Escolar Documentos

Profissional Documentos

Cultura Documentos

Material Reference

Enviado por

Roshin99Direitos autorais

Formatos disponíveis

Compartilhar este documento

Compartilhar ou incorporar documento

Você considera este documento útil?

Este conteúdo é inapropriado?

Denunciar este documentoDireitos autorais:

Formatos disponíveis

Material Reference

Enviado por

Roshin99Direitos autorais:

Formatos disponíveis

Material Reference

The chart below is intended to help in the material selection stage of designing rubber parts / products. Rubber compounding is a very broad and

technical field, since basic rubbers or elastomers are mixed with various chemicals and ingredients (and even with each other) to obtain desired

physical properties.

A wide variety of basic polymers (rubbers) are available, and a literally infinite array of compounds exhibiting unique physical properties as well as

chemical, fluid, and temperature resistances are possible. This chart, therefore, deals only with very general features of the most common basic rubber

or elastomer compounds, but more specific information is available upon request.

Common

Name(s)

Designation

(2)

Composition Min/Max Temp

Operating

Range (F) (5)

General

Properties(1)

General Chemical Resistance (3)

Resistant to: Attacked by:

Neoprene CR Chloroprene -30 F / 212 F Good Weathering

Resistance. Flame

retarding.

Moderate

resistance to

petroleum-based

fluids.

Moderate

chemicals and

acids, ozone, oils,

fats, greases,

many oils, and

solvents.

Strong oxidizing

acids, esters,

ketones,

chlorinated,

aromatic and nitro

hydrocarbons.

EPDM EPDM,

EPM

Ethylene-propylene-

diene; Ethylene-

propylene

-40 F / 300 F Excellent ozone,

chemical, and

aging resistance.

Poor resistance to

petroleum-based

fluids.

Animal and

vegetable oils,

ozone, strong and

oxidizing

chemicals.

Mineral oils and

solvents, aromatic

hydrocarbons.

Buna-N NBR Nitrile-butadiene -30 F / 250 F Excellent

resistance to

petroleum-based

fluids. Good

physical properties.

Many

hydrocarbons,

fats, oils, greases,

hydraulic fluids,

chemicals.

Ozone (except

PVC blends),

ketones, esters,

aldehydes,

chlorinated and

nitro hydrocarbons.

Silicone Q, Si Polysiloxane -80 F / 420 F Excellent high and

low temperature

properties. Fair

physical properties.

Moderate or

oxidizing

chemicals, ozone,

concentrated

sodium hydroxide.

Many solvents,

oils, concentrated

acids, dilute

sodium hydroxide.

SBR SBR Styrene-butadiene -20 F / 212F Good physical

properties and

abrasion

resistance. Poor

resistance to

petroleum-based

fluids.

Most moderate

chemicals, wet or

dry, organic acids,

alcohols, ketones,

aldehydes.

Ozone, strong

acids, fats, oils,

greases, most

hydrocarbons.

Butyl IIR Isobutene-isoprene -60 F / 250 F Very good

weathering

resistance.

Excellent dielectric

properties. Low

permeability to air.

Good physical

properties. Poor

resistance to

petroleum-based

fluids.

Animal and

vegetable fats,

oils, greases,

ozone, strong and

oxidizing

chemicals.

Petroleum,

solvents, coal tar

solvents, aromatic

hydrocarbons.

Natural, Gum

Rubber

NR Isoprene, natural -60 F / 220 F Excellent physical

properties

including abrasion

and low

temperature

resistance. Poor

resistance to

petroleum-based

fluids.

Most moderate

chemicals, wet or

dry, organic acids,

alcohols, ketones,

aldehydes.

Ozone, strong

acids, fats, oils,

greases, most

hydrocarbons.

Hypalon (4) CSM Chloro-sulfonyl-

polyethylene

-40 F / 320 F Excellent ozone,

weathering, and

acid resistance.

Good and abrasion

and heat

resistance. Fair

resistance to

petroleum-based

fluids.

Similar to

Neoprene with

improved acid

resistance.

Concentrated

oxidizing acids,

esters, ketones,

chlorinated,

aromatic, and nitro

hydrocarbons.

Urethane AU, EU Polyethylene-apdate,

Poly (oxy-1, 4,

butylene) ether

-40 F / 175 F Good aging and

excellent abrasion,

tear, and solvent

resistance. Poor

high temperature

properties.

Ozone,

hydrocarbons,

moderate

chemicals, fats,

oils, greases.

Concentrated

acids, ketones,

esters, chlorinated

and nitro

hydrocarbons.

Viton (4),

Fluoro-

elastomer

FPM Hexaflouropropylene-

vinylidene fluoride

- 10 F / 400 F Excellent oil and

air resistance both

at low and high

temperatures. Very

good chemical

resistance.

All aliphatic,

aromatic and

halogenated

hydrocarbons,

acids, animal and

vegetable oils.

Ketones, low

molecular weight

esters and nitro

containing

compounds.

Fluoro-silicone FSi Fluorocarbon -60 F / 350 F Offers superior

heat resistance.

resistant to cold,

oils and solvents of

fluorinated rubber.

Good for special

applications where

general resistance

to oxidizing

chemicals,

aromatic and

chlorinated solvent

bases are required.

Narrower Temp

range than silicone

but better fluid

resistance

Moderate or

oxidizing

chemicals, ozone,

aromatic

chlorinated

solvents, bases.

Brake fluids,

hydrazine,

ketones.

Hydrogenated

Nitrile

HNBR Hydrogenated

Acrylonitrile-

butadiene rubber

-22 F / 300 F Excellent heat and

oil resistance,

improved fuel and

ozone resistance

(approximately 5X)

over Nitrile Good

abrasion

resistance.

Decreased

elasticity at low

temperatures with

hydrogenation over

standard nitrile.

Many

hydrocarbons,

transmission

fluids,

refrigerants,

diluted acids,

hydraulic fluids,

silicone oils,

vegetable and

animal fats and

oils, water and

steam.

Chlorated

hydrocarbons,

keytones, strong

acids.

Carboxylated

Nitrile

XNBR Carboxylated Nitrile -20 F / 250 F Excellent Abrasion

and Tear

Resistance, Fair

Ozone and Steam

Resistance. Poor

to Fair Sunlight

and Outdoors.

Good to Excellent

Oil Resistance.

Many

hydrocarbons,

fats, oils, greases,

hydraulic fluids,

chemicals.

Ozone (except

PVC blends),

ketones, esters,

aldehydes,

chlorinated and

nitro hydrocarbons.

Footnotes

1. From the "Sheet Rubber Handbook - Gasket and Packing Materials" publication #IP-40 of the Rubber Manufacturers Association (RMA).

2. ASTM D 1418-79

3. 1979 Yearbook of the Los Angeles Rubber Group, Inc.

4. "Viton" and "Kalrez" are registered trademarks of E.I. Dupont, Inc.

5. The temperature range is determined by the base elastomer used. This chart depicts the maximum temperature range for each elastomer.

The temperature range for a specific compound may not reach these maximum limits. Higher temperatures may be considered if exposure

is short or intermittent.

Você também pode gostar

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)No EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Nota: 4.5 de 5 estrelas4.5/5 (119)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaNo EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaNota: 4.5 de 5 estrelas4.5/5 (265)

- The Little Book of Hygge: Danish Secrets to Happy LivingNo EverandThe Little Book of Hygge: Danish Secrets to Happy LivingNota: 3.5 de 5 estrelas3.5/5 (399)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryNo EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryNota: 3.5 de 5 estrelas3.5/5 (231)

- Never Split the Difference: Negotiating As If Your Life Depended On ItNo EverandNever Split the Difference: Negotiating As If Your Life Depended On ItNota: 4.5 de 5 estrelas4.5/5 (838)

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeNo EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeNota: 4 de 5 estrelas4/5 (5794)

- Team of Rivals: The Political Genius of Abraham LincolnNo EverandTeam of Rivals: The Political Genius of Abraham LincolnNota: 4.5 de 5 estrelas4.5/5 (234)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyNo EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyNota: 3.5 de 5 estrelas3.5/5 (2219)

- The Emperor of All Maladies: A Biography of CancerNo EverandThe Emperor of All Maladies: A Biography of CancerNota: 4.5 de 5 estrelas4.5/5 (271)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreNo EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreNota: 4 de 5 estrelas4/5 (1090)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersNo EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersNota: 4.5 de 5 estrelas4.5/5 (344)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceNo EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceNota: 4 de 5 estrelas4/5 (894)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureNo EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureNota: 4.5 de 5 estrelas4.5/5 (474)

- The Unwinding: An Inner History of the New AmericaNo EverandThe Unwinding: An Inner History of the New AmericaNota: 4 de 5 estrelas4/5 (45)

- The Yellow House: A Memoir (2019 National Book Award Winner)No EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Nota: 4 de 5 estrelas4/5 (98)

- Isolated Foundation Calculation SheetDocumento5 páginasIsolated Foundation Calculation SheetMohammad Tawfiq Wara100% (4)

- Site Engineering Query (SEQ)Documento1 páginaSite Engineering Query (SEQ)Roshin99Ainda não há avaliações

- Diff-Limit State & Working StressDocumento2 páginasDiff-Limit State & Working StressRoshin99100% (1)

- Tank Test CertificatesDocumento1 páginaTank Test CertificatesRoshin99Ainda não há avaliações

- Design of Purlins per IS800 and SP38Documento2 páginasDesign of Purlins per IS800 and SP38MM93% (29)

- Concrete Placement Record ReportDocumento1 páginaConcrete Placement Record ReportRoshin99100% (1)

- PulpDocumento382 páginasPulpBeerBie100% (1)

- Process Design for Coal Liquefaction and Exergy AnalysisDocumento46 páginasProcess Design for Coal Liquefaction and Exergy AnalysisSukaran SinghAinda não há avaliações

- ABS Fire Extinguisher CatalogueDocumento56 páginasABS Fire Extinguisher CatalogueqwertyAinda não há avaliações

- Inspection Report For Field WeldDocumento1 páginaInspection Report For Field WeldRoshin99Ainda não há avaliações

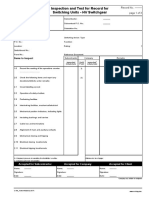

- Inspection Record For Switch HousesDocumento1 páginaInspection Record For Switch HousesRoshin99Ainda não há avaliações

- Inspection Record For Cabinets - ConsolesDocumento2 páginasInspection Record For Cabinets - ConsolesRoshin99Ainda não há avaliações

- Insp Record For Install Accept Safeguarding SystemDocumento1 páginaInsp Record For Install Accept Safeguarding SystemRoshin99Ainda não há avaliações

- Test Record For Overcurrent - Earth Fault - Prot Relay-Induction TypeDocumento1 páginaTest Record For Overcurrent - Earth Fault - Prot Relay-Induction TypeRoshin99Ainda não há avaliações

- Foundation Force TransmissionDocumento8 páginasFoundation Force Transmissiondeepakram04Ainda não há avaliações

- WeldingDocumento1 páginaWeldingVinothAinda não há avaliações

- IR For Cable Tray & LaddersDocumento1 páginaIR For Cable Tray & LaddersSchwihdi ZakAinda não há avaliações

- Inspection Record for Gates SEODocumento1 páginaInspection Record for Gates SEORoshin99Ainda não há avaliações

- Inspection Record For Air Ducting System: Items To InspectDocumento1 páginaInspection Record For Air Ducting System: Items To InspectSchwihdi ZakAinda não há avaliações

- Insp Record For Block WorkDocumento1 páginaInsp Record For Block WorkRoshin99Ainda não há avaliações

- Instion Test Record-PaintingDocumento1 páginaInstion Test Record-PaintingkeronsAinda não há avaliações

- Insp Record For Block WorkDocumento1 páginaInsp Record For Block WorkRoshin99Ainda não há avaliações

- Record of Vessel TestsDocumento1 páginaRecord of Vessel TestsRoshin99Ainda não há avaliações

- Certificate For Mech Completion - Ready For Start UpDocumento1 páginaCertificate For Mech Completion - Ready For Start UpRoshin99Ainda não há avaliações

- Inspection & Test Record Control Valve Pre-InstallationDocumento1 páginaInspection & Test Record Control Valve Pre-InstallationRoshin99Ainda não há avaliações

- Report For Quality Audit PDFDocumento1 páginaReport For Quality Audit PDFRoshin99Ainda não há avaliações

- Incoming Equipment Inspection RecordDocumento1 páginaIncoming Equipment Inspection RecordRoshin99Ainda não há avaliações

- Insp & Test Recds For Outgoing Units-LV SwitchgearDocumento2 páginasInsp & Test Recds For Outgoing Units-LV SwitchgearRoshin99Ainda não há avaliações

- Insp & Test Record Underground Piping PDFDocumento1 páginaInsp & Test Record Underground Piping PDFRoshin99Ainda não há avaliações

- Continuity Test Record For Earthing Conductor For EquipmentDocumento1 páginaContinuity Test Record For Earthing Conductor For EquipmentRoshin99Ainda não há avaliações

- Inspection-Record-AHUDocumento2 páginasInspection-Record-AHUSchwihdi ZakAinda não há avaliações

- Project Site Engineering Query LogDocumento1 páginaProject Site Engineering Query LogRoshin99Ainda não há avaliações

- Insp & Test Records of Switching Units-HV - SwitchgearDocumento3 páginasInsp & Test Records of Switching Units-HV - SwitchgearRoshin99100% (2)

- Synthesis and Charn of in Situ Cross-Linked Hydrogel Based On Self-Assembly of Thiol-Modified Chitosan With PEG DiacrylateDocumento8 páginasSynthesis and Charn of in Situ Cross-Linked Hydrogel Based On Self-Assembly of Thiol-Modified Chitosan With PEG Diacrylatealchemik1515Ainda não há avaliações

- Atoms, Elements & Compounds 1 QP PDFDocumento10 páginasAtoms, Elements & Compounds 1 QP PDFClinton ChikengezhaAinda não há avaliações

- AP Chemistry Unit 6 worksheet key conceptsDocumento5 páginasAP Chemistry Unit 6 worksheet key conceptsburcak gecAinda não há avaliações

- KTM Valve General CatalogDocumento20 páginasKTM Valve General Catalogferdy110276Ainda não há avaliações

- P Block Elements DPP 07 Extra DPP Yakeen 20 2023 PW StarDocumento3 páginasP Block Elements DPP 07 Extra DPP Yakeen 20 2023 PW StarAgnibha MaitiAinda não há avaliações

- Morphology of PolymersDocumento7 páginasMorphology of PolymersYounis Muhsin100% (1)

- Aroso 2015Documento7 páginasAroso 2015H Louis AcuñaAinda não há avaliações

- 12 Astm D 6928Documento7 páginas12 Astm D 6928Joel BecerraAinda não há avaliações

- Ec Clean - SdsDocumento5 páginasEc Clean - SdsMary JosephineAinda não há avaliações

- X. S. Ling Et Al - Superheating and Supercooling of Vortex Matter in A NB Single Crystal: Direct Evidence For A Phase Transition at The Peak Effect From Neutron DiffractionDocumento4 páginasX. S. Ling Et Al - Superheating and Supercooling of Vortex Matter in A NB Single Crystal: Direct Evidence For A Phase Transition at The Peak Effect From Neutron DiffractionKolddeAinda não há avaliações

- Festo OD TubingDocumento40 páginasFesto OD TubingyogitatanavadeAinda não há avaliações

- Advancesin Bricksand Blocksfor Building ConstructionDocumento14 páginasAdvancesin Bricksand Blocksfor Building ConstructionBharath GowdaAinda não há avaliações

- Furadur Kittloesung 20120416 en SD 91070119 PDFDocumento9 páginasFuradur Kittloesung 20120416 en SD 91070119 PDFBarbara Andreina Sanchez AmayaAinda não há avaliações

- Stability Analysis of Geocell Reinforced Slopes by Considering Bending EffectDocumento13 páginasStability Analysis of Geocell Reinforced Slopes by Considering Bending EffectRakesh KapoorAinda não há avaliações

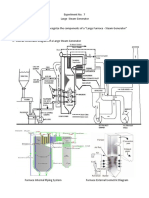

- Large Steam GeneratorDocumento12 páginasLarge Steam GeneratorChe AguilarAinda não há avaliações

- Unistrut Uniper Pipe Support SystemsDocumento24 páginasUnistrut Uniper Pipe Support SystemsmolinachAinda não há avaliações

- Experimental Characterization of Al-Cu Thermal Contact ResistanceDocumento20 páginasExperimental Characterization of Al-Cu Thermal Contact Resistancenozue.tatsuhiro nozueAinda não há avaliações

- LPSR Based Paper - Optik JournalDocumento12 páginasLPSR Based Paper - Optik JournalSK ChaulyaAinda não há avaliações

- Chapter 2 Funtional Group PropertiesDocumento38 páginasChapter 2 Funtional Group Properties伟铭100% (1)

- Waste management in Israel - background, policy, projects & opportunitiesDocumento15 páginasWaste management in Israel - background, policy, projects & opportunitiesLuan NguyenAinda não há avaliações

- PETRONAS Distributor Price List - W.E.F 10-10-23Documento2 páginasPETRONAS Distributor Price List - W.E.F 10-10-23Mujeeb SiddiqueAinda não há avaliações

- Part1 High Voltage Engineering PDFDocumento67 páginasPart1 High Voltage Engineering PDFQais Alsafasfeh0% (1)

- Basic Type Heat ExchangerDocumento25 páginasBasic Type Heat ExchangerTaifurAinda não há avaliações

- DOWSIL™ 795 Structural Glazing Sealant Technical Data SheetDocumento5 páginasDOWSIL™ 795 Structural Glazing Sealant Technical Data SheetTrung Nguyễn NgọcAinda não há avaliações

- MDtrm questions on art elements, principles and mediumsDocumento28 páginasMDtrm questions on art elements, principles and mediumsNicole Dang BallaretAinda não há avaliações

- WPS - 008Documento11 páginasWPS - 008MAT-LIONAinda não há avaliações