1007. The number immediately

following the designation indicates the year of acceptance or the year of last revision.

1. Scope

1.1 This designation outlines the procedure for cali-

brating dial indicators for laboratory and field applications.

1.2 Method A outlines the calibration procedure using

precision gauge blocks; Method B outlines the calibration

procedure using a micrometer fixture.

2. Applicable Documents

2.1 USBR Procedures:

USBR 1000 Standards for Linear Measurement Devices

USBR 3900 Standard Definitions of Terms and Symbols

Relating to Soil Mechanics

2.2 ASMEStandard:

ANSI B89.1.10 Dial Indicators (for Linear Measurement)

2.3 Federal Specification:

GGG-G-15C Gage Blocks and Accessories

3. Summaryof Method

3.1 Comparison readings between a dial indicator and

either precision gauge blocks (method A) or a micrometer

fixture (method B) are used to determine the accuracy,

repeatability, and hysteresis of the dial indicator. The results

are used to evaluate the acceptability of dial indicators for

laboratory and field use.

4. Significance and Use

4.1 Accurate linear measurements are required to

obtain proper data for laboratory and field use.

4.2 Calibrate dial indicators when purchased and

annually thereafter.

5. Terminology

5.1 Definitions are in accordance with USBR 3900.

5.2 Terms not included in USBR 3900 specific to this

designation are:

5.2.1 Accuracy.-The degree to which displayed dial

indicator readings vary from known spindle displacements.

5.2.2 Graduation.-The least measured value which

is marked on the dial indicator face.

5.2.3 Hysceresis.-The difference in displayed dial

indicator readings at any particular spindle displacement

within the specified range, when the dial indicator reading

is approached first with increasing and then with decreasing

spindle displacements.

5.2.4 Range.-The measured values over which the

dial indicator is intended to measure, specified by upper

and lower limits.

5.2.5 Repeatabil#y.-The degree to which displayed

dial indicator readings vary for successive measurements

of the same reference.

6. Apparatus

6.1 Dial Indicator.-A dial indicator used for standard

laboratory or field applications.

6.2 Method A --Precision Gauge Block Calibration:

6.2.1 Precision Gauge Blocks (fig. la).-A set of steel

gauge blocks (inch-pound or metric), usually rectangular,

meeting the requirements of Federal Specifications GGG-

G-15C and those requirements identified in USBR 1000

for precision gauge blocks. A gauge block set should contain

sizes (or combination of sizes) necessary to satisfactorily

perform the "calibration procedure as outlined in

paragraph 10.

6.2.2 Dial Indicator Comparator Stand (fig. lb).-A

stand consisting of a base; ground to a guaranteed flatness

and warp-free stability; a support column and an adjustable

arm onto which the dial indicator can be securely attached.

6.3 MethodB- MicrometerFixtureCalibration:

6.3.1 Micrometer Fixture (fig. 2a).-A precision

instrument capable ofobtaining comparison readings over

the full range of the dial indicator. The spindle must be

nonrotating and spring loaded. The micrometer fixture

is tobe calibrated annuallybythe manufacturer.

6.3.2 MagneticBaseDialIndicatorHolder(fig. 2b).-

A magnetic base with a solid upright post adapted with

a swivel snug, gauge rod, and dial indicat& clamp with.

fine adjustment capabilities.

7. Precautions

7.1 Safety Precautions.-The dial indicator case, stem,

spindle, and contact point are to be examined for burrs

and sharp edges.

7.2 Technical Precautions:

7.2.1 The dial face is to be examined for clarity of

graduations.

USBR bil) ( : l,7

!1; I,: I; It Itl };: 11 D.. h' Jl: i,; 1, ': Ill : ,k i" L J,! r]c ]l k[',l I,I!,

i,] : J:'r , : ilii,ll LILIL,' ' ]IlIl( ;:q.

,k, [>Ld !l,li,;;:l,:.: ;,n:l:q.t:,,i ,.1111,! , .<qr, l:, , z]

l<:,: tttl]a, I :, : i;IiL !;l;i;7>il ;T I t h .] lid ,i I :, tU

]:imm: I I:],i;l m,]it;,, ,:;Lhitr:,rzm,=,J <,:i!,il-,m,L'lll , m,e.d>:.J ,:,,;

722 Th,: ,:t!i;i,l iY,,.diiazm is ,:, bc replJceJ i:: tlxcl.

i' ;,In:y e'<'J.lem:,ce :,t bhn,lin: ,:,: u&rJihl'Lialg ',vlles dJe spmJll,:

i5 t'=,Ll'-,lIel: l Jilnt<: , []:I,L: 5 I: 1VI

7 !!: l E: att!lllt thl,;Itjli,l: ] iS ,le II';( !l 'wt-,en irJs,Crit: : : li: ll.,;

< :i ii i i ] k i l 1,- 1' Ji ['1 ( i ( :l 21/ . r" I Ii I :1 ] I I 71 ] l I : 7 & l II ]1 In t-ll e ,.!l ] k t ]! i Jl < :l i C J 1: . c: i [" [[ ( > j-: l 1" . ', ( ]: ] [

il: l[t!lerc'nce ',!,[ hl lll: : ,eral-i,: >l ,: r l: eliq: ,i]lity , W : d-e d, ia: l

i i l: l icac ,1

e .....

]'<1 ,.: <li, I: ,>h !,;: Jl,ll: .ll.;,* I ; , = I L I , ; E!,;IIIL!: L [I,LI.

>: :'"il.,tl HIIL;, L: Ji;ll i;:;Ji,.t,:,l '[ ];l[]:l;il ` iI:, :1i, ;.>17.

:i i >,I:U[I] i IlL{ 1,:1 I I}[][;1<'{ !1 I[1:11

F[u,c :l :,.i ;,I i]hli, LIE,]IF ,: ;lllilliI;tlli,: .ll {'l: t;illiIIIJ( q]l I" I: K j :

7.!.]; [)i;I] il]lLL:iLk][l:)'S il[t! 1:1 L]'L. <;l':'C':[ ,in Stl.il::,le'

17, , l:, :k: (iF LZI ;C ',,. IJl1:l I]';)[ i]l l.:lq

8. CaJ[ibrr, tion and SarMardiizatu:)n

8.1 '..2c l :i f). I 11l;],t i;lLll.ge: bllli(ks tll.;u<:l l(/r ii:)I-:l,[[l[i:]l]g; dii;LI

Ji[],:]iClt,;J,l" ICll ['[]']]1;]]]S'[IIn " e:]d [ }gl;;I ( r l l * U r L Il u ( : , , : l k ) alKe .:lLirrel!( ]3';

a I R ii D) Fa EL ' L'k i rll ; 1 'L 'C ,I ) y J: t* [ i C e V..' i *] ] 1: _ : S ;i I '[L) O I: : }. ] t " [ I1- C .!;/ LII .yC

::} ] I: }el{: C ] 1:I" 1 [ 1( :l:l i El [-Jll;:]l[ k.:L]I'7Jl[, ].]l('lt(}l:l]] [})C cz,:liz:,r:ii:.zq

bef<,.te .l>:ih-,g; :he gatJg;e k)[(]lCl.:s, fi: }] hi> pr<,.,x.d urc

S.2: X,TCI;ii: }' t}']: g [t'le' ]I]]J: c;<: I'I'II,LttJ[" i: i.: lL: lI'O hl>; }7: 1ec1

,:ltlrrenl:l:}. cail ibr:teJI b!.' d- II]]LlI]Lt]:ACll"LilE(r til-e cllil:l;,{i<;,]l

i"; :*CIIt CLIYZTee'r]lL!, Fl'Q'I-fIIk)[':]']l the callibrci,:an bcf,,:.'c LIIhiJr],I tll].:

]lliCrc, mee:t: f : i : , f t l r e I f: Fr:let[],:3,cI BI ) fl: }:1" t l,i>; j", I '(jlI I C:, eCt!L]F(:

USBR 1007

9. Conditioning

9.1 Perform this calibration in an environment as close

to 68 F (20 C) as possible.

9.2 The dial indicator, calibration gauge blocks, and

dial indicator comparator stand and base should be in the

environment in which they are to be calibrated for at least

24 hours prior to calibration.

10. Procedure

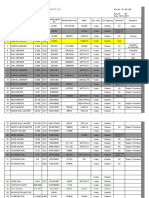

10.1 All data are to be recorded on the "Dial Indicator

Calibration Sheet" as shown on figure 3.

10.2 Record the range and graduation of the dial

indicator to be calibrated.

10.3 Locate and record the manufacturer and serial

number of the dial indicator to be calibrated. If it has no

serial number, record the model number and any identifying

marking.

10.4 Record the type and serial number of the reference

standard to be used.

10.5 MethodA -- PrecisionGaugeBlock Calibration:

10.5.1 Mount the dial indicator on the dial indicator

comparator stand as shown on figure 4a.

10.5.2 Accuracy Determination:

10.5.2.1 Positionthedial indicatoron the dial indi-

cator comparator stand. Adjust the dial indicator in such

a manner that when the contact point of the spindle rests

firmly on the comparator stand base, the hand registers

0.000.

10.5.2.2 Record the zero reading on the dial

indicator calibration form.

10.5.2.3 Displace the dial indicator spindle by

inserting gauge blocks of appropriate thicknesses between

the comparator base and the contact point of the dial

indicator as shownon figure 4b. These gauge blocks should

be of such thickness that the hand can be displaced in

approximately equal increments (a minimum of four

increments per revolution of the dial indicator hand) over

the entire range of the dial. Record the gauge block(s)

used (reference standard length) and the dial indicator

reading at each increment. Record the dial indicator

readings to the highest readability possible--based on

smallest graduation of the dial indicator dial.

10.5.3 Hysteresis Determination:

10.5.3.1 Displace the spindle of the dial indicator

by inserting the same gauge blocks as used in subpara-

graph 10.5.2.3. This time insert the gauge blocks in reverse

order; i.e., thickest block to thinnest.

10.5.3.2 Read and record dial indicator readings

for each gauge block used.

10.5.4 Repeatabffity Determination:

10.5.4.1 Remove all gauge blocks from beneath

the contact point. Readjust the dial indicatoron the support

column so that the hand registers 0.000 with the contact

point resting on the comparator base and record the value.

10.5.4.2 Rotate the hand of the dial indicator by

displacing the dial indicator spindle using an appropriate

size (or combination of) gauge block(s). (See subpar.

10.5.4.6.)

10.5.4.3 Read and record the dial gauge reading

and the gauge block(s) used.

10.5.4.4 Remove the gauge block(s) and record

the dial indicator reading.

10.5.4.5 Repeat subparagraphs 10.5.4.1 through

10.5.4.4 a minimum of three times.

10.5.4.6 Subparagraph 10.5.4 should be followed

at approximately 25, 50, and 75 percent of full range of

the dial indicator.

10.6 MethodB- Micrometer FixtureCalibration:

10.6.1 Mount the dial indicator on the bench of the

micrometerfixtureutilizing the magneticbasedial indicator

holder as shown on figure 5.

10.6.2 Accuracy Determination:

10.6.2.1 Displace the dial indicator spindle so the

indicator hand registers 0.000 by turning the micrometer

head.

10.6.2.2 Set the micrometer head to read 0.000.

10.6.2.3 Read and record the zeroreadings on the

dial indicator calibration form.

10.6.2.4 Displace the dial indicator spindle by

turning the micrometer head in equal increments (a

minimumof four increments per revolution of the dial

indicator hand) over the entire range of the dial. Read

and record the readings of both the dial indicator and the

micrometer fixture at each increment. Record the dial

indicator readings to the highest readability possible--

based on smallest graduation of the dial indicator hand.

10.6.3 Hysteresis Determination:

10.6.3.1 Displace the spindle of the dial indicator

by turning the micrometer head in the opposite direction

tothat used in subparagraph 10.6.2.1.

10.6.3.2 Read and record dial indicator and

micrometer fixture readings at the same increments as

performed in subparagraph 10.6.2.4.

10.6.4 Repeatability Determination:

10.6.4.1 Adjust both the dial indicator and the

micrometer fixturetoread 0.000.

10.6.4.2 Displace the spindle of the dial indicator

byturning the micrometer fixture tocause the appropriate

revolution of the dial indicator hand. (See subpar. 10.6.4.8.)

10.6.4.3 Turn the micrometer fixture head toread

0.000.

10.6.4.4 Read and record the micrometer reading

and corresponding dial indicator reading.

10.6.4.5 Turn the micrometer fixture head to

return the micrometer back to zero.

10.6.4.6 Read and record the micrometer reading

and corresponding dial indicator reading.

10.6.4.7 Repeat subparagraphs 10.6.4.1 through

10.6.4.6 a minimumof three times.

10.6.4.8 Subparagraph 10.6.4 should be followed

at approximately 25, 50, and 75 percent of full range of

the dial indicator.

11. Calculations

11.1 Calculations for determining the accuracy,

hysteresis, and repeatability of the dial indicator are as

shown on the "Dial Indicator Calibration Sheet" (fig. 3).

10

USBR 1007

7-2349 (5.86)

Bureauof Recl amati on

DIAL INDICATORCALIBRATIONSHEET

Desi i nat|onUSBR 1007---8_

DIALINDICATORRANGE/GRADUATIONS

MANUFACTURER Example

REFERENCE STANDARDUSED:.

CALIBRATIONPERFORMED BY

CALIBRATIONCHECKEDBY

0-1.000 i nch / 0.001 inch

[] GAUGE BLOCKS

I MICROMETER FIXTURE

SERIAL NO

SERIAL NO

SERIALNO.

DATE

DATE

D1-115281

MF- I00

ACCURACY HYSTEREEl S REPEATABILITY

TRIAL REFERENCE

NO. STANDARD

LENGTH

(1 ) (2)

I 0. 000

2 0. 025

3 .0;050

4 0. 075

5 O. lO0

6 O. 1 25

7 O. 150

8 0. 175

9 0.200

DIAL DIFFER- TRIAL REFERENCE DIAL

INDICATOR ENCE NO. STANDARD INDICATOR

READINGS (2) -(3) LENGTH READING

(3) (4) (5) (6) (7)

0.000 0.000 89 .0.000 0.000

0.025 0.000 88 0.025 0.024

o.o56o.- ooo- 87 0.o5o 0.050

0.075 0.000 86 0.075 0.074

0.100 0.000 85 0.1 00 0.100

0.125 "0.000 84 0;125 0.125

0.150 0.000 83 0.150 0.150

0.175 0.000 82 0.175 0.175

0.200 0.000 81 0.200 0.1 99

HYSTER-

ESIS

(3) - (7)

(8)

O. 000

O.001

0.000

O.001

0.000

0.000

0.000

0.000

0.001

BASE

DIAL

READING

(9)

RETRACTED RETURN REPEAT-

READING READING ASILITY

(to) (11) (g)- (tl)

I 12 REV{)LUTI ON

0.050 0.000 0.000

0.050 0.ooo o.ooo

0.050 0.000 0.000

0.000

0.000

0.000

2 I/ 2 REVC _UTIONS---

0.000 0.250 0.000 0.000

0.000 0.250 0.000 0.000

0.000 0.250 0.000 0.O00

ACCURACY: ACCEPT []

REJECT []

HYSTERESIS: ACCEPT []

REJECT []

REPEATABILITY: ACCEPT []

REJECT []

REMARKS: Only partial calibration data shown.

Figure 3. - Dial indicator calibration sheet --example.

GDO 850-947

l l

USBR ]LC07

}x:i,z;,,re , l'J'i;LI hklic:m :, i. allil[)l;Iti 'I1 :l;SeIllJZ:'[Ji!f' I -,L: I,:d I!I,L ,: ,, n', +:,,:':i, I,,US. ,::ILuL in,Jicah:,l

!1 ,LLde, I, [: ,:thtl i J,l i , ; I , : :,u, : i ,L!: ': , :' m ice,: :,,I JeEe I s,d

1L2.. lnter'preatio.r o,f Re.su]l.ts

li2.1J Table I s]>,.',vs mu:,i,num a]lL,,wable ,J.eviad,:m md

is t.,::, k>e tl.,iud tc,, e,altllae El++c >LC<% tT>t+bJlJc:' ':': the ,J[=l

i n<;I ic4 ,:<:,,

/. 2.2: If: dc:viii,::,n ,;>f {}q,,c dlia] iJ-tuLic++c:,.r e>+ceedls d-:,e limit>i,

liisted ilq, tab]ie l t+,:.J " rcpeal+.Lbi]ity> tryse':esis+ or ,++,,.:L'xrac? ',.

tl'll,e Cli;]] i!l'J'L]jiIl::k:e*II:)m" ] -J I L ] S, + be rei, ee'd

13. Repo'+

] -', !1 The ep,:>rt it> t,l. c<:,,r>.ist ,i,f t c< :,.tqT>h,::tc'd an.l ct:ecked

is ::, be fiilec[ v,,id,+ d,+e l:l/-*<:,t,:w'S: equiF:'l:,ent calil_-:,.rzLti:,n

1 C C ' I, ,d s.

] !."i kl]l C;1]Ct]l]+t/Ljl:)l]{; dil; {<1, ? ,lji;)',x.r ;+ll c{llc'c'i<lqil;ll:k.

12

USBR 1007

Table 1. -Dial indicator maximum deviation.

Accuracy

Smallest Repeatability Hysteresis First 2-1/3 First 10

graduation revolutions revolutions

inch mm

First 20*

revolutions

Deviation inunitsof smallest graduation

0.00005 0.00l +0.2 0.50 __l _____4

.00010 .002 +0.2 .50 1 3 _____4

.00050 .010 ___+0.2 -33 __--+1 ---+3 ---4

.00100 .020 ---0.2 .33 ,,,1 _____2 ---4

*Over 20 revolutions consult with individual manufacturers for standard procedure.

Table 1 taken from ANSI B 89.1.10-1978 dial indicators for linear measurements.

13

Você também pode gostar

- Manual Ultrasonic Testing Procedure for 26Documento12 páginasManual Ultrasonic Testing Procedure for 26Rohit Kumar Mishra100% (1)

- 2022 KaliperDocumento469 páginas2022 KaliperЖжук БолградAinda não há avaliações

- PTDocumento28 páginasPTglazetm100% (1)

- Yoke Calibration ProcedureDocumento1 páginaYoke Calibration ProcedureArjun Rawat100% (3)

- Calibration Procedure FOR Calipers General: Technical ManualDocumento8 páginasCalibration Procedure FOR Calipers General: Technical ManualrcmetrologyAinda não há avaliações

- Calibration of Dial GaugeDocumento21 páginasCalibration of Dial GaugeAnthony Burns82% (11)

- Calibration Procedure PMIDocumento8 páginasCalibration Procedure PMIbmkale100% (1)

- Ansi B89.1.10M-2001Documento26 páginasAnsi B89.1.10M-2001arabcal100% (1)

- Instrument Calibration ProcedureDocumento10 páginasInstrument Calibration ProcedureMohammad Nurayzat JohariAinda não há avaliações

- Cp16 Issue Renewal and Recertification of PCN Levels 1 & 2 CertificatesDocumento19 páginasCp16 Issue Renewal and Recertification of PCN Levels 1 & 2 Certificatesndt_inspectorAinda não há avaliações

- Interpretation of Weld RadiographsDocumento10 páginasInterpretation of Weld RadiographsarianaseriAinda não há avaliações

- ACUREN Thickness Measurement ProcedureDocumento15 páginasACUREN Thickness Measurement ProcedureAhmed Ben Nouma0% (1)

- Calibrate Outside MicrometersDocumento2 páginasCalibrate Outside MicrometerserharsinghAinda não há avaliações

- Subic Drydoc NDT Quality ManualDocumento14 páginasSubic Drydoc NDT Quality ManualHarry Doble100% (2)

- Radiographic Examination ProceduresDocumento22 páginasRadiographic Examination ProceduresIwan F Simbolon100% (3)

- Ut Proceduregeneral 141118232235 Conversion Gate02Documento24 páginasUt Proceduregeneral 141118232235 Conversion Gate02Danem HalasAinda não há avaliações

- Iso 9712Documento19 páginasIso 9712Daniel100% (1)

- FLOORMAP3Di-R High Speed MFL Floor Scanner with STARS Top & Bottom Defect DiscriminationDocumento6 páginasFLOORMAP3Di-R High Speed MFL Floor Scanner with STARS Top & Bottom Defect Discriminationjose ocanaAinda não há avaliações

- Pi Tape Calibration ProcedureDocumento11 páginasPi Tape Calibration ProcedureAaron QuinnAinda não há avaliações

- Magnetic Particle Testing Level 2 Course OutlineDocumento7 páginasMagnetic Particle Testing Level 2 Course OutlinezulzainalAinda não há avaliações

- 05a Kit Rep Calipers Rymeautomotive 2015Documento86 páginas05a Kit Rep Calipers Rymeautomotive 2015RymeAutomotive100% (1)

- Calibration of The YokeDocumento2 páginasCalibration of The YokeHussain Shariff100% (1)

- Lead Gauge Cal 7Documento2 páginasLead Gauge Cal 7John Dolan100% (3)

- MT Tta NDT Mpi 01 AsmeDocumento13 páginasMT Tta NDT Mpi 01 AsmeTuan DangAinda não há avaliações

- EN 15317 AnglaisDocumento25 páginasEN 15317 Anglaisbarbier100% (1)

- Measure tool readings with vernier callipers and micrometer screw gaugeDocumento2 páginasMeasure tool readings with vernier callipers and micrometer screw gaugeMohamad Rizal MukhtarAinda não há avaliações

- Appointment Letter NDE Level IIIDocumento2 páginasAppointment Letter NDE Level IIIandreas sembiring100% (1)

- RT Procedure 10.09.16Documento9 páginasRT Procedure 10.09.16mukeshsingh6Ainda não há avaliações

- AWS D1.1 Phased Array GuidelineDocumento40 páginasAWS D1.1 Phased Array GuidelineMario Perez100% (1)

- PMI Guide for Ferrous and Nonferrous AlloysDocumento8 páginasPMI Guide for Ferrous and Nonferrous AlloysJhonny Rafael Blanco CauraAinda não há avaliações

- Measuring & Test EquipmentDocumento12 páginasMeasuring & Test EquipmentPalkesh TrivediAinda não há avaliações

- MeasurementsDocumento32 páginasMeasurementsshuganesh100% (2)

- Exercise On CalipersDocumento6 páginasExercise On CalipersEvelyn Chua100% (1)

- Calibration ValidationDocumento12 páginasCalibration ValidationAlberto LobonesAinda não há avaliações

- Hardness ProcedureDocumento7 páginasHardness ProceduremanojballaAinda não há avaliações

- Astm E797Documento8 páginasAstm E797Ricardo Martins SilvaAinda não há avaliações

- Sample Calibration ProceduresDocumento37 páginasSample Calibration ProceduresGabriel Dediu100% (1)

- Vision Requirements SNT-TC-1ADocumento1 páginaVision Requirements SNT-TC-1ARameez Farouk100% (1)

- Dial Indicator Calibration Procedure TS-0051Documento3 páginasDial Indicator Calibration Procedure TS-0051alexrferreiraAinda não há avaliações

- Calibrating Lead Gauge StandardsDocumento3 páginasCalibrating Lead Gauge StandardsJohn Dolan100% (1)

- Calibrating Pressure GaugesDocumento4 páginasCalibrating Pressure GaugesRonny AndalasAinda não há avaliações

- E797e797m 21Documento9 páginasE797e797m 21Jlaraneda SantiagoAinda não há avaliações

- ASME UT Procedure WritingDocumento7 páginasASME UT Procedure WritingReiaz Hosein100% (3)

- Measurement Instruments and ToolsDocumento91 páginasMeasurement Instruments and ToolsNishanth Shannmugam100% (2)

- X-Series Manual: Including X-50, X-100, X-200, X-300 Model Handheld X-Ray Fluorescence AnalyzersDocumento34 páginasX-Series Manual: Including X-50, X-100, X-200, X-300 Model Handheld X-Ray Fluorescence AnalyzersRahul DubeyAinda não há avaliações

- Ultrasonic Examination Procedure: Doc. No.: QUAL/UT/001: of 10 Revision: 00 Date: 25.04.05 1.0Documento10 páginasUltrasonic Examination Procedure: Doc. No.: QUAL/UT/001: of 10 Revision: 00 Date: 25.04.05 1.0smsunil12345Ainda não há avaliações

- Ferrite Meter Manual OPMS FMP30Ferit 902-530 enDocumento36 páginasFerrite Meter Manual OPMS FMP30Ferit 902-530 enFmc2100% (1)

- Jis B 7184 SummaryDocumento2 páginasJis B 7184 SummaryVimal100% (1)

- Calibration of Metal TapesDocumento16 páginasCalibration of Metal Tapesarabcal100% (1)

- Calibration of Metal TapesDocumento16 páginasCalibration of Metal Tapesarabcal100% (1)

- Methodology On Technical Inspection: Equipment NDT Procedure Inspection DevicesDocumento1 páginaMethodology On Technical Inspection: Equipment NDT Procedure Inspection DevicesEphraim John Tangelon AquinoAinda não há avaliações

- Micrometer Calibration (T.O. 33K6-4-15-1)Documento8 páginasMicrometer Calibration (T.O. 33K6-4-15-1)Hernando Sanchez100% (1)

- DKD Calibration of Torque DKD K 09301 EQS 8010 Datasheet SCHATZ enDocumento2 páginasDKD Calibration of Torque DKD K 09301 EQS 8010 Datasheet SCHATZ enMohamedSafeerAinda não há avaliações

- TTSF 2008 Final Report Tensile Test Steel Flat SpecimensDocumento53 páginasTTSF 2008 Final Report Tensile Test Steel Flat SpecimensmirelamanteamirelaAinda não há avaliações

- Sicc Ac CP 01 Snttc1aDocumento15 páginasSicc Ac CP 01 Snttc1aEnrique Campos CannavaroAinda não há avaliações

- Fluorescent Magnetic TestingDocumento29 páginasFluorescent Magnetic TestingAlzaki Abdullah100% (1)

- Procedure For Ferrit TestingDocumento11 páginasProcedure For Ferrit TestingKarrar TalibAinda não há avaliações

- Calibration Certificate Basic 315Documento1 páginaCalibration Certificate Basic 315Anonymous xnpIPaMoAinda não há avaliações

- Ultrasonic Exam RequirementsDocumento2 páginasUltrasonic Exam RequirementsAngelTinocoAinda não há avaliações

- NDT Weld Visual Inspection ProcedureDocumento4 páginasNDT Weld Visual Inspection ProcedureAvneet MaanAinda não há avaliações

- Inspection Report Bifab Ut On Duplex Stainless Steel Piping PDFDocumento11 páginasInspection Report Bifab Ut On Duplex Stainless Steel Piping PDFquiron2014Ainda não há avaliações

- Thermocouple Calibration FurnaceDocumento4 páginasThermocouple Calibration FurnaceAHMAD YAGHIAinda não há avaliações

- Digltalmeasuringinstrumentsfor Measurementandcontrol: Indian StandardDocumento14 páginasDigltalmeasuringinstrumentsfor Measurementandcontrol: Indian StandardSriniramu SriniramuAinda não há avaliações

- E125-97 MT Ref PhotosDocumento2 páginasE125-97 MT Ref PhotosveluAinda não há avaliações

- Is 13875 1 1993Documento17 páginasIs 13875 1 1993KOSAKA LABAinda não há avaliações

- 6.4 - NDT-Magnetic Particle ExaminationDocumento38 páginas6.4 - NDT-Magnetic Particle ExaminationKatsaras SotirisAinda não há avaliações

- Ultrasonic Thickness Gauge TT130 ReviewDocumento20 páginasUltrasonic Thickness Gauge TT130 Reviewelmek jayaAinda não há avaliações

- Industrial radiography A Complete Guide - 2019 EditionNo EverandIndustrial radiography A Complete Guide - 2019 EditionAinda não há avaliações

- Usbr1050 PDFDocumento4 páginasUsbr1050 PDFJeya PrakashAinda não há avaliações

- Calibrating Pressure Transducers: Procedure ForDocumento4 páginasCalibrating Pressure Transducers: Procedure ForVladu IulianAinda não há avaliações

- CaliDocumento7 páginasCaliYogesh AnapAinda não há avaliações

- Threads-Over Wires Calibration-Thread Plug GaugeDocumento2 páginasThreads-Over Wires Calibration-Thread Plug GaugearabcalAinda não há avaliações

- Daftar Barang Habispakai Semester Ganjil 2021/2022Documento5 páginasDaftar Barang Habispakai Semester Ganjil 2021/2022habibie irshanAinda não há avaliações

- Mini Catálogo Insize 2012Documento32 páginasMini Catálogo Insize 2012Augusto OliveiraAinda não há avaliações

- 5 Slip GaugesDocumento15 páginas5 Slip GaugesGovindrajAinda não há avaliações

- Gauges Master List E.QA.09Documento4 páginasGauges Master List E.QA.09vijay dhanawadeAinda não há avaliações

- Egyptian Accreditation Council Egac: Calibration Laboratory-Quality Center - WHS Plastic EgyptDocumento2 páginasEgyptian Accreditation Council Egac: Calibration Laboratory-Quality Center - WHS Plastic EgyptDarshAwadAinda não há avaliações

- Micrometers Calipers WorksheetDocumento4 páginasMicrometers Calipers WorksheetAuliaAinda não há avaliações

- Pdf-Crop - 2023-01-19T161057.257Documento3 páginasPdf-Crop - 2023-01-19T161057.257Thermo PlastAinda não há avaliações

- MMM - CIE 1 QP Scheme and Solution November 2021Documento8 páginasMMM - CIE 1 QP Scheme and Solution November 2021Naveena mAinda não há avaliações

- Media Wysiwyg Le Chameau Size Guide RulerDocumento1 páginaMedia Wysiwyg Le Chameau Size Guide RulerLeader AlfasonAinda não há avaliações

- Mahr SchutzDocumento4 páginasMahr SchutzCarlos RamirezAinda não há avaliações

- Vernier CallipersDocumento21 páginasVernier CallipersazaharAinda não há avaliações

- CMMDocumento28 páginasCMMArun Raj A CAinda não há avaliações

- Master Inspection Data Sheet YCTDocumento2 páginasMaster Inspection Data Sheet YCTboby RachmanAinda não há avaliações

- S1. Master List of Measuring InstrumentsDocumento2 páginasS1. Master List of Measuring InstrumentsShirish DaphalAinda não há avaliações

- Ruler QuizDocumento1 páginaRuler Quizmkono2088Ainda não há avaliações

- File Alat UkkDocumento3 páginasFile Alat UkkAzizAinda não há avaliações

- Verniers Micrometers and Measurement Uncertainty and Digital2Documento30 páginasVerniers Micrometers and Measurement Uncertainty and Digital2Raymond ScottAinda não há avaliações

- Vernier and MicrometerDocumento27 páginasVernier and MicrometerEster FatmawatiAinda não há avaliações

- 05a Kit Rep Calipers Rymeautomotive 2015Documento86 páginas05a Kit Rep Calipers Rymeautomotive 2015pegasoxtAinda não há avaliações

- Tkro - Pekerjaan Dasar Teknik Otomotif Kelas X (Respons)Documento14 páginasTkro - Pekerjaan Dasar Teknik Otomotif Kelas X (Respons)murdiAinda não há avaliações

- 2658Documento7 páginas2658rohanmanimaniAinda não há avaliações

- Daftar Alat TSMDocumento2 páginasDaftar Alat TSMagus ImawanAinda não há avaliações

- 24 Calibration Plan 2020-2021Documento6 páginas24 Calibration Plan 2020-2021Pradip GangardeAinda não há avaliações