Escolar Documentos

Profissional Documentos

Cultura Documentos

Proyecto X Roja PDF

Enviado por

adry220490Descrição original:

Título original

Direitos autorais

Formatos disponíveis

Compartilhar este documento

Compartilhar ou incorporar documento

Você considera este documento útil?

Este conteúdo é inapropriado?

Denunciar este documentoDireitos autorais:

Formatos disponíveis

Proyecto X Roja PDF

Enviado por

adry220490Direitos autorais:

Formatos disponíveis

Statistical Engineering Apprentice Training

CTIS # 20306

Version Date: 07-20-07

Statistical Engineering

Introduction

Statistical Engineering

Introduction

1-1

Statistical Engineering Apprentice Training

CTIS # 20306

Version Date: 07-20-07

Learning Objectives

At the end of this course the participant will

understand:

Red X Terms

The Importance of Strategic Thinking

How to Use Apprentice Level Red X Tools

1-2

Statistical Engineering Apprentice Training

CTIS # 20306

Version Date: 07-20-07

History Overview

Dorian Shainin (1940s)

Shainin Consulting (1970s)

GM & Shainin Relationship (1980s)

GMs Red X Strategies (2000)

Statistical Engineering (2003)

1-3

Statistical Engineering Apprentice Training

CTIS # 20306

Version Date: 07-20-07

Red X Strategies vs. Traditional Problem Solving

Quality Network

5 Whys

Fishbone

DFSS

Advanced Reliability

Methods

Brainstorming

Go Fast

Taguchi

Others

Red X Strategies

1-4

Statistical Engineering Apprentice Training

CTIS # 20306

Version Date: 07-20-07

Red X Strategies IS NOT FINDING WAYS TO FIX

PROBLEMS!

Any competent repairman can do that.

Red X Strategies IS GAINING AN

UNDERSTANDING OF HOW PROBLEMS REALLY

WORK!

With this level of understanding the fix becomes an

economic decision.

1-5

Statistical Engineering Apprentice Training

CTIS # 20306

Version Date: 07-20-07

What Can Red X Do for Me?

Interpreting the Response

If its not simple, its wrong.

Albert Einstein

1-6

Statistical Engineering Apprentice Training

CTIS # 20306

Version Date: 07-20-07

Red X Strategy Overview

The Guiding Principles of Red X Strategies Are:

Understand the physical world Learn how

the world is organized to develop efficient

strategies

Talk to the system Look for contrast and

leverage

Progressive search Start with an open mind

and throw out those things which do not fit

the clues

Keep it simple

1-7

Statistical Engineering Apprentice Training

CTIS # 20306

Version Date: 07-20-07

What Can Red X Do for Me?

Discipline fact based

Logic progressive convergence

Focused Pareto driven

Small Sample Size knowledge from extremes

Confidence statistically based

Always make good decisions!

Simple Understanding!

1-8

Statistical Engineering Apprentice Training

CTIS # 20306

Version Date: 07-20-07

What Red X Is Not?

Red X Strategies is not a new way of thinking

Red X is NOT for the obvious

1-9

Statistical Engineering Apprentice Training

CTIS # 20306

Version Date: 07-20-07

Where does Red X Strategies Fit in GM?

Seven Diamonds Process

Is the correct PRODUCTION PROCESS being

followed?

Are the correct PRODUCTION TOOLS being

used?

Are the correct PARTS being used?

Are the PARTS TO SPECIFICATION?

Is there VARIATION?

Is a DESIGN CHANGE required?

Is this an EXTREMELY COMPLEX

PROBLEM?

1

2

3

4

5

6

7

Red X

Strategies

(Design change not required)

(Mean shift)

Check

the

Obvious

1-10

Statistical Engineering Apprentice Training

CTIS # 20306

Version Date: 07-20-07

The Importance of Understanding the

Physical World

Lawn Mower Example

Situation Description:

Saturday morning

Beautiful weather

Must mow the lawn

Take lawnmower out of garage

Pull the cord the lawnmower will not start

Now what?

1-11

Statistical Engineering Apprentice Training

CTIS # 20306

Version Date: 07-20-07

Thanks for coming over everyone. I have my

lapt op and flipchart so t hat we can jump right

int o t his issue of why my lawnmower wont

st art .

Id like t o brainst orm as many causes as we can

t hink of. Then we can choose t he most likely

reason and work on t hat first .

Whod like t o be t he scribe?

Would You Do This At Home?

1-12

Statistical Engineering Apprentice Training

CTIS # 20306

Version Date: 07-20-07

Where Do You Start? With a Best Guess?

Lawnmower

Won't Start

SPARK COMPRESS

FUEL

POWER

TRANSMISSION

STARTER

SYSTEM

Fuel valve

OFF

Throttle lever

in wrong

position

Fuel Controls

Out of fuel

Bad fuel

Plug fouled

Plug

improperly

gapped.

Plug's

insulator

cracked

Engine flooded

Fuel filter

clogged

Fuel line clogged

or pinched

Carburetor

malfunction

Ignition

malfunction

(magneto)

AIR

Valves stuck

Mower deck clogged

Air filter clogged

Blades loose, bent, damaged

Bent crankshaft

Rings Worn

Cracked block

Water in

ignition system

Head Leak

Valves stuck

Mower too low

Pull cord

damaged/

snagged

Bearings damaged

No oil in

crankcase

Cracked

wire

A Cause-Effect Diagram for Faulty

Lawnmowers

1-13

Statistical Engineering Apprentice Training

CTIS # 20306

Version Date: 07-20-07

How Do We Typically Fix Problems?

Try Something and Wait

Do What Has Been Done in the Past

Do What the Experts Say

Brainstorm

Develop a Fishbone Diagram

Have a Meeting and Vote

Change the Design

Attribute It to Normal Variation

Assign a Task Force

Do a Deep Dive

Dont Tell Anyone

Blame the Supplier

Just Do Something

1-14

Statistical Engineering Apprentice Training

CTIS # 20306

Version Date: 07-20-07

?Fuel/Air

?Compression

?Spark

The Lawnmower Wont Start

How can you start to fix a lawnmower if you do

not understand how it works?

1-15

Statistical Engineering Apprentice Training

CTIS # 20306

Version Date: 07-20-07

Key Concepts and Definitions

Lawnmower Example Asking the Right Questions

Lawnmower

Won't Start

SPARK COMPRESS

FUEL

POWER

TRANSMISSION

STARTER

SYSTEM

Fuel valve

OFF

Throttle lever

in wrong

position

Fuel Controls

Out of fuel

Bad fuel

Plug fouled

Plug

improperly

gapped.

Plug's

insulator

cracked

Engine flooded

Fuel filter

clogged

Fuel line clogged

or pinched

Carburetor

malfunction

Ignition

malfunction

(magneto)

AIR

Valves stuck

Mower deck clogged

Air filter clogged

Blades loose, bent, damaged

Bent crankshaft

Rings Worn

Cracked block

Water in

ignition system

Head Leak

Valves stuck

Mower too low

Pull cord

damaged/

snagged

Bearings damaged

No oil in

crankcase

Cracked

wire

Does the blade turn when pulling on pull cord? YES!

Does the engine start with the air filter off? NO!

Do you feel air pressure with your finger on the

spark plug hole? YES!

Did the spark plug terminal arc when attached to its

wire? YES!

Is there gasoline in the fuel tank? YES!

Statistical Engineering

1-16

Statistical Engineering Apprentice Training

CTIS # 20306

Version Date: 07-20-07

Red X Process

Simple Understanding

1. Listen to the customer

2. Observe the failure

3. Measure the contrast

4. Converge to the major influence

5. Confirmthe major influence

6. Implement control

1-17

Statistical Engineering Apprentice Training

CTIS # 20306

Version Date: 07-20-07

1. Air

2. Flame

3. Propane

1. Air

2. Propane

3. Flame

We Must Understand

The physical world requires you to understand

how it is organized if you are to work with it

Thinking about the world in terms of physics

helps one understand that various combinations

of the same inputs can have quite different

results:

1-18

Statistical Engineering Apprentice Training

CTIS # 20306

Version Date: 07-20-07

The greatest obstacle to discovery

is not ignorance

- it is the illusion of knowledge

Daniel Boorstin

Former Librarian of Congress

1-19

Statistical Engineering Apprentice Training

CTIS # 20306

Version Date: 07-20-07

Notes

1-20

Statistical Engineering Apprentice Training

CTIS # 20306

Version Date: 07-20-07

Red X Terminology

Red X Terminology

2-1

Statistical Engineering Apprentice Training

CTIS # 20306

Version Date: 07-20-07

Red X Terminology

Pareto

Green Y

BOB and WOW

Red X

Defect

Event

Feature

Contrast

Leverage

2-2

Statistical Engineering Apprentice Training

CTIS # 20306

Version Date: 07-20-07

Vilfredo Pareto

1848 - 1923

The Pareto Principle

20% of our problems account for 80% of the

cost

20% of our problems account for 80% of

customer complaints

Separates the vital few from the trivial many

Even if we have many problems, we must first

focus on the vital few that will provide the best

return on investment

2-3

Statistical Engineering Apprentice Training

CTIS # 20306

Version Date: 07-20-07

Lotus Notes Pareto

You cannot send e-mail messages because your

inbox exceeds its storage limit. Which messages

do you delete to free up space?

2-4

Statistical Engineering Apprentice Training

CTIS # 20306

Version Date: 07-20-07

Pareto of Lotus Notes Inbox Message Sizes

0

500,000

1,000,000

1,500,000

2,000,000

2,500,000

3,000,000

3,500,000

4,000,000

4,500,000

P

O

L

I

C

Y

N

O

T

I

F

I

C

A

T

I

O

N

R

e

d

X

I

n

p

u

t

C

l

u

t

c

h

A

s

s

e

m

b

l

y

T

P

S

C

o

m

m

u

n

i

c

a

t

i

o

n

T

P

S

T

h

i

n

k

i

n

g

P

r

o

j

e

c

t

M

a

i

l

C

o

d

e

s

U

n

t

i

t

l

e

d

R

e

v

i

s

e

d

P

y

r

a

m

i

d

T

u

r

b

i

n

e

S

h

e

l

l

C

o

s

t

f

o

r

R

e

d

X

C

l

a

s

s

T

P

S

P

e

r

f

o

r

m

a

n

c

e

S

u

m

m

a

r

y

C

P

I

T

S

u

r

v

e

y

R

e

s

u

l

t

s

4

T

6

5

P

r

o

j

e

c

t

L

i

s

t

C

P

I

T

P

r

o

j

e

c

t

L

i

s

t

4

T

6

5

P

r

o

j

e

c

t

L

i

s

t

J

.

D

.

P

o

w

e

r

T

r

a

c

k

i

n

g

S

t

u

d

y

N

e

w

P

r

o

j

e

c

t

S

u

b

m

i

s

s

i

o

n

P

r

o

c

e

s

s

D

O

E

D

a

t

a

&

G

r

a

p

h

s

B

o

r

e

#

4

S

t

u

c

k

V

o

l

v

o

N

o

i

s

e

Message Subject Title

M

e

s

s

a

g

e

S

i

z

e

(

b

y

t

e

s

)

Which message would you delete?

Lotus Notes Pareto

2-5

Statistical Engineering Apprentice Training

CTIS # 20306

Version Date: 07-20-07

Pareto

JD Power for GMNA

0.00

2.00

4.00

6.00

8.00

10.00

12.00

14.00

16.00

18.00

G

M

T

8

0

0

C

a

v

a

l

i

e

r

S

a

t

u

r

n

-

S

S

e

r

i

e

s

G

M

T

8

8

0

G

r

a

n

d

P

r

i

x

M

/

L

V

a

n

G

M

T

3

3

0

-

B

l

a

z

e

r

/

J

i

m

m

y

/

B

r

a

v

a

d

a

I

m

p

a

l

a

S

u

n

f

i

r

e

A

l

e

r

o

M

o

n

t

e

C

a

r

l

o

Vehicle Line

V

o

l

u

m

e

W

e

i

g

h

t

e

d

P

P

H

I

m

p

a

c

t

Where should GM focus its resources?

2-6

Statistical Engineering Apprentice Training

CTIS # 20306

Version Date: 07-20-07

Pareto

Breakdown of GMT 800

0.0

1.0

2.0

3.0

4.0

5.0

6.0

7.0

8.0

9.0

10.0

W

i

n

d

n

o

i

s

e

O

t

h

e

r

s

e

a

t

p

r

o

b

l

e

m

s

I

n

s

t

r

u

m

e

n

t

p

a

n

e

l

/

d

a

s

h

b

o

a

r

d

G

a

p

s

/

p

o

o

r

f

i

t

O

t

h

e

r

s

o

u

n

d

s

y

s

t

e

m

p

r

o

b

l

e

m

s

E

n

g

i

n

e

l

a

c

k

s

p

o

w

e

r

S

t

e

e

r

i

n

g

s

y

s

t

e

m

n

o

i

s

e

s

A

i

r

c

o

n

d

i

t

i

o

n

e

r

d

o

e

s

n

'

t

g

e

t

c

o

l

d

B

r

a

k

e

s

d

o

n

'

t

h

a

v

e

e

n

o

u

g

h

s

t

o

p

p

i

n

g

M

o

l

d

i

n

g

l

o

o

s

e

E

n

g

i

n

e

r

e

q

'

d

u

n

s

c

h

e

d

u

l

e

d

r

e

p

a

i

r

s

:

F

a

n

/

b

l

o

w

e

r

n

o

i

s

y

B

r

a

k

e

p

e

d

a

l

r

e

q

u

i

r

e

s

t

o

o

m

u

c

h

e

f

f

o

r

t

C

a

r

p

e

t

F

o

l

d

i

n

g

r

e

a

r

s

e

a

t

d

o

e

s

n

o

t

w

o

r

k

T

r

a

n

s

m

i

s

s

i

o

n

f

l

u

i

d

l

e

a

k

s

C

e

n

t

e

r

c

o

n

s

o

l

e

S

i

d

e

w

i

n

d

o

w

H

e

a

t

e

r

n

o

t

w

o

r

k

i

n

g

p

r

o

p

e

r

l

y

M

a

n

u

a

l

g

e

a

r

s

h

i

f

t

h

a

r

d

t

o

o

p

e

r

a

t

e

I

n

s

t

r

u

m

e

n

t

p

a

n

e

l

l

i

g

h

t

s

d

o

n

'

t

w

o

r

k

P

o

o

r

h

a

n

d

l

i

n

g

s

t

a

b

i

l

i

t

y

F

r

o

n

t

d

e

f

r

o

s

t

e

r

p

r

o

b

l

e

m

S

t

e

e

r

i

n

g

s

y

s

t

e

m

l

e

a

k

s

C

D

p

l

a

y

e

r

w

o

n

'

t

l

o

a

d

C

D

S

u

n

r

o

o

f

C

a

s

s

e

t

t

e

e

a

t

s

t

a

p

e

s

P

P

H

Should we assign resources to

Cassette eats tapes?

2-7

Statistical Engineering Apprentice Training

CTIS # 20306

Version Date: 07-20-07

The Green

The Green Y is the Y axis from Pareto

The Green Y is what you are trying to improve

2-8

Statistical Engineering Apprentice Training

CTIS # 20306

Version Date: 07-20-07

Two-Sided One-Sided

Failures

Failures

Customer

Enthusiasm

CE

The Green Y

The Green Y can be an accounting metric (i.e.

PPH, PPM) or an engineering metric (i.e. mm,

dB)

The Green Y should focus on customer

enthusiasm instead of engineering specification

The Green Y distribution can be one- or two-

sided

2-9

Statistical Engineering Apprentice Training

CTIS # 20306

Version Date: 07-20-07

Eliminate this part of

the distribution

Green Y

CE

WOW BOB

Best of Best (BOB) & Worst of Worst (WOW)

BOBs and WOWs are NOT just good and bad

parts they are the opposite tails of the

distribution

Practically speaking, both BOB and WOW

represent a window from which the problem

solver should select parts

BOBs and WOWs are alike in every way except

for the Green Y difference

2-10

Statistical Engineering Apprentice Training

CTIS # 20306

Version Date: 07-20-07

The Red

The Red X is the largest contributor to the

observed variation (Green Y)

There can be other causes, but there is always

only one Red X

Nothing else matters until the Red X is

controlled

2-11

Statistical Engineering Apprentice Training

CTIS # 20306

Version Date: 07-20-07

Lo Hi

Chamfer Depth

F

l

o

w

(

l

/

m

i

n

)

G

r

e

e

n

Y

Example of a non Red X

Lo Hi

Orifice Diameter

F

l

o

w

(

l

/

m

i

n

)

G

r

e

e

n

Y

Example of a Red X

How the Definitions Fit Together

What separates the single most significant cause

apart from all of the others?

2-12

Statistical Engineering Apprentice Training

CTIS # 20306

Version Date: 07-20-07

Typical Y to X Relationship

Vehicle

WOW

BOB

Customer walks home (initial problem)

Engine Assembly Failure

WOW BOB

Assembly

WOW

BOB

Engine Assembly Failure

Sub-Assembly Failure: Broken Connecting Rod

WOW BOB

Component

WOW

BOB

Sub-Assembly Failure: Broken Connecting Rod

Hard Iron Crack Initiation

WOW BOB

Defect

WOW

BOB

Hard Iron Crack Initiation

Mechanical Impact (Red X)

WOW BOB

2-13

Statistical Engineering Apprentice Training

CTIS # 20306

Version Date: 07-20-07

What Types of Problems Do We Experience?

Gap

Flush

Holes

Chips

Scratches

Noisy Axle

Door Closing

Engine Wont Start

Geometry

Strategy

Physics

Feature

(Doesnt Fit)

Defect

(Damaged)

Event

(Doesnt Work Right)

2-14

Statistical Engineering Apprentice Training

CTIS # 20306

Version Date: 07-20-07

Defect

Defects:

Evidence left behind after an undesirable

event

One time non-repeatable events

Can be quantified as attributes (good/bad)

Examples:

Cracks

Dents

Scratches

Torn

Burned

Dirt in Paint

Rust

2-15

Statistical Engineering Apprentice Training

CTIS # 20306

Version Date: 07-20-07

Event

Events:

Require an input of energy to experience the

event

Events happen over time (i.e. beginning,

middle, end)

Can be measured with either attribute or

variable (number) measurement systems

Examples:

Closing efforts

Noise

Vibration

Electrical function

Vehicle pulls

Harsh shift

2-16

Statistical Engineering Apprentice Training

CTIS # 20306

Version Date: 07-20-07

Feature

Features:

Physical characteristics that create customer

complaints

Measured with variable measurement

systems

Examples:

Gaps

Flushness

Diameter

Height

2-17

Statistical Engineering Apprentice Training

CTIS # 20306

Version Date: 07-20-07

Failure Connectivity Example cont.

FEATURE - Holes misaligned

EVENT Tightening breaks bolt

DEFECT Broken bolt

2-18

Statistical Engineering Apprentice Training

CTIS # 20306

Version Date: 07-20-07

Failure Exercise

Example

Dirt in the paint

Vehicles pull to right during braking

Clicking noise during cold engine start

Burned bearings

High effort to close glove box

Brake pulsation

Gas lid fit

Porosity in aluminum

Splits in sheet metal

Stripped screws

Gap between console and IP

Intermittent operation of power door

lock

Defect Event Feature

2-19

Statistical Engineering Apprentice Training

CTIS # 20306

Version Date: 07-20-07

Failure Exercise

Example

Dirt in the paint

Vehicles pull to right during braking

Clicking noise during cold engine start

Burned bearings

High effort to close glove box

Brake pulsation

Gas lid fit

Porosity in aluminum

Splits in sheet metal

Stripped screws

Gap between console and IP

Intermittent operation of power door

lock

Defect Event Feature

2-20

Statistical Engineering Apprentice Training

CTIS # 20306

Version Date: 07-20-07

Contrast and Leverage

Definition of Contrast

The difference, or degree of difference,

between things having similar or comparable

natures

Definition of Leverage

Strategic advantage, or the power to act

effectively

A contrast you can take advantage of

2-21

Statistical Engineering Apprentice Training

CTIS # 20306

Version Date: 07-20-07

Using Red X Strategy

to Find the Cure for Smallpox

In the late 19th century, Edward Jenner decided

he was going to find a cure for smallpox...

The first thing he needed to understand is who

gets smallpox and who does not. He needed to

find a contrast...

After hearing everyone gets it for a long time, he

finally found the contrast he was looking for...

MILKMAIDS DID NOT GET SMALLPOX...

2-22

Statistical Engineering Apprentice Training

CTIS # 20306

Version Date: 07-20-07

Using Red X Strategy

to Find the Cure for Smallpox

In the 19th century, did Edward Jenner

understand immunity, white blood-cells, viruses,

and vaccines?

NO!

He understood he had a problem to fix and

accepted that he would never be able to

understand everything.

He also understood that he needed to find a

contrast.

2-23

Statistical Engineering Apprentice Training

CTIS # 20306

Version Date: 07-20-07

Using Red X Strategy

to Find the Cure for Smallpox

What can we learn from Edward Jenner?

Stay focused on defining the problem

Look for contrast

Question existing facts

Do not try to understand everything; you only

need to find out what drives the contrast

Understand that there is always going to be

noise

2-24

Statistical Engineering Apprentice Training

CTIS # 20306

Version Date: 07-20-07

How Do Problem-Solvers Document

Convergence and Contrast?

Problem solvers convey this information using

three types of Trees

Problem Definition Tree

Input: Problem

Output: Project Statement

Project Definition Tree

Input: Project Statement

Output: Red X (if an attribute

measurement system is used)

Output: Green Y Distribution (if a

variable measurement system is

used)

Solution Tree

Input: Green Y Distribution

Output: Red X

2-25

Statistical Engineering Apprentice Training

CTIS # 20306

Version Date: 07-20-07

Notes

2-26

Statistical Engineering Apprentice Training

CTIS # 20306

Version Date: 07-20-07

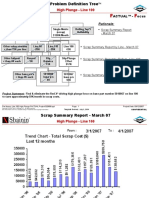

Problem Definition Tree

Problem Definition Tree

Based on customer feedback, what

project should I be working on?

3-1

LISTEN to the Customer Problem Definition

OBSERVE the Failure Project Definition

MEASURE the Contrast Solution Tree

(Isoplot)

CONVERGE to the Solution Tree

Major Influence (Clue Generation)

CONFIRM the Major Solution Tree

Influence (Red X) (Confirmation)

IMPLEMENT: Control the Solution Tree

Major Influence (Red X) (Implementation)

LISTEN to the Customer Problem Definition

OBSERVE the Failure Project Definition

MEASURE the Contrast Solution Tree

(Isoplot)

CONVERGE to the Solution Tree

Major Influence (Clue Generation)

CONFIRM the Major Solution Tree

Influence (Red X) (Confirmation)

IMPLEMENT: Control the Solution Tree

Major Influence (Red X) (Implementation)

Statistical Engineering Apprentice Training

CTIS # 20306

Version Date: 07-20-07

Problem Definition Tree

What is a Problem Definition Tree?

It is a tool to assist in clearly defining projects

It utilizes OPINIONS in the form of

complaints, failures, down time, cost, etc., to

identify which project is most important.

It starts off very broad and ends with a clearly

defined project that ties into the things

management cares about.

3-2

Statistical Engineering Apprentice Training

CTIS # 20306

Version Date: 07-20-07

Problem Definition Tree Example

Use the following data to identify the JD Power

technical project with the highest leverage.

3-3

Statistical Engineering Apprentice Training

CTIS # 20306

Version Date: 07-20-07 3-4

Statistical Engineering Apprentice Training

CTIS # 20306

Version Date: 07-20-07

J.D. Power Tracking Study

Fort Wayne -- Plant Total Total PPH 101

3 Month-of-Build Rolling Average: Sep - Nov, 2003 Sample Size

P P H

Wind noise 6 . 6

Poor/uncomfortable lumbar support 3 . 7

Brake pedal feels mushy/soft 3 . 2

Hard to open/close 3 . 1

Excessive fuel consumption 2 . 6

Automatic shifts roughly 2 . 6

Speakers vibrate/rattle 2 . 4

Paint chip/scratch at delivery 2 . 3

Unusual transmission noises 2 . 0

Windshield wipers 1. 9

Tot al 3 0 . 3

% of Tot al P robl ems # # #

Driver's Side P assenger's Si de

Rear Front Rear Rear Front Rear

Front Side of of Front Side of of Trunk/

Door Door Vehicle Vehicle Door Door Vehicle Vehicle Hatch Hood Roof Sunroof

6 . 6 Wind noise 46% 14% 27% 13% 34% 12% 13% 8% 1% 0%

0 . 5 Water leaks 47% 11% 0% 0% 53% 0% 11% 0% 0% 23% 0%

0 . 7 Molding loose 32% 24% 32% 22% 9% 17% 23% 9% 18% 0%

1. 4 Gaps/poor fit 32% 0% 33% 11% 10% 0% 4% 0% 7% 10% 0%

3 . 1 Hard to open/close 55% 7% 53% 4% 7% 2% 0%

2 . 3 Paint chip/scratch at delivery 36% 3% 21% 19% 10% 3% 5% 23% 6% 8% 4% 0%

1. 7 Paint blemish at delivery 17% 15% 10% 25% 14% 9% 6% 5% 0% 22% 6% 0%

0 . 6 Dents/dings at delivery 32% 0% 10% 24% 0% 0% 10% 8% 17% 8% 0% 0%

0 . 5 Fog/condensation in lenses 90% 0% 0% 10% 0%

0 . 5 Fuel door problem 0. 8 Headlights not aimed properly 0 . 3 Cracked windshield 0 . 0 Spare tire rattles

2 . 4 Other exterior problems

Damaged/ Defect/

Squeak Gap/ Dirty at Blemish in

or Rattle Poor Fit Delivery Materials

1. 8 Instrument panel/dashboard 75% 8% 3% 14%

0 . 5 Glove box 78% 0% 11% 11%

0 . 0 Airbag cover 0% 0% 0% 0%

1. 3 Door panel 64% 24% 19% 8%

0 . 5 Headliner 48% 0% 20% 11%

0 . 5 Carpet 89% 11% 0%

0 . 5 Center console 29% 30% 30% 10%

0 . 1 Overhead console 100% 0% 0% 0%

0 . 0 Rear parcel shelf/cargo cover 0% 0% 0% 0%

0 . 0 Rear compartment floor cover 0% 0% 0% 0%

0 . 3 Fuel gauge inaccurate/doesn't work properly 0 . 7 Distortion/blemish in windshield

0 . 5 Other gauges/instruments don't work properly 0 . 1 Distortion/blemish in rear window

0 . 3 Instrument panel lights don't work properly

2 . 0 Other interior problems

Automati c or Auto/Manual Hybrid M anual

2 . 6 Shifts roughly 0. 4 Clutch chatter

1. 2 Slips/shifts erratically 0 . 1 Gears grind when shifting

0 . 5 Shifts up/down too of t en 0 . 1 Clutch pedal problem

0 . 4 Gearshift hard to operate 0 . 5 Gearshift hard to operate

0 . 9 Difficult to shift in/out of 4WD 2 . 0 Unusual transmission noises 0 . 3 Transmission fluid leaks

1. 3 Other transmission problems

When? Where?

Steady

Engine Engine Stop/Go Highway

Hot Cold Driving Driving

0 . 1 Hard to start 0% 100%

0 . 2 Won't start at all 0% 100%

0 . 7 Stumbles/hesitates/dies 17% 84% 40% 16%

0 . 1 "Check Engine Light" indicated a problem 100% 0% 0% 0%

1. 0 Idles rough/too fast 44% 91%

1. 7 Unusual engine noises 68% 56% 53% 44%

0 . 6 Engine lacks power 59% 33% 43% 25%

0 . 0 Excessive oil consumption 0 . 0 Oil leaks

0 . 6 Exhaust system problems 2 . 6 Excessive fuel consumption

Engine required unscheduled repairs for. . . 0 . 0 Emissions 0 . 3 Computer 0 . 6 Other

0 . 6 Other engine problems

Bold numbers indicate PP100 for the 135 possible problems. Published 2/18/2004 v 1.0

1211

Vehicle

Interior

Transmissio

n

Engine

Vehicle

Exterior

Top 10

Problems

Symptoms

3-5

Statistical Engineering Apprentice Training

CTIS # 20306

Version Date: 07-20-07

Problem Definition Tree (Example)

J. D. Power

Reduce JD Power 3 month average score for

GMT 800 trucks built @ Ft. Wayne Assy.

Other Buckets

< 10.2 PPH

Transmission

10.2 PPH

Ride, Handling

and Braking

20.5 PPH

Vehicle

Exterior

21.5

Other

Categories

< 2.3 PPH

Paint chip and

scratches

2.3 PPH

Hard to Open /

Close

3.1 PPH

Wind Noise

6.6 PPH

Other areas

Passengers

front door 34%

(2 PPH)

Drivers side

front door 46%

(3 PPH)

Eliminate the source of windnoise on the drivers side

front door worth 3 PPH on GMT 800 at Ft. Wayne Asy.

Pareto:

Bucket with

highest PPH

in JDP

Pareto:

Windnoise has

highest PPH in

Vehicle Exterior

Identified

project to reduce

JDP @ Ft. Wayne

Current JDP = 101 PPH

Goal JDP = < 90 PPH

3-6

Pareto:

Area with

highest PPH

for windnoise

Statistical Engineering Apprentice Training

CTIS # 20306

Version Date: 07-20-07

Example - Missing Headliner Retainer

At a quality gate review a problem has been

identified. Here is what was presented at that

meeting:

Total failures at the quality gate were 385 failures

for the week.

The plant builds 50 jobs per hour on 2 shifts (4000

vehicles per week).

159 vehicles were written up this week for missing

headliner retainers.

A supervisor from trim says his guys are installing

retainers on all vehicles and someone must be

pulling them out.

Another person suggests that the headliner

supplier made a change and now the headliners

seem too stiff.

2 other plants build the same product and have no

failures for missing headliner retainers.

The quality gate leader states that the next biggest

issue is an interior console latch problem with 40

failures last week.

The plant manager looks at you and directs you to

eliminate the failures from this gate so he can stop

working overtime in repair.

What would your Problem Definition Tree look like?

3-7

Statistical Engineering Apprentice Training

CTIS # 20306

Version Date: 07-20-07 3-8

Feedback from Quality Gate

Feedback from other Plants

Eliminate the source of Missing Headliner Retainers on

Vehicle 1 at Plant A

Problem Definition Tree

Plant A Vehicle 1 To reduce failures at Quality Gate -

Current 385 failures/4000 vehicles

All other failures

< 40/4000

Plant A 159/4000

Other Plants 0

failures

Interior Console

Latch 40/4000

Missing

Headliners

Retainers

159/4000

Pareto:

Missing H/Liner Retainers

is highest frequency

problem in Quality Gate

Pareto:

Missing H/Liner Retainers

problem only occurs at

Plant A

Assigned project to

reduce Quality Gate

failures @ Plant A

Statistical Engineering Apprentice Training

CTIS # 20306

Version Date: 07-20-07

Project Definition Tree

Project Definition Tree

Based on my observations, what causes the

failure and how am I going to quantify it?

4-1

LISTEN to the Customer Problem Definition

OBSERVE the Failure Project Definition

MEASURE the Contrast Solution Tree

(Isoplot)

CONVERGE to the Solution Tree

Major Influence (Clue Generation)

CONFIRM the Major Solution Tree

Influence (Red X) (Confirmation)

IMPLEMENT: Control the Solution Tree

Major Influence (Red X) (Implementation)

LISTEN to the Customer Problem Definition

OBSERVE the Failure Project Definition

MEASURE the Contrast Solution Tree

(Isoplot)

CONVERGE to the Solution Tree

Major Influence (Clue Generation)

CONFIRM the Major Solution Tree

Influence (Red X) (Confirmation)

IMPLEMENT: Control the Solution Tree

Major Influence (Red X) (Implementation)

Statistical Engineering Apprentice Training

CTIS # 20306

Version Date: 07-20-07

Project Definition Tree

What is a Project Definition Tree?

It is a tool that converts the assigned project

into a Red X candidate or a Green Y variable

measurement

Every project has a Project Definition Tree

It is owned by the problem solver and is

based on their observations

4-2

Statistical Engineering Apprentice Training

CTIS # 20306

Version Date: 07-20-07

...a Fishbone diagram

of all the potential root

causes

carried over to a

solution tree until a

variable Green Y

distribution is defined

generated to

document everything

that was done

Project Definition Tree

employ Pareto and

prioritization to converge

on a Red X or Green Y

leverage attribute data

for creative splits to find a

Red X or define a Green Y

represents a living

document generated at the

beginning of a project and

updated accordingly as

knowledge is gained

4-3

Statistical Engineering Apprentice Training

CTIS # 20306

Version Date: 07-20-07

Anatomy of a Project Definition Tree

Rationale

1. What will be improved

and by how much?

2. What type failure

is this project?

Project Identified in a

Problem Definition Tree

Defect Event Feature

3. With the failure type identified,

ask a question to eliminate a

portion of this new topic.

Continue

Until

Identify a

candidate for

the Red X.

or

Identify a variable

measurement of the event

or feature driving the failure.

4-4

4. How many have you

observed of each?

Statistical Engineering Apprentice Training

CTIS # 20306

Version Date: 07-20-07

Project Definition Tree

4-5

Statistical Engineering Apprentice Training

CTIS # 20306

Version Date: 07-20-07

Project Definition Tree

Retainer

interference

Retainer

installation

depth

Installation

process variation

Retainer variation

Other Strategy

Choices

Location to

Location

Feature

Installed and fell

out 24/25

Never installed

1/25

Event

Continued

Location 5 14/25

See Process Flow Diagram observations

for Headliner install

See Defect analysis. Location 5 = 3 rib

depth. Location 2 & 8 = 6 rib depth.

Concentration Diagram

Joint variation

Plant A - Vehicle 1

Eliminate the source of missing Headliner Retainers on our

GM Vehicle at our GM Plant

21 vehicles observed with missing

retainers

See Strategy Diagram

Of 25 missing retainers, 24 were found

on floor or seat of vehicle.

Location 6 6/25 Location 4 3/25

Other locations

< 2/25

Defect

4-6

Statistical Engineering Apprentice Training

CTIS # 20306

Version Date: 07-20-07

F

r

e

q

u

e

n

c

y

Eliminate the source of varying relationship of headliner to

body at retainer locations on Vehicle 1 at Plant A

Project Definition Tree

Continued

Measure number

of ribs on retainer

Measure

relationship of

Headliner to

body

Better resolution with variable

measurement of headliner to body.

0

1

2

3

4

0 10 20 30 40

Green Y

Current

Required

Customer Enthusiasm

( mm )

4-7

Statistical Engineering Apprentice Training

CTIS # 20306

Version Date: 07-20-07

Notes

4-8

Statistical Engineering Apprentice Training

CTIS # 20306

Version Date: 07-20-07

An important step in the dictionary game is

documenting the type of split used on the Problem

Definition, Project Definition, and Solution Trees.

Some commonly used splits are listed below:

Dictionary Split

A dictionary split eliminates part of the physical world of

the problem in order to get to the smallest dictionary that

contains the full range of variation. Part of the physical

world is thrown way. This split can be used on the

project definition or solution tree.

Focus Split

A focus split is used to concentrate on the most important

problem in order to make the search go faster. This split

can be used on the Problem and Project Definition Trees

in combination with Pareto and Concentration Diagrams.

A focus split implies read-across potential.

An important step in the dictionary game is

documenting the type of split used on the Problem

Definition, Project Definition, and Solution Trees.

Some commonly used splits are listed below:

Dictionary Split

A dictionary split eliminates part of the physical world of

the problem in order to get to the smallest dictionary that

contains the full range of variation. Part of the physical

world is thrown way. This split can be used on the

project definition or solution tree.

Focus Split

A focus split is used to concentrate on the most important

problem in order to make the search go faster. This split

can be used on the Problem and Project Definition Trees

in combination with Pareto and Concentration Diagrams.

A focus split implies read-across potential.

Focus Split:

Based on Pareto

Fix left, read

across to right

Focus Split:

Based on Pareto

Fix left, read

across to right

Decision Splits

Left Side Door

(10 PPH)

Right Side Door

(8 PPH)

Body Shop Paint Shop

Dictionary Split:

Defect found in

Body Shop

Dictionary Split:

Defect found in

Body Shop

4-9

Statistical Engineering Apprentice Training

CTIS # 20306

Version Date: 07-20-07

Strategy Split

A strategy split is used when choosing between 2 or more

approaches to finding a Red X. This split is used in

conjunction with the strategy diagram and is shown on the

Project Definition or Solution Tree.

Aggravation Split

An aggravation split increases the ability to see the

differences between the BOB and WOW.

Connectivity Split

Used when the customers Green Y is connected to another

Green Y which is easier to work on or provides better

contrast.

Strategy Split

A strategy split is used when choosing between 2 or more

approaches to finding a Red X. This split is used in

conjunction with the strategy diagram and is shown on the

Project Definition or Solution Tree.

Aggravation Split

An aggravation split increases the ability to see the

differences between the BOB and WOW.

Connectivity Split

Used when the customers Green Y is connected to another

Green Y which is easier to work on or provides better

contrast.

Aggravation Split:

BOB doesnt rattle

on rough road

profile; WOW

rattles entire cycle

Aggravation Split:

BOB doesnt rattle

on rough road

profile; WOW

rattles entire cycle

Connectivity Split:

All parts that rattle

contact at surface A;

measure clearance (mm)

Connectivity Split:

All parts that rattle

contact at surface A;

measure clearance (mm)

Decision Splits (continued)

Clearance

(variable)

Rattle

(attribute)

Road simulator:

rough road profile #5

Regular roads

Side to Side

Same Car

Other

Strategies

Strategy Split:

Provides most

contrast and best

leverage

Strategy Split:

Provides most

contrast and best

leverage

4-10

Statistical Engineering Apprentice Training

CTIS # 20306

Version Date: 07-20-07

Decision Splits (exercise)

Which Decision Split best describes each of the following?

1

2

3

4

5

GMT 900 Vortec

5300 V-8

Other Engines

Pareto shows highest noise

frequency occurs on GMT

900 Vortec 5300 V-8. Will

read across to other engines

Split

Cracked

Case

Other Possible

Causes

All blocks that leak

have a cracked wall

Split

Operation 50

Other Operations

Burrs are found on pistons

after Operation 50

Split

Induce 100 thermal

cycles on dyno

Drive Vehicle

Quickly recreate

failure environment

Split

Part to Part

Other Strategies

Provides best

contrast and leverage

Split

4-11

Statistical Engineering Apprentice Training

CTIS # 20306

Version Date: 07-20-07

Decision Splits (exercise)

Which Decision Split best describes each of the following?

1

2

3

4

5

GMT 900 Vortec

5300 V-8

Other Engines

Pareto shows highest noise

frequency occurs on GMT

900 Vortec 5300 V-8. Will

read across to other engines

Focus Split

Cracked

Case

Other Possible

Causes

All blocks that leak

have a cracked wall

Connectivity Split

Operation 50

Other Operations

Burrs are found on

pistons after Operation 50

Dictionary Split

Induce 100 thermal

cycles on dyno

Drive Vehicle

Quickly recreate

failure environment

Aggravation Split

Part to Part

Other Strategies

Provides best

contrast and leverage

Strategy Split

4-12

Statistical Engineering Apprentice Training

CTIS # 20306

Version Date: 07-20-07

Solution Tree

Solution Tree

Based on my measurements, what is

the largest source of contrast (? P)?

5-1

LISTEN to the Customer Problem Definition

OBSERVE the Failure Project Definition

MEASURE the Contrast Solution Tree

(Isoplot)

CONVERGE to the Solution Tree

Major Influence (Clue Generation)

CONFIRM the Major Solution Tree

Influence (Red X) (Confirmation)

IMPLEMENT: Control the Solution Tree

Major Influence (Red X) (Implementation)

LISTEN to the Customer Problem Definition

OBSERVE the Failure Project Definition

MEASURE the Contrast Solution Tree

(Isoplot)

CONVERGE to the Solution Tree

Major Influence (Clue Generation)

CONFIRM the Major Solution Tree

Influence (Red X) (Confirmation)

IMPLEMENT: Control the Solution Tree

Major Influence (Red X) (Implementation)

Statistical Engineering Apprentice Training

CTIS # 20306

Version Date: 07-20-07

Solution Tree

What is a Solution Tree?

It documents convergence to the Red X

utilizing the variable measurement system

It always starts with a distribution of the

Green Y

The first split on the Solution Tree always

questions the measurement system

A Solution Tree ends with a proven Red X, a

corrective action, and proof that the corrective

action was effective

5-2

Statistical Engineering Apprentice Training

CTIS # 20306

Version Date: 07-20-07

Solution Tree

...a Fishbone diagram of all

the potential root causes

generated to document

everything that was done

require a variable

measurement of the Green Y

start with the Green Y as

defined by the Project

Definition Tree and ends with

the identification and

elimination of the Red X

typically show the first split

as product variation versus

measurement variation

5-3

Statistical Engineering Apprentice Training

CTIS # 20306

Version Date: 07-20-07

Anatomy of a Solution Tree

Rational

1. Green Y Distribution

identified from Project

Definition Tree

2. How much variation is in my

process and measurement system?

? P = 70 ? M = 5 3. Is my measurement

system good enough?

(DR > 6)

4. Which strategy shows the most

contrast?

5. Strategy Diagram

identifies ? P = ?

for each strategy

Continue

Until

Identify a

candidate for

the Red X.

6. All questions are

answered with ? P

CONFIRMED RED X

5-4

Statistical Engineering Apprentice Training

CTIS # 20306

Version Date: 07-20-07

Solution Tree

5-5

Statistical Engineering Apprentice Training

CTIS # 20306

Version Date: 07-20-07

To Project Definition Tree

Regular Wheel Base

Extended Wheel

Base

Highest problem frequency

occurs on extended wheel base.

Find and eliminate the Red X causing high effort to tilt the second row seat

assembly in U-vans built at Doraville

Project assigned by

management at the end of the

Problem Definition Tree.

First Row

(0/25)

Third Row

(0/25)

Second Row

(25/25)

The second row is the only seat

location with this complaint

Function

18 PPH

Appearance

3 PPH

Highest failure for the seat

assembly.

Tilt Seat Assembly

(25/30)

Tilt Seat Back

(1/30)

Comfort Adjustments

(4/30)

Verbatims state complaints are

for high effort when tilting the

seat to gain access.

Seat Assembly

21 PPH

Seat Belts

11 PPH

Highest complaint type.

PROBLEM DEFINITION TREE

Exterior

22 PPH

Seats

32 PPH

Reduce J.D. Power customer complaints on U-vans built at Doraville

The current J.D. Power rate is

180 PPH while the J.D. Power

goal is 140 PPH.

Other Categories

Less than 15 PPH

Highest complaint category.

How the Trees Relate

5-6

Statistical Engineering Apprentice Training

CTIS # 20306

Version Date: 07-20-07

How the Trees Relate

From Problem

Definition Tree

To Solution Tree

5-7

Statistical Engineering Apprentice Training

CTIS # 20306

Version Date: 07-20-07

How the Trees Relate

From Project

Definition Tree

Are we done?

5-8

Statistical Engineering Apprentice Training

CTIS # 20306

Version Date: 07-20-07

Problem Project Solution Strategy

General Statement,

i.e., improve JDP,

Warranty, etc.

Focused Project

Statement

Problem

A

20 pph

Other

Issues

<20 pph

Focused Project

Statement

Management tool

based on Pareto to

tell you what

project to work on.

USE

PARETO

Feature Event Defect

OBSERVE

THE

FAI LURE

Green Y Distribution

Establish a

measurable Green Y

or find the Red X

(attribute).

Green Y Distribution

Delta

P

Delta

M

Part to

Part

Other

Strategies

Find and confirm

the Red X and

implement

corrective action.

Understand the

contrast in all the

families of

variation.

To

Same A

A

To

A

Same B

B

To

B

Same C

Time

To

Time

80 90 100 110 120 130 140

Green Y(units)

Current

Required

CEL

80 90 100 110 120 130 140

Green Y(units)

Current

Required

CEL

Problem Project Solution Strategy

General Statement,

i.e., improve JDP,

Warranty, etc.

Focused Project

Statement

Problem

A

20 pph

Other

Issues

<20 pph

Focused Project

Statement

Management tool

based on Pareto to

tell you what

project to work on.

USE

PARETO

Feature Event Defect

OBSERVE

THE

FAI LURE

Green Y Distribution

Establish a

measurable Green Y

or find the Red X

(attribute).

Green Y Distribution

Delta

P

Delta

M

Part to

Part

Other

Strategies

Find and confirm

the Red X and

implement

corrective action.

Understand the

contrast in all the

families of

variation.

To

Same A

A

To

A

Same B

B

To

B

Same C

Time

To

Time

80 90 100 110 120 130 140

Green Y(units)

Current

Required

CEL

80 90 100 110 120 130 140

Green Y(units)

Current

Required

CEL

Problem, Project, & Solution Tree Flow Chart

5-9

Statistical Engineering Apprentice Training

CTIS # 20306

Version Date: 07-20-07

What is wrong with this Tree?

BEWARE: When Trees Become Fishbones

5-10

Statistical Engineering Apprentice Training

CTIS # 20306

Version Date: 07-20-07

Process Flow Diagrams

Process Flow Diagrams

What is the current

manufacturing process?

6-1

LISTEN to the Customer Problem Definition

OBSERVE the Failure Project Definition

MEASURE the Contrast Solution Tree

(Isoplot)

CONVERGE to the Solution Tree

Major Influence (Clue Generation)

CONFIRM the Major Solution Tree

Influence (Red X) (Confirmation)

IMPLEMENT: Control the Solution Tree

Major Influence (Red X) (Implementation)

LISTEN to the Customer Problem Definition

OBSERVE the Failure Project Definition

MEASURE the Contrast Solution Tree

(Isoplot)

CONVERGE to the Solution Tree

Major Influence (Clue Generation)

CONFIRM the Major Solution Tree

Influence (Red X) (Confirmation)

IMPLEMENT: Control the Solution Tree

Major Influence (Red X) (Implementation)

Statistical Engineering Apprentice Training

CTIS # 20306

Version Date: 07-20-07

Process Flow Diagram

Guidelines

WALK THE PROCESS

This cannot be done at your desk

Show the input and output of each operation

Diagram all possible product flow paths

Show all the relevant potential families of

variation

i.e.Orientation, fixturing, raw materials

A process flow diagram can be much more than

a list of words with arrows between them

6-2

Statistical Engineering Apprentice Training

CTIS # 20306

Version Date: 07-20-07

Input Process Function

Rough machined Op. 20 Rough bore, 2 spindles

block Bore Bore on one head

1 3

Same

Bore Bore

2 4

Mill the half rounds

Mill the bulkheads

Mill slivers

Left Right

Finish bore the

Bore Bore counterbore geometry

1 3

Same

Bore Bore

2 4

Clean, leak free Op. 60 Install 4 cold liners

block and randomly into the

purchased bore block

liners

Rap liners

Bore Bore

1 3

Rap liners

Bore Bore

2 4

Machined block Op. 130 Op. 130 Finish mill the head

with liner and B-side A-side deck

bedplate. Rough bore, chamfer and

Bore Bore Bore Bore finish hole

1 3 1 3

Same

Bore Bore Bore Bore

2 4 2 4

Gage all bores

1 2 3 4 1 2 3 4 automatically

10

8L

L850 Block Process Flow Diagram

Note: Only operations which relate to the bore are listed.

11

12

Operation

2R

6L

4R

2R

1

14

12R

7R

8R

9R

5R

11R

12R

13R

6-3

Statistical Engineering Apprentice Training

CTIS # 20306

Version Date: 07-20-07

Process Flow Diagram

Missing Headliner Retainers

1

8 7

6

5 4

3

2

1

8 7

6

5 4

3

2

1

8 7

6

5 4

3

2

10 job lengths

Headliner Install

Common Headliner Retainer used

at all locations on both sides.

Same installation process used at

all locations on both sides.

Side Trim Install

Windshield/Sunroof/Trim Install

Other Operations

Quality Gate Inspection

First observation of missing

retainers.

1

8 7

6

5 4

3

2

6-4

Statistical Engineering Apprentice Training

CTIS # 20306

Version Date: 07-20-07

The Essence of Strategy

The Essence of Strategy

How can I efficiently eliminate

what is not causing the failure?

7-1

LISTEN to the Customer Problem Definition

OBSERVE the Failure Project Definition

MEASURE the Contrast Solution Tree

(Isoplot)

CONVERGE to the Solution Tree

Major Influence (Clue Generation)

CONFIRM the Major Solution Tree

Influence (Red X) (Confirmation)

IMPLEMENT: Control the Solution Tree

Major Influence (Red X) (Implementation)

LISTEN to the Customer Problem Definition

OBSERVE the Failure Project Definition

MEASURE the Contrast Solution Tree

(Isoplot)

CONVERGE to the Solution Tree

Major Influence (Clue Generation)

CONFIRM the Major Solution Tree

Influence (Red X) (Confirmation)

IMPLEMENT: Control the Solution Tree

Major Influence (Red X) (Implementation)

Statistical Engineering Apprentice Training

CTIS # 20306

Version Date: 07-20-07

Rules: Using a dictionary as an aid

Ask any question with Yes or No as the

only response

Objective: Determine the correct previously chosen

word with the fewest number of

questions

Hints: 1. What do I know about a dictionary?

2. How can I use this to ask strategic

questions?

The Dictionary Game

7-2

Statistical Engineering Apprentice Training

CTIS # 20306

Version Date: 07-20-07

Notes

7-3

Statistical Engineering Apprentice Training

CTIS # 20306

Version Date: 07-20-07

The Game

Good Questions

A good question has no emotion tied to the

response

A good question leads you to the next question

Poor Questions

A poor question leads to a dead end

Examples include:

Noun Verb

Animal Vegetable Mineral

Vowel Consonant

Be willing to change your strategy

Always question your measurement system

7-4

Statistical Engineering Apprentice Training

CTIS # 20306

Version Date: 07-20-07

Eliminate all other factors, and the one

which remains must be the truth. How

often have I said to you that when you

have eliminated the impossible,

whatever remains, however improbable,

must be the truth?

It is a capital mistake to theorize before

one has data. Insensibly, one begins to

twist facts to suit theories, instead.

Sherlock Holmes

Sir Arthur Conan Doyle

Strategy in Literature

7-5

Statistical Engineering Apprentice Training

CTIS # 20306

Version Date: 07-20-07

Heres my strategy on the Cold War -

We win, they lose.

Ronald Wilson Reagan

Strategy in Politics

7-6

Statistical Engineering Apprentice Training

CTIS # 20306

Version Date: 07-20-07

X to Y Thinking

Scientific Method

Strategy: Change one or more causes (X) to

determine whether they create a change in

effect (Y)

Assumption: I know the relationship between

cause and effect

7-7

Statistical Engineering Apprentice Training

CTIS # 20306

Version Date: 07-20-07

Y to X Thinking

Red X Strategies

Strategy: Look for differences in various causes

(X) at the extremes of the effect (Y) to

progressively narrow in on the one cause (X)

driving the variation

Assumption: I can understand the physics by

observing the extremes

7-8

Statistical Engineering Apprentice Training

CTIS # 20306

Version Date: 07-20-07

Remember.

Statistical Engineer = Technical Detective

1. Identification of CONTRAST

2. Asking questions that ELIMINATE primary contributors to

that contrast

3. Factual data to identify the PARETO to support the

elimination decision

All 3 must be present for each decision made in a

Problem Definition, Project Definition or Solution Tree.

7-9

Statistical Engineering Apprentice Training

CTIS # 20306

Version Date: 07-20-07

Notes

7-10

Statistical Engineering Apprentice Training

CTIS # 20306

Version Date: 07-20-07

Strategy Diagram

Strategy Diagram

Where can I observe the most contrast?

8-1

LISTEN to the Customer Problem Definition

OBSERVE the Failure Project Definition

MEASURE the Contrast Solution Tree

(Isoplot)

CONVERGE to the Solution Tree

Major Influence (Clue Generation)

CONFIRM the Major Solution Tree

Influence (Red X) (Confirmation)

IMPLEMENT: Control the Solution Tree

Major Influence (Red X) (Implementation)

LISTEN to the Customer Problem Definition

OBSERVE the Failure Project Definition

MEASURE the Contrast Solution Tree

(Isoplot)

CONVERGE to the Solution Tree

Major Influence (Clue Generation)

CONFIRM the Major Solution Tree

Influence (Red X) (Confirmation)

IMPLEMENT: Control the Solution Tree

Major Influence (Red X) (Implementation)

Statistical Engineering Apprentice Training

CTIS # 20306

Version Date: 07-20-07

Strategy Diagrams

What is a Strategy Diagram?

Strategy diagrams are a way to document

possible contrasts for the Green Y that you

can leverage during your project

A Strategy Diagram should be developed

prior to observing the failure

First contrast family always questions the

repeatability of a Green Y measurement

8-2

Statistical Engineering Apprentice Training

CTIS # 20306

Version Date: 07-20-07

Defect Strategy Diagram

Defect Strategy Diagram

Where can I observe the most contrast

when I have a defect type failure?

9-1

LISTEN to the Customer Problem Definition

OBSERVE the Failure Project Definition

MEASURE the Contrast Solution Tree

(Isoplot)

CONVERGE to the Solution Tree

Major Influence (Clue Generation)

CONFIRM the Major Solution Tree

Influence (Red X) (Confirmation)

IMPLEMENT: Control the Solution Tree

Major Influence (Red X) (Implementation)

LISTEN to the Customer Problem Definition

OBSERVE the Failure Project Definition

MEASURE the Contrast Solution Tree

(Isoplot)

CONVERGE to the Solution Tree

Major Influence (Clue Generation)

CONFIRM the Major Solution Tree

Influence (Red X) (Confirmation)

IMPLEMENT: Control the Solution Tree

Major Influence (Red X) (Implementation)

Statistical Engineering Apprentice Training

CTIS # 20306

Version Date: 07-20-07

Strategy Diagram Development

1. What is the failure?

Windshields are breaking at a high rate

2. Does anyone know why?

Lots of theories, but problem will not go away

Develop a Strategy Diagram

9-2

Statistical Engineering Apprentice Training

CTIS # 20306

Version Date: 07-20-07

What type failure do we have?

There are three types of failures:

Defect, Event, and Feature

Cracked windshields are a defect

Strategy Diagram Development

9-3

Statistical Engineering Apprentice Training

CTIS # 20306

Version Date: 07-20-07

Defect

to Defect

Same Location

Is there repeatability in the observation

of cracks in the windshield?

C

r

a

c

k

o

r

N

o

C

r

a

c

k

Strategy Diagram Development

9-4

Statistical Engineering Apprentice Training

CTIS # 20306

Version Date: 07-20-07

Location

to Location

Same Edge

Are there locations that do not

have cracks along the same edge?

C

r

a

c

k

N

o

C

r

a

c

k

Strategy Diagram Development

9-5

Statistical Engineering Apprentice Training

CTIS # 20306

Version Date: 07-20-07

Edge

to Edge

Same Vehicle

Are there edges that do not have

cracks on the same vehicle?

Crack

N

o

C

r

a

c

k

No Crack

N

o

C

r

a

c

k

Strategy Diagram Development

9-6

Statistical Engineering Apprentice Training

CTIS # 20306

Version Date: 07-20-07

Vehicle

to Vehicle

Same Time

Are there vehicles that do not have

cracks at the same time?

Crack

No Crack

Strategy Diagram Development

9-7

Statistical Engineering Apprentice Training

CTIS # 20306

Version Date: 07-20-07

Time to

Time

Are there times that have

lower failure rates?

Cracked Windshields

0

10

20

30

40

50

J

a

n

F

e

b

M

a

r

A

p

r

M

a

y

J

u

n

e

J

u

l

y

A

u

g

S

e

p

t

O

c

t

N

o

v

D

e

c

Time

#

o

f

F

a

i

l

u

r

e

s

Low Failure Rate

for Cracked

Windshields

High Failure Rate

for Cracked

Windshields

Strategy Diagram Development

9-8

Statistical Engineering Apprentice Training

CTIS # 20306

Version Date: 07-20-07

Is there repeatability in the

observation of cracks in the

windshield?

Strategy Question

Are there locations that do not have

cracks along the same edge?

Are there edges that do not have

cracks on the same vehicle?

Are there vehicles that do not have

cracks at the same time?

Are there times that have lower

failure rates?

Time to

Time

Defect

to Defect

Same Location

Vehicle

to Vehicle

Same Time

Edge

to Edge

Same Vehicle

Location

to Location

Same Edge

Defect Strategy Diagram Example

Cracked Windshield

9-9

Statistical Engineering Apprentice Training

CTIS # 20306

Version Date: 07-20-07

Defect

to

Defect

Is observation of Headliner

Retainer present or not

repeatable?

Same Location

Location

to

Location

Are the Headliner

Retainers missing from the

same location?

Same Side

Side

to

Side

Are the Headliner

Retainers missing from the

same side?

Same Vehicle

Vehicle

to

Vehicle

Are the Headliner

Retainers missing from all

vehicles?

Same Model

Model

to

Model

Are the Headliner

Retainers missing on all

models?

Same Shift

Shift

to

Shift

Are the Headliner

Retainers missing on both

shifts?

Same Plant

Plant

to

Plant

Are the Headliner

Retainers missing at all

Plants?

Same Time

Missing Headliner Retainers

Defect Strategy Diagram

Continuation of the Missing Headliner Retainers Project

9-10

Statistical Engineering Apprentice Training

CTIS # 20306

Version Date: 07-20-07

Notes

9-11

Statistical Engineering Apprentice Training

CTIS # 20306

Version Date: 07-20-07

Defect Strategy Diagram Exercise

Problem Description:

Engine beauty covers are found with one or

more of the four retaining tabs broken resulting

in a loose cover.

Each car has only one beauty cover and either a

6.0 liter or a V8 engine.

Layout the Strategy Diagram

6.0L

V8

Beauty Cover

Broken Tab

9-12

Statistical Engineering Apprentice Training

CTIS # 20306

Version Date: 07-20-07

Defect Strategy Diagram

Broken Tabs on Beauty Cover

9-13

Statistical Engineering Apprentice Training

CTIS # 20306

Version Date: 07-20-07

Defect Strategy Diagram Exercise Answer

Do multiple

observations of the

same part give the

same result?

Which location broke

and which locations did

not break?

Which side of the

part are the broken

tabs found?

What is the current

failure rate of the

broken tabs?

Are there times when

the failure rate for

broken tabs has been

less?

Time to

Time

Defect

to Defect

Same Location

Vehicle

to Vehicle

Same Model

Side

to Side

Same Vehicle

Location

to Location

Same Side

Model

to Model

Same Time

Do other models have

a lower failure rate for

broken tabs?

Repeatable Response

of broken or not broken

Broken

Not Broken

Broken

Not Broken

Not Broken Broken

0% Broken

5.3L

5% Broken

6.0L

0

1

2

3

4

5

Time

%

B

r

o

k

e

n

Good Time

Bad Time

Observation

9-14

Statistical Engineering Apprentice Training

CTIS # 20306

Version Date: 07-20-07

Event Strategy Diagram

Event Strategy Diagram

How can I observe contrast

with an Event type failure?

10-1

LISTEN to the Customer Problem Definition

OBSERVE the Failure Project Definition

MEASURE the Contrast Solution Tree

(Isoplot)

CONVERGE to the Solution Tree

Major Influence (Clue Generation)

CONFIRM the Major Solution Tree

Influence (Red X) (Confirmation)

IMPLEMENT: Control the Solution Tree

Major Influence (Red X) (Implementation)

LISTEN to the Customer Problem Definition

OBSERVE the Failure Project Definition

MEASURE the Contrast Solution Tree

(Isoplot)

CONVERGE to the Solution Tree

Major Influence (Clue Generation)

CONFIRM the Major Solution Tree

Influence (Red X) (Confirmation)

IMPLEMENT: Control the Solution Tree

Major Influence (Red X) (Implementation)

Statistical Engineering Apprentice Training

CTIS # 20306

Version Date: 07-20-07

Event Measurement Systems

Events can be quantified with attribute or variable

measurement systems.

Attribute Measurements Variable Measurements

Rattle in the dash Door Closing Efforts

Waterleak Vehicle Pulls and Leads

Tail Lamp Doesnt Work Loose Fasteners

Windnoise Voltage Drain

Both require:

1. Experiencing the same event the customer

complains about

2. Definition of the test required to reproduce the

event

Attribute Measurement Requires:

Ability to rate each test event as good or bad

Variable Measurement Requires:

Ability to measure the results of each test with a

number (measurement)

10-2

Statistical Engineering Apprentice Training

CTIS # 20306

Version Date: 07-20-07

Event Strategy Diagram Example

(Variable Measurement System)

Non Conformity Code (NCC) 736: Excessive

Time to Shift from Neutral to Reverse

Problem Description:

The 4T40 transmission has two lines and ten

test stands

The test stand measures the amount of time,

in milliseconds, that it takes the transmission

to shift from neutral to reverse

The plant makes two different models

Develop a Strategy Diagram

10-3

Statistical Engineering Apprentice Training

CTIS # 20306

Version Date: 07-20-07

Non Conformity Code (NCC) 736 Flow Diagram

The diagrams below show the importance of getting

out to the floor to view the process. Two lines and ten

test stands can be interpreted two ways, as follows:

Line 2

Line 1

T.S. #1

T.S. #10

Test Stand to

Test Stand

Same Line

In this case, each test stand can run parts from only

one line. Thus the line contains the test stands.

1

Line 1

Line 2

T.S. #1

T.S. #10

Line to Line

Same Test Stand

In this case, each test stand can run parts from either

line. Thus the test stand contains the lines.

2

10-4

Statistical Engineering Apprentice Training

CTIS # 20306

Version Date: 07-20-07

Repeatability of time measured in milli-

seconds

Do any shift correctly?

Is one model better then the rest?

Are all test stands rejecting transmissions?

Have we always had this problem?

Time to

Time

Event

to Event

Same Transmission

Stand

to Stand

Same Line

Model

to Model

Same Test Stand

Trans.

to Trans.

Same Model

NCC 736: Excessive Time to shift from Neutral to Reverse

Event Strategy Diagram Exercise Answer

Are the failures unique to one line?

Line

to Line

Same Time

10-5

Statistical Engineering Apprentice Training

CTIS # 20306

Version Date: 07-20-07

Event Strategy Diagram Exercise

(Attribute Measurement System)

Problem Description:

Clicking noise in an engine compartment with

a hot engine at idle on GMT800 5300 V-8

5 V-8 engine options available on GMT800

Several plants produce GMT800 products

Product has been in production for multiple

years

10-6

Layout a Strategy Diagram

Statistical Engineering Apprentice Training

CTIS # 20306

Version Date: 07-20-07

Event Strategy Diagram Exercise Answer

Event

to Event

Same Location

Location

to Location