Escolar Documentos

Profissional Documentos

Cultura Documentos

Functional Specification Diesel Fuel System PDF

Enviado por

dndudcTítulo original

Direitos autorais

Formatos disponíveis

Compartilhar este documento

Compartilhar ou incorporar documento

Você considera este documento útil?

Este conteúdo é inapropriado?

Denunciar este documentoDireitos autorais:

Formatos disponíveis

Functional Specification Diesel Fuel System PDF

Enviado por

dndudcDireitos autorais:

Formatos disponíveis

SHELL PETROLEUM DEVELOPMENT COMPANY

OF NIGERIA LIMITED

CONCEPTUAL DESIGN FOR CAWTHORNE CHANNEL GAS

INJECTION / SUPPLY PROJECT

FUNCTIONAL SPECIFICATION FOR

DIESEL FUEL SYSTEMS

B1 15.09.99 ISSUED FOR EPC TENDER J .B. NITZSCHE F. J . SHAW E. A. AKINSIPE T. DU-FRAYER

A3 05.07.99 RELEASED A. LENEVEU A. LENEVEU P. KERGUSTANC E. W. OBOTT

A2 17.05.99 RE-ISSUED FOR COMMENT A. LENEVEU A. LENEVEU P. KERGUSTANC E. W. OBOTT

A1 14.04.99 ISSUE FOR COMMENT A. LENEVEU A. LENEVEU P. KERGUSTANC E. W. OBOTT

R1 06.04.99 ISSUE FOR IDC A. LENEVEU A. LENEVEU P. KERGUSTANC E. W. OBOTT

REV DATE REASON FOR ISSUE PREPARED CHECKED APPROVED APPROVED

NETCO/TECHNIP GEOPRODUCTION

NTPG

DISCIPLINE

ENGINEER

DISCIPLINE

CHECK

PROJ ECT

MANAGER

QA

2 AJ OSE ADEOGUN STREET

PO BOX 74173 VICTORIA ISLAND

LAGOS

SPDC APPROVAL SIGNATURE:

CONTRACT NUMBER E-06501 Document No.: CCH-SF-P-009 REV B1

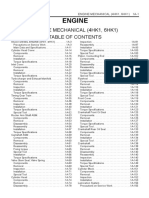

FUNCTIONAL SPECIFICATION FOR DIESEL FUEL SYSTEMS

CCHSFP009B1 Page 2 of 5 Revision B1

TABLE OF CONTENTS

1.0 GENERAL

2.0 PROCESS DESCRIPTION

3.0 SYSTEM LIMITS AND INTERFACES

4.0 RELIEF AND BLOWDOWN

5.0 PERFORMANCE REQUIREMENTS

6.0 INSTRUMENTATION AND ELECTRICAL

7.0 MATERIAL REQUIREMENTS

FUNCTIONAL SPECIFICATION FOR DIESEL FUEL SYSTEMS

CCHSFP009B1 Page 3 of 5 Revision B1

1.0 GENERAL

1.1 Introduction

This specification describes the functional requirements for the Diesel

Systems for the Cawthorne Channel Gas Injection/Supply Project for Shell

Petroleum Development Company of Nigeria Ltd. (SPDC). It shall be read in

conjunction with the documents and drawings referenced in Sections 1.2

below and the codes, standards and specifications referenced therein.

Diesel systems are required to provide fuel to the new Awoba and Cawthorne

Channel gas plants emergency diesel generators.

The diesel system shall include the following equipment:

Awoba Cawthorne Channel

Diesel Strainer AWGP-S-6201 CCGP-S-6201

Diesel Storage Tank, AWGP-T-6201 CCGP-T-6201

Diesel Transfer Pumps, AWGP-P-6201 A/B CCGP-P-6201 A/B

1.2 Reference Documents

SPDC Specifications

SPDCE-AGP-001 DEP and SPDC Standards to be used for AG Projects

SPDCE-AGP-009 Common Design Philosophy

Project Specifications/Documents

CCH-SP-M-001 Unfired Pressure Vessels

CCH-SP-M-008 Centrifugal Pumps

Utility Engineering Flow Schemes

AWGP-DW-P-313 Awoba GP Diesel Fuel System

CCGP-DW-P-313 Cawthorne Channel GP Diesel Fuel System

2.0 PROCESS DESCRIPTION

The function of the diesel supply system is to provide pumping and storage

facilities for sufficient quantity of diesel fuel such that replenishment is

required only on an infrequent basis. Details of the system requirements are

shown on the UFS and UEFS referenced in Section 1.2.

The diesel system shall supply diesel to the Emergency Diesel Power

Generator Package.

There will be no diesel treatment facilities at the new gas plants as the diesel

should be supplied by barge free of water. Prior to transfer of diesel from a

barge, the barge diesel tanks should be sampled. Transfer of diesel from a

barge shall only commence when the samples confirm that the diesel is

water free. In addition, the diesel storage tank should be sampled several

FUNCTIONAL SPECIFICATION FOR DIESEL FUEL SYSTEMS

CCHSFP009B1 Page 4 of 5 Revision B1

hours after delivery to check for any settled water in the diesel. If water is

found in the tank, it should be drained off.

Diesel shall be pumped from the Diesel Storage Tank to the emergency

power generator by one of the two (one duty, one stand-by) Diesel Transfer

Pumps. The diesel transfer pump shall be started/stopped manually as

required to keep the emergency power generator diesel day tank full.

The diesel storage tank shall be sized to contain sufficient fuel to permit the

emergency generator to run continuously for at least two weeks at full load.

The following working volumes are indicative only:

Awoba 25 m

3

Cawthorne Channel 50 m

3

3.0 SYSTEM LIMITS & INTERFACES

The limits for the diesel system (excluding drain connections) are given

below:

Quick release hose coupling to the Diesel Storage Tank

Outlet to the emergency generator diesel day tank.

Outlet to the non-hazardous open drains header.

The diesel day tank for the emergency generator is a part of that package

and does not form part of the diesel system.

Site conditions are described in Common Design Philosophy No. SPDCE-

AGP-009.

4.0 RELIEF AND BLOWDOWN

There are no requirements for the Diesel System to be connected to either

the LP or HP flare systems

Diesel Storage Tank will be vented locally to a safe location via a vermin trap

and flame arrestor.

5.0 PERFORMANCE REQUIREMENTS

The minimum performance requirement for the diesel supply system are as

follows;

Provide a reliable fuel supply to the emergency generator, at least

sufficient to run the emergency generator for 14 days at full load.

Provide pumping capacity allowing to fill the emergency generator daily

tank in less than 5 minutes.

Strainer filtration, at inlet of Diesel Storage Tank shall be in line with diesel

engine requirements.

FUNCTIONAL SPECIFICATION FOR DIESEL FUEL SYSTEMS

CCHSFP009B1 Page 5 of 5 Revision B1

6.0 INSTRUMENTATION AND ELECTRICAL

The instrumentation requirements are shown on the various UEFSs

referenced in Section 1.2.

Diesel storage tank level will be transmitted to the control room for monitoring

and alarm purposes.

The diesel transfer pumps shall be provided with stop/start push buttons

located adjacent to the pumps.

7.0 MATERIAL REQUIREMENTS

The materials for all equipment within the diesel system should be the

Vendor's standard materials, but as a minimum shall conform with the

following:

MINIMUM MATERIAL REQUIREMENTS

Component

Material

Corrosion

Allowance

(mm)

Diesel Storage Tank Carbon Steel +internal lining 1.0

Diesel Transfer Pumps API 610 Code S.1

Piping (Note 1): Carbon Steel 1.0

Notes:

1. For full details of piping material requirements, see the Project Specification

for Piping and Valve Materials, CCGP-SP-L-001 and the UEFS referenced in

Section 1.2.

Você também pode gostar

- Brutus Service ManualDocumento631 páginasBrutus Service ManualThomas Porter78% (9)

- Off LeakDocumento26 páginasOff LeakPatriciaH20Ainda não há avaliações

- Diesel Generator Specs For 625 KVA & 250 KVADocumento18 páginasDiesel Generator Specs For 625 KVA & 250 KVAAbhinav TewariAinda não há avaliações

- Coal Fired Power Plant Project ProposalDocumento5 páginasCoal Fired Power Plant Project Proposalsugeng ubel100% (1)

- Cat C15 Specifications PDFDocumento30 páginasCat C15 Specifications PDFdiony182Ainda não há avaliações

- 32.29.20.10-Gen Safeguarding and Instrumented Protective Functions For Rotating EquipmentDocumento42 páginas32.29.20.10-Gen Safeguarding and Instrumented Protective Functions For Rotating EquipmentPrajeeth Ganesh MosuriAinda não há avaliações

- Cat 3406 Genset Specs enDocumento6 páginasCat 3406 Genset Specs enAndrei Bleoju80% (5)

- Bill of Material: Top ViewDocumento1 páginaBill of Material: Top ViewSudar Wanto100% (1)

- ABS FloatingOffshoreLNGGuideDocumento352 páginasABS FloatingOffshoreLNGGuideMarcelAinda não há avaliações

- 02.design Basis - Design Philosophy PDFDocumento20 páginas02.design Basis - Design Philosophy PDFshareyhouAinda não há avaliações

- Rigging Safety in Cranes PDFDocumento170 páginasRigging Safety in Cranes PDFLuis AcuaAinda não há avaliações

- MB Powertrain Truck VI 2021Documento37 páginasMB Powertrain Truck VI 2021jamesAinda não há avaliações

- Operations Manual: Emergency Diesel GeneratorDocumento14 páginasOperations Manual: Emergency Diesel GeneratorJevgenij ChupinAinda não há avaliações

- Check List - Air Compressor InspectionDocumento1 páginaCheck List - Air Compressor Inspectiondndudc100% (4)

- 54 Desmi PumpsDocumento323 páginas54 Desmi PumpsTejeshwar SinghAinda não há avaliações

- Nissan EMDocumento423 páginasNissan EMStephen Samuel Jr.Ainda não há avaliações

- Operation Manning PhilosophyDocumento2 páginasOperation Manning Philosophymohamad hafizAinda não há avaliações

- Study of Breakwaters Constructed With One Layer of Armor Stone PDFDocumento58 páginasStudy of Breakwaters Constructed With One Layer of Armor Stone PDFdndudcAinda não há avaliações

- Commissioning Work Permit GuidelineDocumento30 páginasCommissioning Work Permit GuidelineDion Alfred EucogcoAinda não há avaliações

- DayDiesel - TWD 740 GEDocumento2 páginasDayDiesel - TWD 740 GEMuhammad rizki100% (2)

- Isuzu 4H6H - Mecha - enDocumento177 páginasIsuzu 4H6H - Mecha - enJose nildo lobato Mendes MendesAinda não há avaliações

- Izombe Pareto Analysis Report 2016Documento88 páginasIzombe Pareto Analysis Report 2016Wariebi Oghene Lawani100% (1)

- 5 - Technical Specifications For Sand & Murrum Filling Works - Pile Foundation For Tanks - ParadeepDocumento21 páginas5 - Technical Specifications For Sand & Murrum Filling Works - Pile Foundation For Tanks - ParadeepArup NathAinda não há avaliações

- Operation and Maintenance Instructions Manual: Ju/Jw Model Engines FOR Fire Pump ApplicationsDocumento38 páginasOperation and Maintenance Instructions Manual: Ju/Jw Model Engines FOR Fire Pump ApplicationsangelvhAinda não há avaliações

- Diesel PP SpecsDocumento19 páginasDiesel PP SpecsMico AndresAinda não há avaliações

- 0909-GS-R-TA-12002 - A1 - LP, MP Gas Compressors Tag No. 923XT001A-B - Instrument I-O ScheduleDocumento18 páginas0909-GS-R-TA-12002 - A1 - LP, MP Gas Compressors Tag No. 923XT001A-B - Instrument I-O SchedulechuminhAinda não há avaliações

- CHT BIP Shell Best Practice - MasterplanningDocumento27 páginasCHT BIP Shell Best Practice - MasterplanningRAJEEVKANNATTMUKUNDAAinda não há avaliações

- Volvo Penta D12-Short SpecDocumento4 páginasVolvo Penta D12-Short Speczulu800% (1)

- Ras Markaz Crude Oil Park Project (Phase1)Documento37 páginasRas Markaz Crude Oil Park Project (Phase1)ANIL PLAMOOTTILAinda não há avaliações

- Atlas Copco - Marine - SolutionsDocumento88 páginasAtlas Copco - Marine - SolutionsCuong TranHung0% (1)

- Dep 31.38.01.13-Compilation of Bill of Material For Piping IsometricsDocumento12 páginasDep 31.38.01.13-Compilation of Bill of Material For Piping Isometricssudeep9666Ainda não há avaliações

- DEP 33655031-TSO, V44 Feb 2020Documento54 páginasDEP 33655031-TSO, V44 Feb 2020Cherd KeereesantikulAinda não há avaliações

- Plant Commissioning Start Up ProcedureDocumento100 páginasPlant Commissioning Start Up Proceduremsaad292% (124)

- Functional Specification Export Gas Compressor PDFDocumento7 páginasFunctional Specification Export Gas Compressor PDFdndudcAinda não há avaliações

- Functional Specification Export Gas Compressor PDFDocumento7 páginasFunctional Specification Export Gas Compressor PDFdndudcAinda não há avaliações

- VDO Diesel IAM Roadmap Q1 2019 Update ENDocumento15 páginasVDO Diesel IAM Roadmap Q1 2019 Update ENsilverdollarAinda não há avaliações

- Section 3 - Technical PackageDocumento39 páginasSection 3 - Technical PackageMohsin RazaAinda não há avaliações

- Quay Construction With Concrete Caisson PDFDocumento5 páginasQuay Construction With Concrete Caisson PDFdndudcAinda não há avaliações

- Construction of DieselDocumento63 páginasConstruction of Dieselryan fernandez100% (1)

- P2986-MRP-002 (Dec 12)Documento52 páginasP2986-MRP-002 (Dec 12)tvpham123Ainda não há avaliações

- FCM Bombas Manuais PDFDocumento76 páginasFCM Bombas Manuais PDFDaniel VieiraAinda não há avaliações

- KKS Plant TaggingDocumento6 páginasKKS Plant TaggingIshwar Alt100% (1)

- Complete O&M Management System - Rev 10 Jan 02 2015Documento569 páginasComplete O&M Management System - Rev 10 Jan 02 2015Farrukh MajeedAinda não há avaliações

- Construction Presentation - Container Terminal PDFDocumento60 páginasConstruction Presentation - Container Terminal PDFdndudc100% (1)

- Construction of LPG ShipsDocumento41 páginasConstruction of LPG ShipsElena100% (1)

- Quality Procedure Technical Queries PDFDocumento7 páginasQuality Procedure Technical Queries PDFdndudc100% (2)

- Commissioning and Progress System IntegratedDocumento19 páginasCommissioning and Progress System IntegratedvrajakisoriDasiAinda não há avaliações

- Quay Wall Construction PDFDocumento8 páginasQuay Wall Construction PDFdndudcAinda não há avaliações

- Field Instrument List V1 R1Documento12 páginasField Instrument List V1 R1sudhansu8beheraAinda não há avaliações

- Anchor Handling Tug Pre-Mob InspectionDocumento8 páginasAnchor Handling Tug Pre-Mob Inspectiondndudc100% (1)

- Offshore Pipelaying Dynamic PDFDocumento150 páginasOffshore Pipelaying Dynamic PDFdndudcAinda não há avaliações

- Iami Section A - Motor EkDocumento9 páginasIami Section A - Motor Ekstelios0% (1)

- 2017-04-07 - Guidance For Fuel Oil Monitoring - Rev06Documento10 páginas2017-04-07 - Guidance For Fuel Oil Monitoring - Rev06joujoukos kritikosAinda não há avaliações

- RP 158 PDFDocumento40 páginasRP 158 PDFDeependra SinghAinda não há avaliações

- EIL Shedule of Rates ENQ - REV0Documento20 páginasEIL Shedule of Rates ENQ - REV0kotiAinda não há avaliações

- Gas &HFO Based Power Plant Desing Info Study PDFDocumento63 páginasGas &HFO Based Power Plant Desing Info Study PDFmgkvprAinda não há avaliações

- 3115-BWK-PRQ-021.5 Lube Oil Cleaning Procedure - B1Documento16 páginas3115-BWK-PRQ-021.5 Lube Oil Cleaning Procedure - B1Dannis AnantoAinda não há avaliações

- Offshore Book 2010Documento117 páginasOffshore Book 2010Mos Woraphon100% (1)

- Construction Quality ManualDocumento42 páginasConstruction Quality ManualBob Madlener100% (7)

- EPA-600-2-85-106 Evaluation of The Efficiency of Industrial Flares: Flare Head Design and Gas CompositionDocumento140 páginasEPA-600-2-85-106 Evaluation of The Efficiency of Industrial Flares: Flare Head Design and Gas CompositionkrcomeyAinda não há avaliações

- BL 1649 US Chemical Injection For Oil and Gas Tcm11-7888Documento12 páginasBL 1649 US Chemical Injection For Oil and Gas Tcm11-7888Veera ManiAinda não há avaliações

- Volume 1 - General - V1-CH05-Process Design Basis Rev1Documento13 páginasVolume 1 - General - V1-CH05-Process Design Basis Rev1MohamedAinda não há avaliações

- Critical Path Method (CPM) in Project ManagementDocumento11 páginasCritical Path Method (CPM) in Project ManagementdndudcAinda não há avaliações

- 55117-EnI-SF-SA-PA-301-01-Supply Specification For Diesel Engine Driven Firewater Pump PA 1100 ADocumento20 páginas55117-EnI-SF-SA-PA-301-01-Supply Specification For Diesel Engine Driven Firewater Pump PA 1100 ASihem GhamlouliAinda não há avaliações

- Ea 001Documento101 páginasEa 001Momchil PekovAinda não há avaliações

- NPCIL Diesel PumpDocumento66 páginasNPCIL Diesel PumpKg SubramanianAinda não há avaliações

- GFDP COM 52 TEL SP GE 006 Specification For PublicDocumento24 páginasGFDP COM 52 TEL SP GE 006 Specification For PublicHaider HassanAinda não há avaliações

- Oisd STD 144 PDFDocumento133 páginasOisd STD 144 PDFRADHAMADHABA SAHANI0% (1)

- Arl Internship ReportDocumento19 páginasArl Internship ReportChaudhry RashidAinda não há avaliações

- Lco Tank Relief Valve (2016.04.11.) - For ApprovalDocumento87 páginasLco Tank Relief Valve (2016.04.11.) - For ApprovalEnoch TwumasiAinda não há avaliações

- ESD DiscussionDocumento4 páginasESD DiscussionNazim SalehAinda não há avaliações

- Belzona 1831 Instruction For UseDocumento2 páginasBelzona 1831 Instruction For UseshambhoiAinda não há avaliações

- DME As Alternative Gas Turbine FuelDocumento3 páginasDME As Alternative Gas Turbine FuelJacob RobinsonAinda não há avaliações

- FF Design and Project ExecutionDocumento24 páginasFF Design and Project ExecutionDuan QingBinAinda não há avaliações

- FW Visbreaker HeatersDocumento5 páginasFW Visbreaker HeatersZita MoreiraAinda não há avaliações

- Livening Up NotesDocumento1 páginaLivening Up NotesAceel FitchAinda não há avaliações

- Fuel System-4Documento23 páginasFuel System-4Gian Carlo RamirezAinda não há avaliações

- Petronas Pressol: Premium Grade Air Compressor OilsDocumento1 páginaPetronas Pressol: Premium Grade Air Compressor OilsMujeeb SiddiqueAinda não há avaliações

- Conversion of CNG, Liter To KGDocumento1 páginaConversion of CNG, Liter To KGเสกสรรค์ จันทร์สุขปลูกAinda não há avaliações

- 2240s PDFDocumento100 páginas2240s PDFHenry MoralesAinda não há avaliações

- ERD-00-02 Technical Authorisies System.Documento23 páginasERD-00-02 Technical Authorisies System.kattabommanAinda não há avaliações

- Indian Oil & GasDocumento15 páginasIndian Oil & GasMeena HarryAinda não há avaliações

- SP 2041 V0 (Specification For Selection of Cracking Resistant Materials For H2S Containing Enviro)Documento10 páginasSP 2041 V0 (Specification For Selection of Cracking Resistant Materials For H2S Containing Enviro)Quality IA FLOWAinda não há avaliações

- 1221 - 1010KVA DG Set SpecificationDocumento36 páginas1221 - 1010KVA DG Set SpecificationKhiem Le100% (1)

- Fuel Oil SystemDocumento14 páginasFuel Oil Systemcherrym805Ainda não há avaliações

- Application Note Cummins PT Fuel SystemsDocumento10 páginasApplication Note Cummins PT Fuel Systemsref.mtu.533Ainda não há avaliações

- Cathodic Protection 2007Documento141 páginasCathodic Protection 2007arsssyAinda não há avaliações

- Primavera (P6)Documento316 páginasPrimavera (P6)Abde Ali83% (6)

- Behaviour of Reinforced Earth Behind Quay Walls PDFDocumento9 páginasBehaviour of Reinforced Earth Behind Quay Walls PDFdndudcAinda não há avaliações

- Metode Konstruksi Reklamasi PantaiDocumento55 páginasMetode Konstruksi Reklamasi PantaiHosea Luahambowo100% (1)

- Study of Reflection of New Low-Reflectivity Quay Wall Caisson PDFDocumento11 páginasStudy of Reflection of New Low-Reflectivity Quay Wall Caisson PDFdndudcAinda não há avaliações

- Gasoline Direct Injection - 2Documento14 páginasGasoline Direct Injection - 2Umar HayatAinda não há avaliações

- EN DX300LC-7 Brochure D4600650 01-2020 LowResDocumento28 páginasEN DX300LC-7 Brochure D4600650 01-2020 LowResمحمود المستكاويAinda não há avaliações

- Engine Data Sheet: CFP83-F10, F20, F30 2218 G Drive 26110 Cummins Fire Power FR - 90242, 90243Documento6 páginasEngine Data Sheet: CFP83-F10, F20, F30 2218 G Drive 26110 Cummins Fire Power FR - 90242, 90243Reynaldo MarianoAinda não há avaliações

- DG Maintenance PlanDocumento2 páginasDG Maintenance PlanYasir Mehmood100% (1)

- Deutz F6L914 - 02931400 - 04234638 - 04236676 - Deutz 914 Series - Construction and Industrial Diesel Engine - 62-85kW - Engine FamilyDocumento8 páginasDeutz F6L914 - 02931400 - 04234638 - 04236676 - Deutz 914 Series - Construction and Industrial Diesel Engine - 62-85kW - Engine FamilyAnugrah RamadhanAinda não há avaliações

- Section 1F3 Diesel Engine ControlsDocumento30 páginasSection 1F3 Diesel Engine ControlsAnonymous wpUyixsjAinda não há avaliações

- Valve Failure Clues Read em and WeepDocumento5 páginasValve Failure Clues Read em and WeepahmedalgaloAinda não há avaliações

- HYW-20 T5: Generating RatesDocumento12 páginasHYW-20 T5: Generating RatesRagowo Tri WicaksonoAinda não há avaliações

- Waste Plastic To Diesel Oil Plant - Making Diesel From PlasticDocumento8 páginasWaste Plastic To Diesel Oil Plant - Making Diesel From PlasticRaju GummaAinda não há avaliações

- Lab ReportDocumento14 páginasLab ReportHammad Hassan100% (5)

- S 60 MCC 8Documento407 páginasS 60 MCC 8tayzar LynnAinda não há avaliações

- Fillrite PDFDocumento17 páginasFillrite PDFpanagosAinda não há avaliações

- Pipe 4Documento19 páginasPipe 4Mark AllenAinda não há avaliações

- Doosan Engine De12 Operation Maintenance Manual 2012Documento10 páginasDoosan Engine De12 Operation Maintenance Manual 2012patricia100% (21)

- Canter 3 5 FE84DDocumento4 páginasCanter 3 5 FE84DShahul Hameed Jawahar100% (2)

- Power and Propulsion PDFDocumento13 páginasPower and Propulsion PDFahmedalgaloAinda não há avaliações

- Rss 120-m Recycling Shredder Screener Brochure Ppb-1480-00-En PDFDocumento8 páginasRss 120-m Recycling Shredder Screener Brochure Ppb-1480-00-En PDFamolsinha1Ainda não há avaliações

- Espec Tecnica MAN 440HP@1800 RPMDocumento3 páginasEspec Tecnica MAN 440HP@1800 RPMjoroma58Ainda não há avaliações

- Cummins Qsz13-g10 Spare PartsDocumento2 páginasCummins Qsz13-g10 Spare PartsIbrahim YunusAinda não há avaliações