Escolar Documentos

Profissional Documentos

Cultura Documentos

Reinforced Concrete Masonry Techniques - tcm68-1375445 PDF

Enviado por

hala_azhari0 notas0% acharam este documento útil (0 voto)

28 visualizações4 páginasan article I found very helpful in understanding masonry

Título original

Reinforced Concrete Masonry Techniques_tcm68-1375445.pdf

Direitos autorais

© © All Rights Reserved

Formatos disponíveis

PDF, TXT ou leia online no Scribd

Compartilhar este documento

Compartilhar ou incorporar documento

Você considera este documento útil?

Este conteúdo é inapropriado?

Denunciar este documentoan article I found very helpful in understanding masonry

Direitos autorais:

© All Rights Reserved

Formatos disponíveis

Baixe no formato PDF, TXT ou leia online no Scribd

0 notas0% acharam este documento útil (0 voto)

28 visualizações4 páginasReinforced Concrete Masonry Techniques - tcm68-1375445 PDF

Enviado por

hala_azharian article I found very helpful in understanding masonry

Direitos autorais:

© All Rights Reserved

Formatos disponíveis

Baixe no formato PDF, TXT ou leia online no Scribd

Você está na página 1de 4

M

asonry i s strong i n com-

p r e s s i o n b u tw e a k i nt e n-

si on. Steel , i n contrast,

i s s t r o n g i n t e n s i o n b u t , w h e n

formed i nto l ong thi n bars, can

buckl e i n compressi on. I n rei n-

forced masonry, however, grout

enabl es these materi al s to work

i n harmony to resi st wi nd and

sei smi c forces.

Even where codes dont requi re

rei nforced masonry, thi s bui l di ng

method can offer economi c bene-

fi ts because i t al l ows the bui l d-

i ng of tal l er, l onger, and thi nner

wal l s. The movement away from

empi ri cal and toward engi neered

desi gn has l ed to i ncreased speci -

fi cati on of rei nforced masonry

nati onwi de. Several stepsfrom

careful materi al sel ecti on to grout

r e c o n s o l i d a t i o n m u s t b e f o l -

l owed, however, to ensure the op-

ti mal performance of rei nforced

masonry.

Selecting materials

The type and qual i ty of mason-

ry uni ts and grout used on a rei n-

forced masonry job i mpact pro-

d u c t i v i t y, t h e a m o u n t o f s t e e l

n e e d e d f o r r e i n f o r c e m e n t , a n d

t h e a b i l i t y o f t h e g r o u t t o c o m-

pl etel y encase the steel and bond

wi th the uni ts.

Concrete block. Where avai l -

abl e, doubl e or si ngl e open-end,

H- or A-shaped concrete masonry

uni ts may be used. Masons can

easi l y l ay these uni ts around re-

bar al ready i n pl ace; so they dont

have to l i ft the bl ock up hi gh to

t h r e a dt h e r e b a r t h r o u g ht h ec e l l s .

Open-end uni ts permi t the use

of l onger rei nforci ng rods, thus re-

du c i n gt h e a m o u n t o fs t e e l n e e d e d

for l aps. (Where open-end bl ock

are not avai l abl e, rebar posi ti on-

ers can be pl aced i n cl osed-end

bl ock and the rebar dropped i n

pri or to grouti ng.)

Ken Nessl er of Phoeni x-based

Sun Val l ey Masonry recommends

a speci al H-shaped, bond-beam

concrete bl ock wi th ends that i n-

terl ock wi th other uni ts, el i mi -

nati ng the need for mortar at the

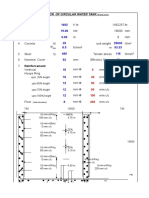

head joi nts (see Fi gure 1). The

uni ts center web does not extend

the ful l hei ght of the bl ock; the

space at the bottom and top of the

web provi des room for hori zontal

r e b a r a n d a l l o w s g r o u t t o f l o w

more freel y when ful l y grouted

wal l s are requi red.

Wi th another concrete bl ock

desi gna propri etary si ngl e-cel l ,

o p e n - e n d u n i t m a s o n s d o n t

need speci al posi ti oners to hol d

rebar i n pl ace duri ng grouti ng

(see Speci al Bl ock for Rei nforc-

Reinforced

concrete

masonry

techniques

Consi der these ti ps on sel ecti ng materi al s, i nstal l i ng rebar, and pl aci ng grout

By Carolyn Schierhorn

Figure 1. Special H-shaped block has

ends that interlock with other units,

eliminating the need for mortar at the

head joints. Source: Superlite B lock Inc.

In rei nforced masonry, grout enables ma-

sonry units and steel to work together to re-

sist wind and seismic forces.

i ng, Masonry Construction, June

1991). The cel l i nteri ors fl are i n-

ward at the bottom to hol d verti -

cal steel back from the face shel l s;

mol ded protrusi ons keep the ver-

ti cal steel i n pl ace. Thi s bl ock al -

so has notched webs to recei ve

hori zontal rebar (Ref. 1).

W h e n p r e q u a l i f y i n g h i g h -

s t r e n g t h c o n c r e t e b l o c k f o r h i g h -

ri se jobs, make sure the manufac-

turer produces uni ts wi th some

t e x t u r e i n t h e c e l l s , s u g g e s t s

G e o r g e M a r n e l l o f L a s Ve g a s -

based Marnel l Masonry. Hi gh-

strength concrete bl ock i s dense

and tends to be sl i ck because i t

has a hi gh concentrati on of ce-

ment. I f the cel l s are too sl i ck,

t h e r e m a y b e a p r o b l e m w i t h

grout bondi ng.

Grout. ASTM C 476 (Standard

Speci fi cati on for Grout for Mas o n-

r y ) d e s c r i b e sg r o u t p r o p o r t i o n s by

vol ume for fi ne and coarse grout.

Accordi ng to ASTM C 404 (Stan-

dard Speci fi cati on for Aggregates

for Masonry Grout), grouts are

cl assi fi ed as fi ne or coarse, de-

pendi ng on the maxi mum aggre-

gate si ze. I f the maxi mum aggre-

gate si ze i s

3

8 i nch to

1

2 i nch, the

grout i s coarse. Fi ne grout con-

tai ns onl y sand aggregates.

Grout must be fl ui d enough to

fl ow around rei nforci ng steel and

f i l l c e l l s a n d c a v i t i e s w i t h o u t

l eavi ng voi ds. The grout sl ump

s h o u l d b e 8 t o 1 0 i n c h e s . U s e

about an 8-i nch sl ump for mason-

ry uni ts wi th l ow absorpti on and

about a 10-i nch sl ump for mason-

r y u n i t s w i t h h i g h a b s o r p t i o n

(Ref. 2).

A l t h o u g h i t i s e a s y t o m e e t

mi ni mum standards for grout,

obtai ni ng the best mi x desi gn for

a job i s tri cky. Consi der goi ng to a

t e s t i n g l a b o r a t o r y, w h i c h w i l l

hel p you establ i sh desi gn cri teri a

and make tri al batches to meet

those cri teri a at the l owest mate-

ri al cost (see Desi gni ng Grout

Mi xes, Masonry Construction,

June 1991). But dont use more

than two or three grout mi xes on

a si ngl e job or i t wi l l be too com-

pl i cated to pl ace the ri ght mi x at

the ri ght l ocati on (Ref. 2).

When prequal i fyi ng grout, be

wary of certai n admi xtures. Some

grout manufacturers are more

accustomed to produci ng ready

mi x concrete than grout, Marnel l

observes. They may use water-

reduci ng admi xtures, whi ch work

w e l l i n c o n c r e t e b u t c a u s e t h e

grout not to bond to the concrete

b l o c k . Yo u p o u r i t a t a 1 0 - i n c h

s l u m pa n di tg o e st oa 3 - i n c hs l u m p

i n 30 mi nutes. Grout requi res

suffi ci ent water for absorpti on by

the concrete masonry uni ts and

to fl ow freel y around and under

steel and i nto voi ds.

Installing rebar

Verti cal steel rei nforcement

must be secured i n the proper

posi ti on and suffi ci entl y l apped

where necessary before grouti ng.

Be sure to fol l ow the pl ans and

speci fi cati ons and the l ocal codes

(see How to I nstal l Rei nforci ng

S t e e l , M a s on r y C on s t r u ct i on,

June 1991).

Verti cal steel rei nforcement

may be erected ei ther before l ay-

i ng masonry uni ts or after wal l

erecti on. Open-end uni ts make i t

easy to l ay hol l ow uni ts around

i nstal l ed rebar. When open-end

uni ts are not used, masons thread

the uni ts over shorter l engths of

s t e e l , w h i c h s h o u l d b e c a p p e d

f o r s a f e t y. T h e s e r o d s m u s t b e

a d e q u a t e l y l a p p e d , s o t h a t t h e

stresses are transferred from one

bar to the other. For Grade 60

steel , l ap the spl i ce at l east 36

bar di ameters i n compressi on (i n

col umns) and 48 bar di ameters i n

tensi on (i n wal l s and beams).

The rei nforci ng steel must be

surrounded by grout to functi on

properl y. The di stance between

the surface of a verti cal bar and

any surface of a masonry uni t

must be at l east

1

4 i nch for fi ne

grout and

1

2 i nch for coarse grout

(Ref. 3).

When i nstal l i ng rebar after the

uni ts have been l ai d, use ti e wi re

or speci al posi ti oners to hol d the

rods i n the proper posi ti on duri ng

grouti ng. Thi s al so ensures suffi -

ci ent grout cover. The Uniform

Building Code (UBC) requi res

that rebar posi ti oners be pl aced

i n masonry uni ts at verti cal i n-

terval s of not more than 200 bar

di ameters (Ref. 4). I deal l y, pl ace

a posi ti oner at the fi rst course to

ti e i t to the foundati on dowel s,

and pl ace one at the second course

from the top for stabi l i ty.

As they l ay up the wal l , ma-

sons i nstal l the hori zontal steel

at the appropri ate i nterval s. Then

pri or to grouti ng, they thread the

ful l -l ength verti cal rods through

the posi ti oners i n the masonry

uni ts.

One popul ar type of posi ti oner

for verti cal rebar di vi des the cel l

i nto a ti c-tac-toe pattern, al l ow-

i ng rebar to be pl aced i n any of

n i n e l o c a t i o n s . To s e c u r e i t i n

pl ace, the posi ti oner has l egs that

turn downward i nto the cel l at an

angl e (see Fi gure 2).

Cradl e-type posi ti oners can be

used i n the bond beam course to

posi ti on and hol d both hori zontal

and verti cal rebar si mul taneous-

l y. Suspended across the open cel l

from each face shel l , the cradl e

has di vi ders that separate the

vari ous rei nforci ng bars (see Fi g-

ure 3). These posi ti oners hol d the

hori zontal rebar above the cross

web, al l owi ng for grout to com-

pl etel y surround the steel .

Low-lift grouting

Some contractors favor l ow-l i ft

grouti ng because cl eanouts are

not requi red. However, any mor-

tar droppi ngs or debri s sti l l must

be removed from the bottom of

the space or cel l . The i nspector

c a n l o o k d o w n t h e c e l l s t o s e e

that they are al i gned and free of

excessi ve mortar and that the

steel i s i n the proper l ocati on.

I n l ow-l i ft grouti ng, the wal l i s

bui l t i n i ncrements, and the grout

pours must be 5 feet or l ess i n

hei ght. Be sure to al l ow enough

ti me for the mortar joi nts to set

To create the cleanout holes required in

high-lift grouting, you can cut holes in

the face shells (as shown), remove face

shells, or leave out masonry units.

so they can wi thstand the grout

pressure. Pour grout i nto al l rei n-

forced cel l s to a hei ght at l east 1

1

2

i nches bel ow the l ast mortared

bed joi nt, to create a shear key

or prevent a pl ane of weakness

where mortar and grout joi nts

meet. Pour the l ast segment to

the top of the wal l .

I f the g r o u tp o u r sa r em o r et h a n

1 2 i n c h e s i n h e i g h t , t h e g r o u t

must be consol i dated and recon-

sol i dated by mechani cal vi bra-

ti on; i f the pours are 12 i nches or

l ess, the grout may be consol i dat-

ed by puddl i ng or vi brati on.

High-lift grouting

H i g h - l i f t g r o u t i n gr e q u i r e m e n t s

m u s t b e s a t i s f i e d w h e n g r o u t

pours exceed 5 feet. Thi s method

al l ows wal l s to be bui l t to thei r

ful l hei ght before grouti ngup to

24 feet. Cl eanout hol es are re-

qui red at the bottom of any cel l

w i t h v e r t i c a l r e i n f o r c e m e n t i n

hol l ow grouted constructi on and

every 32 i nches or l ess i n mul ti -

wythe constructi on. These hol es

al l ow easy removal of debri s from

the grout space before grouti ng

and enabl e an i nspector to veri fy

that the grout space i s cl ean and

t h er e i n f o r c e m e n tp r o p e r l yl o c a t e d .

When youre usi ng cl eanouts,

i ts i mportant to put sand i n the

bottom cel l s, so any mortar that

drops to the bottom doesnt sti ck,

says Dave Eatherton of Denver-

based Eatherton Masonry I nc.

Otherwi se, you wi l l have a di ffi -

cul t ti me getti ng the mortar drop-

pi ngs out.

There are several ways to cre-

ate cl eanouts. You can l eave out

m a s o n r yu n i t s ,r e m o v e

f a c es h e l l s ,o r c u t h o l e s

i n t h e f a c e s h e l l s .

Cl eanout hol es should

be at least 3 i nches

long and 3 i nches hi gh

(Ref. 5).

You must remove al l

mortar fi ns that pro-

trude more than

1

2 i nch

from the masonry i nto

the grout space. A l ot

of speci fi cati ons say to

use ei ther pressuri zed

water or ai r, Eather -

ton observes. But i f

you l eave 2000-psi

mortar protrudi ng i nto

the cel l space, i t wi l l be

hard to break off wi th

ai r. We prefer to rod

the cel l out; we bounce

rebar up and down to

di sl odge mortar parti cl es.

To r e m o v et h ed e b r i sf r o mc l e a n-

out hol es, Eatherton uses metal

condui t. We just cut the condui t

i nto 16-i nch-l ong pi eces, fl atten

out the end, and bend i t i nto an

L-shaped scoop. Pressuri zed ai r

or water can be used to bl ow or

wash out l oose debri s.

Pl ace grout i n l i fts of not more

than 6 feet. I n hi gh-l i ft grouti ng,

a g r o u t l i f t i s a l a y e r o f g r o u t

p l a c e d i n a s i n g l ec o n t i n u o u so p e r-

ati on; a pour i s the enti re hei ght

of grout pl aced i n one day and

m a yc o n s i s t o fs e v e r a l l i f t s( R e f . 3 ) .

I n hi gh-l i ft grouti ng jobs, grout

usual l y i s pumped rather than

p o u r e d .R e a d ym i xg r o u ti sb r o u g h t

t o t h e j o b s i t e i n a t r a n s i t m i x

truck, l oaded i nto a grout pump,

and pumped i nto the masonry

cel l s through a l ong hose.

Consolidating grout

Grout must be vibrated twice,

e m p h a s i z e s D o n Wa k e f i e l d o f

Masonry I nformation Servi ce in

S a n d y, Utah. Contr actors some-

times try to take shortcuts i n thi s

step of grouting.

The fi rst vibrati oncal led con-

soli dati ontakes place ri ght aft e r

t h e g r o u t h a s b e e n p l a c e d . C o n-

sol idati on moves the grout around

and fi ll s in all the voids, s u c h a s

a n y u n d e r h o r i z o n t a l steel or

head joi nts that arent completel y

ful l, Wakefiel d expl ai ns.

Then when the grout i s sti l l

pl asti canywhere from 15 to 35

mi nutes l ater, dependi ng on the

temperature and how absorpti ve

the masonry uni ts arei t must

be reconsol i dated. Thi s col l apses

al l the ai r pockets l eft when the

l i qui d i s absorbed by the masonry

uni ts. Reconsol i dati on al so hel ps

prevent settl ement and

shri nkage separati ons from the

rei nforci ng steel and promotes

bondi ng to the masonry uni ts.

For consol i dati on and reconsol -

i dati on, use a l ow-vel oci ty vi bra-

tor wi th a

3

4-i nch head (Ref. 6).

I n hol l ow sol i d-grouted masonry,

pl ace the vi brator i nto the grout-

ed cel l s down to the bottom of the

l i f t , a c t i v a t i n gi tf o r 1 t o 2 s e c o n d s .

We sti ck that vi brator down,

One worker positions rebar in the proper location,

while another pumps grout into cells of this single-

wythe wall.

Figure 2. Positioner for vertical rebar

divides cell in a tic-tac-toe pattern.

Source: R ef. 3

Figure 3. Cradle-type positioners can

hold both vertical and horizontal rebar.

S o u rce: W C R Fabricators.

turn i t on, and pul l i t up, notes

R e n n i e Te j e d a , o w n e r o f R & R

M a s o n r y i n N o r t h H o l l y w o o d ,

Cal i f. I f you l eave i t down there

too l ong, i t vi brates so much that

i t breaks the wal l apart.

Someti mes, i f cel l s are too con-

gested wi th steel , you can pl ace

the vi brator i n adjacent grouted

cel l s. When sol i d-grouti ng a mul -

ti wythe wal l , pl ace the vi brator

i n the grout at poi nts spaced 12

i nches to 16 i nches apart (Ref. 6).

Use inspection

Si nce many cri ti cal steps are

i nvol ved i n rei nforced masonry

constructi on, i t i s i mportant to

have an i nspector make sure that

no shortcuts are taken (Ref. 7).

By speci fyi ng i nspecti on, desi gn-

ers can be sure thei r pl ans and

s p e c i f i c a t i o n s a r ef o l l o w e d .T h eI n-

ternati onal Conference of Bui l d-

i ng Offi ci al s i ncl udes an econom-

i c i n c e n t i v e t o s p e c i f y w h a t i s

known as speci al i nspecti on i n

the UBC (see The Benefi ts of I n-

spected Constructi on, Masonry

Construction, December 1994).

When masonry structures are

rei nforced, they can wi thstand

the extreme l ateral l oadi ng con-

d i t i o n s o f e a r t h q u a k e s , h u r r i -

canes, and tornadoes. I n areas

not i mpacted by such l oads, rei n-

forcement as requi red al l ows for

more effi ci ent, cost-effecti ve con-

structi on.

References

1. Kenneth A. Hooker, Special Block for

Reinforcing, Masonry Construction, June

1991, pages 214-215.

2. Bruce A. Suprenant and Jeffrey L. Groom,

Designing Grout Mixes, Masonry Con-

struction, June 1991, pages 218-220.

3. Reinforced Concrete Masonry Construc-

ti o n I ns p ec to rs H and b o o k, e d i t e d b y

James E. Amrhein and Michael W. Merrigan,

Masonry Institute of America, 2550 Beverly

Blvd., Los Angeles, CA 90057.

4. How to Install Reinforcing Steel, Ma-

sonry Construction, June 1991, pages 225-

227.

5. Brent A. Gabby and J. Gregg Borchelt,

How to Place Grout, Masonry Construc-

tion, June 1991, pages 216-220.

6. ACI 530.1/ASCE 6/TMS 602 Specifica-

tio ns f o r M as o nry S truc tures, M a s o n ry

Standards Joint Committee, 1992, The Ma-

sonry Society, 3775 Iris Ave., Ste. 6, Boul-

der, CO 80301.

7. Carolyn Schierhorn, The Benefits of In-

spected Construction, Masonry Construc-

tion, December 1994, pages 568-571.

Grout must be consolidated right after

the grout has been placed, then recon-

solidated while still plastic.

PUBLI CATI ON #M950579

Copyright 1995, The Aberdeen Group

Al l rights reserved

Você também pode gostar

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeNo EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeNota: 4 de 5 estrelas4/5 (5794)

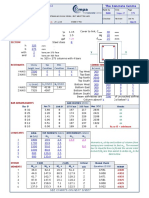

- RCC51 Column Load Take-Down DesignDocumento7 páginasRCC51 Column Load Take-Down Designhala_azhariAinda não há avaliações

- TCC52 Column Chart GenerationDocumento9 páginasTCC52 Column Chart Generationhala_azhari100% (2)

- Spreadsheets To BS 8110: L (M) H (MM) BW (MM) HF (MM) Type BF (MM)Documento10 páginasSpreadsheets To BS 8110: L (M) H (MM) BW (MM) HF (MM) Type BF (MM)hala_azhariAinda não há avaliações

- TCC71 Stair Flight & Landing - SingleDocumento7 páginasTCC71 Stair Flight & Landing - Singlehala_azhariAinda não há avaliações

- TCC42 Post Tensioned Analysis & DesignDocumento17 páginasTCC42 Post Tensioned Analysis & Designhala_azhariAinda não há avaliações

- RCC51 Column Load Take-Down DesignDocumento7 páginasRCC51 Column Load Take-Down Designhala_azhariAinda não há avaliações

- RCC61 Basement WallDocumento11 páginasRCC61 Basement Wallhala_azhariAinda não há avaliações

- Two-Way Slabs (Tables)Documento5 páginasTwo-Way Slabs (Tables)hala_azhariAinda não há avaliações

- Column DesignDocumento18 páginasColumn Designhala_azhari100% (1)

- Slab PunchingDocumento14 páginasSlab Punchinghala_azhariAinda não há avaliações

- RCC42 Post Tensioned Analysis & DesignDocumento8 páginasRCC42 Post Tensioned Analysis & Designhala_azhariAinda não há avaliações

- TCC32 Ribbed Slabs (A & D)Documento56 páginasTCC32 Ribbed Slabs (A & D)hala_azhari100% (2)

- RCC42 Post Tensioned Analysis & DesignDocumento8 páginasRCC42 Post Tensioned Analysis & Designhala_azhariAinda não há avaliações

- Core Wall DesignDocumento10 páginasCore Wall Designhala_azhari50% (2)

- Spreadsheets To BS 8110 Etc: The Concrete CentreDocumento11 páginasSpreadsheets To BS 8110 Etc: The Concrete Centrehala_azhariAinda não há avaliações

- Spreadsheets To BS 8110: Advisory Group Beam C1-2, Level 3Documento4 páginasSpreadsheets To BS 8110: Advisory Group Beam C1-2, Level 3hala_azhariAinda não há avaliações

- Nameof Work:-Design of Circular Water Tank: ReinforcementDocumento56 páginasNameof Work:-Design of Circular Water Tank: Reinforcementhala_azhariAinda não há avaliações

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceNo EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceNota: 4 de 5 estrelas4/5 (895)

- The Yellow House: A Memoir (2019 National Book Award Winner)No EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Nota: 4 de 5 estrelas4/5 (98)

- The Little Book of Hygge: Danish Secrets to Happy LivingNo EverandThe Little Book of Hygge: Danish Secrets to Happy LivingNota: 3.5 de 5 estrelas3.5/5 (400)

- The Emperor of All Maladies: A Biography of CancerNo EverandThe Emperor of All Maladies: A Biography of CancerNota: 4.5 de 5 estrelas4.5/5 (271)

- Never Split the Difference: Negotiating As If Your Life Depended On ItNo EverandNever Split the Difference: Negotiating As If Your Life Depended On ItNota: 4.5 de 5 estrelas4.5/5 (838)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyNo EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyNota: 3.5 de 5 estrelas3.5/5 (2259)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureNo EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureNota: 4.5 de 5 estrelas4.5/5 (474)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryNo EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryNota: 3.5 de 5 estrelas3.5/5 (231)

- Team of Rivals: The Political Genius of Abraham LincolnNo EverandTeam of Rivals: The Political Genius of Abraham LincolnNota: 4.5 de 5 estrelas4.5/5 (234)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaNo EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaNota: 4.5 de 5 estrelas4.5/5 (266)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersNo EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersNota: 4.5 de 5 estrelas4.5/5 (345)

- The Unwinding: An Inner History of the New AmericaNo EverandThe Unwinding: An Inner History of the New AmericaNota: 4 de 5 estrelas4/5 (45)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreNo EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreNota: 4 de 5 estrelas4/5 (1090)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)No EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Nota: 4.5 de 5 estrelas4.5/5 (121)

- Jungbluth Main Catalogue-LanacDocumento60 páginasJungbluth Main Catalogue-LanacMilenkoBogdanovicAinda não há avaliações

- David Sacks Resume February 16 2015Documento1 páginaDavid Sacks Resume February 16 2015api-279280948Ainda não há avaliações

- Compal Confidential: Ziwb2/Ziwb3/Ziwe1 DIS M/B Schematics DocumentDocumento56 páginasCompal Confidential: Ziwb2/Ziwb3/Ziwe1 DIS M/B Schematics DocumentSuhpreetAinda não há avaliações

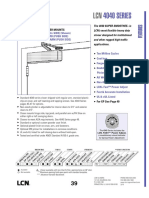

- 4040 SERIES: Hinge (Pull Side) (Shown) Top Jamb (Push Side) Parallel Arm (Push Side)Documento11 páginas4040 SERIES: Hinge (Pull Side) (Shown) Top Jamb (Push Side) Parallel Arm (Push Side)Melrose FabianAinda não há avaliações

- Being Agile. Staying Resilient.: ANNUAL REPORT 2021-22Documento296 páginasBeing Agile. Staying Resilient.: ANNUAL REPORT 2021-22PrabhatAinda não há avaliações

- Charging Station For E-Vehicle Using Solar With IOTDocumento6 páginasCharging Station For E-Vehicle Using Solar With IOTjakeAinda não há avaliações

- Pemisah ZirconDocumento10 páginasPemisah ZirconLorie Banka100% (1)

- Maxwell's Equations and Stoke's TheoremDocumento26 páginasMaxwell's Equations and Stoke's TheoremTuya ErdenejargalAinda não há avaliações

- Cisco Nexus 7000 Introduction To NX-OS Lab GuideDocumento38 páginasCisco Nexus 7000 Introduction To NX-OS Lab Guiderazzzzzzzzzzz100% (1)

- Orange County Sheriff's Office SeaWorld Death Investigative ReportDocumento43 páginasOrange County Sheriff's Office SeaWorld Death Investigative ReportWESH2News100% (1)

- The Names of Allah and Their ReflectionsDocumento98 páginasThe Names of Allah and Their ReflectionsSuleyman HldAinda não há avaliações

- 14 Days of Prayer and FastingDocumento40 páginas14 Days of Prayer and FastingntsakoramphagoAinda não há avaliações

- Cascade Configuration Tool: Installation and Operations ManualDocumento22 páginasCascade Configuration Tool: Installation and Operations ManualAndrés GarciaAinda não há avaliações

- RTRT User GuideDocumento324 páginasRTRT User GuideAlae Khaoua100% (3)

- Membrane and TransportDocumento25 páginasMembrane and TransportHafsa JalisiAinda não há avaliações

- California Academy For Lilminius (Cal) : Lesson PlanDocumento4 páginasCalifornia Academy For Lilminius (Cal) : Lesson Plandarryl franciscoAinda não há avaliações

- Assignment On Unstable or Astatic Gravimeters and Marine Gravity SurveyDocumento9 páginasAssignment On Unstable or Astatic Gravimeters and Marine Gravity Surveyraian islam100% (1)

- SBU PlanningDocumento13 páginasSBU PlanningMohammad Raihanul HasanAinda não há avaliações

- Science: BiologyDocumento22 páginasScience: BiologyMike RollideAinda não há avaliações

- Two Occult Philosophers in The Elizabethan Age: by Peter ForshawDocumento10 páginasTwo Occult Philosophers in The Elizabethan Age: by Peter ForshawFrancesco VinciguerraAinda não há avaliações

- State of The Art in Research On MicrogridsDocumento36 páginasState of The Art in Research On MicrogridsDulal MannaAinda não há avaliações

- Periodicity Review SL KeyDocumento4 páginasPeriodicity Review SL KeyYeyoung ParkAinda não há avaliações

- BROMINE Safety Handbook - Web FinalDocumento110 páginasBROMINE Safety Handbook - Web Finalmonil panchalAinda não há avaliações

- Bach Polonaise G Min BWV 119 A4Documento1 páginaBach Polonaise G Min BWV 119 A4vincenzovaiaAinda não há avaliações

- Refrigerant Unit Lab ReportDocumento19 páginasRefrigerant Unit Lab Reportakmal100% (2)

- The Four Types of Gaps and How To Play Them PDFDocumento17 páginasThe Four Types of Gaps and How To Play Them PDFshaikiftakar100% (2)

- Yazaki BrochureDocumento4 páginasYazaki Brochureguzman_10Ainda não há avaliações

- Chapter 34 Esip For FinalDocumento35 páginasChapter 34 Esip For FinalJeaniel BorlingAinda não há avaliações

- D4462045416 PDFDocumento3 páginasD4462045416 PDFSamir MazafranAinda não há avaliações

- Safe Motherhood Ao2016-0035 Quality Antenatal Care PDFDocumento9 páginasSafe Motherhood Ao2016-0035 Quality Antenatal Care PDFGa B B OrlonganAinda não há avaliações