Escolar Documentos

Profissional Documentos

Cultura Documentos

Basic Strength of Materials Concepts

Enviado por

Florasaurus17Descrição original:

Título original

Direitos autorais

Formatos disponíveis

Compartilhar este documento

Compartilhar ou incorporar documento

Você considera este documento útil?

Este conteúdo é inapropriado?

Denunciar este documentoDireitos autorais:

Formatos disponíveis

Basic Strength of Materials Concepts

Enviado por

Florasaurus17Direitos autorais:

Formatos disponíveis

1/25/2008

Basic

Concepts

4

School of

Engineering

Prof. J. Bonet Prof. J. Bonet

EG EG- -120 120

Strength of Strength of

Materials Materials

BASIC CONCEPTS

BASIC CONCEPTS

PRINCIPLES:

Governing principles

St. Venant's principle

INTERNAL FORCES AND STRESSES:

Internal forces

Direct stress

Shear stress

DISPLACEMENTS AND STRAINS:

Displacements

Linear strain

Shear strain

MATERIAL BEHAVIOUR:

Stress-Strain relationships

Superposition principle

Material properties

Strain energy

Material failure

Time effects

1/25/2008

Basic

Concepts

5

School of

Engineering

Prof. J. Bonet Prof. J. Bonet

EG EG- -120 120

Strength of Strength of

Materials Materials

GOVERNING PRINCIPLES

GOVERNING PRINCIPLES

The way in which materials transmit loads is

governed by two basic principles:

Equilibrium: the sum of forces and moments on a

body or any part of the body must be equal to zero.

Certain problems can be solved using only

equilibrium considerations. These are known as

statically determinate.

Compatibility: the movements resulting from the

external loads must be internally compatible (i.e. the

material must not break) and compatible with the

external support conditions.

F F M

x y

= = =

0 0 0 ; ;

1/25/2008

Basic

Concepts

6

School of

Engineering

Prof. J. Bonet Prof. J. Bonet

EG EG- -120 120

Strength of Strength of

Materials Materials

ST.

ST.

VENANT'S

VENANT'S

PRINCIPLE

PRINCIPLE

A useful further principle is St. Venants Principle: no

matter how complex the distribution of external

forces at a small region on the surface of a body is,

the resulting effect at a small distance away will only

depend on the statically equivalent force.

1/25/2008

Basic

Concepts

7

School of

Engineering

Prof. J. Bonet Prof. J. Bonet

EG EG- -120 120

Strength of Strength of

Materials Materials

INTERNAL FORCES

INTERNAL FORCES

Consider a bar with an external load and its Free

Body Diagram:

Taking a cut through a section of a bar, equilibrium

and Newtons third law of action and reaction imply

the existence of an equal internal force acting on

each section of the bar:

On a given slice we have:

F

F

F

F F F F

F F

1/25/2008

Basic

Concepts

8

School of

Engineering

Prof. J. Bonet Prof. J. Bonet

EG EG- -120 120

Strength of Strength of

Materials Materials

DIRECT STRESS

DIRECT STRESS

Stress is the amount of internal force per unit area:

Units: Newtons/metre

2

or N/m

2

or Pascal. Typically

engineers use MN/m

2

, i.e. 10

6

N/m

2

or N/mm

2

.

Stress can be tensile (+) or compressive (-):

F

F

A

=

F

A

Tension (+) Compression (-)

1/25/2008

Basic

Concepts

9

School of

Engineering

Prof. J. Bonet Prof. J. Bonet

EG EG- -120 120

Strength of Strength of

Materials Materials

SHEAR STRESS

SHEAR STRESS

The force acting on an area may be normal or

tangential to the area. The direct stress is then the

normal force per unit area and the shear stress is

the tangential force per unit area:

Signs:

= =

F

A

F

A

n t

and

F

n

F

F

F

t

A

x

y

+

1/25/2008

Basic

Concepts

10

School of

Engineering

Prof. J. Bonet Prof. J. Bonet

EG EG- -120 120

Strength of Strength of

Materials Materials

DISPLACEMENTS

DISPLACEMENTS

As a result of the external actions materials will

deform. This deformation manifests itself in small

movements or displacements of material points. It

has units of length (m or mm):

In the case of a beam where the displacement is

perpendicular to the structure, it is known as

deflection:

u

F

F

d

1/25/2008

Basic

Concepts

11

School of

Engineering

Prof. J. Bonet Prof. J. Bonet

EG EG- -120 120

Strength of Strength of

Materials Materials

LINEAR STRAIN

LINEAR STRAIN

All materials deformwhen subject to external actions

such as loads or temperature changes. The

deformation, i.e. change in shape is measured by the

strain at a point:

Linear Strain is defined as the change in length over

the initial length:

Strain is dimensionless. It is often given as a %.

=

l

l

l

l

l l +

1/25/2008

Basic

Concepts

12

School of

Engineering

Prof. J. Bonet Prof. J. Bonet

EG EG- -120 120

Strength of Strength of

Materials Materials

SHEAR STRAIN

SHEAR STRAIN

Deformation can also imply distortion which is

measured by the shear strain as the change in

angle:

The shear strain is dimensionless and often given as

a percentage %.

1/25/2008

Basic

Concepts

13

School of

Engineering

Prof. J. Bonet Prof. J. Bonet

EG EG- -120 120

Strength of Strength of

Materials Materials

STRESS

STRESS

-

-

STRAIN RELATIONSHIPS

STRAIN RELATIONSHIPS

Derived from tensile tests:

Strain is related to stress via the stress-strain curve :

Proportionality

Limit

Linear

Elastic

Range

Breaking

Point

Strain Gauge

F F

1/25/2008

Basic

Concepts

14

School of

Engineering

Prof. J. Bonet Prof. J. Bonet

EG EG- -120 120

Strength of Strength of

Materials Materials

SUPERPOSITION PRINCIPLE

SUPERPOSITION PRINCIPLE

In the linear elastic range the effect of more than one

load can be obtained by adding the effect of each

individual load acting alone:

F

1

F

2

F

1

F

2

=

+

1/25/2008

Basic

Concepts

15

School of

Engineering

Prof. J. Bonet Prof. J. Bonet

EG EG- -120 120

Strength of Strength of

Materials Materials

MATERIAL PROPERTIES

MATERIAL PROPERTIES

In the elastic range, direct stress is proportional to

linear strain. The proportionality coefficient is

Youngs Modulus E of the material:

Shear stress is proportional to shear strain. The

proportionality coefficient is the Shear Modulus G:

Thermal effects. Changes in temperature lead to a

linear strain which is proportional to the temperature

change. The proportionality coefficient is the

Coefficient of Thermal Expansion :

= E

= G

T

T =

1/25/2008

Basic

Concepts

16

School of

Engineering

Prof. J. Bonet Prof. J. Bonet

EG EG- -120 120

Strength of Strength of

Materials Materials

POISSON'S RATIO

POISSON'S RATIO

The result of a direct stress in one direction is a

direct strain in the same direction plus a lateral

strain:

The ratio between direct and lateral strain is given by

Poissons coefficient (typically 0.3):

l

d

d

l

1 2

= =

l

l

and

d

d

=

2

1

1/25/2008

Basic

Concepts

17

School of

Engineering

Prof. J. Bonet Prof. J. Bonet

EG EG- -120 120

Strength of Strength of

Materials Materials

MATERIAL PARAMETERS: Typical Values

MATERIAL PARAMETERS: Typical Values

Material E(GN/m

2

)

(

o

C

-1

)

u

(MN/m

2

)

l

(MN/m

2

)

Mild Steel

200 1.2 10

-5

370 280

High Steel

200 1.3 10

-5

1550 770

Concrete T

14 1.2 10

-5

3 -

Concrete C

14 1.2 10

-5

30 -

Carbon Fibre

170 - 1400 -

Glass Fibre

60 - 1600 -

Aluminium

70 2.3 10

-5

430 280

Titanium

120 0.9 10

-5

690 385

Magnesium

45 2.7 10

-5

280 155

1/25/2008

Basic

Concepts

18

School of

Engineering

Prof. J. Bonet Prof. J. Bonet

EG EG- -120 120

Strength of Strength of

Materials Materials

STRAIN ENERGY

STRAIN ENERGY

When a material is deformed, the work done by the

external forces is accumulated as elastic strain

energy in the material.

The strain energy per unit volume w is the area

under the stress-strain relationship:

For linear elastic materials w is:

F

W F A V = = =

z z z

d d d l l

F

w E

E

= = =

1

2

1

2

2

1

2

2

w =

z

( )d

1/25/2008

Basic

Concepts

19

School of

Engineering

Prof. J. Bonet Prof. J. Bonet

EG EG- -120 120

Strength of Strength of

Materials Materials

MATERIAL FAILURE

MATERIAL FAILURE

All materials fail at different values of stress.

Depending on the amount of strain (or strain energy)

before failure, the material is said to be brittle or

ductile:

Breaking Point Breaking Point

DUCTILE MATERIAL BRITTLE MATERIAL

1/25/2008

Basic

Concepts

20

School of

Engineering

Prof. J. Bonet Prof. J. Bonet

EG EG- -120 120

Strength of Strength of

Materials Materials

TIME EFFECTS

TIME EFFECTS

Creep: the deformation of materials under load

increases with time:

Fatigue: materials subject to cyclic loads eventually

fail at a lower than the short term failure stress:

Mild Steel

Aluminium

Endurance

limit

tertiary creep

secondary creep

primary creep

u

No. Cycles

10

4

10

5

10

7

10

6

Você também pode gostar

- Chapter 1 - STRESS AND STRAIN PDFDocumento34 páginasChapter 1 - STRESS AND STRAIN PDFnurul eryn100% (1)

- Engg Mech and Strength of MaterialsDocumento73 páginasEngg Mech and Strength of MaterialsClaire NecesitoAinda não há avaliações

- Chapter ObjectivesDocumento73 páginasChapter Objectivesmazin jaderAinda não há avaliações

- C E D C A E: Ollege of Ngineering Epartment of Ivil & Rchitectural NgineeringDocumento27 páginasC E D C A E: Ollege of Ngineering Epartment of Ivil & Rchitectural Ngineeringhend mahmoudAinda não há avaliações

- Mechanics of SolidDocumento15 páginasMechanics of SolidSreerag Kunnathu SugathanAinda não há avaliações

- INTRODUCTION (Cont..) : TIN 205-TIN31 Engineering MechanicsDocumento47 páginasINTRODUCTION (Cont..) : TIN 205-TIN31 Engineering Mechanicsgundul paculAinda não há avaliações

- SOM 2 MarksDocumento8 páginasSOM 2 MarksSiva ShanmugamAinda não há avaliações

- IEEE Student Branch ConstitutionDocumento8 páginasIEEE Student Branch ConstitutionAayushGoyalAinda não há avaliações

- IEEE Student BranchDocumento8 páginasIEEE Student BranchPrajakta PatilAinda não há avaliações

- Chapter 1 - Stress and StrainDocumento49 páginasChapter 1 - Stress and StrainLuke Nate SarmientoAinda não há avaliações

- Rectilinear Motion, Motion Graphs, Projectile and Curvilinear Motion, and Tangential and Normal Motion Sample ProblemsDocumento16 páginasRectilinear Motion, Motion Graphs, Projectile and Curvilinear Motion, and Tangential and Normal Motion Sample ProblemsJohn AngeloAinda não há avaliações

- Tension Compression and ShearDocumento27 páginasTension Compression and ShearRizal Muhammad FaradayAinda não há avaliações

- Mechanical Engineering Stress AnalysisDocumento33 páginasMechanical Engineering Stress AnalysisagniflameAinda não há avaliações

- 1-Stress &Strain-Mechanics of MaterialsDocumento55 páginas1-Stress &Strain-Mechanics of MaterialsFelix Wahyu UtomoAinda não há avaliações

- Rectilinear Motion TheoryDocumento26 páginasRectilinear Motion Theoryswati sorteAinda não há avaliações

- Lecture 01Documento91 páginasLecture 01usman cheemaAinda não há avaliações

- Solid Mechanics Two MarksDocumento13 páginasSolid Mechanics Two MarksVignesh DuraiAinda não há avaliações

- Module 1 - Introduction To DynamicsDocumento15 páginasModule 1 - Introduction To DynamicsRozelGhettiVillanueva100% (1)

- Chapter 1 - Stress and StrainDocumento72 páginasChapter 1 - Stress and StrainNazhan HaziqAinda não há avaliações

- Mechanical PropertiesDocumento25 páginasMechanical PropertiesUmesh ChandraAinda não há avaliações

- Curvilinear Motion and ProjectilesDocumento15 páginasCurvilinear Motion and ProjectilesAltammar1367% (3)

- Mechanics of Materials Lecture Notes PDFDocumento130 páginasMechanics of Materials Lecture Notes PDFNaveed HassanAinda não há avaliações

- Facility layout design and REL chart analysisDocumento27 páginasFacility layout design and REL chart analysissivasundaram anushanAinda não há avaliações

- Stresses in Machine ElementsDocumento18 páginasStresses in Machine ElementsthirumalaikumaranAinda não há avaliações

- Strength of Materials: (SI Units)Documento11 páginasStrength of Materials: (SI Units)Fitra VertikalAinda não há avaliações

- Stress-Strain Diagram - Strength of Materials Review PDFDocumento6 páginasStress-Strain Diagram - Strength of Materials Review PDFKent Joshua AkiatanAinda não há avaliações

- Strength of Materials NotesDocumento66 páginasStrength of Materials NotesHimanshu MishraAinda não há avaliações

- Case StudyDocumento57 páginasCase StudyPhuong NguyenAinda não há avaliações

- Chapter - 1 Stress and Strain PDFDocumento21 páginasChapter - 1 Stress and Strain PDFAnonymous rT6y7298% (44)

- Design Against Static Load and Failure ModesDocumento23 páginasDesign Against Static Load and Failure ModesDiVik BhargAvaAinda não há avaliações

- Simple Stress and Strain PDFDocumento29 páginasSimple Stress and Strain PDFRubem JesusAinda não há avaliações

- x14 Statics - Frames and MachinesDocumento24 páginasx14 Statics - Frames and Machinessuniljha121Ainda não há avaliações

- MTPPT4 - Design of Isolated FootingDocumento19 páginasMTPPT4 - Design of Isolated FootingMineski Prince GarmaAinda não há avaliações

- Lecture 5 Case StudyDocumento19 páginasLecture 5 Case StudyRecallAinda não há avaliações

- Module-1 Stresses and StrainsDocumento33 páginasModule-1 Stresses and StrainsC.E.M JEFFREYSAinda não há avaliações

- Curved BeamsDocumento20 páginasCurved BeamsRAGHAVARAJA BAinda não há avaliações

- Strength of MaterialsDocumento18 páginasStrength of Materialskurddoski28Ainda não há avaliações

- Simple Stresses and Strains PDFDocumento104 páginasSimple Stresses and Strains PDFyaminiAinda não há avaliações

- ME 6306 Strength of Materials Course OverviewDocumento8 páginasME 6306 Strength of Materials Course OverviewGokulraju Rangasamy100% (2)

- MoM Summary PointsDocumento39 páginasMoM Summary PointsAmmarAinda não há avaliações

- Strength of MaterialsDocumento29 páginasStrength of Materialsrubyshaji96Ainda não há avaliações

- 2-Mechanics of Material - I (Final Exam)Documento115 páginas2-Mechanics of Material - I (Final Exam)irum,Ainda não há avaliações

- ME2252 Strength of Materials eLearningDocumento1.053 páginasME2252 Strength of Materials eLearningaftab_civil2006100% (1)

- Strength of Materials TerminologiesDocumento8 páginasStrength of Materials TerminologiesBriant Dominik PongolAinda não há avaliações

- CE2155 - Combined LoadingsDocumento21 páginasCE2155 - Combined LoadingsJuliaAinda não há avaliações

- Moist Air As Mixture of Ideal Gases: ME 306 Applied Thermodynamics 1Documento33 páginasMoist Air As Mixture of Ideal Gases: ME 306 Applied Thermodynamics 1Harsh ChandakAinda não há avaliações

- Mechanics of Materials: TorsionDocumento17 páginasMechanics of Materials: TorsionMomina AliAinda não há avaliações

- MOM Final Manual PDFDocumento129 páginasMOM Final Manual PDFzohairahmedAinda não há avaliações

- CE8395 Strength of materials for Mechanical EngineersDocumento59 páginasCE8395 Strength of materials for Mechanical EngineersKarthikeyan RajamaniAinda não há avaliações

- Design Beams Flexural MembersDocumento25 páginasDesign Beams Flexural Membersdan0427100% (1)

- Stress Strain DiagramDocumento4 páginasStress Strain DiagramAhsaamAinda não há avaliações

- MoistDocumento19 páginasMoistMagesh subas chandra boseAinda não há avaliações

- STRENGTH of MaterialsDocumento8 páginasSTRENGTH of MaterialskousikkumaarAinda não há avaliações

- 5 - Cylinders and Vessels (Part-1)Documento17 páginas5 - Cylinders and Vessels (Part-1)Rubab ZahraAinda não há avaliações

- Solid Mechanics Short Questions and AnswersDocumento61 páginasSolid Mechanics Short Questions and Answerssampathsiddam77% (31)

- CEG 221 - LecturesDocumento18 páginasCEG 221 - LecturesMoshood Mubarak AyindeAinda não há avaliações

- Lecture 1 Stresses and StrainsDocumento25 páginasLecture 1 Stresses and Strainssamurai7_77Ainda não há avaliações

- EMG 1204 Lecture 8Documento55 páginasEMG 1204 Lecture 8James musambakiAinda não há avaliações

- Mechanical properties overviewDocumento59 páginasMechanical properties overviewNeil BoseAinda não há avaliações

- Thermodynamics 1 - Energy Analysis of Closed SystemsDocumento26 páginasThermodynamics 1 - Energy Analysis of Closed SystemsFlorasaurus17100% (2)

- Thermodynamics 1 - Basic Concepts of ThermodynamicsDocumento31 páginasThermodynamics 1 - Basic Concepts of ThermodynamicsFlorasaurus17100% (1)

- Thermodynamics 1 - Properties of Pure SubstancesDocumento26 páginasThermodynamics 1 - Properties of Pure SubstancesFlorasaurus1767% (3)

- Thermodynamics 1 - Energy, Energy Transfer, and General Energy AnalysisDocumento21 páginasThermodynamics 1 - Energy, Energy Transfer, and General Energy AnalysisFlorasaurus17100% (1)

- EG160 Lecture NotesDocumento45 páginasEG160 Lecture NotesAtbin Ma0% (1)

- Thermodynamics I - IntroductionDocumento20 páginasThermodynamics I - IntroductionFlorasaurus17Ainda não há avaliações

- Material Data Sheet: Material Number Country DesignationsDocumento21 páginasMaterial Data Sheet: Material Number Country DesignationsSan ReyAinda não há avaliações

- Procedia Structural Integrity ECF 21 June 2016Documento16 páginasProcedia Structural Integrity ECF 21 June 2016Tapash NagAinda não há avaliações

- Swiss Federal Roads Office Guidelines For Integral Bridges 2010-12-09Documento7 páginasSwiss Federal Roads Office Guidelines For Integral Bridges 2010-12-09Walter KaufmannAinda não há avaliações

- Creep and Rupture Properties Continued: Comparison of Stress To Produce 1% Creep in 1,000 HoursDocumento4 páginasCreep and Rupture Properties Continued: Comparison of Stress To Produce 1% Creep in 1,000 HourssuiafwgehjdfAinda não há avaliações

- Lecture 1 - Properties of MaterialDocumento59 páginasLecture 1 - Properties of MaterialKhushbu KumariAinda não há avaliações

- EPS in Road Construction-Current Situation in GermanyDocumento19 páginasEPS in Road Construction-Current Situation in GermanyNCS40 Trương Quốc BảoAinda não há avaliações

- SA253MA DetailDocumento16 páginasSA253MA Detailksquare2001100% (1)

- Heat TreatmentDocumento33 páginasHeat TreatmentPinto CarlosAinda não há avaliações

- Aggregates & Binders in ConcreteDocumento53 páginasAggregates & Binders in Concretehoda melhemAinda não há avaliações

- Ryton Mechanical PropertiesDocumento12 páginasRyton Mechanical PropertiesClaudia MmsAinda não há avaliações

- Calculation of Deflection and Crack Width in Prestressed ConcreteDocumento48 páginasCalculation of Deflection and Crack Width in Prestressed Concreteajith chandranAinda não há avaliações

- Low Alloy Steel Creep PropertiesDocumento3 páginasLow Alloy Steel Creep Propertiesqueno1Ainda não há avaliações

- Elongationfactoringeosynthetics Proc Slope 2015Documento8 páginasElongationfactoringeosynthetics Proc Slope 2015dm IqbalAinda não há avaliações

- PLAXIS (2018) PLAXIS 2D MAterial Models Manual 2018 PDFDocumento256 páginasPLAXIS (2018) PLAXIS 2D MAterial Models Manual 2018 PDFJonathan WhiteAinda não há avaliações

- CELCON® M90™ - POM - Unfilled: DescriptionDocumento6 páginasCELCON® M90™ - POM - Unfilled: Description. .Ainda não há avaliações

- Creep TestDocumento18 páginasCreep Testdeemi75Ainda não há avaliações

- Metallurgical Challenges Associated With Using Grade 91 Steels at Elevated TemperatureDocumento21 páginasMetallurgical Challenges Associated With Using Grade 91 Steels at Elevated TemperatureKuthuraikaranAinda não há avaliações

- Introduction To Reinforced Concrete Design Part 1Documento6 páginasIntroduction To Reinforced Concrete Design Part 1jhess QuevadaAinda não há avaliações

- Creep (Deformation) PDFDocumento13 páginasCreep (Deformation) PDFAdamRaczAinda não há avaliações

- Testing of Plastics and RubberDocumento56 páginasTesting of Plastics and RubberJosua S100% (1)

- PEEK PropertiesDocumento56 páginasPEEK Propertiesa100acom50% (2)

- Mechanical Properties of Metals - IIDocumento33 páginasMechanical Properties of Metals - IIarulmuruguAinda não há avaliações

- Manufacturing Process 2nd Edition by U K Singh and Manish DwivediDocumento290 páginasManufacturing Process 2nd Edition by U K Singh and Manish DwivediManjunath MaratheAinda não há avaliações

- Deform ManualDocumento98 páginasDeform ManualAhmed Hasan33% (3)

- Analysis of creep effects on prestressed concrete bridge designDocumento14 páginasAnalysis of creep effects on prestressed concrete bridge designRammiris ManAinda não há avaliações

- Rheological Behavior of Tomato Fruits Affected by Various Loads Under Storage ConditionsDocumento8 páginasRheological Behavior of Tomato Fruits Affected by Various Loads Under Storage ConditionsAJER JOURNALAinda não há avaliações

- Plain & Reinforced Concrete-1: Lecture # 1Documento48 páginasPlain & Reinforced Concrete-1: Lecture # 1Adil Javed Chaudhary100% (1)

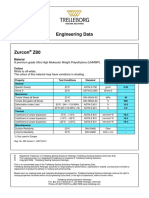

- Zurcon Z80 PDFDocumento1 páginaZurcon Z80 PDFLuz SmithAinda não há avaliações

- D 907 - 03 Rdkwny0wmwDocumento12 páginasD 907 - 03 Rdkwny0wmwMarceloAinda não há avaliações

- Oiml Bulletin Oct 1998Documento95 páginasOiml Bulletin Oct 1998libijahansAinda não há avaliações