Escolar Documentos

Profissional Documentos

Cultura Documentos

Influence of Blade Outlet Angle On Performance of Low-Specific-Speed Centrifugal Pump

Enviado por

Vignesh KumaranTítulo original

Direitos autorais

Formatos disponíveis

Compartilhar este documento

Compartilhar ou incorporar documento

Você considera este documento útil?

Este conteúdo é inapropriado?

Denunciar este documentoDireitos autorais:

Formatos disponíveis

Influence of Blade Outlet Angle On Performance of Low-Specific-Speed Centrifugal Pump

Enviado por

Vignesh KumaranDireitos autorais:

Formatos disponíveis

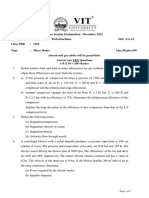

Journal of Thermal Science Vol.22, No.

2 (2013) 117122

DOI: 10.1007/s11630-013-0601-6

Article ID: 1003-2169(2013)02-0117-06

Influence of Blade Outlet Angle on Performance of Low-specific-speed

Centrifugal Pump

Cui Baoling, Wang Canfei, Zhu Zuchao, Jin Yingzi

The Province Key Laboratory of Fluid Transmission Technology, Zhejiang Sci-Tech University, Hangzhou 310018, China

Science Press and Institute of Engineering Thermophysics, CAS and Springer-Verlag Berlin Heidelberg 2013

In order to analyze the influence of blade outlet angle on inner flow field and performance of low-specific-speed

centrifugal pump, the flow field in the pump with different blade outlet angles 32.5and 39 was numerically calculated. The external performance experiment was also carried out on the pump. Based on SIMPLEC algorithm,

time-average N-S equation and the rectified k- turbulent model were adopted during the process of computation.

The distributions of velocity and pressure in pumps with different blade outlet angles were obtained by calculation. The numerical results show that backflow areas exist in the two impellers, while the inner flow has a little

improvement in the impeller with larger blade outlet angle. Blade outlet angle has a certain influence on the static

pressure near the long-blade leading edge and tongue, but it has little influence on the distribution of static pressure in the passages of impeller. The experiment results show that the low-specific-speed centrifugal pump with

larger blade outlet angle has better hydraulic performance.

Keywords: centrifugal pump; blade outlet angle; numerical simulation; external characteristic

Introduction

The blade outlet angle is one of the most important

geometric parameters for the impeller of centrifugal

pump, which has a significant influence on the pump

head, efficiency and so on. Some researches had been

done on the effect of blade outlet angle on the pump performance using theoretical analysis and experimental

method. T. Shigemitsu et al. [1] studied three types of

rotors with different outlet angles in the mini turbopumps. He investigated the effect of the blade outlet angle on performance and internal flow field of mini

turbo-pumps. Also Gonzlez et al. [2] found that different

blade outlet angles have significant influence on the

moment characteristics of the pump. Guangwen Li [3]

measured the internal flow field accurately using two

dimensional laser Doppler velocimeter when the centrifugal pump delivering water with large blade outlet

angle operated at the best and small flow conditions.

Xianfang Wu et al [4] had analyzed the influence of blade

outlet angle on performance characteristic of centrifugal

pump with different specific speeds. Based on the multiple regression method, Xijie He [5, 6] researched on the

effect degree and sequence of impeller geometric parameters on performance characteristic of centrifugal

pump, and the results showed that blade outlet angle has

significant influence on the pump head. With the rapid

progress of computer technology and computational fluid

dynamics, many numerical studies have been carried out

on centrifugal pump [7, 8], but few are on the lowspecific-speed centrifugal pump. So, it is necessary to

investigate the effect of different blade outlet angles on

Received: October 2012

CUI Baoling: Professor

This investigation was supported by National Natural Science Foundation of China granted No.50976105, No.51276172 and Zhejiang Provincial Natural Science Foundation Granted No.R1100530.

www.springerlink.com

118

J. Therm. Sci., Vol.22, No.2, 2013

performance of low-specific-speed centrifugal pump. In

this paper, to analysis the influence of blade outlet angle

on performance and internal flow of low-specific-speed

centrifugal pump, the flow field in the pump with different blade outlet angles is numerically calculated using

commercial software Fluent. The external performance

experiment is also carried out on the pump.

Computation model

Geometrical model

The design parameters of the low-specific-speed centrifugal pump studied are flowrate Q = 1.5m3/h, head H =

15m, the rotating speed n = 2900r/min. The specific

speed ns=28. The impeller is a complex one with four

long blades and eight short blades. To achieve better suction performance, a variable-pitch inducer is designed

upstream of the impeller. The three dimensional model of

pump is shown in Fig.1.

computational domains include impeller, inducer, the

extension of inlet and outlet, volute and clearance between impeller with the front shroud and hub. To ensure

the stability of calculation result, there is a proper extension at the outlet of impeller. The numerical grids are

obtained by Gambit, and interfaces are formed between

the two adjacent faces. Because the computational domains, which are inducer, impeller and volute, are in different levels of geometrical complexity, meshing is finished separately for different parts. Meanwhile, unstructured grid having strong adaptability is adopted. The numerical grid is shown in Fig.3.

Fig. 3

Fig. 1

The three dimensional model of pump

In the impeller(see Fig.2), inlet diameter D1 = 40 mm

outlet diameter D2 = 105mm, inlet width b1=11 mm, outlet width b2=4mm. Two impellers have the same parameters except for blade outlet angle. The blade outlet angles

are 2=32.5and 2=39 respectively.

Numerical grids

Calculation

In the numerical analysis, the commercial software

Fluent is used. Fluid is assumed under the steady condition and the RNG k- model is adopted as the turbulence

model. The numerical calculation of whole flow field for

the two different blades outlet angles is conducted at different flow rates based on the SIMPLEC algorithm which

couples the pressure and velocity. The specific boundary

conditions are as follows.

1) The inlet boundary condition: The constant velocity

is given as the boundary condition at inlet and the axial

velocity is determined by the law of mass conservation

and the assumption of zero-entry swirl.

2) The outlet boundary condition: The outflow is used

as the outlet boundary condition. Suppose the flow at the

outlet is fully developed.

3) The wall condition: Non-slip boundary condition is

adopted for the solid wall. The standard wall function is

utilized for the domains near the wall.

Numerical results analysis

(a) Centrifugal impeller

(b) Blade outlet angle

Fig. 2 Sketch Map of Centrifugal Impeller

Computational domain and grid

In this research, the whole flow field is calculated. The

Pressure analysis on the mid-section

In order to investigate the influence of blade outlet angle on the internal flow and performance of centrifugal

pump, the numerical analyses are performed at design

flow rates for different blade outlet angles 2=32.5 and

39 separately.

Cui Baoling et al.

Influence of Blade Outlet Angle on Performance of Low-specific-speed Centrifugal Pump

The static pressure distribution on the mid-section

with two different blade outlet angles is shown in Fig4 (a)

and (b). From Fig.4, it can be seen that the static pressure

in two impellers both increases from the inlet to outlet,

and the pressure on the pressure surface is higher than

that on the suction surface at the same radius. The static

pressure distribution in two impellers is uniform and

regular while there is a little fluctuation near the impeller

outlet because of the effect of the volute tongue. Low

pressure regions appear near the leading edge on the suction surface of the four long blades and it is found that

there are different size low pressure regions separately.

The low pressure region at the suction side of the blade is

also the place where is easy to occur cavitation.

(a) 2 = 32.5

Fig. 5

119

(b) 2 = 39

Static pressure near the tongue

Circumferential pressure distribution

The monitoring points are set on the interface between

impeller outlet and volute inlet and near volute wall

every 10 degrees. Therefore, there are 36 monitoring

points along the circumference. The section of the

volute is defined as circumferential angle 0, and the

positive rotation is counter-clockwise.

Static and total pressure distribution on the interface

(R = 52.6mm) between impeller outlet and volute inlet is

shown in Fig.6. From Fig.6, it is found that the flow in

(a) 2 = 32.5

(a) Static pressure distribution

(b) 2 = 39

Fig. 4 Static pressure on the mid-section

Pressure analysis near the tongue

The static pressure distribution near the tongue area is

shown in Fig.5. It can be seen that the pressure distribution near the tongue is uneven, and there is an obvious

pressure change from the tongue to the exit diffusion

segment. The pressure fluctuation is also found at the

tongue region. The low pressure area near the tongue is

larger in Fig.5 (a), and the pressure near the wall of exit

diffusion segment is relatively low. The low pressure

near the tongue may be caused by the impact and backflow in the exit diffusion segment, which will result in

certain hydraulic loss.

(b) Total pressure distribution

Fig. 6

Pressure distribution on the interface

120

J. Therm. Sci., Vol.22, No.2, 2013

the impeller is unstable because of the rotor-stator interaction between impeller and volute. The pressure fluctuation distribution along the circumference is uneven and

changes like sine signal. And the number of wave peak is

nearly the same as the number of impeller blades, which

means it produces rotor-stator interaction between blades

and volute while the blade passes the volute. Also it can

be seen that the static pressure and total pressure of

2=39 is larger than that of 2=32.5. Besides, the fluctuation range of total pressure is larger than that of static

pressure.

The static and total pressure distribution near the volute wall is shown in Fig.7. It is found that the range of

pressure fluctuation becomes very small compared with

that on the interface, and the static pressure of 2=39 is

higher. The static pressure near the wall increases with

the increasing of circumferential angle because the dynamic pressure transforms into static pressure with the

increasing of section area for spiral volute. Due to the

hydraulic loss during the transformation the total pressure near the volute wall decreases gradually along with

the circumference. The total pressure of 39 outlet angle

is basically higher than that of 2=32.5.

Streamline distribution on the mid-section

The streamline distribution for the two different blade

outlet angles on the mid-section is shown in Fig.8. It is

found that the internal flow of the two impellers is

non-uniform. There exist backflows at inlet of the impeller which may be caused by the uneven of the circumferential velocity at the edge of rotational blade. Besides,

the backflows are also observed near the pressure side at

blade outlet in two impellers. Compared with the streamline distribution in them, the larger blade outlet angle can

improve the flow condition in the impeller so as to improve the discharge capacity of the passage.

(a) 2 = 32.5

(a) Static pressure distribution

(b) 2 = 39

Fig. 8

(b) Total pressure distribution

Fig. 7

Pressure distribution near volute wall

Streamline distribution on the mid-section

Velocity distribution

The circumferential and radial velocity distribution on

the interface is shown in Fig.9. It is easy to find that the

circumferential velocity is larger than the radial one, so

the fluid on the interface flows along the volute in the

helix direction. Compared with the circumferential velocity, there is negative value for the radial velocity near

the tongue and the circumferential angle of 240, which

means the vortexes occur in the impeller passage because

the fluid rotates with the impeller at high speed and

brings the reverse fluid.

Cui Baoling et al.

Fig. 9

Influence of Blade Outlet Angle on Performance of Low-specific-speed Centrifugal Pump

(a) Radial velocity

(a) Radial velocity

(b) Circumferential velocity

(b) Circumferential velocity

Velocity distribution on the interface

121

Fig. 10 Velocity distribution on the volute wall

From Fig.9 (b), it is found that there is certain fluctuation for the circumferential velocity and it decreases with

the increasing of circumferential angle. Because of the

spiral volute, the section area increases with the increasing of circumferential angle.

The circumferential and radial velocity distribution

near the volute wall is shown in Fig.10. Compared with

the velocity distribution on the interface, the velocity

fluctuation range near the volute wall becomes smaller.

With the increasing of circumferential angle, the radial

velocity approximates to a straight line, and it is basically

the same for blade outlet angle 32.5and 39. Along the

circumferential direction, the circumferential velocity

reduces gradually. That is because the distance between

the volute wall and impeller outlet is more and more far,

and the force coming from impeller on the fluid near the

wall is getting smaller and smaller.

Fig.11, it can be seen that the numerical result is close to

the experimental one at different outlet angle conditions.

The trend of the numerical result basically agrees with

that of experimental result. From Fig.11 (a), the computational head at blade outlet angle 2=32.5 is higher than

that of blade outlet angle 2=39 at small flow rate. And

then when blade outlet angle 2=39, it is higher with the

increasing of flow rate. For the computational efficiency,

there is little difference between two blade outlet angles

when the flow rate is less than 1.2m3/h. At design point,

when blade outlet angle 2=32.5, the computational

head Hs1 = 15.58m and efficiency s1 = 13.65%, while the

experimental head Ht1 = 16.5m and efficiency t1 =

10.32%. When the blade outlet angle 2=39, the computational head Hs2 = 16.58m and efficiency s2 = 14.57%,

while the experimental head Ht2 =17.36m and efficiency

t2 =12.64%.

External experiment

Conclusions

The characteristic performance curves of pump obtained by the experiment and the simulation are shown in

Fig.11 when blade outlet angle 2=32.5 and 39. From

To investigate the influence of blade outlet angle on

the performance and internal flow, the centrifugal pump

with complex impeller at different outlet angles is ana-

122

J. Therm. Sci., Vol.22, No.2, 2013

Acknowledgement

This investigation was supported by National Natural

Science Foundation of China granted No.50976105,

No.51276172 and Zhejiang Provincial Natural Science

Foundation Granted No.R1100530.

References

[1] T. Shigemitsu, J. Fukutomi , R. Nasada and K. Kaji. The

Effect of Blade Outlet Angle on Performance and Internal

Flow Condition of Mini Turbo-Pump. Journal of Thermal

(a) H-Q curves

Science, vol.20, pp.3238, (2011).

[2] Gonzlez J , Santolaria C. Unsteady flow structure and

global variables in a centrifugal pump. ASME Journal of

Fluids Engineering, vol.128, pp.937946, (2006).

[3] Guangwen Li. The flow measurement of centrifugal

pump impeller with great outlet angle[J]. Journal of agricultural machinery, vol.30, pp.5459, (1999).

[4] Xianfang Wu, Minggao Tan, Houlin Liu, Yong Wang. Kai

Wang. The influence of blade outlet angle on the centrifugal pump performance. Journal of Agricultural

Mechanization Research, vol.9, pp.166175, (2010).

[5] Xijie He, Yuwen Huang, Yanxiao Zhao, Shuhong Li, Aixi

Zhang. The influence of parameters in centrifugal pump

(b) -Q curves

Fig. 11

Performance curves

lyzed by numerical simulation and experiment. The trend

of the numerical result basically agrees with that of experimental result. The outlet angle has effect on the low

pressure area at the suction side of long-blade leading

edge and near the tongue, but has little influence on the

pressure distribution in the passage of impeller. The larger blade outlet angle can improve the flow condition in

the impeller so as to improve the discharge capacity of

the passage. With the larger blade outlet angle, the

low-specific-speed centrifugal pump achieves better hydraulic performance. Further, it is important to design the

suitable blade outlet angle to improve the hydraulic performance of centrifugal pump.

on the efficiency. Drainage and Irrigation Machinery,

vol.20, pp. 910, (2002).

[6] Xijie He. The effect of main parameters on the low specific speed centrifugal pump. General Machinery, vol.1,

pp. 6365, (2004).

[7] V. I. Veselov. Effect of the outlet angle 2 on the characteristics of low specific speed centrifugal pumps [J].

Power Technology and Engineering, vol.16, pp.267273.

(1982).

[8] Jos Gonzlez, Joaqun Fernndez, Eduardo Blanco, et a1.

Numerical Simulation of the Dynamic Effects due to ImpellerVolute Interaction in a Centrifugal Pump[J].

Transactions of the ASME, vol.124, pp.348 354,

(2002).

Você também pode gostar

- Analysis of A Centrifugal Pump Impeller Using ANSYS-CFXDocumento6 páginasAnalysis of A Centrifugal Pump Impeller Using ANSYS-CFXBilal WaseemAinda não há avaliações

- An Investigation On The Performance Characteristics of A Centrifugal CompressorDocumento7 páginasAn Investigation On The Performance Characteristics of A Centrifugal CompressorIJERDAinda não há avaliações

- jecet.V4I1.C 10Documento13 páginasjecet.V4I1.C 10Anonymous kqgdxmYvRAinda não há avaliações

- Numerical Flow Analysis of An Axial Flow PumpDocumento6 páginasNumerical Flow Analysis of An Axial Flow Pumpbinho58Ainda não há avaliações

- Compressible Flow Across A Varying Area PassageDocumento4 páginasCompressible Flow Across A Varying Area PassageGaurav VaibhavAinda não há avaliações

- CFD Analysis of The Volute Geometry Effect On The Turbulent Air Flow Through The Turbocharger CompressorDocumento10 páginasCFD Analysis of The Volute Geometry Effect On The Turbulent Air Flow Through The Turbocharger CompressorbcshendeAinda não há avaliações

- Usha IJFMTS 2020Documento10 páginasUsha IJFMTS 202001988Ainda não há avaliações

- Zhao 2017Documento17 páginasZhao 2017Muhammad UsamaAinda não há avaliações

- Effects of Probe Support On The Flow Field of A Low-Speed Axial CompressorDocumento7 páginasEffects of Probe Support On The Flow Field of A Low-Speed Axial CompressorUmair MunirAinda não há avaliações

- Stability Improvement of High-Pressure-Ratio Turbocharger Centrifugal Compressor by Asymmetric Flow Control-Part I Non-Axisymmetrical Flow in Centrifugal CompressorDocumento9 páginasStability Improvement of High-Pressure-Ratio Turbocharger Centrifugal Compressor by Asymmetric Flow Control-Part I Non-Axisymmetrical Flow in Centrifugal CompressorjswxieAinda não há avaliações

- Pressure Recovery and Loss Coefficient Variations in The Two Different Centrifugal Blower Volute DesignsDocumento9 páginasPressure Recovery and Loss Coefficient Variations in The Two Different Centrifugal Blower Volute DesignsJoseph Alexander BorgAinda não há avaliações

- Research Paper1Documento6 páginasResearch Paper1Mitul PatelAinda não há avaliações

- Research Article: Numerical Investigation On Pressure Fluctuations For Different Configurations of Vaned Diffuser PumpsDocumento10 páginasResearch Article: Numerical Investigation On Pressure Fluctuations For Different Configurations of Vaned Diffuser Pumpsbakri10101Ainda não há avaliações

- 基于受限空间欠采样条件下涡轮燃气发动机关键截面流场重构技术研究进展06132023Documento12 páginas基于受限空间欠采样条件下涡轮燃气发动机关键截面流场重构技术研究进展06132023JUN LAIAinda não há avaliações

- Analysis of Cooling Gas Compressors Discharge Silencer: Dr. S. B. Wadkar, Viraj GhogreDocumento7 páginasAnalysis of Cooling Gas Compressors Discharge Silencer: Dr. S. B. Wadkar, Viraj GhogreresearchinventyAinda não há avaliações

- Experiment 4Documento10 páginasExperiment 4Anonymous Y3e0XfdxH1Ainda não há avaliações

- Centrifugal Pump Impeller Vane ProfileDocumento32 páginasCentrifugal Pump Impeller Vane Profiletomsiri100% (1)

- Experimental Analysis On A Low Speed Centrifugal CompressorDocumento15 páginasExperimental Analysis On A Low Speed Centrifugal CompressorInternational Journal of Application or Innovation in Engineering & ManagementAinda não há avaliações

- Vacuum Journal CFturbo Influence Blade Outlet Angle Centrifugal Pump PerformanceDocumento8 páginasVacuum Journal CFturbo Influence Blade Outlet Angle Centrifugal Pump PerformanceEA MQAinda não há avaliações

- Energies: Influence of Prewhirl Regulation by Inlet Guide Vanes On Cavitation Performance of A Centrifugal PumpDocumento16 páginasEnergies: Influence of Prewhirl Regulation by Inlet Guide Vanes On Cavitation Performance of A Centrifugal PumpMuhammad ImranAinda não há avaliações

- Cavitacion e Inducers BombasDocumento15 páginasCavitacion e Inducers Bombaspablotorresbozzo2686Ainda não há avaliações

- The Internal Flow Investigation of A Centrifugal PumpDocumento8 páginasThe Internal Flow Investigation of A Centrifugal Pumppreetham108Ainda não há avaliações

- Ijri Me 01 003Documento5 páginasIjri Me 01 003ijripublishersAinda não há avaliações

- Design, Development and Testing of An Impeller ofDocumento6 páginasDesign, Development and Testing of An Impeller ofbhaveshlibAinda não há avaliações

- 5 2 HergtMiKTeX V5N2Documento11 páginas5 2 HergtMiKTeX V5N2anggacenter_19Ainda não há avaliações

- InTech-Analysis of Cavitation Performance of InducersDocumento15 páginasInTech-Analysis of Cavitation Performance of InducersTGrey027Ainda não há avaliações

- Empirical Correlation For Ejector Design: International Journal of Refrigeration August 1999Documento11 páginasEmpirical Correlation For Ejector Design: International Journal of Refrigeration August 1999ThiagarajanAinda não há avaliações

- Cav03 OS 4 010Documento7 páginasCav03 OS 4 010Emad ElsaidAinda não há avaliações

- Hydraulic Efficiencies of Impeller and PumpDocumento9 páginasHydraulic Efficiencies of Impeller and PumpJohn Archie MendozaAinda não há avaliações

- Performance Analysis of Backward Curved Centrifugal Fan in Heating Ventilation and Air-ConditioningDocumento3 páginasPerformance Analysis of Backward Curved Centrifugal Fan in Heating Ventilation and Air-ConditioningIjsrnet Editorial100% (1)

- Ecp 1106304Documento9 páginasEcp 1106304boroumandAinda não há avaliações

- Model Paper For Publishing - PDF (Imp)Documento13 páginasModel Paper For Publishing - PDF (Imp)PARTHIBANAinda não há avaliações

- Wind Turbine Oblique FlowDocumento7 páginasWind Turbine Oblique FlowAnonymous gxAd4liAinda não há avaliações

- Analysis of The Flow Field Into A Two Stages and Double Entry Storage Pump Taking Into Account Two Geometries of Stator BladesDocumento11 páginasAnalysis of The Flow Field Into A Two Stages and Double Entry Storage Pump Taking Into Account Two Geometries of Stator BladesIan AsAinda não há avaliações

- CFD Modelling of Supersonic Airflow Generated by 2D NozzleDocumento7 páginasCFD Modelling of Supersonic Airflow Generated by 2D NozzleSkanda HebbarAinda não há avaliações

- Cowl DeflectionDocumento7 páginasCowl DeflectionSrinivasan GunasekaranAinda não há avaliações

- Numerical Study For The Effects of Injection Parameters On Flow Fields of The Blockerless Thrust ReverserDocumento2 páginasNumerical Study For The Effects of Injection Parameters On Flow Fields of The Blockerless Thrust ReversergoogleAinda não há avaliações

- 94 GT 126Documento12 páginas94 GT 126Ivan MagriniAinda não há avaliações

- Effect of Area Ratio On Flow Separation in Annular Diffuser PDFDocumento9 páginasEffect of Area Ratio On Flow Separation in Annular Diffuser PDFArun GuptaAinda não há avaliações

- Analysis On Centrifugal Pump Performance in Single, Serial, and ParallelDocumento8 páginasAnalysis On Centrifugal Pump Performance in Single, Serial, and ParallelFaiz AkbarsyahAinda não há avaliações

- Energies: Corner Separation Control by Boundary Layer Suction Applied To A Highly Loaded Axial Compressor CascadeDocumento14 páginasEnergies: Corner Separation Control by Boundary Layer Suction Applied To A Highly Loaded Axial Compressor Cascadeinam vfAinda não há avaliações

- Iaetsd-Jaras-Cfd Simulation of Twin Screw Vacuum Pump WithDocumento4 páginasIaetsd-Jaras-Cfd Simulation of Twin Screw Vacuum Pump WithiaetsdiaetsdAinda não há avaliações

- Summary of The ReportsDocumento6 páginasSummary of The ReportsStanley BoswellAinda não há avaliações

- Performances of A Centrifugal Pump at Low Mass FlowDocumento12 páginasPerformances of A Centrifugal Pump at Low Mass FlowtechnicaAinda não há avaliações

- Numerical Investigation On The Effect Pressure On Flow Characteristics in Converging Diverging NozzleDocumento5 páginasNumerical Investigation On The Effect Pressure On Flow Characteristics in Converging Diverging NozzleInternational Journal of Innovative Science and Research TechnologyAinda não há avaliações

- 2012 MIT KFUPM McGovern Ejector Efficiency PDFDocumento12 páginas2012 MIT KFUPM McGovern Ejector Efficiency PDFeldwin_dj7216Ainda não há avaliações

- Numerical Simulation of Centrifugal Blower Using CFX: Yogesh R. Pathak Beena D. Baloni Dr.S.A.ChanniwalaDocumento6 páginasNumerical Simulation of Centrifugal Blower Using CFX: Yogesh R. Pathak Beena D. Baloni Dr.S.A.ChanniwalaSugianto BarusAinda não há avaliações

- Journal of EEA, Vol. 28, 2011: Keywords: Centrifugal Pump, FLUENTDocumento7 páginasJournal of EEA, Vol. 28, 2011: Keywords: Centrifugal Pump, FLUENTMohammed El-ShahatAinda não há avaliações

- Empuje Axial en Bombas VerticalesDocumento6 páginasEmpuje Axial en Bombas VerticalesKaler Soto PeraltaAinda não há avaliações

- Diffuser TypeDocumento6 páginasDiffuser TypeEric21Ainda não há avaliações

- Influence of Diffuser Angle On A Bluff Body in Ground EffectDocumento7 páginasInfluence of Diffuser Angle On A Bluff Body in Ground EffectVyssion100% (2)

- Flowing Well PerformanceDocumento57 páginasFlowing Well PerformanceTogoumas Djide100% (4)

- Flowing Well PerformanceDocumento57 páginasFlowing Well PerformancemkwendeAinda não há avaliações

- Detailed Performance of A Radial-Bladed Centrifugal Pump Impeller in WaterDocumento56 páginasDetailed Performance of A Radial-Bladed Centrifugal Pump Impeller in Waterzakibrant23Ainda não há avaliações

- Wind Tunnel Techniques: Dr. Venugopal MMDocumento15 páginasWind Tunnel Techniques: Dr. Venugopal MMVenugopal M MAinda não há avaliações

- tq312l eDocumento10 páginastq312l eanildhakeAinda não há avaliações

- Numerical Prediction of Stability Limit in Centrifugal Compressors With Vaneless DiffuserDocumento9 páginasNumerical Prediction of Stability Limit in Centrifugal Compressors With Vaneless DiffuserMiguelMazzucchelliAinda não há avaliações

- Modern Borehole Analytics: Annular Flow, Hole Cleaning, and Pressure ControlNo EverandModern Borehole Analytics: Annular Flow, Hole Cleaning, and Pressure ControlAinda não há avaliações

- Biomass PDFDocumento59 páginasBiomass PDFVignesh KumaranAinda não há avaliações

- Energy Efficiency and Maintenance Costs of Pumping Systems For Groundwater ExtractionDocumento14 páginasEnergy Efficiency and Maintenance Costs of Pumping Systems For Groundwater ExtractionVignesh KumaranAinda não há avaliações

- Design For Manufacturing Applied To Turbomachine Components: Original ArticleDocumento11 páginasDesign For Manufacturing Applied To Turbomachine Components: Original ArticleVignesh KumaranAinda não há avaliações

- A Simplified 3d Model Approach in Constructing The Plain Vane Profile of A Radial Type Submersible Pump ImpellerDocumento5 páginasA Simplified 3d Model Approach in Constructing The Plain Vane Profile of A Radial Type Submersible Pump ImpellerVignesh KumaranAinda não há avaliações

- Bearing Life Calculations SelectionDocumento3 páginasBearing Life Calculations SelectionVignesh KumaranAinda não há avaliações

- Soal Faa PowerplantDocumento136 páginasSoal Faa PowerplantDidi PurnowiantoAinda não há avaliações

- GE - LNG SolutionDocumento18 páginasGE - LNG Solutionman_y2kAinda não há avaliações

- Compressor Stall and Airflow ControlDocumento25 páginasCompressor Stall and Airflow ControlGayan Weerasinghe100% (1)

- R514A CVHE Centravac Centrifugal Chiller Dimension DrawingsDocumento13 páginasR514A CVHE Centravac Centrifugal Chiller Dimension DrawingsBegundalz PotterAinda não há avaliações

- 09 DATUMsmDocumento12 páginas09 DATUMsmkiddjoe1470Ainda não há avaliações

- MEAE 235 - Fluid Mechanics & Hydraulic Machinery LabDocumento63 páginasMEAE 235 - Fluid Mechanics & Hydraulic Machinery LabAnshikha NautiyalAinda não há avaliações

- ACMV TrainingDocumento227 páginasACMV Traininghbitho100% (3)

- The Effects of Two Shaft Gas Turbine Operating Conditions On The Overall PerformanceDocumento16 páginasThe Effects of Two Shaft Gas Turbine Operating Conditions On The Overall PerformanceAhmad Mohammad Abdul-Aziz100% (1)

- Gas Turbine Powerplant - 2018Documento55 páginasGas Turbine Powerplant - 2018Karam Ali Khuwaja100% (1)

- Custom Centrifugal FanDocumento8 páginasCustom Centrifugal FankamatamoghAinda não há avaliações

- AerationDocumento92 páginasAerationGigih HaryAinda não há avaliações

- Gas Turbine Operation & Maintenance CourseDocumento100 páginasGas Turbine Operation & Maintenance CourseMohammed El-Shahat83% (6)

- Hydraulic and Compressible Flow Turbomachines PDFDocumento146 páginasHydraulic and Compressible Flow Turbomachines PDFThomasCarry67% (3)

- ABB Turbocharging TPS - . - D / E - The PerformerDocumento4 páginasABB Turbocharging TPS - . - D / E - The PerformerTibor AngeloAinda não há avaliações

- HowdenCompressorsUSBrochure PDFDocumento16 páginasHowdenCompressorsUSBrochure PDFMohsen NorouziAinda não há avaliações

- GTE B1 2019 All SessionDocumento17 páginasGTE B1 2019 All SessionChalla Amarsrinu100% (1)

- A320 Exam 2 Q & Points - NorestrictionDocumento34 páginasA320 Exam 2 Q & Points - NorestrictionHENIGUEDRIAinda não há avaliações

- 210479820563440B840B297C6C79B23CDocumento3 páginas210479820563440B840B297C6C79B23CyashvantAinda não há avaliações

- TGI Sabana Gas Transport: Operating Conditions Normal D E F A B CDocumento3 páginasTGI Sabana Gas Transport: Operating Conditions Normal D E F A B Chernan plazasAinda não há avaliações

- Technical Bid Evaluation Criteria and Vendor Offer Review With PDFDocumento12 páginasTechnical Bid Evaluation Criteria and Vendor Offer Review With PDFSurabhi SolankiAinda não há avaliações

- Technical Service Manual: Rooftop PackageDocumento103 páginasTechnical Service Manual: Rooftop PackageKim Nicolas Saiki100% (1)

- 3 2 Kisor ApprovedDocumento40 páginas3 2 Kisor Approvedsujiv_sujiv1278Ainda não há avaliações

- AssignmentDocumento2 páginasAssignmentHumera khanAinda não há avaliações

- SME Unit - I MCQ With Answer KeyDocumento25 páginasSME Unit - I MCQ With Answer KeyliveAinda não há avaliações

- Rotating Equipment Installation Procedure Method StatementDocumento28 páginasRotating Equipment Installation Procedure Method Statementmanoj thakkarAinda não há avaliações

- Material Handling & TransportDocumento23 páginasMaterial Handling & TransportKhadeejaAinda não há avaliações

- Blower Technologies Loera 061712Documento32 páginasBlower Technologies Loera 061712mahdiAinda não há avaliações

- Btech Ip 6th SemDocumento11 páginasBtech Ip 6th SemSoumya SoniAinda não há avaliações

- Fan Impeller Concept DesignDocumento15 páginasFan Impeller Concept DesignLucky Cham AguilaAinda não há avaliações

- Diseño de Impulsor de Bomba CentrifugaDocumento23 páginasDiseño de Impulsor de Bomba CentrifugaqwepoolAinda não há avaliações