Escolar Documentos

Profissional Documentos

Cultura Documentos

Fire Sprinkler For Non-Storage Facilities PPT Presentation PDF

Enviado por

MickoAngeloRamirezAquino100%(2)100% acharam este documento útil (2 votos)

204 visualizações62 páginasThe document discusses fire protection systems and sprinkler systems. It provides information on the classification of fires and hazards, operating principles of sprinklers, types of sprinklers, temperature ratings, and types of sprinkler systems. It also discusses occupancy hazard classification and categories based on the type of occupancy. The document appears to be from the Philippine Society of Mechanical Engineers Quezon City Central Chapter and contains technical details on fire protection standards and sprinkler systems.

Descrição original:

Título original

Fire Sprinkler For Non-Storage Facilities PPT Presentation.pdf

Direitos autorais

© © All Rights Reserved

Formatos disponíveis

PDF, TXT ou leia online no Scribd

Compartilhar este documento

Compartilhar ou incorporar documento

Você considera este documento útil?

Este conteúdo é inapropriado?

Denunciar este documentoThe document discusses fire protection systems and sprinkler systems. It provides information on the classification of fires and hazards, operating principles of sprinklers, types of sprinklers, temperature ratings, and types of sprinkler systems. It also discusses occupancy hazard classification and categories based on the type of occupancy. The document appears to be from the Philippine Society of Mechanical Engineers Quezon City Central Chapter and contains technical details on fire protection standards and sprinkler systems.

Direitos autorais:

© All Rights Reserved

Formatos disponíveis

Baixe no formato PDF, TXT ou leia online no Scribd

100%(2)100% acharam este documento útil (2 votos)

204 visualizações62 páginasFire Sprinkler For Non-Storage Facilities PPT Presentation PDF

Enviado por

MickoAngeloRamirezAquinoThe document discusses fire protection systems and sprinkler systems. It provides information on the classification of fires and hazards, operating principles of sprinklers, types of sprinklers, temperature ratings, and types of sprinkler systems. It also discusses occupancy hazard classification and categories based on the type of occupancy. The document appears to be from the Philippine Society of Mechanical Engineers Quezon City Central Chapter and contains technical details on fire protection standards and sprinkler systems.

Direitos autorais:

© All Rights Reserved

Formatos disponíveis

Baixe no formato PDF, TXT ou leia online no Scribd

Você está na página 1de 62

PSME-QCC Chapter

Philippine Society of Mechanical Engineers

Quezon City Central Chapter

Caveman and Fire Destroys

McDonalds video clips.

PSME-QCC Chapter

Philippine Society of Mechanical Engineers

Quezon City Central Chapter

OXYGEN

HEAT

FUEL

is a chemical reaction.

Chemical

Reaction

PSME-QCC Chapter

Philippine Society of Mechanical Engineers

Quezon City Central Chapter

Classification of Fires (NFPA 10, Standard for Portable Fire Extinguishers)

Class A Ordinary combustible materials (wood,

cloth, paper, rubber, and many plastics)

Class B Flammable liquids, combustible liquids,

petroleum greases, tars, oils, oil-based

paints, solvents, lacquers, alcohols, and

flammable gases

Class C Energized electrical equipment

Class D Combustible metals (magnesium, titanium,

zirconium, sodium, lithium, potassium)

Class K Cooking appliances/media (vegetable

or animal oils and fats)

PSME-QCC Chapter

Philippine Society of Mechanical Engineers

Quezon City Central Chapter

Types of Hazard (NFPA 13, Standard for the Installation of Sprinkler Systems)

LIGHT or LOW - few combustibles (office, church,

schoolroom, assembly hall)

ORDINARY or MODERATE - small quantities of

combustibles capable of rapid fire growth

(mercantile storage and display area, auto

showroom, parking garage; offices and schoolrooms

that contain sufficient amount of combustible materials)

EXTRA or HIGH- combustibles whose nature or

configuration could readily support rapid fire growth and

large fire size (woodworking areas, aircraft hangar,

high-piled storage warehouse)

PSME-QCC Chapter

Philippine Society of Mechanical Engineers

Quezon City Central Chapter

Types of Extinguishment

Water

Aqueous Foam

Water Mist

Dry Chemical

Inert Gas

Halocarbon Agent

Automatic Sprinklers

PSME-QCC Chapter

Philippine Society of Mechanical Engineers

Quezon City Central Chapter

Thermosensitive device designed to react at a

predetermined temperature

AUTOMATIC SPRINKLER

Automatically release a stream of water and

distribute it in specified pattern and quantity over

designated areas

Designed to operate during early stages of fire

development and minimize the fires overall impact

NFPA 13 provides standardized rules for design,

installation, and acceptance testing of sprinkler

systems.

PSME-QCC Chapter

Philippine Society of Mechanical Engineers

Quezon City Central Chapter

Development of Sprinklers

Manually operated water supply on steel pipe

networks with drilled holes.

Heat-actuated device (1875) by Henry Parmelee;

the first automatic sprinkler.

Parmelee Sprinkler Neracher Sprinkler

New Grinell Sprinkler Kane Sprinkler

National Manufacturing Company Sprinkler

PSME-QCC Chapter

Philippine Society of Mechanical Engineers

Quezon City Central Chapter

Operating Principles of a Sprinkler

Heat detection is the basis of sprinkler system response.

Heat-actuation by convective heat transfer

PSME-QCC Chapter

Philippine Society of Mechanical Engineers

Quezon City Central Chapter

Types of Sprinklers

Fusible

Sprinkler

Bulb Sprinkler

PSME-QCC Chapter

Philippine Society of Mechanical Engineers

Quezon City Central Chapter

Standard Spray Sprinkler

Standard Spray Upright (SSU)

Standard Spray Pendent (SSP)

Types of Sprinklers

Recessed Sprinkler

Concealed Sprinkler

PSME-QCC Chapter

Philippine Society of Mechanical Engineers

Quezon City Central Chapter

Types of Sprinklers

Flush-type Sprinkler

Side-wall Sprinkler

Residential Sprinkler

PSME-QCC Chapter

Philippine Society of Mechanical Engineers

Quezon City Central Chapter

Types of Sprinklers

Early Supression Fast Response (ESFR) Sprinkler

K = 14 (Km = 200) ESFR Sprinkler (Left) Compared to K = 5.6 (Km = 80) Standard Spray Sprinkler (Right)

Widespread use

starting 1990s for

Storage Occupancies

PSME-QCC Chapter

Philippine Society of Mechanical Engineers

Quezon City Central Chapter

Temperature Ratings, Classifications, and Color Codings

Maximum Ceiling Temperature Temperature Rating

Temperature

Classification

Color Code Glass Bulb Colors

C F C F

38 100 5777 135170 Ordinary Uncolored or black Orange or red

66 150 79107 175225 Intermediate White Yellow or green

107 225 121149 250300 High Blue Blue

149 300 163191 325375 Extra high Red Purple

191 375 204246 400475 Very extra high Green Black

246 475 260302 500575 Ultra high Orange Black

329 625 343 650 Ultra high Orange Black

Source: NFPA 13, Standard for the Installation of Sprinkler Systems.

Temperature Ratings of Automatic Sprinklers

Principal Distribution Pattern of Water from SS Sprinklers

PSME-QCC Chapter

Philippine Society of Mechanical Engineers

Quezon City Central Chapter

Hypothetical Sprinkler System Installation

(Illustrating various water supply sources and system attachments)

NFPA 20, Standard for the Installation of Stationary Pumps for Fire Protection

NFPA 22, Standard for Water Tanks for Private Fire Protection

NFPA 13, Standard for the Installation of Sprinkler Systems

PSME-QCC Chapter

Philippine Society of Mechanical Engineers

Quezon City Central Chapter

System Types

1. Wet Pipe System (and Antifreeze)

Typical Alarm Valve

Easiest to design and install and simplest to maintain.

Contain water under pressure at all times and utilize closed sprinklers.

Shall only be applied at temperatures above 4

0

C(40

0

F).

PSME-QCC Chapter

Philippine Society of Mechanical Engineers

Quezon City Central Chapter

System Types

Alarm Check Valve - Operation

PSME-QCC Chapter

Philippine Society of Mechanical Engineers

Quezon City Central Chapter

2. Dry Pipe System

System Types

Shall only be applied at temperatures below 4

0

C(40

0

F).

Contains no water prior to system activation but is rather charged with

air or nitrogen under pressure.

Air pressure drops when one or more sprinklers open. Dry pipe valve

opens, allowing water to flow through the open sprinklers.

PSME-QCC Chapter

Philippine Society of Mechanical Engineers

Quezon City Central Chapter

3. Pre-action System

System Types

Similar to a dry pipe system except that air pressure charge is less.

Pre-action Valve holds back the water.

Supplemental detection system opens pre-action valve.

PSME-QCC Chapter

Philippine Society of Mechanical Engineers

Quezon City Central Chapter

System Types

4. Deluge System

Deliver large quantities of water over specified areas in a relatively short period of time.

Utilizes open sprinklers to protect against rapidly growing and spreading fires.

Supplemental fire detection system activates the deluge valve.

System piping is at atmospheric pressure.

PSME-QCC Chapter

Philippine Society of Mechanical Engineers

Quezon City Central Chapter

Occupancy Hazard Classification (NFPA 13)

Defining the hazard is the first step in selecting and designing the system.

Animal shelters

Churches

Clubs

Eaves and overhangs, if of combustible construction

with no combustibles beneath

Educational

Hospitals, including animal hospitals and veterinary

facilities

Institutional

Kennels

Light hazard occupancies

Libraries, except large stack rooms

Museums

Nursing or convalescent homes

Offices, including data processing

Residential

Restaurant seating areas

Theaters and auditoriums, excluding stages and

prosceniums

Unused attics

Ordinary hazard occupancies (Group 1)

Automobile parking and showrooms

Bakeries

Beverage manufacturing

Canneries

Dairy products manufacturing and processing

Electronic plants

Glass and glass products manufacturing

Laundries

Restaurant service areas

PSME-QCC Chapter

Philippine Society of Mechanical Engineers

Quezon City Central Chapter

Agricultural facilities

Barns and stables

Cereal mills

Chemical plants ordinary

Confectionery products

Distilleries

Dry cleaners

Exterior Loading Docks

Feed mills

Horse stables

Leather goods manufacturing

Ordinary hazard occupancies (Group 2)

Racetrack stable/kennel areas, including those

stable/kennel areas, barns, and associated

buildings at state, county, and local fairgrounds

Repair garages

Resin application area

Stages

Textile manufacturing

Tire manufacturing

Tobacco products manufacturing

Wood machining

Libraries large stack room

areas

Machine shops

Metal working

Mercantile

Paper and pulp mills

Paper process plants

Piers and wharves

Post offices

Printing and publishing

Wood product assembly

Extra hazard occupancies (Group 1)

Aircraft hangars (except as governed by NFPA 409, Standard

on Aircraft Hangars)

Combustible hydraulic fluid use areas

Die casting

Metal extruding

Plywood and particle board manufacturing

Printing [using inks having flash points below 100F (38C)]

Rubber reclaiming, compounding, drying, milling,

vulcanizing

Saw mills

Textile picking, opening, blending, garnetting, or carding,

combining of cotton, synthetics, wool shoddy, or burlap

Upholstering with plastic foams

Extra hazard occupancies (Group 2)

Asphalt saturating

Flammable liquids spraying

Flow coating

Manufactured home or modular building assemblies

(where finished enclosure is present and has

combustible interiors)

Open oil quenching

Plastics processing

Solvent cleaning

Varnish and paint dipping

PSME-QCC Chapter

Philippine Society of Mechanical Engineers

Quezon City Central Chapter

Hazard Categories Based on Occupancy

Occupancy Description of Occupancy Exceptions

Hazard

Category

-Apartments Lightly loaded non-storage and Libraries with stack rooms larger in HC-1

-Churches

-Concealed spaces

-Hospitals and hospital laboratories

-Hotel rooms

-Institutions

-Kitchens

-Libraries

-Meeting rooms in convention

centers and hotels

-Museums

-Nursing or convalescent homes

-Offices

-Restaurant seating areas

nonmanufacturing areas with ordinary

combustibles.

Expect fires with relatively low rates of

heat release in these occupancies.

size than defined in Appendix A;

facilities with storage of electronic and

plastic media (see the applicable

storage data sheet).

Laboratories where exposed storage

and processing of flammable liquids is

considered excessive (see the

applicable flammable liquids data

sheet).

-Unused attics

Comparatively FM Global in its Property Loss Prevention Data Sheet 3-26 -Fire

Protection Water Demand for Non-storage Sprinklered Properties classifies occupancies into

four groups: HC-1 or Hazard Category-1, HC-2, HC-3 and HC-4.

Occupancy Hazard Classification (FM Global DS 3-26)

-Interior loading docks Moderately to heavily loaded areas Facilities that use hydraulic and HC-3

-Modular building subassembly

-Plastics processing and molding

-Vehicle repair garages and

assembly operations where

vehicles are repaired, tested, or

assembled with fuel in tanks

-Highway trailers, trucks, boxcars,

some mobile homes or similar

metal vehicles with combustible

interiors with the potential for

shielded fire

-Convention centers, Theaters and

Auditoriums with moderate to

with or without plastics.

Manufacturing and nonmanufacturing

facilities with higher concentrations of

combustibles or shielding of

combustibles where the fire hazard

could approach the equivalent of 1.8 m

(6 ft) high in-process storage of

cartoned unexpanded plastic

commodities.

flammable liquids (see DS 7-98).

Electronic media storage (see DS 8-9).

heavily loaded areas

PSME-QCC Chapter

Philippine Society of Mechanical Engineers

Quezon City Central Chapter

-Atriums Lightly and moderately loaded Operations involving hydraulic fluid or HC-2

-Auto parking garages

-Back stage of theaters and

auditoriums

-Boat mfg. and assembly

-Boiler buildings

-Casinos

-Clubs

-Convention centers

-Display halls

-Electronic-electrical mfg. and

assembly

-Food processing

-Gymnasiums

-Leather tanning and working

-Mercantile areas

-Metalworking

-Mineral processing

-Movie and TV studios

-Paper processing

-Retail areas

-Rubber processing

-Schools and universities

-Sports Arenas

-Theater and auditoriums

- Utility and equipment rooms

non-storage, nonmanufacturing, and

manufacturing areas with ordinary

combustibles.

flammable liquid (see DS 7-32, DS 7-29,

and DS 7-98); aluminum rolling mills

(see DS 7-64/13-28); paper machine

areas that involve inks with flashpoints

below 42

0

C (110

0

F) (see DS 7-4 and DS

7-96); aircraft hangars (see DS 7-93N).

PSME-QCC Chapter

Philippine Society of Mechanical Engineers

Quezon City Central Chapter

-Non-storage occupancies with Heavily loaded non-storage Facilities that use hydraulic and HC-4

heavily loaded areas with or

without plastics

occupancies

Expect fires with relatively high rates of

heat release in these occupancies.

flammable liquids (see DS 7-98).

Source: FM Global DS 3-26, Fire Protection Water Demand for Non-storage Sprinklered Properties.

Ceiling Construction

- Affects a sprinklers activation time and discharge pattern in terms of the depth,

spacing, and openness of the structural and other members.

(1) obstructed

(2) unobstructed

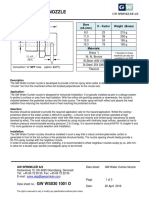

Sprinkler Characteristics Identification

Nominal

K-Factor

gpm/(psi)1/2

K-Factor

Range

gpm/(psi)1/2

K-Factor Range

dm3/min/(kPa)1/2

Percentage of

Nominal K = 5.6

Discharge

Thread

Type Thread

Type

Nominal Orifice Size

mm in.

1.4 1.31.5 1.92.2 25.0 in. NPT 6.4 1/4

1.9 1.82.0 2.62.9 33.3 in. NPT 8.0 5/16

2.8 2.62.9 3.84.2 50.0 in. NPT 9.5 3/8

4.2 4.04.4 5.96.4 75.0 in. NPT 11.0 7/16

5.6 5.35.8 7.68.4 100.0 in. NPT 12.7 1/2

8.0 7.48.2 10.711.8 140.0 in. NPT 13.5 17/32

in. NPT

11.2 11.011.5 15.916.6 200.0 in. NPT 15.9 5/8

in. NPT

14.0 13.514.5 19.520.9 250.0 in. NPT 19.0 3/4

16.8 16.017.6 23.125.4 300.0 in. NPT

19.6 18.620.6 27.230.1 350.0 1 in. NPT

22.4 21.323.5 31.134.3 400.0 1 in. NPT

25.2 23.926.5 34.938.7 450.0 1 in. NPT

28.0 26.629.4 38.943.0 500.0 1 in. NPT

Source: NFPA 13, Standard for the Installation of Sprinkler Systems.

PSME-QCC Chapter

Philippine Society of Mechanical Engineers

Quezon City Central Chapter

System Components and Materials

K-factor describes the size and angle for the inlet of the sprinklers orifice.

5.6 K-factor or 12.7-mm (-inch) orifice sprinkler is considered the standard orifice sprinkler

and generally serves as a benchmark against which to compare the discharge of other sprinklers

Sprinkler Discharge Characteristic

PSME-QCC Chapter

Philippine Society of Mechanical Engineers

Quezon City Central Chapter

Pipe and Tube

Pipe or Tube Materials and Dimensions

Materials and Dimensions Standard

Ferrous Piping (Welded and Seamless)

Specification for Welded and Seamless Steel Pipe

Black and Hot-Dipped Zinc Coated (Galvanized)

ANSI/ASTM A53

Specification for Black and Hot-Dipped

Zinc Coated (Galvanized) Welded

and Seamless Steel Pipe for Fire Protection Use

ASTM A795

Wrought Steel Pipe ANSI B36.10M

Specification for Elec.-Resistance Welded Steel

Pipe

ASTM A135

Specification for Welded and Seamless Steel Pipe

Black and Hot-Dipped Zinc Coated (Galvanized)

PSME -

Specially Listed Steel Pipe

Copper Tube: Concern over the failure of solder materials or the brazing materials used to join the

copper tube was expressed as being a potential failure point of the system during a fire.

Nonmetallic Pipe: Concern with plastic pipe is failure when exposed to fire and even

its possible contribution to fire growth.

Chlorinated polyvinyl chloride (CPVC)

(a) Limited for use in systems that comply with NFPA 13D; NFPA 13R, Standard for the Installation of Sprinkler Systems in Residential

Occupancies up to and Including Four Stories in Height; and NFPA 13 (light-hazard occupancies only)

(b) Can be used in all wet pipe systems but limited for dry pipe and preaction systems

(c) Must be installed behind a thermal barrier. Note that CPVC pipe may be installed exposed if used with listed residential pipe may

be installed exposed if used with listed residential sprinklers that are installed in accordance with their listing or if used with listed

quick-response (QR) sprinklers, where the QR sprinklers are installed within 8 in. (203 mm) of the ceiling

(d) Must be joined with listed fittings or materials

(e) Not permitted to be installed in concealed combustible spaces that require

sprinkler protection

PSME-QCC Chapter

Philippine Society of Mechanical Engineers

Quezon City Central Chapter

Fittings are used in pipe and sprinkler systems to connect straight pipe or tubing sections,

to adapt to different sizes or shapes, and for other purposes, such as regulating or

measuring fluid flow.

Screwed Fittings

Fittings Materials and Dimensions

Materials and Dimensions Standard

Malleable Iron

Malleable iron threaded fittings, Class 150 and 300 steel ASME B16.3

Factory-made wrought steel buttweld fittings ASME B16.9

Buttwelding ends for pipe, valves, flanges, and fittings ASME B16.25

Specification for piping fittings of wrought carbon steel

and alloy steel for moderate and elevated temperatures

ASTM A 234

Steel pipe flanges and flanged fittings ASME B16.5

Forged steel fittings, socket welded and threaded copper ASME B16.11

Cast Iron

Cast iron threaded fittings, Class 125 and 250 ASME B16.4

Cast iron pipe flanges and flanged fittings ASME B16.1

PSME-QCC Chapter

Philippine Society of Mechanical Engineers

Quezon City Central Chapter

Buttweld Fittings

Pipe Flanges

Mechanical Groove Coupling

OLET Fittings

PSME-QCC Chapter

Philippine Society of Mechanical Engineers

Quezon City Central Chapter

System Valves

Isolating Valve: To shut off the system.

One way or Check Valve: To limit the flow to one direction only.

Pressure Regulating Valve: To permit pressure entering part of the system to be

maintained at a certain level.

OS & Y Gate Valve

Butterfly Valve

Indicator Post and Valve

PSME-QCC Chapter

Philippine Society of Mechanical Engineers

Quezon City Central Chapter

Fire Department Connection

Swing Check Valves

Wafer Check Valve

Hose and Gate Valves

PSME-QCC Chapter

Philippine Society of Mechanical Engineers

Quezon City Central Chapter

Installation Rules for Automatic Sprinkler Systems

The basic principles of NFPA 13 concerning sprinkler system installation are as follows:

1. Sprinklers are to be installed throughout the premises.

2. The maximum allowed protection area per sprinkler is not to be exceeded.

3. Sprinklers are to be positioned to allow for timely operation and distribution.

Sprinklers shall be positioned to provide protection of the area consistent with the overall objectives

of the standard by controlling the positioning and allowable area of coverage for each sprinkler.

Areas of Coverage

Sprinklers under Smooth Ceilings

Area of Coverage: Multiply L and S

STANDARD SPRAY PENDENT AND UPRIGHT SPRINKLERS

L = distance between sprinkler heads

across branchlines

S = distance between sprinkler heads

along the same branchline

Sprinkler spacing dimensions should

be as square as possible.

Protection Areas and Maximum Spacing (Standard Spray Upright/Standard Spray Pendent) for Ordinary Hazard

Construction

Type

System

Type

Protection

Area

Spacing

(Maximum)

m

2

ft

2

m ft

All All 12.1 130 4.6 15

Source: NFPA 13, Standard for the Installation of Sprinkler Systems.

PSME-QCC Chapter

Philippine Society of Mechanical Engineers

Quezon City Central Chapter

Protection Areas and Maximum Spacing (Standard Spray Upright/Standard Spray Pendent) for Light Hazard

Protection Area Spacing (Maximum)

Construction Type System Type m

2

ft

2

m ft

Noncombustible obstructed

and

unobstructed and

combustible

unobstructed with members

less than

0.9 m (3 ft) on center

Pipe schedule 18.6 200 4.60 15

Hydraulically

calculated

20.9 225 4.60 15

Combustible obstructed with

members less

than 0.9 m (3 ft) on center

All 15.6 168 4.60 15

Combustible with members

less than 0.9 m

(3 ft) on center

All 12.1 130 4.60 15

Combustible concealed space

under a pitched

roof having combustible

wood joist or

wood truss construction

with members

less than 3 ft (0.9 m) on

center with slopes

having a pitch of 4 in 12 or

greater

All 11.1 120 4.60 parallel to

the slope

3.05 perpendicular

to the slope

15 parallel to the

slope

10 perpendicular

to the slope

Source: NFPA 13, Standard for the Installation of Sprinkler Systems.

PSME-QCC Chapter

Philippine Society of Mechanical Engineers

Quezon City Central Chapter

Protection Areas and Maximum Spacing (Standard Spray Upright/Standard Spray Pendent) for Extra Hazard

Construction

Type System Type

Protection Area

Spacing

(Maximum)

m

2

ft

2

m ft

All Pipe schedule 8.4 90 3.7 12

(In buildings with storage bays 7.6 m [25 ft] wide,

3.8 m [12 ft 6 in.] shall be permitted)

All Hydraulically calculated

with

9.3 100 3.7 12

density 0.25 (In buildings with storage bays 7.6 m [25 ft] wide,

3.8 m [12 ft 6 in.] shall be permitted)

All Hydraulically calculated

with

density <0.25

12.1 130 4.6 15

Source: NFPA 13, Standard for the Installation of Sprinkler Systems.

Protection Areas and Maximum Spacing (Standard Spray Upright/Standard Spray Pendent) for High-Piled Storage

Construction

Type

System Type

Protection Area

Spacing

(Maximum)

m

2

ft

2

m ft

All Hydraulically 9.3 100 3.7 12

calculated with

density 0.25

(In buildings with storage bays 7.6 m

[25 ft] wide, 3.8 m [12 ft 6 in.] shall

be permitted)

All Hydraulically 12.1 130 4.6 15

calculated with

density <0.25

Source: NFPA 13, Standard for the Installation of Sprinkler Systems.

PSME-QCC Chapter

Philippine Society of Mechanical Engineers

Quezon City Central Chapter

Sprinklers at Pitched Roofs; Branch Lines Run Up the Slope

Thermal sensing element shall be located at a minimum

of 25 mm (1 in.) and a maximum of 300 mm (12 in.)

vertically below the underside of the ceiling.

Linear distance between sprinklers is measured along the

slope of the ceiling.

Maintain a minimum 0.9 m (3 ft) clearance between the

deflector of a sprinkler and any combustibles located below it.

Generally, minimum spacing between sprinklers in any

direction is 2.1 m (7 ft).

In any case , the maximum area of coverage of a sprinkler

shall not exceed 59.7 m

2

(196 ft

2

).

Sprinklers shall be located a minimum of 102 mm (4 in.)

from a wall.

Sprinklers shall be spaced not less than 1.8 m (6 ft) on center.

Deflectors of sprinklers shall be aligned parallel to ceilings or

roofs.

PSME-QCC Chapter

Philippine Society of Mechanical Engineers

Quezon City Central Chapter

STANDARD SPRAY SIDEWALL SPRINKLERS

Sidewall sprinklers shall only be installed along walls, lintels, or soffits where the distance from the ceiling to the

bottom of the lintel or soffit is at least 51 mm (2 in.) greater than the distance from the ceiling to sidewall sprinkler

deflectors. Where soffits are used for the installation of sidewall sprinklers, they shall not exceed 203 mm (8 in.) in

width or projection from the wall.

Sidewall sprinkler deflectors (vertical type) shall be located not more than 152 mm (6 in.) nor less than 102 mm (4 in.)

from ceilings.

Sidewall sprinklers, where installed under a sloped ceiling, shall be located at the

high point of the slope and positioned to discharge downward along the slope.

Sidewall sprinkler deflectors shall be located not more than

6 in. (152 mm) nor less than 102 mm (4 in.) from walls.

PSME-QCC Chapter

Philippine Society of Mechanical Engineers

Quezon City Central Chapter

Positioning of Sprinklers to Avoid Obstructions to Discharge (Standard Spray Upright/Standard Spray Pendent)

Distance From Sprinklers

Maximum Allowable Distance of Deflector Above

Bottom of

to Side of Obstruction [A] Obstruction, mm (in.) [B]

Less than 0.30 m (1 ft) 0 (0)

0.30 m (1 ft) to less than 0.46 m (1.5 ft) 63.5 (2)

0.46 m (1.5 ft) to less than 0.61 m (2 ft) 88.9 (3)

0.61 m (2 ft) to less than 0.76 m (2.5 ft) 139.7 (5)

0.76 m (2.5 ft) to less than 0.91 m (3 ft) 190.5 (7)

0.91 m (3 ft) to less than 1.07 m (3.5 ft) 241.3 (9)

1.07 m (3.5 ft) to less than 1.22 m (4 ft) 304.8 (12)

1.22 m (4 ft) to less than 1.37 m (4.5 ft) 355.6 (14)

1.37 m (4.5 ft) to less than 1.52 m (5 ft) 419.1 (16)

1.52 m (5 ft) and greater 457.2 (18)

Source: NFPA 13, Standard for the Installation of Sprinkler Systems.

Obstruction Area To Umbrella Pattern Of Pendent And Upright Non-storage Sprinklers

Source: FM Global Property Loss Prevention Data Sheet 2-0 Installation Guidelines for Automatic Sprinklers

PSME-QCC Chapter

Philippine Society of Mechanical Engineers

Quezon City Central Chapter

Positioning of Sprinklers to Avoid Obstructions (Standard Sidewall Spray Sprinklers)

Distance From Sprinklers

Maximum Allowable Distance of Deflector Above

Bottom of

to Side of Obstruction [A] Obstruction, mm (in.) [B]

Less than 1.22 m (4 ft) Not allowed

1.22 m (4 ft) to less than 1.52 m (5 ft) 25.4 (1)

1.52 m (5 ft) to less than 1.68 m (5.5 ft) 50.8 (2)

1.68 m (5.5 ft) to less than 1.83 m (6 ft) 76.2 (3)

1.83 m (6 ft) to less than 1.98 m (6.5 ft) 101.6 (4)

1.98 m (6.5 ft) to less than 2.13 m (7 ft) 152.4 (6)

2.13 m (7 ft) to less than 2.29 m (7.5 ft) 177.8 (7)

2.29 m (7.5 ft) to less than 2.44 m (8 ft) 228.6 (9)

2.44 m (8 ft) to less than 2.59 m (8.5 ft) 279.4 (11)

2.59 m (8.5 ft) or greater 355.6 (14)

Source: NFPA 13, Standard for the Installation of Sprinkler Systems.

Obstruction Area To Umbrella Pattern away from the mounting of Sidewall Non-storage Sprinklers

Source: FM Global Property Loss Prevention Data Sheet 2-0 Installation Guidelines for Automatic Sprinklers

PSME-QCC Chapter

Philippine Society of Mechanical Engineers

Quezon City Central Chapter

System Protection Area Limitation

Maximum Floor Area Supplied By Any One Sprinkler Riser Or Combined System Riser

Light Hazard 4,831 m

2

(52,000 sq ft)

Ordinary Hazard 4,831 m

2

(52,000 sq ft)

Extra Hazard

Pipe Schedule 2,323 m

2

(25,000 sq ft)

Hydraulically Calculated 3,716 m

2

(40,000 sq ft)

StorageHigh-piled storage

(as defined in NFPA 13) and storage covered by other

standards

3,716 m

2

(40,000 sq ft)

Source: NFPA 13, Standard for the Installation of Sprinkler Systems.

In buildings of light or ordinary hazard occupancy, 65 mm (2 in.) hose valves for fire department use shall be

permitted to be attached to wet pipe sprinkler system risers.

The minimum size of the riser shall be 100 mm (4 in.) unless hydraulic calculations indicate that a smaller size riser

will satisfy sprinkler and hose stream allowances.

Each combined sprinkler and standpipe riser shall be equipped with a riser control valve to permit isolating a riser

without interrupting the supply to other risers from the same source of supply.

Exception No. 1: The floor area occupied by mezzanines shall not be

included in the above area.

Exception No. 2: Where single systems protect extra hazard, high-piled

storage, or storage covered by other NFPA standards, and ordinary or

light hazard areas, the extra hazard or storage area coverage shall not

exceed the floor area specified for that hazard and the total area

coverage shall not exceed 4,831 m

2

(52,000 sq ft).

PSME-QCC Chapter

Philippine Society of Mechanical Engineers

Quezon City Central Chapter

Design Considerations for Automatic Sprinkler Systems

1. PIPE SCHEDULE METHOD basically uses a prescribed schedule that specifies the

number of sprinklers that can be supplied by a given size pipe.

The pipe schedule method shall be permitted only for new installations of 465 m

2

(5,000 ft

2

)

or less or for additions or modifications to existing pipe schedule systems sized according to

the pipe schedule

The pipe schedule method shall be permitted for additions or modifications to

existing extra hazard pipe schedule systems.

PIPE SCHEDULES

Light Hazard Pipe Schedule

Steel Copper

25 mm (1 in.) 2 sprinklers 25 mm (1 in.) 2 sprinklers

32 mm (1 in.) 3 sprinklers 32 mm (1 in.) 3 sprinklers

40 mm (1 in.) 5 sprinklers 40 mm (1 in.) 5 sprinklers

50 mm (2 in.) 10 sprinklers 50 mm (2 in.) 12 sprinklers

65 mm (2 in.) 30 sprinklers 65 mm (2 in.) 40 sprinklers

80 mm (3 in.) 60 sprinklers 80 mm (3 in.) 65 sprinklers

90 mm (3 in.) 100 sprinklers 90 mm (3 in.) 115 sprinklers

100 mm (4 in.) See TABLE 11.01 100 mm (4 in.) See TABLE 11.01

Source: NFPA 13, Standard for the Installation of Sprinkler Systems.

PSME-QCC Chapter

Philippine Society of Mechanical Engineers

Quezon City Central Chapter

Ordinary Hazard Pipe Schedule

Steel Copper

25 mm (1 in.) 2 sprinklers 25 mm (1 in.) 2 sprinklers

32 mm (1 in.) 3 sprinklers 32 mm (1 in.) 3 sprinklers

40 mm (1 in.) 5 sprinklers 40 mm (1 in.) 5 sprinklers

50 mm (2 in.) 10 sprinklers 50 mm (2 in.) 12 sprinklers

65 mm (2 in.) 20 sprinklers 65 mm (2 in.) 25 sprinklers

80 mm (3 in.) 40 sprinklers 80 mm (3 in.) 45 sprinklers

90 mm (3 in.) 65 sprinklers 90 mm (3 in.) 75 sprinklers

100 mm (4 in.) 100 sprinklers 100 mm (4 in.) 115 sprinklers

125 mm (5 in.) 160 sprinklers 125 mm (5 in.) 180 sprinklers

150 mm (6 in.) 275 sprinklers 150 mm (6 in.) 300 sprinklers

200 mm (8 in.) See TABLE 11.01 200 mm (8 in.) See TABLE 11.01

Source: NFPA 13, Standard for the Installation of Sprinkler Systems.

Number of Sprinklers Greater Than 3.7 m (12 ft) Separations

Steel Copper

65 mm (2 in.) 15 sprinklers 65 mm (2 in.) 20 sprinklers

80 mm (3 in.) 30 sprinklers 80 mm (3 in.) 35 sprinklers

90 mm (3 in.) 60 sprinklers 90 mm (3 in.) 65 sprinklers

Source: NFPA 13, Standard for the Installation of Sprinkler Systems.

PSME-QCC Chapter

Philippine Society of Mechanical Engineers

Quezon City Central Chapter

Extra hazard occupancies shall be hydraulically calculated.

Extra Hazard Pipe Schedule

Steel Copper

25 mm (1 in.) 1 sprinkler 25 mm (1 in.) 1 sprinkler

32 mm (1 in.) 2 sprinklers 32 mm (1 in.) 2 sprinklers

40 mm (1 in.) 5 sprinklers 40 mm (1 in.) 5 sprinklers

50 mm (2 in.) 8 sprinklers 50 mm (2 in.) 8 sprinklers

65 mm (2 in.) 15 sprinklers 65 mm (2 in.) 20 sprinklers

80 mm (3 in.) 27 sprinklers 80 mm (3 in.) 30 sprinklers

90 mm (3 in.) 40 sprinklers 90 mm (3 in.) 45 sprinklers

100 mm (4 in.) 55 sprinklers 100 mm (4 in.) 65 sprinklers

125 mm (5 in.) 90 sprinklers 125 mm (5 in.) 100 sprinklers

150 mm (6 in.) 150 sprinklers 150 mm (6 in.) 170 sprinklers

Source: NFPA 13, Standard for the Installation of Sprinkler Systems.

PSME-QCC Chapter

Philippine Society of Mechanical Engineers

Quezon City Central Chapter

Water Supply Requirements for Pipe Schedule Sprinkler Systems

Occupancy

Classification

Minimum

Residual

Pressure

Required

Acceptable Flow

at Base of Riser

(Including Hose Stream Allowance)

Duration

in

kPa psi L/min gpm Minutes

Light hazard 103.42 15 18922839 500750 3060

Ordinary

hazard

137.90 20 32175677 8501500 6090

Source: NFPA 13, Standard for the Installation of Sprinkler Systems.

Where inside hose stations are planned or are required, the following shall apply:

(a) A total water allowance of 189 L/min (50 gpm) for a single hose station

installation shall be added to the sprinkler requirements.

(b) A total water allowance of 378 L/min (100 gpm) for a multiple hose station

installation shall be added to the sprinkler requirements.

(c) The water allowance shall be added in 189 L/min (50 gpm) increments beginning

at the most remote hose station, with each increment added at the

pressure required by the sprinkler system design at that point.

Hose connection's supply pipes shall not be connected to any pipe smaller than 65 mm (2 in.) in diameter.

This table is limited to installations no larger than 464.7 m

2

(5,000 ft

2

).

The flow is a minimum, and in the case of light-hazard occupancy, that flow must be made available at the base of the

system riser at a pressure of 103.4 kPa (15 psi) plus the pressure that is necessary to reach the highest sprinkler.

The pipe schedule method shall be permitted for use in systems exceeding 464.7 m

2

(5,000 ft

2

) where the flows

required in the table above are available at a minimum residual pressure of 344.8 kPa (50 psi) at the highest elevation

of sprinkler.

PSME-QCC Chapter

Philippine Society of Mechanical Engineers

Quezon City Central Chapter

Acceptance Requirements

Hydrostatic Test

Maintain 200 psi (13.8 bar) pressure without loss for 2 hours.

Systems normally subjected to system working pressures in excess of 150 psi

(10.4 bar) shall be tested at a pressure of 50 psi (3.5 bar) in excess of system

working pressure.

Systems Operational Test

Waterflow detecting devices including the associated alarm circuits shall be flow

tested through the inspector's test connection and shall result in an audible

alarm on the premises within 5 minutes after such flow begins and until such

flow stops.

The automatic operation of a deluge or preaction valve shall be tested in

accordance with the manufacturer's instructions.

Deluge and Preaction Systems Test

PSME-QCC Chapter

Philippine Society of Mechanical Engineers

Quezon City Central Chapter

2. HYDRAULIC DESIGN/CALCULATION METHOD

Density/Area Curve Source: NFPA 13, Standard for the Installation of Sprinkler Systems.

Minimum area of 139.4 m

2

(1,500 ft

2

) for light- and ordinary-hazard occupancies and

232.3 m

2

(2,500 ft

2

) for extra-hazard occupancies.

Match selected area to a corresponding discharge density

as shown in the Density/Area curve above.

PSME-QCC Chapter

Philippine Society of Mechanical Engineers

Quezon City Central Chapter

Number of Sprinklers =

System Area of Operation, A

Area of Coverage by a Sprinkler, S

Q = A x Density

TABLE 13.01 Water Hose Stream Allowance and Water Supply Duration

Requirements for Hydraulically Calculated Systems

Occupancy

Inside Hose

Total Combined Inside

and Outside Hose

Duration

(minutes) L/m gpm L/m gpm

Light hazard 0, 189, 379 0, 50, or 100 379 100 30

Ordinary hazard 0, 189, 379 0, 50, or 100 946 250 6090

Extra hazard 0, 189, 379 0, 50, or 100 1893 500 90120

Source: NFPA 13, Standard for the Installation of Sprinkler Systems.

Flow from the Sprinkler:

Water Hose Stream Allowance and Water Supply Duration

Number of Sprinklers

PSME-QCC Chapter

Philippine Society of Mechanical Engineers

Quezon City Central Chapter

Room Design Method

The water supply requirements for sprinklers only shall be based upon the room that

creates the greatest demand.

(1) For areas of sprinkler operation less than 139 m

2

(1,500 ft

2

) used for light and

ordinary hazard occupancies, the density for 139 m

2

(1,500 ft

2

) shall be used.

(2) For areas of sprinkler operation less than 232 m

2

(2,500 ft

2

) for extra hazard

occupancies, the density for 232 m

2

(2,500 ft

2

) shall be used.

Hydraulic Design information Sign

The installing contractor shall identify a hydraulically designed sprinkler system with a

permanently marked weatherproof metal or rigid plastic sign secured with corrosion-resistant

wire, chain, or other approved means. Such signs shall be placed at the alarm valve, dry pipe

valve, preaction valve, or deluge valve supplying the corresponding hydraulically designed area.

The sign shall include the following information:

(1) Location of the design area or areas

(2) Discharge densities over the design area or areas

(3) Required flow and residual pressure demand at the base of the riser

(4) Occupancy classification or commodity classification and maximum

permitted storage height and configuration

(5) Hose stream allowance included in addition to the sprinkler demand

(6) The name of the installing contractor.

PSME-QCC Chapter

Philippine Society of Mechanical Engineers

Quezon City Central Chapter

Hanging and Bracing of Water-Based Systems

Common Types of Acceptable Hangers

In general, the hanger components are

expected to support five times the

weight of the water-filled piping plus a

load of 114 kg (250 lb) at any point of

piping support.

PSME-QCC Chapter

Philippine Society of Mechanical Engineers

Quezon City Central Chapter

TABLE 14.01 Maximum Distance Between Hangers (m)

Nominal Pipe Size (mm)

20 25 32 40 50 65 80 90 100 125 150 200

Steel pipe except

Threaded lightwall

N/A 3.66 3.66 4.57 4.57 4.57 4.57 4.57 4.57 4.57 4.57 4.57

Threaded lightwall

steel pipe

N/A 3.66 3.66 3.66 3.66 3.66 3.66 N/A N/A N/A N/A N/A

Copper tube 2.44 2.44 3.05 3.05 3.66 3.66 4.57 4.57 4.57 4.57 4.57 4.57

CPVC 1.68 1.83 1.98 2.13 2.44 2.74 3.05 N/A N/A N/A N/A N/A

Ductile Iron Pipe N/A N/A N/A N/A N/A N/A 4.57 N/A 4.57 N/A 4.57 4.57

Source: NFPA 13, Standard for the Installation of Sprinkler Systems.

The distance between a hanger and the centerline of an upright sprinkler shall not be less than 76 mm (3 in.).

The unsupported length between the end sprinkler and the last hanger on the line shall not be greater than 0.9 m

(36 in.) for 25 mm (1 in.) pipe, 1.2 m (48 in.) for 32 mm (1 in.) pipe, and 1.5 m (60 in.) for 40 mm (1 in.) or larger

pipe.

The cumulative horizontal length of an unsupported armover to a sprinkler, sprinkler drop, or sprig shall not exceed

610 mm (24 in.) for steel pipe or 305 mm (12 in.) for copper tube.

Sprigs 1.2 m (4 ft) or longer shall be restrained against lateral movement.

PSME-QCC Chapter

Philippine Society of Mechanical Engineers

Quezon City Central Chapter

TABLE 14.02 Hanger Rod Sizes

Pipe Size Diameter of Rod

mm in. mm in.

100

Up to and

including 4

in.

9.5

125 5 12.7

150 6 12.7

200 8 12.7

250 10 15.9

300 12 15.9

Source: NFPA 13, Standard for the Installation of Sprinkler Systems.

Longitudinal bracing must be provided for all feed and

cross mains at maximum 24.4 m (80 ft) intervals. The last

brace must be within 12.2 m (40 ft) of the end of the

main.

Lateral bracing must be provided for all feed and cross

mains, and for branch lines with diameters 65 mm (2

in.) and larger, although 65 mm (2 in.) branch line

starter pieces are not required to be braced if they do not

exceed 6.1 m (12 ft) in length. The traditional maximum

brace spacing of 12.2 m (40 ft) still applies, but in

situations involving high lateral forces or heavy branch

lines, the maximum spacing may need to be reduced.

Risers shall be supported by riser clamps or by hangers

located on the horizontal connections within 610 mm (24

in.) of the centerline of the riser. Riser clamps supporting

risers by means of set screws shall not be used. Riser

clamps anchored to walls using hanger rods in the

horizontal position shall not be permitted to vertically

support risers

PSME-QCC Chapter

Philippine Society of Mechanical Engineers

Quezon City Central Chapter

Private Fire Service Mains

A private fire service main is that pipe between a source of water and the water supply side of the first

above ground connection to a sprinkler or standpipe system.

Minimum pipe size of 150 mm (6 in.) is recommended. Pipe shall be designed to withstand a system

working pressure of not less than 10.3 bar (150 psi). If the main does not supply hydrants a pipe size of less

than 6 in. (150 mm) may be used if:

a) hydraulic calculations have determined that the main will supply the total

demand at the appropriate pressure and

b) the main size shall be at least as large as the riser. Future needs and hose

stream flows also should be taken into consideration.

Yard Hydrants

PSME-QCC Chapter

Philippine Society of Mechanical Engineers

Quezon City Central Chapter

TABLE 15.01 Description of Pipe and Joints

Material

1

Cast

2

and

Ductile Iron

Steel Asbestos

Cement

Plastic

Polyethylene Polyvinyl

Chloride

(PVC)

Fiber

reinforced

Composite

Standard

3

(ANSI/AWWA)

C110/A21.10

C150/A21.50

C200 C400 C901 C900 C950

Working

pressure

See Factory

Mutual

Research

Approval Guide

Reference:

C110/A21.10

C150/A21.50

See C200

Also Data

Sheet 2-8N,

Installation of

Sprinkler

Systems

(NFPA)

Class 150

150 psi (1035

kPa, 10.3 bar)

Class 200

200 psi (1380

kPa, 13.8 bar)

See Factory Mutual Research

Approval Guide

Reference: AWWA Standard

Joint type Approved

push-on,

standardized

mechanical,

ball and

socket, poured

lead bell and

spigot

Welded,

threaded,

Flagged,

Approved

Grooved

couplings

Approved

push-on cast

iron

Butt fusion or

Approved

adapters

Push-on, bell

and spigot,

cast iron or

Approved

materials

Approved

using solvent

cement,

push-on

cast iron

Restraint

4

Approved, rods

and clamps,

thrust blocks

Not necessary Thrust blocks Thrust blocks

1

Acceptance of pipe, joints and fittings that are not Approved is based on satisfactory experience and conformity to specifications of recognized

engineering bodies. Cast and ductile iron, steel, and asbestos cement pipe are acceptable on that basis.

2

Cast Iron Standards, C106/A21.6 and C108/A21.8 withdrawn in 1982 and 1979 respectively. Ductile iron pipe has replaced cast i ron.

3

AWWA: American Water Works Association. ANSI: American National Standards Institute, Inc.

4

Thrust blocks are the preferred method of restraint.

Source: FM Global Property Loss Prevention Data Sheet 3-10 Private Fire Service Mains

PSME-QCC Chapter

Philippine Society of Mechanical Engineers

Quezon City Central Chapter

TABLE 15.02 Area of Bearing Surface of Concrete Thrust Blocks

Pipe Size

mm (in.)

90 Bend or 14 Bend

m

2

(ft

2

)

45 Bend or 18 bend

m

2

(ft

2

)

Tees, Hydrants,

Caps, Plugs

m

2

(ft

2

)

100 (4) 0.2 (2) 0.2 (2) 0.2 (2)

150 (6) 0.5 (5) 0.3 (3) 0.4 (4)

200 (8) 0.7 (8) 0.5 (5) 0.6 (6)

250 (10) 1.2 (13) 0.7 (7) 0.8 (9)

300 (12) 1.7 (18) 0.9 (10) 1.2 (13)

350 (14) 2.3 (25) 1.3 (14) 1.7 (18)

400 (16) 3.0 (32) 1.7 (18) 2.1 (23)

Areas in this table were derived using 225 psi (1551 kPa, 15.5 bar) water pressure and 2000 lb/ft

2

(96

kPa, 1 bar) soil resistance. This is

typical of sand and gravel with clay. For other soils, multiply the table values by the following factors:

Soft clay 4 Sand and gravel cemented with clay 0.5

Sand 2 Shale, hardpan 0.4

Sand and gravel 1.3

Note: Wide variations of bearing load capacity may be encountered within each

soil type.

Source: FM Global Property Loss Prevention Data Sheet 3-10 Private Fire Service Mains

Bearing Thrust Block

PSME-QCC Chapter

Philippine Society of Mechanical Engineers

Quezon City Central Chapter

Steel Suction Tank Open-Top Concrete Tank with Attached Pump House

Fixed Water Storage Supplies for Fire Protection

PSME-QCC Chapter

Philippine Society of Mechanical Engineers

Quezon City Central Chapter

Ground-Level Tanks

Elevated Tanks

Ground-level tanks that either provide a suction supply for an adjacent fire pump or act as gravity tanks to

provide sufficient water pressure for the fire protection system are the most common type in areas where

seismic protection is required.

The four main seismic considerations are as follows:

1. Flexibility of pipe connections to tank. two flexible couplings on the pipe should be provided between the

tank and the pump. One should be as close to the tank wall as possible and the other within 0.6 m (24 in.) of the

pump.

2. Anchorage of the tank and foundation to prevent horizontal and vertical displacement. Ground-level tanks

should be anchored for seismic protection for the appropriate seismic ground motion. Anchorage and

foundation design details are best provided and/or reviewed by a qualified structural engineer.

3. Clearance around pipe penetrations through pump house or other structural walls. At least 50 mm (2 in.)

clearance should be provided on all sides of piping that passes through structural walls or other fixed structures.

4. Proper steel thickness near base of tank to avoid elephant footing. In areas with a high probability of

strong ground motion, unanchored tanks may have significant vertical and horizontal displacements.

Elevated tanks, where the tank body is mounted on legs or a pedestal, are less common in areas where seismic

protection is required. Because of the complexity of any seismic analysis for this type of tank, a qualified structural

engineer can best handle seismic analysis and design.

PSME-QCC Chapter

Philippine Society of Mechanical Engineers

Quezon City Central Chapter

Tank Capacities

TABLE 16.01 Common Sizes of Steel Pump Suction Tanks

m3 * gal m3 * gal

190 50,000 950 250,000

290 75,000 1100 300,000

380 100,000 1500 400,000

475 125,000 2000 500,000

575 150,000 3000 750,000

750 200,000 4000 1,000,000

*Figures rounded off as approximations from nominal customary American tank sizes.

Tanks should be designed and installed according to NFPA 22, Standard for Water Tanks for

Private Fire Protection, which gives full requirements for construction materials, loads, unit

stresses, details of design, foundations, accessories, and workmanship. Welding of towers should

conform to code requirements for welding in building construction. The volume of suction

storage should be sufficient to supply the pump or pumps at 150 percent of the pumps rated

capacity for the required duration of the water demand. This is normally 1 to 4 hours.

Aboveground, underground, or fire well tanks filled with potable water are recommended for

supplying fire pumps.

PSME-QCC Chapter

Philippine Society of Mechanical Engineers

Quezon City Central Chapter

Centrifugal Fire Pumps

The NFPA standard on fire pumps is NFPA 20, Standard for the Installation of Stationary Pumps for

Fire Protection (hereinafter referred to NFPA 20).

Listed horizontal and vertical fire pumps are available with rated capacities from 95 to 18 925 L/min

(25 to 5000 gpm). Pressure ratings range from 276 to 2758 kPa (40 to 394 psi) for horizontal pumps

and 517 to 3448 kPa (26 to 510 psi) for vertical turbine pumps. Listed centrifugal fire pump designs

include horizontal-end-suction, vertical in-line, split-case (horizontal and vertical shaft), and vertical-

turbine types.

Volute Casing and Impeller Horizontal Shaft, Single-Stage Centrifugal Pump

PSME-QCC Chapter

Philippine Society of Mechanical Engineers

Quezon City Central Chapter

Vertical Turbine Fire Pump

TABLE 17.01 Summary of Centrifugal Fire Pump Data

Pump

Rating

(L/min)

Minimum Pipe Sizes

Suction

*

Discharg

e*

Relief

Valve

Relief

Valve

Discharge

Mete

r

Devi

ce

Number

and

Size of

Hose

Valves

Hose

Head

er

Supp

ly

95 25 25 20 25 32 1 40 25

189 40 32 32 40 50 1 40 40

379 50 50 40 50 65 1 65 65

568 65 65 50 65 80 1 65 65

757 80 80 50 65 80 1 65 65

946 90 80 50 65 90 1 65 80

1,136 100 100 65 90 90 1 65 80

1,514 100 100 80 125 100 2 65 100

1,703 125 125 80 125 100 2 65 100

1,892 125 125 100 125 125 2 65 100

2,839 150 150 100 150 125 3 65 150

3,785 200 150 150 200 150 4 65 150

4,731 200 200 150 200 150 6 65 200

5,677 200 200 150 200 200 6 65 200

7,570 250 250 150 250 200 6 65 200

9,462 250 250 200 250 200 8 65 250

11,355 300 300 200 300 200 12 65 250

13,247 300 300 200 300 250 12 65 300

15,140 350 300 200 350 250 16 65 300

17,032 400 350 200 350 250 16 65 300

18,925 400 350 200 350 250 20 65 300

*Actual diameter of pump flange is permitted to be different from pipe diameter.

PSME-QCC Chapter

Philippine Society of Mechanical Engineers

Quezon City Central Chapter

The characteristic curves (Figure 17.04) of a horizontal-, centrifugal-, or vertical-turbine-type

pump are as follows:

1. Total head versus discharge (ft of head or psi of pressure versus gpm)

2. Brake horsepower versus discharge

3. Efficiency versus discharge (water hp/input hp versus gpm)

FIGURE 17.04 Typical Centrifugal Fire Pump Characteristic Curves

PSME-QCC Chapter

Philippine Society of Mechanical Engineers

Quezon City Central Chapter

Location and Housing of Centrifugal Fire Pumps

Fire pumps are preferably housed in buildings of fire-resistant or noncombustible construction.

Even when the climate is so mild that there is no danger of freezing, sufficient enclosure is needed to

protect against dirt, corrosion, and tampering.

A dry location above-grade is preferred.

Pump rooms should be large enough to facilitate easy access to all equipment and devices for

inspection, testing, and maintenance.

Fire pumps are located as close as possible to those areas where protection is most important.

In some large properties, it may be necessary to have water supplies at more than one point to obtain

the most favorable distribution system.

PSME-QCC Chapter

Philippine Society of Mechanical Engineers

Quezon City Central Chapter

Typical Fire Pump Installation

PSME-QCC Chapter

Philippine Society of Mechanical Engineers

Quezon City Central Chapter

PSME-QCC Chapter

Philippine Society of Mechanical Engineers

Quezon City Central Chapter

Você também pode gostar

- Dry Type Fire HydrantDocumento6 páginasDry Type Fire HydrantAdil MominAinda não há avaliações

- Ansul R-102Documento4 páginasAnsul R-102heliopintoAinda não há avaliações

- T&C FireDocumento5 páginasT&C FireAssem ElhajjAinda não há avaliações

- HydraulicDocumento8 páginasHydraulicOsama OmayerAinda não há avaliações

- Bernoulli Equation: Z P P V G HLDocumento2 páginasBernoulli Equation: Z P P V G HLKorichiKarimAinda não há avaliações

- Equivalent Pipe Length Elbow Tee Stop Valve Bore of Pipe MMDocumento152 páginasEquivalent Pipe Length Elbow Tee Stop Valve Bore of Pipe MMAwokeAinda não há avaliações

- Table of Pipe SizingDocumento6 páginasTable of Pipe SizingprokjongAinda não há avaliações

- HVWS SystemDocumento1 páginaHVWS Systemabhinay02meAinda não há avaliações

- Engineering Solutions For Fire Truck AccesDocumento21 páginasEngineering Solutions For Fire Truck AccesRizalAinda não há avaliações

- GAPS Guidelines: Ventilation of Fire Pump RoomsDocumento3 páginasGAPS Guidelines: Ventilation of Fire Pump RoomsViswanathanAinda não há avaliações

- FF SupDocumento8 páginasFF SupMurugan RaghuAinda não há avaliações

- Abstract of Cost ProjectDocumento3 páginasAbstract of Cost ProjectamritAinda não há avaliações

- Studs and Bolts Chart For BFVDocumento1 páginaStuds and Bolts Chart For BFVtejasp8388Ainda não há avaliações

- System Design FFSDocumento5 páginasSystem Design FFSvivekpecAinda não há avaliações

- Nordtest Method NT Fire 049Documento16 páginasNordtest Method NT Fire 049mail2021Ainda não há avaliações

- Isle of Wight Fire & Rescue Service: Record of Fire Safety Equipment Testing Fire Drills & TrainingDocumento18 páginasIsle of Wight Fire & Rescue Service: Record of Fire Safety Equipment Testing Fire Drills & TrainingcaptalaaAinda não há avaliações

- PEERLEES Fire Pump PDFDocumento175 páginasPEERLEES Fire Pump PDFN. AndradeAinda não há avaliações

- SOFTWARE Fire FightingDocumento34 páginasSOFTWARE Fire Fightingkhalidnadeem2005Ainda não há avaliações

- NAFS 125 Technical DataDocumento6 páginasNAFS 125 Technical DataRupon RupAinda não há avaliações

- Kaiflex MasterSpecificationDocumento8 páginasKaiflex MasterSpecificationnaseema1Ainda não há avaliações

- Vortex Inhibitor VortibreakDocumento1 páginaVortex Inhibitor VortibreakNabil RamehAinda não há avaliações

- Specification For Fire Water MonitorsDocumento6 páginasSpecification For Fire Water MonitorsThiru AnanthAinda não há avaliações

- Fmconfnfpa 45Documento39 páginasFmconfnfpa 45M Ahmed LatifAinda não há avaliações

- FoamDocumento23 páginasFoamSam JoseAinda não há avaliações

- Pentair Training Program: First Week Office LecturesDocumento37 páginasPentair Training Program: First Week Office LecturesCobra_007Ainda não há avaliações

- Product Manual DCP Trolley Mounted 25-50-75 KGDocumento6 páginasProduct Manual DCP Trolley Mounted 25-50-75 KGm4l4ysiaAinda não há avaliações

- Water Curtain (20.04.16)Documento3 páginasWater Curtain (20.04.16)احمد الجزار2007Ainda não há avaliações

- Ansul Foam Generator PDFDocumento6 páginasAnsul Foam Generator PDFSuhail EhtishamAinda não há avaliações

- Fs2011 FullDocumento242 páginasFs2011 FullryankckoAinda não há avaliações

- A Comparison of The Fire Suppression Performance o PDFDocumento34 páginasA Comparison of The Fire Suppression Performance o PDFDayanne MartinsAinda não há avaliações

- EST EST2 v3.5 Serial Number Log Book PDFDocumento22 páginasEST EST2 v3.5 Serial Number Log Book PDFAhamed KyanaAinda não há avaliações

- Foam CalculationsDocumento8 páginasFoam Calculationsahmed salemAinda não há avaliações

- 18.detail Standard Fire FightingDocumento1 página18.detail Standard Fire FightingMuhammad ArifAinda não há avaliações

- Asd 640Documento2 páginasAsd 640RICHI100% (1)

- Cálculo Inergen PDFDocumento12 páginasCálculo Inergen PDFamardonesAinda não há avaliações

- Complation Check ListDocumento1 páginaComplation Check ListAhmed OusamaAinda não há avaliações

- Calculation of Invert LevelsDocumento15 páginasCalculation of Invert LevelsUsama ChatthaAinda não há avaliações

- Stand Pipe System: Prepared BY Homer C. Panganiban Jr. PMEDocumento39 páginasStand Pipe System: Prepared BY Homer C. Panganiban Jr. PMEJay Mark CayonteAinda não há avaliações

- Alarm Valve SprinklerDocumento20 páginasAlarm Valve SprinklerKevin TsuiAinda não há avaliações

- Selection, Installation and Maintenance of Automatic Fire Detection and Alarm System - Code of PracticeDocumento21 páginasSelection, Installation and Maintenance of Automatic Fire Detection and Alarm System - Code of Practiceabhirami91Ainda não há avaliações

- Specification For Sprinkler LPC - FSD Circular 2006 - 03Documento46 páginasSpecification For Sprinkler LPC - FSD Circular 2006 - 03James Li100% (1)

- Misting SystemDocumento16 páginasMisting SystemPrabhudas PinisettiAinda não há avaliações

- Pump Design - 2Documento1 páginaPump Design - 2kapsarcAinda não há avaliações

- Et 323 07-28-15Documento5 páginasEt 323 07-28-15Shishan AhmadAinda não há avaliações

- SLXBobinwoundfiltersDocumento1 páginaSLXBobinwoundfiltersKAMALAinda não há avaliações

- Lakasa Sand InterceptorDocumento1 páginaLakasa Sand InterceptorIswadi Bin ZulkarnainAinda não há avaliações

- LYE Book Fitting ms1919Documento16 páginasLYE Book Fitting ms1919khai rule100% (1)

- Bladder Tank PresentationDocumento5 páginasBladder Tank PresentationNikhil RajanAinda não há avaliações

- Nfs2-8 Instal Manual WebDocumento0 páginaNfs2-8 Instal Manual WebDota NgAinda não há avaliações

- UPVC Pipe SizeDocumento2 páginasUPVC Pipe Sizeahmedomar_953724702Ainda não há avaliações

- UP04We 03 Water Spray SystemsDocumento4 páginasUP04We 03 Water Spray SystemsDucVikingAinda não há avaliações

- Equipment Selection & Design - 2Documento5 páginasEquipment Selection & Design - 2Nabeel SiddiqueAinda não há avaliações

- SAT Schedule From SAFID 16-11-2016Documento1 páginaSAT Schedule From SAFID 16-11-2016Rama Lakshmi SaradhiAinda não há avaliações

- MIFAB Control Flo Roof DrainsDocumento5 páginasMIFAB Control Flo Roof DrainsjavedwestAinda não há avaliações

- Inspection and Test Plan For Painting: Inspecta Middle EastDocumento2 páginasInspection and Test Plan For Painting: Inspecta Middle Eastdaha333Ainda não há avaliações

- K 115 CheckDocumento31 páginasK 115 Checkranjit343Ainda não há avaliações

- Underground Steam & Condensate Piping PDFDocumento26 páginasUnderground Steam & Condensate Piping PDFZacky JoeAinda não há avaliações

- Module 4 - Basic of Design & ApproachesDocumento36 páginasModule 4 - Basic of Design & ApproachesJustin EvangelistaAinda não há avaliações

- Concorde Corodex Fire Protection and Automation-LowDocumento16 páginasConcorde Corodex Fire Protection and Automation-LowZaheer AhamedAinda não há avaliações

- Api List of SLDocumento2 páginasApi List of SLpopoAinda não há avaliações

- SL MC Test s2 Models of Bonding - Structure (Second Test)Documento7 páginasSL MC Test s2 Models of Bonding - Structure (Second Test)Amira Selpa KhairunnisaAinda não há avaliações

- Cell CultureDocumento17 páginasCell CultureHaridhar KrishAinda não há avaliações

- Toothpickase Lab ActivityDocumento6 páginasToothpickase Lab Activityrachel4151Ainda não há avaliações

- Dust Management PPT 030813 VISHVA KIRANDocumento42 páginasDust Management PPT 030813 VISHVA KIRANVishva KiranAinda não há avaliações

- Kaffir LimeDocumento3 páginasKaffir LimeSuci Ika PratiwiAinda não há avaliações

- A Course On Reciprocating PumpDocumento11 páginasA Course On Reciprocating PumpSwami VedatitanandaAinda não há avaliações

- Calculating MolarityDocumento4 páginasCalculating MolarityPrincess SaniaAinda não há avaliações

- Supplier+Quality+Manual+V+01 - ChemicalDocumento62 páginasSupplier+Quality+Manual+V+01 - ChemicalTrinhTruongAinda não há avaliações

- Sterlization of WaterDocumento21 páginasSterlization of WaterAnonymous eQLybzbh50% (2)

- Chemistry MCQ2Documento28 páginasChemistry MCQ2SABARI SRINIVAS AAinda não há avaliações

- Elsa Manual SabreDocumento50 páginasElsa Manual SabrerijalharunAinda não há avaliações

- Modified Atmosphere Storage of 'Honey' Mango by Using CA (OH) 2 As Chemical AbsorbentDocumento7 páginasModified Atmosphere Storage of 'Honey' Mango by Using CA (OH) 2 As Chemical AbsorbentInternational Journal of Innovative Science and Research TechnologyAinda não há avaliações

- KDP Well Test Procedures ManualDocumento77 páginasKDP Well Test Procedures ManualJacob Keemink100% (2)

- 01 KPPK AZA Legislative Requirements Industrial Waste Management in Malaysia-16Feb2017Documento80 páginas01 KPPK AZA Legislative Requirements Industrial Waste Management in Malaysia-16Feb2017zafaniAinda não há avaliações

- Ansul Line ProportionersDocumento4 páginasAnsul Line ProportionerskambiadoAinda não há avaliações

- Pcog Lec Midterms PDFDocumento18 páginasPcog Lec Midterms PDFMikaela YumulAinda não há avaliações

- Upper Face BotoxDocumento32 páginasUpper Face Botoxyaseer arafat67% (3)

- Modified and Controlled AtmospheresDocumento6 páginasModified and Controlled AtmospheresOliver TalipAinda não há avaliações

- Catalog Whatman 2018.compressedDocumento214 páginasCatalog Whatman 2018.compressedRakha Milan BachtiarAinda não há avaliações

- Blue Green AlgaeDocumento3 páginasBlue Green Algaeapi-234699482Ainda não há avaliações

- E Ciency Studies of Combination Tube Boilers: Alexandria Engineering JournalDocumento10 páginasE Ciency Studies of Combination Tube Boilers: Alexandria Engineering JournalJuan Sebastian AlarconAinda não há avaliações

- Greenhouse ManagementDocumento49 páginasGreenhouse ManagementAnouer Belkadi43% (14)

- Maharastra PWD 2012-13Documento278 páginasMaharastra PWD 2012-13chiranjeeviyarla0% (1)

- GeopolymerDocumento20 páginasGeopolymerAhmed TahaAinda não há avaliações

- Design and Layout Problem For A Combined GasDocumento119 páginasDesign and Layout Problem For A Combined GasAshley Espeso VeluzAinda não há avaliações

- Chm142l - FR 1Documento7 páginasChm142l - FR 1Adrian OblenaAinda não há avaliações

- Hy-Tuf - AMS 6425 PDFDocumento2 páginasHy-Tuf - AMS 6425 PDFapurv bhartiAinda não há avaliações

- Handbook Sewage HandlingDocumento147 páginasHandbook Sewage HandlingMannar MannanAinda não há avaliações

- SPE 87261 Optimisation of Carbon Steels For Sour Service: DR - Cornelius O. Emenike and Dr. Fikry F. Borouky, ZadcoDocumento5 páginasSPE 87261 Optimisation of Carbon Steels For Sour Service: DR - Cornelius O. Emenike and Dr. Fikry F. Borouky, ZadcoWaleed Barakat MariaAinda não há avaliações