Escolar Documentos

Profissional Documentos

Cultura Documentos

3 CASE ADT 30 Ton Hydraulic Section PDF

Enviado por

Baciu Nicolae0 notas0% acharam este documento útil (0 voto)

322 visualizações40 páginasTítulo original

3 CASE ADT 30 Ton Hydraulic Section.pdf

Direitos autorais

© © All Rights Reserved

Formatos disponíveis

PDF, TXT ou leia online no Scribd

Compartilhar este documento

Compartilhar ou incorporar documento

Você considera este documento útil?

Este conteúdo é inapropriado?

Denunciar este documentoDireitos autorais:

© All Rights Reserved

Formatos disponíveis

Baixe no formato PDF, TXT ou leia online no Scribd

0 notas0% acharam este documento útil (0 voto)

322 visualizações40 páginas3 CASE ADT 30 Ton Hydraulic Section PDF

Enviado por

Baciu NicolaeDireitos autorais:

© All Rights Reserved

Formatos disponíveis

Baixe no formato PDF, TXT ou leia online no Scribd

Você está na página 1de 40

HYDRAULIC

25 & 30 TON ARTICULATED DUMP TRUCKS

1

HYDRAULIC SYSTEM

Hydraulic Circuits and Components

CONTENTS

Description Page

Specifications ....................................................1

Description ........................................................2

Steering - dumping component location.........3

Braking component location ........................5

Component port identification7

Troubleshooting ..............................................22

Bleeding the hydraulic circuits ......................24

Hydraulic system diagram ..........................25

Checks and verification ................................. 33

SPECIFICATIONS

Main hydraulic pump

Displacement .........................................................................117 cm/rev (7.14 in/rev)

Maximum delivery at engine full speed ...................................... 271 l/min (71.6 gal/min)

Brake hydraulic pump

Displacement ...........................................................................19.5 cm/rev (1.9 in/rev)

Maximum delivery at engine full speed .........................................23 l/min (6.07 gal/min)

Maximum pressure ............................................................................. 175 bar (2538 psi)

Steering emergency electric-pump 25 TON Truck

Displacement ..........................................................................5.8 cm/rev (0.35 in/rev)

Maximum delivery ........................................................................19 l/min (5.02 gal/min)

Maximum pressure ............................................................................ 120 bar (1740 psi)

DC power supply volt 24 V

Steering emergency transmission driven pump 30 Ton Truck

Displacement ...........................................................................32 cm/rev (1.95 in/rev)

Hoist cylinder rods

Length of Cylinder, extended 25 Ton Truck ................................. 2470 mm (97.24 in)

Length of Cylinder, extended 30 Ton Truck .................................. 1736 mm (68.34 in)

Length of Cylinder, retracted.............................................................. 930 mm (36.61 in)

Hoist control valve

Main Relief valve pressure 25 Ton Truck ....................................... 140 bar (2030 psi)

Main Relief valve pressure 30 Ton Truck ....................................... 160 bar (2320 psi)

Circuit Relief valve retracting pressure .................................................. 50 bar (725 psi)

Circuit Relief valve extending pressure .............................................. 225 bar (3263 psi)

Power steering

Max. pressure ................................................................................... 185 bar (2683 psi)

Counterbalancing valve

Pressure setting ................................................................................. 100 bar (1450 psi)

Flow amplifier

Steering pressure relief pressure ....................................................... 185 bar (2683 psi)

Circuit Relief valve relief pressure ..................................................... 240 bar (3481 psi)

HYDRAULIC

25 & 30 TON ARTICULATED DUMP TRUCKS

2

HYDRAULIC SYSTEM DESCRIPTION

The system is divided into three main hydraulic circuits, the steering, load dumping and

braking circuits. Each system operates with the same hydraulic fluid, coming from a

single reservoir that serves them all.

HYDRAULIC SYSTEM DESCRIPTION

1. Hydraulic oil reservoir

2. Steering emergency pump

3. Main hydraulic pump

4. Brake hydraulic pump

5. Steering hydraulic circuit

6. Load dumping hydraulic circuit

7. Brake hydraulic circuit

HYDRAULIC

25 & 30 TON ARTICULATED DUMP TRUCKS

3

Steering Control System

On the Articulated Dump Trucks, a system for the delivery of high flow (flow

amplification) to the steering cylinders is used. This system consists of a steering

control valve, a Flow-amplifier and steering cylinders.

These systems with a steering control orbital valve and Flow-Amplifier also include a

priority flow divider valve in the Flow Amplifier which ensures that the steering takes

priority. When the steering wheel is turned, the oil flow is divided in the Flow-Amplifier in

such a way as to ensure that the necessary oil flow is led to the steering system. The

rest of the oil flow is available for the working hydraulics to raise and lower the dump

body.

Steering Control System

HYDRAULIC

25 & 30 TON ARTICULATED DUMP TRUCKS

4

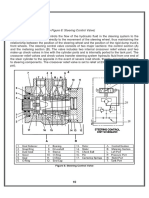

Steering Control Orbital Valve

The steering control orbital valve unit consists of a rotary valve and a rotary meter. Via

a steering column, the steering unit is connected to the steering wheel of the vehicle.

Oil is supplied to the steering control orbital valve from the Flow Amplifier. When the

steering wheel is turned, oil is directed via the rotary valve and rotary meter to the

orbital valve cylinder ports L or R, depending on the direction of the turn. The rotary

meter varies the oil flow to the Flow Amplifier in proportion to the angular rotation of the

steering wheel.

This steering system is of the load sensing design. In load sensing steering systems

both the steering system and the working hydraulics can be supplied from just one

pump. The load sensing steering unit has an extra connection for load sensing (LS), so

that a steering load pressure signal can be directed via the steering control orbital valve

to a priority valve in the Flow Amplifier. The load sensing signal controls the oil flow

from the priority valve to the steering cylinders. The LS connection is open to the

reservoir when the steering control orbital valve is in the neutral position.

HYDRAULIC

25 & 30 TON ARTICULATED DUMP TRUCKS

5

Steering Control Orbital Valve

HYDRAULIC

25 & 30 TON ARTICULATED DUMP TRUCKS

6

Steering Flow-Amplifier

On the Articulated Dump Trucks, a system for the delivery of high flow (flow

amplification) to the steering cylinders is used. This system consists of a steering

control orbital valve, and a Flow-amplifier.

The Flow-Amplifier contains a directional valve, a flow amplification stage, a priority

valve, a pilot pressure relief valve and circuit relief and anti-cavitation valves. In

addition, the Flow-Amplifier contains a backpressure valve to assure that oil is available

for manual steering when the engine is not running. The Flow-Amplifier provides more

oil to the steering cylinders than would be possible to flow through the steering orbital

valve. The Flow-Amplifier uses the lower flow through the orbital valve to provide a

control flow to cause the amplifier spool of the Flow Amplifier to send about 8 times

more oil to the CL or CR steering cylinder ports than what is going through the orbital

valve. The amplified flow is proportional to the rate of the steering wheel rotation. If the

oil flow from the pump fails, the Flow-Amplifier cuts off the amplification and manual

steering through the steering orbital valve is possible.

HYDRAULIC

25 & 30 TON ARTICULATED DUMP TRUCKS

7

Steering Flow-Amplifier

L Left Turn Signal from Orbital Valve LS Load sensing signal, same pressure as L or R

CL Left Turn Pressure to Steering Cylinder HP Main flow from Pump

CR Right Turn Pressure to Steering Cylinder PP Pressure sense line of fluid flow to Orbital Valve

R Right Turn Signal from Orbital Valve P Fluid supply flow to Orbital Valve

EF Oil flow to Body Lifting Control Valve

T Oil returning from the Orbital Valve

HT Oil returned to the Reservoir

HYDRAULIC

25 & 30 TON ARTICULATED DUMP TRUCKS

8

Load Dumping Control Hydraulic System

25 TON TRUCK STEERING & DUMP CONTROL COMPONENT LOCATION

A. Emergency Steering Electric Pump

B. Oil filter inside reservoir

C. Hydraulic oil reservoir

D. Flow amplifier

E. Load dumping control valve

F. System pressure test ports

G. High pressure oil filter

H. Rear Cab Oil Porting Manifold

I. Main hydraulic pump

J. Differential lock control solenoid valve

K. Power steering Orbital valve

L. Hydraulic Oil Cooler

M. Steering cylinder

N. Hoist cylinders

O. Rear chassis connection manifold (with

counter-balancing valve)

HYDRAULIC

25 & 30 TON ARTICULATED DUMP TRUCKS

9

30 TON TRUCK STEERING & DUMP CONTROL COMPONENT LOCATION

A. Auxiliary Steering By-pass valve

B. Oil filter inside reservoir

C. Hydraulic oil reservoir

D. Flow amplifier

E. Load dumping control valve

F. System pressure test ports

G. High pressure oil filter

H. Rear Cab Oil Porting Manifold

I. Main hydraulic pump

J. Differential lock control solenoid valve

K. Power steering Orbital valve

L. Hydraulic Oil Cooler

M. Steering emergency pump

N. Transmission Differential locking valve

O. Steering cylinder

P. Hoist cylinders

Q. Rear chassis connection manifold (with

counter-balancing valve)

R. Center Axle Differential Lock Solenoid

Valve

Rear Chassis 30 Ton Truck

HYDRAULIC

25 & 30 TON ARTICULATED DUMP TRUCKS

10

25 TON TRUCK BRAKE CIRCUIT COMPONENT LOCATION

P. Brake pump

Q. Oil filter (brake system)

R. Service Brake Accumulators

S. Parking brake solenoid valve

T. Accumulator charging valve

U. Brake control valve

HYDRAULIC

25 & 30 TON ARTICULATED DUMP TRUCKS

11

30 TON TRUCK BRAKE CIRCUIT COMPONENT LOCATION

R. Brake pump

S. Oil filter (brake system)

T. Accumulator charging valve

U. Service Brake Accumulators

V. Parking brake solenoid valve

W. Brake control valve

X. Park Brake Accumulator

HYDRAULIC

25 & 30 TON ARTICULATED DUMP TRUCKS

12

A. 25 TON TRUCK EMERGENCY STEERING ELECTRIC PUMP

1. Oil inlet pipe from Tee at brake pump 2. outlet pipe to one-way check valve

A. 30 TON TRUCK AUXILIARY STEERING BY-PASS VALVE

Located inside the right rear corner of the front chassis. Emergency steering pump

mounted to the rear of the transmission.

B. OIL FILTER INSIDE RESERVOIR

1. Oil intake pipe

2. Hydraulic Reservoir Oil Fill

3. Pump Suction filtering element

4. Hydraulic oil reservoir

HYDRAULIC

25 & 30 TON ARTICULATED DUMP TRUCKS

13

C. HYDRAULIC RESERVOIR

1. Filler cap

2. Oil level gauge

3. Inspection cover

HYDRAULIC

25 & 30 TON ARTICULATED DUMP TRUCKS

14

D. FLOW AMPLIFIER

1. Inlet from one-way check valve (HP)

2. Oil supply to Load dumping control

valve (EF Port)

3. Steering load sense pressure port (LS)

4. RH steering control (R) to steering

cylinders

5. Steering return (T) from orbital valve

6. LH steering (L) from orbital valve

7. Return to reservoir (HT)

8. RH steering (R) from orbital valve

9. Oil supply (P) to orbital valve

10. LH steering control (L) to steering

cylinders

HYDRAULIC

25 & 30 TON ARTICULATED DUMP TRUCKS

15

E. LOAD DUMPING CONTROL VALVE

1. Load dumping control manual lever

2. Inlet from flow amplifier (to P Port)

3. Body Raise control flow

4. Supply to axle differential lock solenoid

valve (located inside left front access

cover on 30 Ton Truck & near flow

amplifier on 25 Ton Truck)

5. Body lower control flow

6. To Pressure test port connection

7. Return to oil cooler and reservoir

HYDRAULIC

25 & 30 TON ARTICULATED DUMP TRUCKS

16

G. 25 TON TRUCK HIGH PRESSURE OIL FILTER

G. 30 TON TRUCK HIGH PRESSURE OIL FILTER

1. Inlet pipe from main pump

2. Inlet pipe from emergency Steering

pump

3. Delivery pipe to flow amplifier (HP Port)

4. Pressure switch for emergency steering

5. Check valve from filter to flow amplifier

6. High pressure oil filter

HYDRAULIC

25 & 30 TON ARTICULATED DUMP TRUCKS

17

H. REAR CAB OIL PORTING MANIFOLD

1. Body lowering from control valve (B

Port)

2. LH steering control

3. RH steering control

4. Center axle Differential lock control

5. Parking brake control

6. Rear service brake control

7. Body raising from control valve (A Port)

8. Transmission pressure test port (30

Ton Truck only)

9. Transmission pressure test port (30

Ton Truck only)

10. Electrical Harness connector

I. MAIN HYDRAULIC PUMP

1. Inlet pipe from reservoir

2. Outlet pipe to high pressure filter

3. Supply pipe to emergency steering

pump on 30 Ton Truck

HYDRAULIC

25 & 30 TON ARTICULATED DUMP TRUCKS

18

J. 30 TON TRUCK TRANSMISSION DIFFERENTIAL LOCK CONTROL VALVE

HYDRAULIC

25 & 30 TON ARTICULATED DUMP TRUCKS

19

K. POWER STEERING ORBITAL VALVE

1. Load sensing line to flow amplifier (LS)

2. RH steering control to flow amplifier (R)

3. Steering control inlet (P) from flow

amplifier

4. Return pipe to flow amplifier (T)

5. LH steering control to flow amplifier (L)

L. HYDRAULIC OIL COOLER

1. Oil return pipe to reservoir

2. Inlet pipe from load dumping control

valve (T Port)

3. Hydraulic Oil Cooler

HYDRAULIC

25 & 30 TON ARTICULATED DUMP TRUCKS

20

M. 30 TON TRUCK EMERGENCY STEERING PUMP

1. Emergency Steering Pump

2. Inlet from Hydraulic Reservoir

3. Pump outlet to emergency Steering

solenoid control valve

N. CENTER AXLE DIFFERENTIAL LOCK CONTROL SOLENOID VALVE

1. Oil return pipe to reservoir (T Port)

2. Transmission differential lock control

(A2 Port), Not used on 30 Ton Truck

3. Center tandem differential lock control

(A1 Port)

4. Supply line from load dumping control

valve (P Port)

5. To Center Axle Differential Lock

Pressure test Coupler (MA Port)

6. Center Axle Differential Lock Pressure

Regulator

7. Center Axle Differential Lock Control

Solenoid

8. Trans. Diff. Lock Sol., Not on 30 Ton

HYDRAULIC

25 & 30 TON ARTICULATED DUMP TRUCKS

21

O. STEERING CYLINDER

1. LH steering control pipe 2. RH steering control pipe

P. HOIST CYLINDER

1. Body raise control pipe 2. Body lower control pipe

HYDRAULIC

25 & 30 TON ARTICULATED DUMP TRUCKS

22

Q. REAR CHASSIS CONNECTION MANIFOLD ASSEMBLY

1. Body Raise control pipe

2. Body Raise RH cylinder control pipe

3. Body Raise LH cylinder control pipe

4. Body Lowering RH cylinder control pipe

5. Body Lowering LH cylinder control pipe

6. LH steering control pipe

7. RH steering control pipe

8. Body Lower control pipe

9. Differential lock control pipe

10. Parking brake control pipe

11. Rear Axle Service brake control pipe

12. Dump Body Counterbalance Valve

HYDRAULIC

25 & 30 TON ARTICULATED DUMP TRUCKS

23

R. BRAKE PUMP

1. Oil Supply to steering emergency pump

Not used on 30 Ton Truck

2. Oil inlet pipe from reservoir

3. Oil return pipe to reservoir

4. Delivery pipe to high pressure brake

filter

S. BRAKE OIL FILTER

1. Starter Unloading Solenoid valve

2. Delivery pipe to accumulator recharging

valve

3. Return pipe to reservoir

4. Inlet pipe from pump

5. Brake Filter

HYDRAULIC

25 & 30 TON ARTICULATED DUMP TRUCKS

24

T. ACCUMULATOR RECHARGING VALVE

1. Supply line from brake filter on 30 Ton,

Supply line from starter unloading solenoid

valve on 25 Ton Truck

2. Front brake accumulator S1 supply line

3. Rear brake accumulator S2 supply line

4. Parking brake accumulator S3 supply

line

5. Oil return pipe to reservoir (main circuit)

6. Oil discharge pipe to reservoir (drive

circuit)

7. Low brake pressure switch

HYDRAULIC

25 & 30 TON ARTICULATED DUMP TRUCKS

25

U. 25 TON TRUCK ACCUMULATORS

U. 30 TON TRUCK ACCUMULATORS

1. Supply line from valve A1 of

accumulator recharging valve

2. Supply line to valve P (upper) of service

brake pressure control valve

3. Supply line from valve A 2 of

accumulator recharging valve

4. Supply line to valve P (lower) of service

brake pressure control valve

5. Supply line from one-way check valve

on recharging valve to park brake accum.

6. Supply line to parking brake control

solenoid valve

HYDRAULIC

25 & 30 TON ARTICULATED DUMP TRUCKS

26

V. PARKING BRAKE CONTROL SOLENOID VALVE

1. Supply line from park brake accumulator

2. Parking brake control pipe

3. Return pipe to reservoir

4. Park Brake Solenoid Control valve

5. Park Brake Pressure Switch

6. Park Brake Solenoids

W. SERVICE BRAKE CONTROL VALVE

1. Supply line from recharging valve (A 1 )

2. Supply line from recharging valve (A 2 )

3. Front axle brake control pipe

4. Rear axles brake control pipe

5. Front brake return pipe to reservoir

6. Rear brakes return pipe to reservoir

7. Brake Light Pressure switch

HYDRAULIC

25 & 30 TON ARTICULATED DUMP TRUCKS

27

TROUBLESHOOTING

PROBLEM POSSIBLE CAUSES REMEDY

Slow hydraulic functions Oil level low

2. Oil cold

3. Oil not correct

4. Engine speed too low

5. Pump worn

6. Pump intake pipe

crimped

7. Suction filter in reservoir

restricted

1. Fill the reservoir to the

full level

2. Wait a few minutes with

the engine running before

using the vehicle

3. The oil used is not

suitable. Drain the reservoir

and use the correct type

4. Increase engine rpm

5. Replace the pump

6. Check condition of tubes

and replace them in the

event of damage and/or

crimping. Do not repair

7. Clean or replace the

suction screen

Hydraulic system oil

overheats

Oil not correct

2. Air leakage into pump

intake pipe

3. Oil level low

4. Filters restricted

5. Pump worn

6. Oil cooler obstructed

7. Pressure relief valve

8. Contaminated oil

9. Hydraulic components

not adjusted correctly

1. The oil used is not

suitable. Drain the reservoir

and use the correct type

2. Check condition of tubes

and replace them in the

event of damage and/or

crimping. Do not repair

3. Fill the reservoir to the

indicated level

4. Replace with new filters

5. Replace the pump

6. Clean and straighten

fins, if bent

7. Check operation of valve

and replace it, if required

8. Drain the reservoir and

use the correct type of oil

9. Check correct

adjustment of hydraulic

components

HYDRAULIC

25 & 30 TON ARTICULATED DUMP TRUCKS

28

Emulsified oil 1. Air leakage into pump

intake pipe

2. Oil pipes twisted or

damaged

3. Oil not correct

4. Water in oil

5. Oil level either high or

low

1. Check condition of tubes

and replace them in the

event of damage and/or

crimping. Do not repair

2. Arrange pipes correctly

and check that they are not

damaged. Replace the

seals, if required. Do not

repair

3. The oil used is not

suitable. Drain the reservoir

and use the correct type

4. Change the oil

5. Restore correct oil level

by adding or removing oil

Low or insufficient oil

pressure

1. Oil not correct

2. Hydraulic components

not adjusted correctly

3. No oil in system

4. Worn cylinder seal

5. Pressure relief valve

incorrectly adjusted

1. The oil used is not

suitable. Drain the reservoir

and use the correct type

2. Check correct

adjustment of hydraulic

components

3. Add oil to reach indicated

level

4. Replace the seals

5. Check operation of valve

and replace it, if required

No hydraulic function

(noisy pumps)

1. Hydraulic pump not

working and/or worn

2. No oil in system

3. Intake pipes damaged

4. Intake filter obstructed

1. Replace the pump

2. Add oil to reach indicated

level

3. Replace the pipes

4. Clean filter and replace,

if required

HYDRAULIC

25 & 30 TON ARTICULATED DUMP TRUCKS

29

BLEEDING THE HYDRAULIC CIRCUITS

NOTE: The vehicle is equipped with a

single hydraulic system split into three

circuits: braking circuit; steering circuit;

and load dumping circuit. Bleed each of

the three circuits separately.

BRAKING CIRCUIT

1. Press the brake pedal fully and hold it

pressed down.

2. Remove the dust cap, then fit a

transparent tube on the bleeder (1).

Submerge one end of the tube in a bowl

containing oil.

3. Loosen the valve, letting out the oil and

the air bubbles. Close it after a few

seconds.

NOTE: Close the valve if the end of the

clear tube is not submerged.

4. Fully release the brake pedal.

5. Repeat the operation until oil without

bubbles comes out of the bleeder.

6. Close the bleeder.

7. Fit the cap and repeat the operation on

the other braking units of the vehicle.

7. At the end of the operation, check the oil

level in the reservoir and add more if

required.

STEERING CIRCUIT

1. Start the engine, steer slowly and fully

to the right and then to the left.

2. Repeat the operation a few times to

eliminate the air bubbles in the circuit.

3. At the end of the operation, check the oil

level in the reservoir and add more if

required.

LOAD DUMPING CIRCUIT

1. Start the engine and tip the bucket to fill

the circuit.

2. Bring the bucket back to home position.

3. Repeat the operation several times to

eliminate the air in the cylinders.

4. At the end of the operation, check the oil

level in the reservoir and add more, if

required.

HYDRAULIC

25 & 30 TON ARTICULATED DUMP TRUCKS

30

25 TON TRUCK HYDRAULIC SYSTEM DIAGRAM

1. Emergency steering pump (19 L/min - 24V DC) (5 gal/min - 24V DC)

2. Main hydraulic pump (117 cm

3

/rev) (7.13 in

3

/rev)

3. Hydraulic brake pump (19.5 cm

3

/rev - 175 bar) (1.18 in

3

/rev - 2539 psi)

4. Steering Orbital valve

5. Flow amplifier

6. Load dumping valve

7. Counterbalancing valve

8. Parking brake control valve

9. Differential Lock control valve

10. Intake oil filter (125 )

11. Accumulator recharge valve

12. Service brake pressure control valve

13. Hydraulic oil heat exchanger

14. Pressurized filter (25 )

15. Steering flow check valve

17. Emergency steering pressure switch

18A. Load dumping control hydraulic pressure test point A

18B. Steering control hydraulic pressure test point B

18C. Differential Lock control hydraulic pressure test point C

18E. Service Brake pressure test point E (At manifold at front of rear chassis)

19. Steering cylinders

20. Hoist cylinders

21. Hydraulic accumulators (1.4 liters - 65 bar) (1.5 qt. - 942 psi)

22. Park Brake check valve

23. Service brake accumulator pressure switch (125 Bar 1813 psi)

24. Brake stop light pressure switch (3 Bar 44 psi)

26. Parking brake light switch

28. Brake pressure filter

29. Brake filter restriction indicator switch

30. Center axle differential Lock cylinder

31. ZF Transmission Differential Lock shift cylinder

32. Parking brake calipers

33. Front axle brake calipers

34. Rear axle brake calipers

35. Center axle brake calipers

36. Hydraulic oil cooler bypass restrictor

37. Starter unloading solenoid valve (Brake Circuit)

38. Rear cab oil porting manifold

39. Rear chassis connection manifold assembly

ARTICULATED DUMP TRUCKS

31

ARTICULATED DUMP TRUCKS

32

HYDRAULIC

25 & 30 TON ARTICULATED DUMP TRUCKS

33

PAGE LEFT

INTENTIONALLY

BLANK

HYDRAULIC

25 & 30 TON ARTICULATED DUMP TRUCKS

34

30 TON TRUCK HYDRAULIC SYSTEM DIAGRAM

1. Emergency steering pump (32 cm

3

/rev) (1.95 in

3

/rev)

2. Main hydraulic pump (117 cm

3

/rev) (7.13 in

3

/rev)

3. Hydraulic brake pump (19.5 cm

3

/rev - 175 bar) (1.18 in

3

/rev - 2539 psi)

4. Steering Orbital valve

5. Flow amplifier

6. Load dumping valve

7. Counterbalancing valve

8. Parking brake control valve

9. Center axle differential Lock control valve

10. Intake oil filter (125 )

11. Accumulator recharge valve

12. Service brake pressure control valve

13. Hydraulic oil heat exchanger

14. Pressurized filter (25 )

15. Steering flow check valve

16. Emergency steering flow check valve

17. Emergency steering pressure switch

18A. Load dumping control hydraulic pressure test point A

18B. Steering control hydraulic pressure test point B

18C. Center axle Differential Lock control hydraulic pressure test point C

18D. ZF Transmission Differential Lock control hydraulic pressure test point D

18E. Service Brake pressure test point E (At manifold at front of rear chassis)

19. Steering cylinders

20. Hoist cylinders

21. Hydraulic accumulators (1.4 liters - 65 bar) (1.5 qt. - 942 psi)

22. Park Brake check valve

23. Service brake accumulator pressure switch (125 Bar 1813 psi)

24. Brake stop light pressure switch (3 Bar 44 psi)

25. Emergency steering control solenoid valve

26. Parking brake light switch

27. ZF Transmission Differential Lock control valve

28. Brake pressure filter

29. Brake filter restriction indicator switch

30. Center axle differential Lock cylinder

31. ZF Transmission Differential Lock shift cylinder

32. Parking brake calipers

33. Front axle brake calipers

34. Rear axle brake calipers

35. Center axle brake calipers

36. Hydraulic oil cooler bypass restrictor

38. Rear cab oil porting manifold

39. Rear chassis connection manifold assembly

ARTICULATED DUMP TRUCKS

36

HYDRAULIC

25 & 30 TON ARTICULATED DUMP TRUCKS

37

CHECKS AND VERIFICATION

HYDRAULIC PRESSURE TEST POINTS

A. Load dumping Valve pressure test point

B. Steering pressure test point

C. Center Axle Differential Lock pressure

test point

D. Transmission Differential Lock pressure

test point on 30 Ton Truck Central

greasing point for front chassis on 25 Ton

Truck

LOAD DUMPING VALVE PRESSURE

TEST POINT (A)

A hex wrench is used to adjust the main

pressure.

1. Position the vehicle on a solid, level,

surface with the engine running.

2. Raise the dump body to its full extent.

3. Connect a suitable pressure gauge to

the load dumping valve system test point

(A).

4. With the body raised to full extent and

control lever operated, bring the engine to

full speed. The pressure gauge should

show 1605 bar (2248 to 2393 psi).

IMPORTANT: The pressure must never

exceed 165 bar (2393 psi) in all conditions.

5. Remove the external plug and insert a

hex wrench (1) into the adjustment plug on

the main valve block. To increase

pressure, turn adjustment device

clockwise. To decrease pressure, turn

adjustment device counterclockwise.

HYDRAULIC

25 & 30 TON ARTICULATED DUMP TRUCKS

38

CHECKS AND VERIFICATION (continued)

STEERING PRESSURE TEST POINT (B)

1. Position the vehicle on a solid, level

surface with the engine running.

2. Connect a suitable pressure gauge to

the steering pressure test point (B).

3. Turn the steering wheel to the left until

you reach full lock and maintain full lock

until the adjustment is complete.

4. With the steering wheel still at full lock,

bring the engine to full speed. The

pressure gauge should show 185 bar

(2684 psi).

5. The steering pressure adjustment

device is located on the flow amplifier (2).

You are advised not to change the original

setting. Requires a 5 mm hex wrench to

adjust.

CENTER AXLE DIFFERENTIAL LOCK

PRESSURE TEST POINT (C)

1. Position the vehicle on a solid, level

surface with the engine running.

2. Connect a suitable pressure gauge to

the center axle differential lock pressure

test point (C). The pressure gauge should

show a value in the range of 5 to 8 bar (72

to 116 psi).

3. The adjustment device is located on the

reduction valve (3) situated near the flow

amplifier on the 25 Ton Truck and inside

the left front access cover on the NA 30

Ton Truck

IMPORTANT: The pressure must not

exceed 8 bar (116 psi). This is the

maximum required pressure. Higher

values could damage the cylinder.

HYDRAULIC

25 & 30 TON ARTICULATED DUMP TRUCKS

39

CHECKS AND VERIFICATION (continued)

TRANSMISSION DIFFERENTIAL LOCK

PRESSURE TEST POINT (D ON NA 30

TON TRUCK)

1. Position the vehicle on a solid, level

surface with the engine running.

2. Connect a suitable pressure gauge to

the transmission differential lock pressure

test point (D). The pressure gauge should

show a value in the range of 5 to 8 bar (72

to 116 psi).

3. The adjustment device is located on the

reduction valve (3) situated at the front of

the transmission on the NA 30 Ton Truck

IMPORTANT: The pressure must not

exceed 8 bar (116 psi). This is the

maximum required pressure. Higher

values could damage the cylinder.

HYDRAULIC

25 & 30 TON ARTICULATED DUMP TRUCKS

40

PAGE LEFT

INTENTIONALLY

BLANK

Você também pode gostar

- Danfoss OperacionesDocumento28 páginasDanfoss OperacionesDaniel Alfonso Diaz Flores100% (1)

- 777D Off Highway Truck: Service Training MalagaDocumento17 páginas777D Off Highway Truck: Service Training MalagaMAQUINARIAPESADA100% (4)

- Hydraulic Power SteeringDocumento6 páginasHydraulic Power SteeringMohamad Nadzri YahayaAinda não há avaliações

- D6C Power Shift OperationDocumento40 páginasD6C Power Shift OperationJhon AschAinda não há avaliações

- Aircrafts Hydraulic SystemDocumento23 páginasAircrafts Hydraulic SystemPrinnia Zulfiqur BorshaAinda não há avaliações

- 777F MG SistemasDocumento118 páginas777F MG SistemasDenerMendozaLayza100% (6)

- Sistema HidráulicoDocumento36 páginasSistema HidráulicoValdir AlexandreAinda não há avaliações

- EH750-3 Hitachi Euclid Rigid Hauler Hydraulic Training 2nd PartDocumento15 páginasEH750-3 Hitachi Euclid Rigid Hauler Hydraulic Training 2nd Partthan zaw win100% (1)

- Chapter 6 HYDRAULICDocumento93 páginasChapter 6 HYDRAULICShishir GyawaliAinda não há avaliações

- Hydraulic System: Systems OperationDocumento28 páginasHydraulic System: Systems OperationRoberto BaierAinda não há avaliações

- B NG-Hydraulics PDFDocumento15 páginasB NG-Hydraulics PDFanasAinda não há avaliações

- B NG-Hydraulics NoRestrictionDocumento15 páginasB NG-Hydraulics NoRestrictionseansimoesAinda não há avaliações

- Aircraft Hydraulic SystemsDocumento23 páginasAircraft Hydraulic SystemsedwardsilvaAinda não há avaliações

- Búsqueda Del Medio - Senr2934 - 768c Tractor & 769c Truck Power TrainDocumento104 páginasBúsqueda Del Medio - Senr2934 - 768c Tractor & 769c Truck Power TrainAnonymous aufoLkcwhZAinda não há avaliações

- Aircraft Hydraulic System 58a22e86ebd79Documento23 páginasAircraft Hydraulic System 58a22e86ebd79Hein SoeAinda não há avaliações

- 980b Wheel Loader HydraDocumento13 páginas980b Wheel Loader HydraChrissz Noxd0% (1)

- SSP 221Documento56 páginasSSP 221pabloiecAinda não há avaliações

- HEX - 300D - With Tier III Engines - SERV7107 - Sect 2 - TextDocumento15 páginasHEX - 300D - With Tier III Engines - SERV7107 - Sect 2 - TextsergeyAinda não há avaliações

- 80-900 TransmissionDocumento40 páginas80-900 TransmissionjeevaAinda não há avaliações

- 785D Off-Highway Truck Hydraulic System Systems OperationDocumento24 páginas785D Off-Highway Truck Hydraulic System Systems Operation1Ainda não há avaliações

- Section 6 Work EquipmentDocumento37 páginasSection 6 Work EquipmentPriscila RodriguesAinda não há avaliações

- Fluid Power Control and Automation PresentationDocumento18 páginasFluid Power Control and Automation PresentationmuthukumaranAinda não há avaliações

- Hydraulic Control System of ATDocumento4 páginasHydraulic Control System of ATAsmaa EidAinda não há avaliações

- D6R Series III Track Type Tractor Power Train SystemDocumento2 páginasD6R Series III Track Type Tractor Power Train SystemIH Medrano78% (9)

- Hydraulic SystemsDocumento44 páginasHydraulic Systemsrizaazari4530100% (1)

- Electrohydraulic Steering GearDocumento6 páginasElectrohydraulic Steering Gearyoarun5100% (2)

- Phase II Steering Gear Q&ADocumento11 páginasPhase II Steering Gear Q&ANithin Varghese100% (2)

- 797B Power Train System OperationDocumento29 páginas797B Power Train System OperationneedAinda não há avaliações

- Plano de Transmision D6TDocumento2 páginasPlano de Transmision D6TronaldAinda não há avaliações

- Systems Operation: Cerrar SISDocumento138 páginasSystems Operation: Cerrar SISCar GarciaAinda não há avaliações

- Aircraft Hydraulic SystemsDocumento23 páginasAircraft Hydraulic SystemsGopal Jetani0% (1)

- VIBRATORY COMPACTION ROLLER SPECS AND PARTSDocumento213 páginasVIBRATORY COMPACTION ROLLER SPECS AND PARTSDayaRomanAinda não há avaliações

- Eaton Complete Transaxle Repair Guide - Ea11whDocumento45 páginasEaton Complete Transaxle Repair Guide - Ea11whSteve Nah100% (1)

- Citation Sovereign-HydraulicDocumento2 páginasCitation Sovereign-HydraulicfranciscogpdaAinda não há avaliações

- Systems Operation: (Power Shift)Documento36 páginasSystems Operation: (Power Shift)Muhammad Nadim MakhlufAinda não há avaliações

- Diesel fuel system for Caterpillar 3208 engineDocumento36 páginasDiesel fuel system for Caterpillar 3208 engineLynda CarrollAinda não há avaliações

- Hydraulic System: Operación de SistemasDocumento5 páginasHydraulic System: Operación de Sistemasmiguel_catAinda não há avaliações

- 930R e 930T Power TrainDocumento34 páginas930R e 930T Power TrainGilson RodriguesAinda não há avaliações

- As350 Hyd Section SM PDFDocumento34 páginasAs350 Hyd Section SM PDFIvan BastianiAinda não há avaliações

- Diagrama Hidraulico 777FDocumento4 páginasDiagrama Hidraulico 777Ffabioalbor100% (1)

- KWU Text GoverningDocumento43 páginasKWU Text GoverningSam100% (2)

- Aircraft Hydraulic SystemsDocumento23 páginasAircraft Hydraulic SystemsJyotiRanjanBehera100% (1)

- (TM) Land Rover Manual de Taller de Range Rover Evoque Caja ZF 2012 en InglesDocumento446 páginas(TM) Land Rover Manual de Taller de Range Rover Evoque Caja ZF 2012 en InglesMelik ŞekerAinda não há avaliações

- 580 590 Series 3 Variable Volume Pilot Controls PDFDocumento62 páginas580 590 Series 3 Variable Volume Pilot Controls PDFG & C Maquinaria100% (1)

- ME080 Section 2 - Types of Hydraulic CircuitsDocumento55 páginasME080 Section 2 - Types of Hydraulic CircuitsAhmed FaragAinda não há avaliações

- D PWT D6riii PDFDocumento2 páginasD PWT D6riii PDFDennis Olaya100% (1)

- Power Train Hydraulic System 740Documento16 páginasPower Train Hydraulic System 740Jesus Almanzar Santos100% (4)

- Operator's Guide to General Purpose Steam Turbines: An Overview of Operating Principles, Construction, Best Practices, and TroubleshootingNo EverandOperator's Guide to General Purpose Steam Turbines: An Overview of Operating Principles, Construction, Best Practices, and TroubleshootingNota: 5 de 5 estrelas5/5 (1)

- Marvel Carbureter and Heat Control As Used on Series 691 Nash Sixes Booklet SNo EverandMarvel Carbureter and Heat Control As Used on Series 691 Nash Sixes Booklet SAinda não há avaliações

- Troubleshooting Process Plant Control: A Practical Guide to Avoiding and Correcting MistakesNo EverandTroubleshooting Process Plant Control: A Practical Guide to Avoiding and Correcting MistakesNota: 1 de 5 estrelas1/5 (2)

- Hydraulics and Pneumatics: A Technician's and Engineer's GuideNo EverandHydraulics and Pneumatics: A Technician's and Engineer's GuideNota: 4 de 5 estrelas4/5 (8)

- Stan Shiels on centrifugal pumps: Collected articles from 'World Pumps' magazineNo EverandStan Shiels on centrifugal pumps: Collected articles from 'World Pumps' magazineNota: 5 de 5 estrelas5/5 (1)

- Prevention of Actuator Emissions in the Oil and Gas IndustryNo EverandPrevention of Actuator Emissions in the Oil and Gas IndustryAinda não há avaliações

- Parts Catalogue JLG 3508Documento520 páginasParts Catalogue JLG 3508KaloyanAinda não há avaliações

- Service Manual: Models 266, 307 & 266 LoproDocumento126 páginasService Manual: Models 266, 307 & 266 LoproBaciu Nicolae100% (1)

- Service Manual: Models 266, 307 & 266 LoproDocumento126 páginasService Manual: Models 266, 307 & 266 LoproBaciu Nicolae100% (1)

- Transaxle & BrakeDocumento103 páginasTransaxle & BrakeBaciu NicolaeAinda não há avaliações

- Electrical SystemDocumento196 páginasElectrical SystemBaciu NicolaeAinda não há avaliações

- JLG Telehandlers EN15000 Service TrainingDocumento54 páginasJLG Telehandlers EN15000 Service TrainingBaciu Nicolae100% (1)

- JLG Telehandlers EN15000 Service TrainingDocumento54 páginasJLG Telehandlers EN15000 Service TrainingBaciu Nicolae100% (1)

- Periodic Maintenance: J45-70XN (A276)Documento87 páginasPeriodic Maintenance: J45-70XN (A276)Baciu Nicolae100% (1)

- Group 5 TroubleshootingDocumento1 páginaGroup 5 TroubleshootingBaciu NicolaeAinda não há avaliações

- Electrical SystemDocumento196 páginasElectrical SystemBaciu NicolaeAinda não há avaliações

- Periodic Maintenance: J45-70XN (A276)Documento87 páginasPeriodic Maintenance: J45-70XN (A276)Baciu Nicolae100% (1)

- Ac Motor RepairDocumento71 páginasAc Motor RepairBaciu Nicolae100% (1)

- Hydraulic SystemDocumento88 páginasHydraulic SystemBaciu NicolaeAinda não há avaliações

- Transaxle & BrakeDocumento103 páginasTransaxle & BrakeBaciu NicolaeAinda não há avaliações

- Group 5 TroubleshootingDocumento1 páginaGroup 5 TroubleshootingBaciu NicolaeAinda não há avaliações

- Group 2 operational checks and troubleshooting for forkliftsDocumento3 páginasGroup 2 operational checks and troubleshooting for forkliftsstefan corjucAinda não há avaliações

- Section 3 Power Train System: Group 1 Structure and OperationDocumento29 páginasSection 3 Power Train System: Group 1 Structure and OperationBaciu NicolaeAinda não há avaliações

- GROUP 2 REMOVAL AND INSTALLATION OF UNITDocumento17 páginasGROUP 2 REMOVAL AND INSTALLATION OF UNITBaciu NicolaeAinda não há avaliações

- Group 4 Removal and Installation: 1. ForksDocumento9 páginasGroup 4 Removal and Installation: 1. ForksBaciu NicolaeAinda não há avaliações

- Section 7 Electrical System: Group 1 Component LocationDocumento1 páginaSection 7 Electrical System: Group 1 Component LocationBaciu NicolaeAinda não há avaliações

- How to Access and Adjust Parameters in a Deep Sea Electronics Wiring Diagram Configuration EditorDocumento2 páginasHow to Access and Adjust Parameters in a Deep Sea Electronics Wiring Diagram Configuration EditorBaciu NicolaeAinda não há avaliações

- Section 4 Brake System: Group 1 Structure and FunctionDocumento19 páginasSection 4 Brake System: Group 1 Structure and FunctionBaciu NicolaeAinda não há avaliações

- Group 3 Disassembly and Assembly: 1. Steering UnitDocumento29 páginasGroup 3 Disassembly and Assembly: 1. Steering UnitBaciu NicolaeAinda não há avaliações

- Group 3 Adjustment: 1. Mast Load RollerDocumento2 páginasGroup 3 Adjustment: 1. Mast Load RollerBaciu NicolaeAinda não há avaliações

- Section 7 Electrical System: Group 1 Component LocationDocumento1 páginaSection 7 Electrical System: Group 1 Component LocationBaciu NicolaeAinda não há avaliações

- Group 3 Disassembly and Assembly: 1. Main PumpDocumento12 páginasGroup 3 Disassembly and Assembly: 1. Main PumpBaciu NicolaeAinda não há avaliações

- Group 3 Disassembly and AssemblyDocumento99 páginasGroup 3 Disassembly and AssemblyBaciu NicolaeAinda não há avaliações

- Group 1 Safety Hints: D50ASF01Documento4 páginasGroup 1 Safety Hints: D50ASF01Baciu NicolaeAinda não há avaliações

- Group 3 Disassembly and Assembly: 1. Steering UnitDocumento29 páginasGroup 3 Disassembly and Assembly: 1. Steering UnitBaciu NicolaeAinda não há avaliações

- Section 3 Power Train System: Group 1 Structure and OperationDocumento29 páginasSection 3 Power Train System: Group 1 Structure and OperationBaciu NicolaeAinda não há avaliações

- Jacoby TarboxDocumento7 páginasJacoby TarboxBayu Permana RydhaAinda não há avaliações

- ASSAM - Uniform Zoning Regulation 2000Documento35 páginasASSAM - Uniform Zoning Regulation 2000rajatesh1Ainda não há avaliações

- VENTILADOR INDUSTRIAL enDocumento4 páginasVENTILADOR INDUSTRIAL enFelipe BarrientosAinda não há avaliações

- Ignition Characteristics of Cracked JP-7 FuelDocumento4 páginasIgnition Characteristics of Cracked JP-7 Fuelfahrul3xAinda não há avaliações

- Catalogo General KOBA 1000 - e - 2012revDocumento21 páginasCatalogo General KOBA 1000 - e - 2012revTECNIMETALAinda não há avaliações

- Process Control Plan SCM100113Documento20 páginasProcess Control Plan SCM100113Rohit MakhijaAinda não há avaliações

- The Autolisp TutorialsDocumento285 páginasThe Autolisp Tutorialsmynareshk100% (7)

- FE Exam Formatted ProblemsDocumento12 páginasFE Exam Formatted ProblemsCarlo Galicia100% (1)

- NZS 4298:1998 Materials and Workmanship For Earth Buildings: Skip To Main Content Skip To Primary NavigationDocumento10 páginasNZS 4298:1998 Materials and Workmanship For Earth Buildings: Skip To Main Content Skip To Primary NavigationRui TerrasAinda não há avaliações

- Va80 PDFDocumento4 páginasVa80 PDFomar leonAinda não há avaliações

- TPF 5-165 Task 1 Final ReportDocumento112 páginasTPF 5-165 Task 1 Final ReportLohith Kumar H PAinda não há avaliações

- Profile Summary:: Curriculum VitaeDocumento3 páginasProfile Summary:: Curriculum Vitaepritam banerjeeAinda não há avaliações

- Ewsd BSNL PDFDocumento2 páginasEwsd BSNL PDFAdamAinda não há avaliações

- TS1A-13A: Operation and Maintenance ManualDocumento204 páginasTS1A-13A: Operation and Maintenance ManualJavier AponteAinda não há avaliações

- Oxygen USPDocumento2 páginasOxygen USPMartha Lucia Roa FonsecaAinda não há avaliações

- Banner Printing Set UpDocumento21 páginasBanner Printing Set UpAsanka ChandimaAinda não há avaliações

- Max 223C Pipeline Welding InverterDocumento2 páginasMax 223C Pipeline Welding InvertermtonellyAinda não há avaliações

- API 6D Valves Bonney Forge PDFDocumento12 páginasAPI 6D Valves Bonney Forge PDFSQUALO_122Ainda não há avaliações

- Engineering Data Ip5-3600Documento2 páginasEngineering Data Ip5-3600CESAR SEGURAAinda não há avaliações

- ACSEW Cast Control Centers: Explosionproof, Dust-IgnitionproofDocumento24 páginasACSEW Cast Control Centers: Explosionproof, Dust-IgnitionproofDennis MendozaAinda não há avaliações

- Checklist for Training Cleaning StaffDocumento1 páginaChecklist for Training Cleaning StaffharrydrivesucrazyAinda não há avaliações

- An Experimental Comparative Review - PK NanavatiDocumento9 páginasAn Experimental Comparative Review - PK NanavatiPurvesh NanavatiAinda não há avaliações

- MP3 - Equations of StateDocumento8 páginasMP3 - Equations of StatePatrick ValdezAinda não há avaliações

- Comp Notes 122 PDFDocumento57 páginasComp Notes 122 PDFmuhammad wisalAinda não há avaliações

- 50 KvaDocumento4 páginas50 KvariogadAinda não há avaliações

- ABB 4 Pole Contactor, 230V, 40ADocumento1 páginaABB 4 Pole Contactor, 230V, 40ASEERALANAinda não há avaliações

- Aranya Housing Final To Be Submitted PDFDocumento37 páginasAranya Housing Final To Be Submitted PDFsucheta100% (4)

- 10 Ways To Speed Up Torrent DownloadsDocumento5 páginas10 Ways To Speed Up Torrent DownloadsricoffanyAinda não há avaliações

- Smart is the most intelligent solution yet for urban drivingDocumento8 páginasSmart is the most intelligent solution yet for urban drivingHenrique CorreiaAinda não há avaliações

- Soil Analysis Bitupan LastDocumento25 páginasSoil Analysis Bitupan Lastbitupon boraAinda não há avaliações