Escolar Documentos

Profissional Documentos

Cultura Documentos

Treating Effluent Streams - Bio-Systems SA

Enviado por

Lh KooTítulo original

Direitos autorais

Formatos disponíveis

Compartilhar este documento

Compartilhar ou incorporar documento

Você considera este documento útil?

Este conteúdo é inapropriado?

Denunciar este documentoDireitos autorais:

Formatos disponíveis

Treating Effluent Streams - Bio-Systems SA

Enviado por

Lh KooDireitos autorais:

Formatos disponíveis

10/1/2014 Treating effluent streams Bio-Systems SA

http://www.biosystemssa.co.za/Industrial/effluent-streams 1/3

Treating effluent streams

What is an effluent stream?

An effluent stream is the flow or course taken by wastewater made dirty by the industrial process it

serves. It may be within a plant combining with others in the factory, or from the factory it may

converge with a municipal sewer which will then be carrying mixed effluent.

There are different types of effluent streams. For example:

A sewer carries a sewage stream, which is usually made up of a mixture of domestic, catering

and a small percentage of industrial effluent (depending where in the urban area the stream

is situated).

A dairy or cheese factory discharges a dairy effluent stream, normally high in curds and

milk/butter fat wastes.

In any event, each stream of like effluent should be pre-treated before mixing with a different type of

effluent. For instance, blood effluent (organic COD) and tank wash effluent (caustic chemicals) in an

abattoir. This should be done prior to discharge from the premises. Why? Microorganisms are

substrate selective and there is no one super bug that will degrade everything.

Common effluent stream problems

Ignorance is one of the most common problems. Often the plant designer does not know how

to handle the effluent stream, neither do operating staff.

Incorrect devices are used. For example, static screens (which tend to block) are utilized

instead of the more expensive (and correct) rotary screens.

Frequently, the lack or paucity of finances allocated to the project are also to blame. Since it

is waste water that is being removed the budget is often cut and inferior or undersized

equipment is installed to reduce operating costs.

Production volumes are also culprits: the capex option for average flow, which was taken

when the business started, increases as the business grows and the maximum flow (peak at

start-up) proves to be the norm.

The BIO-SYSTEMS solution

For the conveyance and treatment of effluent streams BIO-SYSTEMS offers a three-prong approach:

1. Consultancy

We have ready access to a number of experts in the effluent field (especially in Southern

Africa). We know where to find the right people experienced in specific effluent streams who

have tried and tested various treatments. We can assist with the design of systems to suit any

challenge and our formidable bank of case histories (both local and international) prevent

our clients from having to re-invent the wheel.

2. Equipment

Our network encompasses specialist manufacturers from whom most effluent treatment

devices are obtainable. Grease interceptor traps play a primary role in cleaning up catering

and mechanical effluents. They are never used on sewage lines.

10/1/2014 Treating effluent streams Bio-Systems SA

http://www.biosystemssa.co.za/Industrial/effluent-streams 2/3

3. Additives

We have specific additives, mostly comprising natural bacteria, with which to improve the

quality of most effluent streams.

Effluent stream before BIO-SYSTEMS treatment

Effluent stream after BIO-SYSTEMS treatment

BIO-SYSTEMS products

BIO-SYSTEMS products contain different types of microbes that attack and degrade various types of

effluent streams. Here are a few of our frequently applied microbial blends

1. BIO-SYSTEMS B350

2. BIO-SYSTEMS B1800

3. BIO-SYSTEMS L2120

4. BIO-SYSTEMS B220R

5. BIO-SYSTEMS B570

6. BIO-SYSTEMS B250

Click on the BIO-SYSTEMS Product table for a complete list of products. Also see our Effluent

stream case history.

Go to Grease traps and interceptors, Oil spills, Odour prevention, Drain dos and donts,

and Industrial catering effluent for more on the industrial effluent disposal system.

Related content

Industrial effluent disposal at a glance

10/1/2014 Treating effluent streams Bio-Systems SA

http://www.biosystemssa.co.za/Industrial/effluent-streams 3/3

Grease traps and interceptors

Oil spills

Odour prevention

Confined spaces

Drain dos and don'ts

Industrial catering effluent

Você também pode gostar

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceNo EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceNota: 4 de 5 estrelas4/5 (895)

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeNo EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeNota: 4 de 5 estrelas4/5 (5794)

- Dow Completes Merger With Rohm and HaasDocumento2 páginasDow Completes Merger With Rohm and HaasLh KooAinda não há avaliações

- D NanoTronDocumento2 páginasD NanoTronLh KooAinda não há avaliações

- Biomass Energy Generation by PTMDocumento24 páginasBiomass Energy Generation by PTMLh KooAinda não há avaliações

- D MicroTronDocumento2 páginasD MicroTronLh KooAinda não há avaliações

- YBPPGA (1) Aug 2011 PDFDocumento6 páginasYBPPGA (1) Aug 2011 PDFLh KooAinda não há avaliações

- TDS Cond Conversion ChartDocumento2 páginasTDS Cond Conversion ChartLh KooAinda não há avaliações

- Taking A Zero Tolerance Approach To Bacteria Control, Delivers Piece of Mind 'Documento2 páginasTaking A Zero Tolerance Approach To Bacteria Control, Delivers Piece of Mind 'Lh KooAinda não há avaliações

- BIM Half Marathon Men Open 18Documento1 páginaBIM Half Marathon Men Open 18Lh KooAinda não há avaliações

- BIM Half Marathon Men Open 19Documento1 páginaBIM Half Marathon Men Open 19Lh KooAinda não há avaliações

- Taking A Zero Tolerance Approach To Bacteria Control, Delivers Piece of Mind 'Documento2 páginasTaking A Zero Tolerance Approach To Bacteria Control, Delivers Piece of Mind 'Lh KooAinda não há avaliações

- Peristaltic Pump With Speed Adjustable Flow: Product Specifications Pump View (MM)Documento1 páginaPeristaltic Pump With Speed Adjustable Flow: Product Specifications Pump View (MM)Lh KooAinda não há avaliações

- BIM Half Marathon Men Open 15Documento1 páginaBIM Half Marathon Men Open 15Lh KooAinda não há avaliações

- BIM Half Marathon Men Open 5Documento1 páginaBIM Half Marathon Men Open 5Lh KooAinda não há avaliações

- Ozone Treatment of Cooling Tower WaterDocumento26 páginasOzone Treatment of Cooling Tower WaterLh KooAinda não há avaliações

- BIM Half Marathon Men Open 14Documento1 páginaBIM Half Marathon Men Open 14Lh KooAinda não há avaliações

- BIM Half Marathon Men Open 16Documento1 páginaBIM Half Marathon Men Open 16Lh KooAinda não há avaliações

- BIM Half Marathon Men Open 13Documento1 páginaBIM Half Marathon Men Open 13Lh KooAinda não há avaliações

- BIM Half Marathon Men Open 11Documento1 páginaBIM Half Marathon Men Open 11Lh KooAinda não há avaliações

- BIM Half Marathon Men Open 12Documento1 páginaBIM Half Marathon Men Open 12Lh KooAinda não há avaliações

- BIM Half Marathon Men Open 9Documento1 páginaBIM Half Marathon Men Open 9Lh KooAinda não há avaliações

- BIM Half Marathon Men Open 8Documento1 páginaBIM Half Marathon Men Open 8Lh KooAinda não há avaliações

- BIM Half Marathon Men Open 7Documento1 páginaBIM Half Marathon Men Open 7Lh KooAinda não há avaliações

- BIM Half Marathon Men Open 6Documento1 páginaBIM Half Marathon Men Open 6Lh KooAinda não há avaliações

- Cleaning, Sanitizing, and Pest Control in Food Processing, Storage, and Service AreasDocumento16 páginasCleaning, Sanitizing, and Pest Control in Food Processing, Storage, and Service AreasLh KooAinda não há avaliações

- BIM Half Marathon Men Open 4Documento1 páginaBIM Half Marathon Men Open 4Lh KooAinda não há avaliações

- BIM Half Marathon Men Open 2Documento1 páginaBIM Half Marathon Men Open 2Lh KooAinda não há avaliações

- BIM Half Marathon Men Open 3Documento1 páginaBIM Half Marathon Men Open 3Lh KooAinda não há avaliações

- BIM Half Marathon Men Open 1Documento1 páginaBIM Half Marathon Men Open 1Lh KooAinda não há avaliações

- The Yellow House: A Memoir (2019 National Book Award Winner)No EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Nota: 4 de 5 estrelas4/5 (98)

- The Little Book of Hygge: Danish Secrets to Happy LivingNo EverandThe Little Book of Hygge: Danish Secrets to Happy LivingNota: 3.5 de 5 estrelas3.5/5 (400)

- Never Split the Difference: Negotiating As If Your Life Depended On ItNo EverandNever Split the Difference: Negotiating As If Your Life Depended On ItNota: 4.5 de 5 estrelas4.5/5 (838)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureNo EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureNota: 4.5 de 5 estrelas4.5/5 (474)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryNo EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryNota: 3.5 de 5 estrelas3.5/5 (231)

- The Emperor of All Maladies: A Biography of CancerNo EverandThe Emperor of All Maladies: A Biography of CancerNota: 4.5 de 5 estrelas4.5/5 (271)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaNo EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaNota: 4.5 de 5 estrelas4.5/5 (266)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersNo EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersNota: 4.5 de 5 estrelas4.5/5 (345)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyNo EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyNota: 3.5 de 5 estrelas3.5/5 (2259)

- Team of Rivals: The Political Genius of Abraham LincolnNo EverandTeam of Rivals: The Political Genius of Abraham LincolnNota: 4.5 de 5 estrelas4.5/5 (234)

- The Unwinding: An Inner History of the New AmericaNo EverandThe Unwinding: An Inner History of the New AmericaNota: 4 de 5 estrelas4/5 (45)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreNo EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreNota: 4 de 5 estrelas4/5 (1090)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)No EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Nota: 4.5 de 5 estrelas4.5/5 (121)

- Selection Letter Abhishek TodkarDocumento1 páginaSelection Letter Abhishek TodkarDipak GiteAinda não há avaliações

- Vayutel Case StudyDocumento10 páginasVayutel Case StudyRenault RoorkeeAinda não há avaliações

- Richard K. Neumann JR., J. Lyn Entrikin - Legal Drafting by Design - A Unified Approach (2018) - Libgen - LiDocumento626 páginasRichard K. Neumann JR., J. Lyn Entrikin - Legal Drafting by Design - A Unified Approach (2018) - Libgen - LiEwertonDeMarchi100% (3)

- Martin, BrianDocumento3 páginasMartin, Brianapi-3727889Ainda não há avaliações

- CTC VoucherDocumento56 páginasCTC VoucherJames Hydoe ElanAinda não há avaliações

- Merger and Acquisition Review 2012Documento2 páginasMerger and Acquisition Review 2012Putri Rizky DwisumartiAinda não há avaliações

- Simple Yellow CartoonDocumento1 páginaSimple Yellow CartoonIdeza SabadoAinda não há avaliações

- Breterg RSGR: Prohibition Against CarnalityDocumento5 páginasBreterg RSGR: Prohibition Against CarnalityemasokAinda não há avaliações

- ModernismDocumento4 páginasModernismSiya SunilAinda não há avaliações

- Morals and Dogma of The Ineffable DegreesDocumento134 páginasMorals and Dogma of The Ineffable DegreesCelephaïs Press / Unspeakable Press (Leng)86% (7)

- PDF Issue 1 PDFDocumento128 páginasPDF Issue 1 PDFfabrignani@yahoo.comAinda não há avaliações

- PRIMER - CFC Young Couples ProgramDocumento3 páginasPRIMER - CFC Young Couples Programgeorgeskie8100% (2)

- Computer Engineering Project TopicsDocumento5 páginasComputer Engineering Project Topicskelvin carterAinda não há avaliações

- (East Central and Eastern Europe in the Middle Ages, 450-1450_ vol. 21) Paul Milliman-_The Slippery Memory of Men__ The Place of Pomerania in the Medieval Kingdom of Poland-Brill Academic Publishers (.pdfDocumento337 páginas(East Central and Eastern Europe in the Middle Ages, 450-1450_ vol. 21) Paul Milliman-_The Slippery Memory of Men__ The Place of Pomerania in the Medieval Kingdom of Poland-Brill Academic Publishers (.pdfRaphael BraunAinda não há avaliações

- Profil AVANCER FM SERVICES SDN BHDDocumento23 páginasProfil AVANCER FM SERVICES SDN BHDmazhar74Ainda não há avaliações

- Mandatory Minimum Requirements For Security-Related Training and Instruction For All SeafarersDocumento9 páginasMandatory Minimum Requirements For Security-Related Training and Instruction For All SeafarersDio Romero FariaAinda não há avaliações

- SAP FICO Course Content - Core Global ITDocumento12 páginasSAP FICO Course Content - Core Global ITVenkatrao VaraganiAinda não há avaliações

- SaveHinduTemples PDFDocumento7 páginasSaveHinduTemples PDFRavi RathoreAinda não há avaliações

- SEBI Management Summary SheetsDocumento398 páginasSEBI Management Summary SheetsPriyanka ChandakAinda não há avaliações

- Research ProposalDocumento21 páginasResearch Proposalkecy casamayorAinda não há avaliações

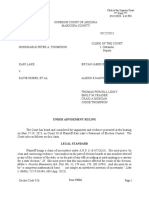

- CV2022095403 5222023 Minute EntryDocumento6 páginasCV2022095403 5222023 Minute EntryJordan Conradson100% (2)

- NegotiationDocumento29 páginasNegotiationNina LeeAinda não há avaliações

- Infinivan Company Profile 11pageDocumento11 páginasInfinivan Company Profile 11pagechristopher sunAinda não há avaliações

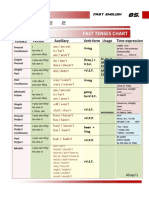

- Table 2: Fast Tenses ChartDocumento5 páginasTable 2: Fast Tenses ChartAngel Julian HernandezAinda não há avaliações

- Future Trends in Mechanical Engineering-ArticleDocumento2 páginasFuture Trends in Mechanical Engineering-ArticleanmollovelyAinda não há avaliações

- Journey Toward OnenessDocumento2 páginasJourney Toward Onenesswiziqsairam100% (2)

- Sales-Management Solved MCQsDocumento69 páginasSales-Management Solved MCQskrishna100% (3)

- Case Presentation and Analysis - Operations JollibeeDocumento7 páginasCase Presentation and Analysis - Operations JollibeeDonnabie Pearl Pacaba-CantaAinda não há avaliações

- Prof. Sujata Patel Department of Sociology, University of Hyderabad Anurekha Chari Wagh Department of Sociology, Savitribaiphule Pune UniversityDocumento19 páginasProf. Sujata Patel Department of Sociology, University of Hyderabad Anurekha Chari Wagh Department of Sociology, Savitribaiphule Pune UniversityHarish KumarAinda não há avaliações

- Annaphpapp 01Documento3 páginasAnnaphpapp 01anujhanda29Ainda não há avaliações