Escolar Documentos

Profissional Documentos

Cultura Documentos

TN42.1005 - Procedure Checking EndPlay in Ball Bearing PDF

Enviado por

arifuddinnurdinDescrição original:

Título original

Direitos autorais

Formatos disponíveis

Compartilhar este documento

Compartilhar ou incorporar documento

Você considera este documento útil?

Este conteúdo é inapropriado?

Denunciar este documentoDireitos autorais:

Formatos disponíveis

TN42.1005 - Procedure Checking EndPlay in Ball Bearing PDF

Enviado por

arifuddinnurdinDireitos autorais:

Formatos disponíveis

TN42-1

Tech Note No. 42 Procedures for Checking Endplay in Ball Bearing Motors

(10/05)

TECH NOTE NO. 42 Reliable Solutions Today!

PROCEDURES FOR CHECKING ENDPLAY IN BALL

BEARING MACHINES

By Chuck Yung

Technical Support Specialist

Electrical Apparatus Service Association

St. Louis, MO

EA SA

E

L

E

C

T

R

IC

AL APPA

R

A

T

U

S

S

E

R

V

IC

E

ASSOC

IA

T

I

O

N

The first response for most technicians would be to

suspect an alignment problem. But another possibility to

consider is insufficient endplay. An electric motor must have

room for thermal expansion of the shaft, or bearing life will

be reduced greatly.

Because the frame dissipates heat generated in the rotor

and windings, the rotor/shaft assembly is considerably

hotter than the stator frame. Thermal expansion of the shaft

exceeds that of the frame. To compensate, allowance must

be made for the shaft to grow axially. Failure to do so will

preload both bearings, causing rapid failure of the one with

the lower load-carrying capacity. That usually is the smaller

bearing on the opposite drive end (ODE).

For carbon steel shafts, the length will increase

0.0000067 per inch of shaft length per F of temperature

change (0.0000117 mm per millimeter of shaft length per

C). A 30 (762 mm) long shaft would therefore grow by

0.016 (0.4 mm) if subjected to a temperature rise of 80 F

(45 C):

30 x 0.0000067 x 80 = 0.016 increase in length

762 x 0.0000117 x 45 = 0.4 mm increase in length

Unless there is at least that much extra room between

one bearing and the shoulder in the end bracket, thermal

growth will preload the bearing.

Most designs locate one end of the shaftusually the

drive end (DE)and provide sufficient room at the other end

for thermal expansion. That means the DE bearing is held

captive by the housing and bearing cap to prevent axial

displacement of the coupling. Too much play in drive end

of the motor shaft can damage the driven equipment.

When a bearing failure damages the shaft, it is often

difficult or impossible to determine the original location of

the bearing shoulder. This uncertainty requires a reliable

method for determining whether the repaired motor has

adequate provision for thermal expansion. By following

some basic steps, the assembly mechanic can assure that

the motor has this room.

Measure room available for shaft growth. With both

end brackets installed, and the bearing caps tight, place a

dial indicator on the ODE bracket to measure axial shaft

movement. Use a soft-face mallet to tap the shaft towards

the DE, zero the indicator, and then tap the shaft towards the

ODE. The only movement should be internal play in the

bearing.

Next, loosen both bearing caps and move the shaft

towards the ODE. The measurement obtained is the avail-

After repair, an electric motor ran fine in the

service center but developed high bearing

temperatures shortly after the customer

installed it. The bearings failed after only a

few hours of operation at full load.

TERMS

DE: ........................ Drive end

ODE: ..................... Opposite drive end

L

10h

bearing life: ... The point, in number of operating

hours, where 10% of that family of

bearings will have failed.

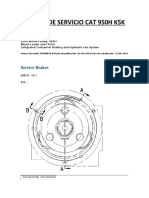

FIGURE 1

PROPER ENDPLAY

This gap allows

for thermal

growth. ("A")

This gap

prevents tension

preload. ("B")

This bearing

is held captive.

Bearing cap

TN42-2

Tech Note No. 42 Procedures for Checking Endplay in Ball Bearing Motors

(10/05)

Copyright 2005 Reliable Solutions Today!

Version 1005 DP2C-1005

Electrical Apparatus Service Association, Inc.

1331 Baur Boulevard St. Louis, MO 63132 U.S.A. (314) 993-2220 Fax (314) 993-1269 www.easa.com

EA SA

E

L

E

C

T

R

IC

AL APPA

R

A

T

U

S

S

E

R

V

I

C

E

ASSO

C

IA

T

I

O

N

able room for thermal growth of the shaft. There must be

enough room for the shaft to grow thermally without preloading

the bearings (compressive preload ). (Rule of thumb:

Allow approximately .010 per foot (.12 mm per meter) of

shaft length between bearings.)

To increase the room for thermal growth, remove the ODE

bracket and machine shoulder A (see Figure 1).

Make sure bearing caps do not preload bearings. If the

motor has enough allowance for thermal growth, the last step

is to make sure the bearing caps are not preloading the

bearings by pulling outwards (tension preload). To check

this, first tighten the DE bearing cap. This pulls the bearing

into its normal operating position.

Now zero the indicator, loosen the DE bearing cap and

tighten the ODE bearing cap. If the shaft moves, then the

bearing caps are preloading the bearings. If this step reveals

a tension preload ( ), either put a spacer between the

ODE bearing cap and bracket or machine the bearing cap

shoulder.

If preload is not corrected, one of two things will happen.

Either a bearing will be dislocated from the shoulder, or the

bearing L

10h

life will be decreased. The reduction in L

10h

bearing life will be proportional to the amount of preload. By

way of example, a .040 (1 mm) preload can decrease L

10h

bearing life to a matter of hours.

Tip: When a stock motor is modified for a direct-couple

application, the DE roller bearing should be replaced with a

standard ball bearing. Because the roller bearing is held

captive, and the ODE bearing served to locate the shaft, this

modification requires that the endplay be adjusted.

One approach would be to assemble the motor, check the

endplay as described above, and then dismantle it to do the

appropriate machine work. A good shortcut is to machine

0.020 (.5 mm) from the ODE bearing cap face B (see

Figure 1) and then machine the bearing fit of the ODE end

bracket A (see Figure 1) 0.040 (1 mm) deeper. This

ensures that the bearings will not be pre-loaded in either

direction. Final endplay checks should still be made as

outlined above, but the shortcut virtually guarantees that the

motor will not have to be dismantled for further machine work.

Place this Tech Note in Section 9 of your EASA

Technical Manual for future reference.

Note its location in Section 15, Future Tech Notes.

Você também pode gostar

- Plymouth and Chrysler-built cars Complete Owner's Handbook of Repair and MaintenanceNo EverandPlymouth and Chrysler-built cars Complete Owner's Handbook of Repair and MaintenanceAinda não há avaliações

- Procedure For Ship Propeller RenewalDocumento24 páginasProcedure For Ship Propeller RenewalJORGEAinda não há avaliações

- The Book of the Singer Junior - Written by an Owner-Driver for Owners and Prospective Owners of the Car - Including the 1931 SupplementNo EverandThe Book of the Singer Junior - Written by an Owner-Driver for Owners and Prospective Owners of the Car - Including the 1931 SupplementAinda não há avaliações

- Odyssey 3,5L 2012 J35 Rocker Arm Assembly - Ticking or Knocking at IdleDocumento4 páginasOdyssey 3,5L 2012 J35 Rocker Arm Assembly - Ticking or Knocking at Idlenuevo correoAinda não há avaliações

- Chevy Differentials: How to Rebuild the 10- and 12-BoltNo EverandChevy Differentials: How to Rebuild the 10- and 12-BoltNota: 5 de 5 estrelas5/5 (8)

- Instruction DisclaimerDocumento5 páginasInstruction DisclaimerBeS BesAinda não há avaliações

- MEO Class 2 Orals Function 4 & 6 Q & ADocumento8 páginasMEO Class 2 Orals Function 4 & 6 Q & Aneeraj118578% (9)

- X30592Documento16 páginasX30592CTN2010Ainda não há avaliações

- Rover 100 TUD5 Overhaul ManualDocumento59 páginasRover 100 TUD5 Overhaul ManualAndy Moe63% (8)

- Proper Ignition Timing for Rotax EnginesDocumento3 páginasProper Ignition Timing for Rotax EnginesARMILITEAinda não há avaliações

- Roatary Actuators - Micromatic Repair Manual - 26-17-0116Documento10 páginasRoatary Actuators - Micromatic Repair Manual - 26-17-0116tungAinda não há avaliações

- 2012 Arctic Cat Service Updates and BulletinsDocumento470 páginas2012 Arctic Cat Service Updates and BulletinsJuan Carlos SuarezAinda não há avaliações

- Pump maintenance standard documentDocumento4 páginasPump maintenance standard documentNaing Min HtunAinda não há avaliações

- One Cylinder ModelsDocumento4 páginasOne Cylinder ModelsPaul MartinAinda não há avaliações

- Cam EV80Documento4 páginasCam EV80Zubair AamirAinda não há avaliações

- 6 Checking and Adjustment of Exhaust Cam LeadDocumento8 páginas6 Checking and Adjustment of Exhaust Cam LeadJomari Saligan100% (1)

- Clutch ManualDocumento16 páginasClutch ManualCO BDAinda não há avaliações

- Valve LashDocumento4 páginasValve Lashrafkaalika627Ainda não há avaliações

- Insulated BearingsDocumento3 páginasInsulated Bearingsuuur35Ainda não há avaliações

- PA Engine Epsilon Kappa U CRDI PDFDocumento46 páginasPA Engine Epsilon Kappa U CRDI PDFJuan MAinda não há avaliações

- C4 4 CalibracionDocumento5 páginasC4 4 CalibracionJaya Abadi100% (1)

- 3408E and 3412E Crankshaft Main Bearings - InstallDocumento6 páginas3408E and 3412E Crankshaft Main Bearings - Installalonso100% (1)

- Ec 290 BLCDocumento361 páginasEc 290 BLCchanlin96% (52)

- LS1 PTV Measuring Procedure DRAFT 20-Apr-13Documento5 páginasLS1 PTV Measuring Procedure DRAFT 20-Apr-13RezinTexasAinda não há avaliações

- 1 Mbe4000 06aDocumento38 páginas1 Mbe4000 06azahar222Ainda não há avaliações

- PUSNES Deck Machinery Installation ProcedureDocumento18 páginasPUSNES Deck Machinery Installation ProcedurexatzaraAinda não há avaliações

- Fin FANDocumento2 páginasFin FANNorman Morales100% (1)

- PropellerDocumento15 páginasPropellerNavin Dipali100% (2)

- CEP Design Features And Parameters ComparisonDocumento35 páginasCEP Design Features And Parameters ComparisonGaurav100% (1)

- C200-019-23 TM-210.1 2.875 Motorhead AssemblyDocumento13 páginasC200-019-23 TM-210.1 2.875 Motorhead AssemblysamanAinda não há avaliações

- C-12 Industrial Engine BDL00001-UP (SEBP3252 - 59) - Reglages SoupapesDocumento4 páginasC-12 Industrial Engine BDL00001-UP (SEBP3252 - 59) - Reglages SoupapesDamien LEGRANDAinda não há avaliações

- How To Replace Damaged Bearings On A Precision CNCDocumento6 páginasHow To Replace Damaged Bearings On A Precision CNCbui huu LongAinda não há avaliações

- Fitting Palloid bevel gearsDocumento2 páginasFitting Palloid bevel gearsEmerson IpialesAinda não há avaliações

- Kia Forte EX 2012Documento8 páginasKia Forte EX 2012Gustavo Gamez100% (1)

- Engine Valve Lash - Inspect/AdjustDocumento4 páginasEngine Valve Lash - Inspect/AdjustHrvoje ŠkaricaAinda não há avaliações

- Sleeve Bearing Specification For MotorDocumento45 páginasSleeve Bearing Specification For MotorThiMinhKhuyen100% (2)

- 12165-70 - 1 Sundry Instr.Documento328 páginas12165-70 - 1 Sundry Instr.kodrysAinda não há avaliações

- 2008 7 8Documento8 páginas2008 7 8Peps Ren100% (2)

- The BG Tuning ManualDocumento13 páginasThe BG Tuning Manuald_u_i_l_i_o100% (1)

- Generator Set Engine DocumentationDocumento4 páginasGenerator Set Engine DocumentationbejoythomasAinda não há avaliações

- 8218 спецификация головки 3116 -с7Documento19 páginas8218 спецификация головки 3116 -с7Евгений АбрамовAinda não há avaliações

- Standard For Suspension InstallationDocumento3 páginasStandard For Suspension InstallationnkprabhakaranAinda não há avaliações

- 3054 Engine Valve Lash - InspectAdjustDocumento5 páginas3054 Engine Valve Lash - InspectAdjustMaxwell Carrasco Santi100% (5)

- Jinford 2017 - eDocumento102 páginasJinford 2017 - eEleazar Benjamin Castro PavonAinda não há avaliações

- Cylinder Blok c4Documento7 páginasCylinder Blok c4lilikAinda não há avaliações

- OWI 1000 DrawworksDocumento54 páginasOWI 1000 DrawworksÖnder Büyükişcan100% (1)

- Brakekit PDFDocumento3 páginasBrakekit PDFTia KeyAinda não há avaliações

- Engine BearingsDocumento22 páginasEngine Bearingsandrew munyivaAinda não há avaliações

- Motor Head AssemblyDocumento16 páginasMotor Head AssemblyAhmed100% (1)

- Replace Rocker Arm Cover Gasket - ctm415 - Service ADVISOR™Documento5 páginasReplace Rocker Arm Cover Gasket - ctm415 - Service ADVISOR™Fernando Aguilar100% (1)

- Crankshaft - InstallDocumento7 páginasCrankshaft - InstallLeonardo PerezAinda não há avaliações

- Desiccant Rotors International: Heat Recovery Wheel (HRW)Documento20 páginasDesiccant Rotors International: Heat Recovery Wheel (HRW)Binod DavisAinda não há avaliações

- Cylinder Liner Projection - Inspect: Testing and AdjustingDocumento5 páginasCylinder Liner Projection - Inspect: Testing and AdjustingВиталийAinda não há avaliações

- XP Manual REV 21APR10Documento32 páginasXP Manual REV 21APR10sylvain croteauAinda não há avaliações

- SKF OKC coupling mounting instructionsDocumento16 páginasSKF OKC coupling mounting instructionsmatchutAinda não há avaliações

- 1 Thru 6in E Series Globe Valves ED ET PDFDocumento16 páginas1 Thru 6in E Series Globe Valves ED ET PDFakhileshkuniyilAinda não há avaliações

- Frenos de Servicio Cat 950H K5KDocumento19 páginasFrenos de Servicio Cat 950H K5KhectorAinda não há avaliações

- SEBF8155 цил.головка 3500Documento30 páginasSEBF8155 цил.головка 3500Евгений Абрамов100% (1)

- ExpertDocumento301 páginasExpertEngine Tuning Up100% (2)

- 24H Engine Valve SetDocumento7 páginas24H Engine Valve SetJohn GrayAinda não há avaliações

- Owner's Manual For The Vehicle.: With A Quick Reference Guide For Your ConvenienceDocumento179 páginasOwner's Manual For The Vehicle.: With A Quick Reference Guide For Your Conveniencealex popAinda não há avaliações

- Sample Drawing (Tube Plug) PDFDocumento1 páginaSample Drawing (Tube Plug) PDFarifuddinnurdinAinda não há avaliações

- TN39.1003 - Procedure Writing PDFDocumento4 páginasTN39.1003 - Procedure Writing PDFarifuddinnurdinAinda não há avaliações

- Double Suction Horizontal Split Case Centrifugal Pumps BSC/BSCM SeriesDocumento56 páginasDouble Suction Horizontal Split Case Centrifugal Pumps BSC/BSCM SeriestdccmpnAinda não há avaliações

- HP HP3-X11 Exam: A Composite Solution With Just One ClickDocumento17 páginasHP HP3-X11 Exam: A Composite Solution With Just One ClicksunnyAinda não há avaliações

- Letter From Attorneys General To 3MDocumento5 páginasLetter From Attorneys General To 3MHonolulu Star-AdvertiserAinda não há avaliações

- LEARNING ACTIVITY Sheet Math 7 q3 M 1Documento4 páginasLEARNING ACTIVITY Sheet Math 7 q3 M 1Mariel PastoleroAinda não há avaliações

- (123doc) - Chapter-24Documento6 páginas(123doc) - Chapter-24Pháp NguyễnAinda não há avaliações

- Methods to estimate stakeholder views of sustainabilityDocumento7 páginasMethods to estimate stakeholder views of sustainabilityAlireza FatemiAinda não há avaliações

- Consensus Building e Progettazione Partecipata - Marianella SclaviDocumento7 páginasConsensus Building e Progettazione Partecipata - Marianella SclaviWilma MassuccoAinda não há avaliações

- Indian Journal of Natural Products and Resources Vol 1 No 4 Phytochemical pharmacological profile Cassia tora overviewDocumento8 páginasIndian Journal of Natural Products and Resources Vol 1 No 4 Phytochemical pharmacological profile Cassia tora overviewPRINCIPAL BHILWARAAinda não há avaliações

- Excess AirDocumento10 páginasExcess AirjkaunoAinda não há avaliações

- Uses and Soxhlet Extraction of Apigenin From Parsley Petroselinum CrispumDocumento6 páginasUses and Soxhlet Extraction of Apigenin From Parsley Petroselinum CrispumEditor IJTSRDAinda não há avaliações

- Paper SizeDocumento22 páginasPaper SizeAlfred Jimmy UchaAinda não há avaliações

- Masteringphys 14Documento20 páginasMasteringphys 14CarlosGomez0% (3)

- 4 Influencing Factors of Learners Career Choice Parents Choice Vs Personal DescisionDocumento24 páginas4 Influencing Factors of Learners Career Choice Parents Choice Vs Personal Descisionmatteo mamaloAinda não há avaliações

- Felizardo C. Lipana National High SchoolDocumento3 páginasFelizardo C. Lipana National High SchoolMelody LanuzaAinda não há avaliações

- Wheeled Loader L953F Specifications and DimensionsDocumento1 páginaWheeled Loader L953F Specifications and Dimensionssds khanhAinda não há avaliações

- Tutorial 1 Discussion Document - Batch 03Documento4 páginasTutorial 1 Discussion Document - Batch 03Anindya CostaAinda não há avaliações

- Peran Dan Tugas Receptionist Pada Pt. Serim Indonesia: Disadur Oleh: Dra. Nani Nuraini Sarah MsiDocumento19 páginasPeran Dan Tugas Receptionist Pada Pt. Serim Indonesia: Disadur Oleh: Dra. Nani Nuraini Sarah MsiCynthia HtbAinda não há avaliações

- 3d Control Sphere Edge and Face StudyDocumento4 páginas3d Control Sphere Edge and Face Studydjbroussard100% (2)

- THE DOSE, Issue 1 (Tokyo)Documento142 páginasTHE DOSE, Issue 1 (Tokyo)Damage85% (20)

- Product Data Sheet For CP 680-P and CP 680-M Cast-In Firestop Devices Technical Information ASSET DOC LOC 1540966Documento1 páginaProduct Data Sheet For CP 680-P and CP 680-M Cast-In Firestop Devices Technical Information ASSET DOC LOC 1540966shama093Ainda não há avaliações

- Dell Compellent Sc4020 Deploy GuideDocumento184 páginasDell Compellent Sc4020 Deploy Guidetar_py100% (1)

- Seminar Course Report ON Food SafetyDocumento25 páginasSeminar Course Report ON Food SafetyYanAinda não há avaliações

- JM Guide To ATE Flier (c2020)Documento2 páginasJM Guide To ATE Flier (c2020)Maged HegabAinda não há avaliações

- Audi Q5: First Generation (Typ 8R 2008-2017)Documento19 páginasAudi Q5: First Generation (Typ 8R 2008-2017)roberto100% (1)

- Assignment Gen PsyDocumento3 páginasAssignment Gen PsyHelenAinda não há avaliações

- Three Comparison of Homoeopathic MedicinesDocumento22 páginasThree Comparison of Homoeopathic MedicinesSayeed AhmadAinda não há avaliações

- Brochure en 2014 Web Canyon Bikes How ToDocumento36 páginasBrochure en 2014 Web Canyon Bikes How ToRadivizija PortalAinda não há avaliações

- ITP Exam SuggetionDocumento252 páginasITP Exam SuggetionNurul AminAinda não há avaliações

- Form 4 Additional Mathematics Revision PatDocumento7 páginasForm 4 Additional Mathematics Revision PatJiajia LauAinda não há avaliações

- Case Study IndieDocumento6 páginasCase Study IndieDaniel YohannesAinda não há avaliações

- Real Estate Broker ReviewerREBLEXDocumento124 páginasReal Estate Broker ReviewerREBLEXMar100% (4)

- To Engineer Is Human: The Role of Failure in Successful DesignNo EverandTo Engineer Is Human: The Role of Failure in Successful DesignNota: 4 de 5 estrelas4/5 (137)

- Pocket Guide to Flanges, Fittings, and Piping DataNo EverandPocket Guide to Flanges, Fittings, and Piping DataNota: 3.5 de 5 estrelas3.5/5 (22)

- Oil and Gas Pipelines and Piping Systems: Design, Construction, Management, and InspectionNo EverandOil and Gas Pipelines and Piping Systems: Design, Construction, Management, and InspectionNota: 4.5 de 5 estrelas4.5/5 (16)

- Industrial Piping and Equipment Estimating ManualNo EverandIndustrial Piping and Equipment Estimating ManualNota: 5 de 5 estrelas5/5 (7)

- Structural Steel Design to Eurocode 3 and AISC SpecificationsNo EverandStructural Steel Design to Eurocode 3 and AISC SpecificationsAinda não há avaliações

- Asset Integrity Management for Offshore and Onshore StructuresNo EverandAsset Integrity Management for Offshore and Onshore StructuresAinda não há avaliações

- Machine Learning and Data Science in the Oil and Gas Industry: Best Practices, Tools, and Case StudiesNo EverandMachine Learning and Data Science in the Oil and Gas Industry: Best Practices, Tools, and Case StudiesPatrick BangertNota: 3 de 5 estrelas3/5 (2)

- Flow Analysis for Hydrocarbon Pipeline EngineeringNo EverandFlow Analysis for Hydrocarbon Pipeline EngineeringAinda não há avaliações

- Machinery Lubrication Technician (MLT) I and II Certification Exam GuideNo EverandMachinery Lubrication Technician (MLT) I and II Certification Exam GuideNota: 2 de 5 estrelas2/5 (1)

- Well Control for Completions and InterventionsNo EverandWell Control for Completions and InterventionsNota: 4 de 5 estrelas4/5 (10)

- Pipeline Integrity: Management and Risk EvaluationNo EverandPipeline Integrity: Management and Risk EvaluationNota: 4.5 de 5 estrelas4.5/5 (6)

- Hydraulic Fracturing in Unconventional Reservoirs: Theories, Operations, and Economic AnalysisNo EverandHydraulic Fracturing in Unconventional Reservoirs: Theories, Operations, and Economic AnalysisAinda não há avaliações

- Climate Adaptation Engineering: Risks and Economics for Infrastructure Decision-MakingNo EverandClimate Adaptation Engineering: Risks and Economics for Infrastructure Decision-MakingAinda não há avaliações

- Practical Reservoir Engineering and CharacterizationNo EverandPractical Reservoir Engineering and CharacterizationNota: 4.5 de 5 estrelas4.5/5 (3)

- Practical Wellbore Hydraulics and Hole Cleaning: Unlock Faster, more Efficient, and Trouble-Free Drilling OperationsNo EverandPractical Wellbore Hydraulics and Hole Cleaning: Unlock Faster, more Efficient, and Trouble-Free Drilling OperationsNota: 5 de 5 estrelas5/5 (1)

- Pile Design and Construction Rules of ThumbNo EverandPile Design and Construction Rules of ThumbNota: 4.5 de 5 estrelas4.5/5 (15)