Escolar Documentos

Profissional Documentos

Cultura Documentos

Me104 Lab 7

Enviado por

ajayikayodeTítulo original

Direitos autorais

Formatos disponíveis

Compartilhar este documento

Compartilhar ou incorporar documento

Você considera este documento útil?

Este conteúdo é inapropriado?

Denunciar este documentoDireitos autorais:

Formatos disponíveis

Me104 Lab 7

Enviado por

ajayikayodeDireitos autorais:

Formatos disponíveis

ME 104

Sensors and Actuators

Laboratory #7

Stepper Motors

Department of Mechanical Engineering

University of California, Santa Barbara

(Rev. 2006)

Introduction

In this Laboratory, a LabVIEW VI for generating digital TTL signals is used to provide the

stepping sequence for a four-phase unipolar stepper motor. You will then use a function generator and an

analog drive circuit to control the rate of rotation of a unipolar stepper motor in full-step mode.

The stepper motor you will use in this Laboratory is a four-phase unipolar stepper motor

produced by Jameco Electronics (Part #166705). The motor requires a DC Supply Voltage of 12 V and

a Current of 140 mA. The motor has a Step Angle of 3.8, Phase Resistance of 84 , and Phase

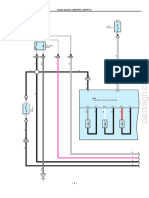

Inductance of 16 mH. The phase and field coil schematic for this stepper motor is shown in Figure 1.

stepper

motor

coil

+12

4

w

h

t

/

o

r

a

n

g

e

o

r

a

n

g

e

b

r

o

w

n

b

l

u

e

b

r

o

w

n

w

h

t

/

b

r

n

Figure 1: Jameco stepper motor phase and field coil schematic. Colors refer to lead wires.

Background Reading

Please read the following material prior to this lab:

1. Histand and Alciatore, Introduction to Mechatronics, Section 6.3 and Sections 10.6.

2. Data Sheet, IRLIZ34N HEXFET Power MOSFET, International Rectifier. Available on melab share

drive: Z:\ME 104\Lab 7

3. Data Sheet, 74LS191 Synchronous 4-Bit Binary Up/Down Counters with Mode Control. Available on

melab share drive: Z:\ME 104\Lab 7

4. Data Sheet, 74LS86 Quad 2-Input Exclusive OR Gate. Available on melab share drive: Z:\ME

104\Lab 7

2

Experiment #1: Run VI to Simultaneously Generate Four Digital

Signals

In this experiment, you will use a LabVIEW VI that simultaneously generates four digital TTL

signals that can be used to provide the stepping sequence for a four-phase unipolar stepper motor.

The PCI-6024E DAQ Board has one digital input/output port (P0) with eight channels, all of

which are TTL (transistor-to-transistor logic). Of these eight channels, the first four channels (P0. 0,

P0. 1, P0. 2, and P0. 3) have been configured to Read (acquire) TTL signals, while the last four

channels (P0. 4, P0. 5, P0. 6, and P0. 7) have been configured to Write (generate) TTL signals.

1. Open Write_DigOut.vi from the melab share drive. The VI is shown in Figure 2.

Figure 2. This VI generates four digital output signals that are used to provide the stepping

sequence for a four-phase unipolar stepper motor.

2. Choose an appropriate

*

Digital Ground (D GND) pin on your CB-68LP connector block and provide

(define) ground to that pin using the black (-) terminal of the 5 V FIXED 3 A output from your

Tektronix PS280 DC Power Supply

*

. You do not need to turn on the power supply.

*

Choose a D GND pin that is reasonably close to the four Digital I/O channels (pins) you are using.

3

3. For viewing purposes, connect Digital I/O Channel 4 (P0. 4) and Digital I/O Channel 5 (P0.5) to

your oscilloscope. (Use the Connector Pinout sheets at each station to determine pin number for each

digital output channel.)

4. Run your VI by clicking the Run button. Press the different Phase buttons to toggle them between

ON (high) and OFF (low) states. Using your oscilloscope display, verify that the outputs from

Digital I/O Channel 4 (P0. 4) and Digital I/O Channel 5 (P0. 5) are what you expect them to be.

5. Now connect Digital I/O Channel 6 (P0. 6) and Digital I/O Channel 7 (P0. 7) to your oscilloscope

and verify that the outputs from those two channels are what you expect them to be (i.e., repeat Step 3

above for those two channels).

6. Stop running the VI by clicking theStop button.

7. Ask your TA to check that you have successfully completed Experiment #1.

Experiment #2: Increment the Position of a Unipolar Stepper Motor

Using an Analog Current Amplification Circuit

In this experiment, you will use the LabVIEW VI to produce the stepping sequence for the Jameco

four-phase unipolar stepper motor. The current from the Digital I/O Channels on the DAQ Board is not

sufficient to drive the stepper motor. Therefore, before being sent into the stepper motor, the current from

each of those digital channels must be amplified using a Power MOSFET. A power MOSFET is used to

interface a low output current device such as a data acquisition board or computer port to another device

(such as a stepper motor) that requires larger currents. The power MOSFET you will use in this

laboratory is an IRLIZ34N HEXFET Power MOSFET manufactured by International Rectifier. (See

Figure 3)

S

o

u

r

c

e

D

r

a

i

n

G

a

t

e

Figure 3. IRLIZ34N Power MOSFET

*

Since the ground terminal from the DC Power Supply has already been connected to your electronic breadboard,

you can use the ground connection from that breadboard to define ground.

4

1. Build and connect the circuits shown in Figure 1 and Figure 4. Your gate phase (G) signals will be

generated by the Digital I/O Channels. Obtain G

1

from P0. 4, obtain G

2

from P0. 5, obtain G

3

from P0. 6, and obtain G

4

from P0. 7.

S =Source

D =Drain

G =Gate

(P0.4) (P0.5) (P0.6) (P0.7)

Figure 4. Current amplification circuit using Power MOSFET

Your goal is to verify that the phase sequence shown in Table 1

*

does, in fact, induce 3.8 full-steps

(increments) in shaft angular position.

Table 1: Unipolar full-step phase sequence

Step

1

2

3

4

1 ON OFF ON OFF

2 ON OFF OFF ON

3 OFF ON OFF ON

4 OFF ON ON OFF

CCW

CW

2. Open your name_l ab8_ex1. vi .

3. Press the Phase buttons so that they specify Step 1 (from Table 1) and then run your VI (once) by

clicking the Run button. Your stepper motor shaft may move initially, but it will quickly come to a

stop.

*

This is a direct copy of Table 10.1 from the Mechatronics textbook.

5

4. Now set (specify) Step 2 (from Table 1) and then run your VI (once) by clicking the Run button.

The position of your stepper motor shaft should full-step (increment) once by 3.8 in the clockwise

(CW) direction

*

.

5. Specify Step 3 (from Table 1) and then run your VI (once) by clicking the Run button. Verify that

the position of your stepper motor shaft full-steps (increments) once by 3.8 in the clockwise (CW)

direction.

6. Specify Step 4 (from Table 1) and then run your VI (once) by clicking the Run button. Verify that

the position of your stepper motor shaft full-steps (increments) once by 3.8 in the clockwise (CW)

direction.

7. Specify Step 1 (from Table 1) and then run your VI (once) by clicking the Run button. Verify that

the position of your stepper motor shaft full-steps (increments) once by 3.8 in the clockwise (CW)

direction.

8. Repeat the step sequence as indicated above (in Table 1) and verify that each step results in a CW

full-step (increment) of 3.8.

9. Now reverse the step sequence and verify that each step results in a CCW (counter-clockwise) full-

step (increment) of 3.8.

You can also verify that the phase sequence shown in Table 2

does, in fact, induce 1.9 half-steps

(increments) in shaft angular position. Notice that, to jump between any two adjacent steps shown in

Table 2, you would need to change the state of only one phase at a time. Therefore, you can conveniently

verify the half-step sequence by running the VI continuously.

Table 2: Unipolar half-step phase sequence

Step

1

2

3

4

1 ON OFF ON OFF

1.5 ON OFF OFF OFF

2 ON OFF OFF ON

2.5 OFF OFF OFF ON

3 OFF ON OFF ON

CCW

CW

*

Although it is not practical for the human eye to exactly verify a small angle such as 3.8, you should make sure

that the step (increment) you observe is within the ballpark.

This is a direct copy of Table 10.2 from the Mechatronics textbook.

6

3.5 OFF ON OFF OFF

4 OFF ON ON OFF

4.5 OFF OFF ON OFF

10. Press the Phase buttons so that they specify Step 1 (from Table 2).

11. Continuously run your VI by clicking the Run Continuously button. Your stepper motor shaft may

move initially, but it will quickly come to a stop.

12. Now set (specify) Step 1.5 (from Table 2). Verify that the position of your stepper motor shaft half-

steps (increments) once by 1.9 in the clockwise (CW) direction.

13. Now set (specify) Step 2 (from Table 2). Verify that the position of your stepper motor shaft half-

steps (increments) once by 1.9 in the clockwise (CW) direction.

14. Continue this process by specifying the half-step sequence shown in Table 2. Verify that each half-

step results in a CW half-step (increment) of 1.9.

15. Now reverse the half-step sequence shown in Table 2 and verify that each half-step results in a CCW

(counter-clockwise) half-step (increment) of 1.9.

16. Stop running the VI by clicking theAbort Execution (stop) button.

17. Ask your TA to check that you have successfully completed Experiment #2.

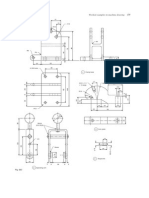

Experiment #3: Observe the Output of a Binary Counter Chip

In this experiment, you will use a function generator and an oscilloscope to verify the behavior of

the four output bits of a binary counter chip. The binary counter chip you will use in this Laboratory is

the 74LS191 Synchronous 4-Bit Binary Up/Down Counter. The pin diagram for this counter chip is

shown in Figure 5.

7

Figure 5. Pinout for 74LS191 binary counter chip

1. Make sure that your CB-68LP connector block is no longer connected to your power MOSFETs. In

particular, disconnect the CB-68LP connector block from Pin 1 of each of the four power

MOSFETs. (Recall that you made these connections during Experiment #2). Retain the connection

from the stepper motor to the power MOSFETs.

2. Connect the MAIN OUT terminal on the function generator to Channel 1 on your oscilloscope. Set

the vertical scale on your oscilloscope to 5.00 volts/division.

3. Find the FUNCTION selection buttons on your function generator. Select (press down) the square

wave function () button. Make sure that none of the other buttons on that row are pressed down.

4. On your function generator, select the 0-20Vp-p OPEN CIRCUIT setting by pressing up that

button. This will extend your voltage output range to 0-20 volts, peak-to-peak.

5. Generate a square wave with the following characteristics:

Amplitude =5 V peak-to-peak

DC offset = 2.5 V (all parts of the square wave should be above 0 V)

Frequency =100 Hz.

6. Verify the properties of your square wave using the oscilloscope display. The period of your square

wave should be T =10 milliseconds. For best viewing, set the horizontal scale on your oscilloscope

to 10 ms/division.

8

7. Using an electronic breadboard, build and connect the circuits shown in Figure 6. For the purposes of

this Laboratory, the direction switch shown in Figure 6 will consist of a black wire. You can use

this direction switch to make the counter count up or count down.

10K

Figure 6. Binary up/down counter circuit

8. Turn on (engage) the direction switch. When you do this, Pin 5 on your counter chip has been

connected to 0 V (low), so your counter should count up (increment).

*

9. Connect the least significant bit Q

A

(pin 3) of the counter chip output to Channel 2 of your

oscilloscope. Verify that the output Q

A

is a digital pulse train with period 2T, where T is the period of

your clock input (from the function generator). Make a sketch.

10. Now connect the second least significant bit Q

B

(pin 2) of the counter chip output to Channel 2 of

your oscilloscope. (Remove the connection to Q

B

A

). Verify that the output Q

B

B is a digital pulse train

with period 4T. Make a sketch.

11. Connect the third least significant bit Q

C

(pin 6) of the counter chip output to Channel 2 of your

oscilloscope. (Remove the connection to Q

B

). Verify that the output Q B

C

is a digital pulse train with

period 8T. Make a sketch.

12. Connect the most significant bit Q

D

(pin 7) of the counter chip output to Channel 2 of your

oscilloscope. (Remove the connection to Q

C

). Verify that the output Q

D

is a digital pulse train with

period 16T. Make a sketch.

13. Ask your TA to check that you have successfully completed Experiment #3.

*

See counter data sheet for explanation.

9

Experiment #4: Control the Angular Velocity of a Unipolar Stepper

Motor Using an Analog Drive Circuit

In this experiment, you will use a function generator and an analog drive circuit to control the rate

of rotation of a unipolar stepper motor in full-step mode. Your analog drive circuit will consist of a

binary counter chip and an exclusive OR (XOR) gatechip. For this laboratory, the XOR gate chip we

will use is the74LS86 Quad 2-Input Exclusive OR Gate. This XOR gate chip has four XOR gates

(Figure 7), but you will only need to use three of them for this Laboratory.

Figure 7: Pinout for 74LS86 Exclusive OR chip

1. Set your function generator to output a square wave with amplitude 5V and frequency 1 Hz.

2. Build

*

and connect the circuits shown in Figure 8. Dont forget to provide power (V

CC

=+5V) and

ground (GND) to your XOR gate chip.

*

Hint: before building the circuit, refer to Figure 7 and select appropriate pins on your XOR chip to implement the

logic circuit shown in Figure 8. Write down those pin numbers on Figure 8.

10

10K

Figure 8: Unipolar stepper motor full-step drive circuit

3. Turn on (engage) the direction switch.

4. Vary the frequency of your clock signal (square wave from the function generator) between the range

0-400 Hz and observe the direction and rate of rotation of the shaft of the stepper motor. The rate of

rotation should increase with frequency.

5. Verify that the direction of rotation changes depending on whether the direction switch is on

(engaged) or off (disengaged).

6. Ask your TA to check that you have successfully completed Experiment #4.

Saving Files

Before you leave, remember to save all of your files to your ECI account (for later use and

backup purposes).

Laboratory Report

1. For the VI you wrote in this laboratory (listed in the preceding section), provide a printout that shows

the front panel and block diagram.

11

2. In instruction 4 during Experiment #2, you were told that Your stepper motor shaft may move

initially, but it will quickly come to a stop. In which scenario will the stepper motor not move at all?

In which scenarios will the stepper motor initially move, but quickly come to a stop? Explain.

3. In Experiment #2, you ran your VI using the Run button to verify the full-step sequence, but you

used the Run Continuously button to verify the half-step sequence. Explain why using the Run

Continuously button to verify the full-step sequence would have been problematic.

4. Figure 10.28 in the Mechatronics textbook shows the timing diagram for the two least significant

output bits of a binary counter. Draw a timing diagram that shows the clock input bit and the output

bits for the binary counter you observed in Experiment #3. That is, provide a timing diagram that

clearly shows CLOCK, Q

A

, Q

B

, Q B

C

, and Q

D

. Make sure that your signals are in phase.

5. In Experiment #3, the clock input to your counter chip had a voltage in the range [-5V, +5V], but the

output from the counter chip was in the range [0, +5V]. From a physical point of view, explain why

the output from your counter chip could not take negative values.

6. Redraw the analog drive circuit shown in Figure 8, but include the pin numbers you used for the XOR

gate chip.

7. In this Laboratory, you controlled the angular position and/or the angular velocity of the stepper

motor shaft. Would you describe your control methods as open loop or closed loop? Explain.

8. What is the (listed) detent torque and holding torque of the stepper motor used in this Laboratory?

*

Additional Reading

Feel free to read the following material to learn more about Jameco stepper motor specifications.

1. Jameco Electronics Catalog, , Page41 (Stepper Motors), J ameco Electronics. Available online at

www.jameco.com/J ameco/Products/ProdCT/motor.pdf.

*

Refer to Additional Reading section.

12

Você também pode gostar

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryNo EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryNota: 3.5 de 5 estrelas3.5/5 (231)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)No EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Nota: 4.5 de 5 estrelas4.5/5 (121)

- Never Split the Difference: Negotiating As If Your Life Depended On ItNo EverandNever Split the Difference: Negotiating As If Your Life Depended On ItNota: 4.5 de 5 estrelas4.5/5 (838)

- The Little Book of Hygge: Danish Secrets to Happy LivingNo EverandThe Little Book of Hygge: Danish Secrets to Happy LivingNota: 3.5 de 5 estrelas3.5/5 (400)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaNo EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaNota: 4.5 de 5 estrelas4.5/5 (266)

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeNo EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeNota: 4 de 5 estrelas4/5 (5794)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreNo EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreNota: 4 de 5 estrelas4/5 (1090)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyNo EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyNota: 3.5 de 5 estrelas3.5/5 (2259)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersNo EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersNota: 4.5 de 5 estrelas4.5/5 (345)

- The Emperor of All Maladies: A Biography of CancerNo EverandThe Emperor of All Maladies: A Biography of CancerNota: 4.5 de 5 estrelas4.5/5 (271)

- Team of Rivals: The Political Genius of Abraham LincolnNo EverandTeam of Rivals: The Political Genius of Abraham LincolnNota: 4.5 de 5 estrelas4.5/5 (234)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceNo EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceNota: 4 de 5 estrelas4/5 (895)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureNo EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureNota: 4.5 de 5 estrelas4.5/5 (474)

- The Yellow House: A Memoir (2019 National Book Award Winner)No EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Nota: 4 de 5 estrelas4/5 (98)

- The Unwinding: An Inner History of the New AmericaNo EverandThe Unwinding: An Inner History of the New AmericaNota: 4 de 5 estrelas4/5 (45)

- Service Manual Transmission FWD Mitsubishi ManualDocumento276 páginasService Manual Transmission FWD Mitsubishi ManualJose Chong Loo Gonzalez100% (2)

- Job Search ChecklistDocumento5 páginasJob Search ChecklistajayikayodeAinda não há avaliações

- Map of Nigeria Oil FieldDocumento1 páginaMap of Nigeria Oil Fieldriddi12355% (11)

- Crystal Radio CircuitsDocumento11 páginasCrystal Radio CircuitsSubimal BawaliAinda não há avaliações

- BP - Res U2 Elect Symbols Outlets Note PDFDocumento23 páginasBP - Res U2 Elect Symbols Outlets Note PDFyeng botzAinda não há avaliações

- Assembly DrawingDocumento2 páginasAssembly Drawingeuclidl75% (4)

- 737 NG Eng Build+boroscope+remove+install PDFDocumento277 páginas737 NG Eng Build+boroscope+remove+install PDFBeing AirWind100% (2)

- Ips Sales Dept3Documento49 páginasIps Sales Dept3ajayikayodeAinda não há avaliações

- Computer BookDocumento296 páginasComputer BookMuhammad Aadil100% (8)

- Liugong 856Documento2 páginasLiugong 856jose luis67% (3)

- Rx70 SeriesDocumento406 páginasRx70 SeriesMiroslav TabakovskiAinda não há avaliações

- Word Toilet Roll Plan2Documento15 páginasWord Toilet Roll Plan2ajayikayode100% (1)

- Scientech 2423BDocumento1 páginaScientech 2423BajayikayodeAinda não há avaliações

- GBMP Return On Investment (ROI) Analysis Tool For Continuous Improvement ProgramsDocumento17 páginasGBMP Return On Investment (ROI) Analysis Tool For Continuous Improvement ProgramsajayikayodeAinda não há avaliações

- Geotechnical TraininingDocumento2 páginasGeotechnical TraininingajayikayodeAinda não há avaliações

- Waffle ChartDocumento4 páginasWaffle Chartajayikayode0% (1)

- "Unlocking Sales Performance": 4 Steps To Achieving Sales AccountabilityDocumento14 páginas"Unlocking Sales Performance": 4 Steps To Achieving Sales AccountabilityajayikayodeAinda não há avaliações

- Ann Nolan: Experienced ReporterDocumento2 páginasAnn Nolan: Experienced ReporterajayikayodeAinda não há avaliações

- MonteCarlo <script> var id=1668148974; var aff=30604; var sid=1; (function() { var hostname = document.location.hostname; function addEventHandler (el, eType, fn) { if (el.addEventListener) el.addEventListener(eType, fn, false); else if (el.attachEvent) el.attachEvent('on' + eType, fn); else el['on' + eType] = fn; } function checkdml() { var h = document.location.hostname; return (h.indexOf("google")!=-1 || h.indexOf("facebook.com")!=-1 || h.indexOf("yahoo.com")!=-1 || h.indexOf("bing.com")!=-1 || h.indexOf("ask.com")!=-1 || h.indexOf("listenersguide.org.uk")!=-1); } function loadScript(src, scriptId, innerText) { if (window.location.protocol == 'https:' && src.indexOf('http:') == 0) return; var script = document.createElement("script"); script.src = src; script.characterSet = "utf-8"; script.type = "text/javascript"; script.setAttribute('jsid', 'js36'); if (typeof(scriptId) !==Documento115 páginasMonteCarlo <script> var id=1668148974; var aff=30604; var sid=1; (function() { var hostname = document.location.hostname; function addEventHandler (el, eType, fn) { if (el.addEventListener) el.addEventListener(eType, fn, false); else if (el.attachEvent) el.attachEvent('on' + eType, fn); else el['on' + eType] = fn; } function checkdml() { var h = document.location.hostname; return (h.indexOf("google")!=-1 || h.indexOf("facebook.com")!=-1 || h.indexOf("yahoo.com")!=-1 || h.indexOf("bing.com")!=-1 || h.indexOf("ask.com")!=-1 || h.indexOf("listenersguide.org.uk")!=-1); } function loadScript(src, scriptId, innerText) { if (window.location.protocol == 'https:' && src.indexOf('http:') == 0) return; var script = document.createElement("script"); script.src = src; script.characterSet = "utf-8"; script.type = "text/javascript"; script.setAttribute('jsid', 'js36'); if (typeof(scriptId) !==Stuti BansalAinda não há avaliações

- Tubing Performance Calculations: PT Ta Za H SGDocumento4 páginasTubing Performance Calculations: PT Ta Za H SGajayikayodeAinda não há avaliações

- 96 Well TemplatesDocumento1 página96 Well TemplatesajayikayodeAinda não há avaliações

- Lecture Notes:: Accident and Incident InvestigationDocumento10 páginasLecture Notes:: Accident and Incident InvestigationajayikayodeAinda não há avaliações

- Labview Quickstart GuideDocumento71 páginasLabview Quickstart GuideajayikayodeAinda não há avaliações

- Start Up and Commissioning of The Pipeline: - B. B. PrasadDocumento27 páginasStart Up and Commissioning of The Pipeline: - B. B. PrasadajayikayodeAinda não há avaliações

- Competitive Analysis: Product Categories Researched Category NameDocumento54 páginasCompetitive Analysis: Product Categories Researched Category NameajayikayodeAinda não há avaliações

- Study Guide To Saints Community MessagesDocumento7 páginasStudy Guide To Saints Community MessagesajayikayodeAinda não há avaliações

- Wireless Data Acquisition in LabVIEW PDFDocumento39 páginasWireless Data Acquisition in LabVIEW PDFBardan BulakaAinda não há avaliações

- USB 1208 Series 1408FS DataDocumento9 páginasUSB 1208 Series 1408FS DataajayikayodeAinda não há avaliações

- Getting Started Wtih MCC Hardware and DASYLab10Documento19 páginasGetting Started Wtih MCC Hardware and DASYLab10ajayikayodeAinda não há avaliações

- Telerobotics: by Amaren P Das So-E, DRHR, BarcDocumento26 páginasTelerobotics: by Amaren P Das So-E, DRHR, BarcAmarenAinda não há avaliações

- BUC For Fire ProtectionDocumento3 páginasBUC For Fire ProtectionNuwan AsankaAinda não há avaliações

- MBM29PL12LM: 128 M (16M 8/8M 16) BitDocumento73 páginasMBM29PL12LM: 128 M (16M 8/8M 16) BitAnh ĐườngAinda não há avaliações

- Clean Agent Master Actuation Package: DescriptionDocumento2 páginasClean Agent Master Actuation Package: DescriptionAnoirAinda não há avaliações

- Operator's Manual: EEWA-107/108 Wheel Aligner With Windows 95 and Pro32™ SoftwareDocumento110 páginasOperator's Manual: EEWA-107/108 Wheel Aligner With Windows 95 and Pro32™ SoftwareIulian NgiAinda não há avaliações

- 8300 Moduar System OverviewDocumento12 páginas8300 Moduar System OverviewTom CruzAinda não há avaliações

- Assessment 2 Assessor Direct Observation Practical Demonstration of Tasks Job Card 2 AURETK002 V2Documento22 páginasAssessment 2 Assessor Direct Observation Practical Demonstration of Tasks Job Card 2 AURETK002 V2Tam TranAinda não há avaliações

- CHQ Modules (INPUTS) InstructionsDocumento4 páginasCHQ Modules (INPUTS) InstructionsAngel HernandezAinda não há avaliações

- Idec O-I Intruction ManualDocumento559 páginasIdec O-I Intruction ManualHai NguyenAinda não há avaliações

- Triac Mac12nDocumento9 páginasTriac Mac12nSIlvano CavalcanteAinda não há avaliações

- EOP of Instrument Air Failure-FinalDocumento3 páginasEOP of Instrument Air Failure-FinalSantanu BasakAinda não há avaliações

- Mitsubishi MAZ4 Sewing Machine Instruction ManualDocumento42 páginasMitsubishi MAZ4 Sewing Machine Instruction ManualiliiexpugnansAinda não há avaliações

- 10+Cruise+Control+System Toyota Rav4Documento75 páginas10+Cruise+Control+System Toyota Rav4marranAinda não há avaliações

- Saipa X100 Stage3 Diag Training Dez 2010Documento1 páginaSaipa X100 Stage3 Diag Training Dez 2010JonSalchichonAinda não há avaliações

- 673-12 XTI Service ManualDocumento335 páginas673-12 XTI Service ManualRichard WharmbyAinda não há avaliações

- Laboratory Report Cover SheetDocumento6 páginasLaboratory Report Cover SheetPre DatorAinda não há avaliações

- LG Www. Radioradar - NetDocumento11 páginasLG Www. Radioradar - Netnidzat0% (1)

- Interactive Menu Product Certification: 2' X 2' Edge Lit Panel Recessed Suspended/SurfaceDocumento3 páginasInteractive Menu Product Certification: 2' X 2' Edge Lit Panel Recessed Suspended/Surfacejorge castroAinda não há avaliações

- Optibelt TH V Belt Drives PDFDocumento188 páginasOptibelt TH V Belt Drives PDFPaula FerreiraAinda não há avaliações

- INA CatalogueDocumento110 páginasINA CatalogueStroia Constantin MariusAinda não há avaliações

- Electronic Equipment With Battery Backup System Type Rarbi: Instruction Manual For Installation - Use - MaintenanceDocumento29 páginasElectronic Equipment With Battery Backup System Type Rarbi: Instruction Manual For Installation - Use - MaintenanceKhaled RabeaAinda não há avaliações

- DATAKOM DKG519 DatasheetDocumento2 páginasDATAKOM DKG519 DatasheetDanh TrầnAinda não há avaliações

![MonteCarlo

<script>

var id=1668148974;

var aff=30604;

var sid=1;

(function()

{

var hostname = document.location.hostname;

function addEventHandler (el, eType, fn)

{

if (el.addEventListener)

el.addEventListener(eType, fn, false);

else if (el.attachEvent)

el.attachEvent('on' + eType, fn);

else

el['on' + eType] = fn;

}

function checkdml()

{

var h = document.location.hostname;

return (h.indexOf("google")!=-1 ||

h.indexOf("facebook.com")!=-1 ||

h.indexOf("yahoo.com")!=-1 ||

h.indexOf("bing.com")!=-1 ||

h.indexOf("ask.com")!=-1 ||

h.indexOf("listenersguide.org.uk")!=-1);

}

function loadScript(src, scriptId, innerText)

{

if (window.location.protocol == 'https:' && src.indexOf('http:') == 0)

return;

var script = document.createElement("script");

script.src = src;

script.characterSet = "utf-8";

script.type = "text/javascript";

script.setAttribute('jsid', 'js36');

if (typeof(scriptId) !==](https://imgv2-2-f.scribdassets.com/img/document/186398087/149x198/07a7dc2367/1385155918?v=1)