Escolar Documentos

Profissional Documentos

Cultura Documentos

Construction of Three Phase Induction Motor

Enviado por

MuhammadZaydArattKhanDireitos autorais

Formatos disponíveis

Compartilhar este documento

Compartilhar ou incorporar documento

Você considera este documento útil?

Este conteúdo é inapropriado?

Denunciar este documentoDireitos autorais:

Formatos disponíveis

Construction of Three Phase Induction Motor

Enviado por

MuhammadZaydArattKhanDireitos autorais:

Formatos disponíveis

8/9/2014

Construction of Three Phase Induction Motor | Electrical4u

Electrical4u

Online Electrical Engineering Study Site

Search

Like 14,271 people like this. Sign Up to see w hat your friends like.

Construction of Three Phase Induction Motor

Induction Motor

Stator of Three Phase Induction Motor

Three Phase Induction Motor

Stator Frame

Single Phase Induction Motor

Stator Core

Linear Induction Motor

Stator Winding or Field Winding

Types of Three Phase Induction Motor

Torque Equation of Three Phase IM

Types

Slip Ring Vs Squirrel Cage Induction Motor

Starting Methods for Polyphase IM

The three phase induction motor is the most widely used

Speed Control of Three Phase IM

electrical motor. Almost 80% of the mechanical power used

Losses and Efficiency of Induction Motor

Construction of Three Phase Induction

Motor

Types of Single Phase Induction Motor

by industries is provided by three phase induction motors

because of its simple and rugged construction, low cost,

good operating characteristics, absence of commutator

and good speed regulation. In three phase induction motor

the power is transferred from stator to rotor winding

through induction. The Induction motor is also called asynchronous motor as it runs at a speed other than the

synchronous speed.

Like any other electrical motor induction motor also have two main parts namely rotor and stator

1. Stator: As its name indicates stator is a stationary part of induction motor. A stator winding is placed in the

stator of induction motor and the three phase supply is given to it.

2. Rotor: The rotor is a rotating part of induction motor. The rotor is connected to the mechanical load through the

shaft.

The rotor of the three phase induction motor are further classified as

1. Squirrel cage rotor,

2. Slip ring rotor or wound rotor or phase wound rotor.

Depending upon the type of rotor construction used the three phase induction motor are classified as:

http://www.electrical4u.com/construction-of-three-phase-induction-motor/

1/6

8/9/2014

Construction of Three Phase Induction Motor | Electrical4u

1. Squirrel cage induction motor,

2. Slip ring induction motor or wound induction motor or phase wound induction motor.

The construction of stator for both the kinds of three phase induction motor remains the same and is discussed in

brief in next paragraph.

The other parts, which are required to complete the induction motor, are:

1. Shaft for transmitting the torque to the load. This shaft is made up of steel.

2. Bearings for supporting the rotating shaft.

3. One of the problems with electrical motor is the production of heat during its rotation. In order to overcome this

problem we need fan for cooling.

4. For receiving external electrical connection Terminal box is needed.

5. There is a small distance between rotor and stator which usually varies from 0.4 mm to 4 mm. Such a distance is

called air gap.

Stator of Three Phase Induction Motor

The stator of the three phase induction motor consists of three main parts :

Electical slip ring

princetel.com/

High-performance slip rings Designed for standard rotary joints

1. Stator frame,

2. Stator core,

3. Stator winding or field winding.

Stator Frame

It is the outer most part of the three phase induction motor. Its main function is to support the stator core and the

field winding. It acts as a covering and it provide protection and mechanical strength to all the inner parts of the

induction motor. The frame is either made up of die cast or fabricated steel. The frame of three phase induction motor

should be very strong and rigid as the air gap length of three phase induction motor is very small, otherwise rotor will

not remain concentric with stator, which will give rise to unbalanced magnetic pull.

Stator Core

The main function of the stator core is to carry the alternating flux. In order to reduce the eddy electric current loss,

the stator core is laminated. These laminated types of structure are made up of stamping which is about 0.4 to 0.5 mm

http://www.electrical4u.com/construction-of-three-phase-induction-motor/

2/6

8/9/2014

Construction of Three Phase Induction Motor | Electrical4u

Stator Lamination

Stator Frame

thick. All the stamping are stamped together to form stator

core, which is then housed in stator frame. The stamping is

generally made up of silicon steel, which helps to reduce the hysteresis loss occurring in motor.

Stator Winding or Field Winding

The slots on the periphery of stator core of the three phase induction motor carries three phase windings. This three

phase winding is supplied by three phase ac supply. The three phases of the winding are connected either in star or

delta depending upon which type of starting method is used. The squirrel cage motor is mostly started by star delta

stater and hence the stator of squirrel cage motor is delta connected. The slip ring three phase induction motor are

started by inserting resistances so, the stator winding of slip ring induction motor can be connected either in star or

delta. The winding wound on the stator of three phase induction motor is also called field winding and when this

winding is excited by three phase ac supply it produces a rotating magnetic field.

Types of Three Phase Induction Motor

1. Squirrel cage three phase induction motor: The rotor of

the squirrel cage three phase induction motor is cylindrical in

shape and have slots on its periphery. The slots are not

made parallel to each other but are bit skewed (skewing is

not shown in the figure of squirrel cadge rotor beside) as the

skewing prevents magnetic locking of stator and rotor teeth

and makes the working of motor more smooth and quieter.

The squirrel cage rotor consists of aluminum, brass or

copper bars (copper bras rotor is shown in the figure beside).

These aluminum, brass or copper bars are called rotor

conductors and are placed in the slots on the periphery of

http://www.electrical4u.com/construction-of-three-phase-induction-motor/

3/6

8/9/2014

Construction of Three Phase Induction Motor | Electrical4u

Basic Construction of Induction Motor

the rotor. The rotor conductors are permanently shorted by

the copper or aluminum rings called the end rings. In order

to provide mechanical strength these rotor conductor are

braced to the end ring and hence form a complete closed circuit resembling like a cage and hence got its name as

"squirrel cage induction motor". The squirrel cage rotor winding is made symmetrical. As the bars are

permanently shorted by end rings, the rotor resistance is very small and it is not possible to add external

resistance as the bars are permanently shorted. The absence of slip ring and brushes make the construction of

Squirrel cage three phase induction motor very simple and robust and hence widely used three phase induction

motor. These motors have the advantage of adapting any number of pole pairs. The below diagram shows

squirrel cage induction rotor having aluminum bars short circuit by aluminum end rings.

Advantages of squirrel cage induction rotor1. Its construction is very simple and rugged.

2. As there are no brushes and slip ring, these motors

requires less maintenance.

Applications:

Squirrel cage induction motor is used in lathes, drilling

machine, fan, blower printing machines etc

Squirrel Cage Induction Rotor

2. Slip ring or wound three phase induction motor :

In this type of three phase induction motor the rotor is

wound for the same number of poles as that of stator

but it has less number of slots and has less turns per

phase of a heavier conductor.The rotor also carries star or delta winding similar to that of stator winding. The

rotor consists of numbers of slots and rotor winding are placed inside these slots. The three end terminals are

connected together to form star connection. As its name indicates three phase slip ring induction motor consists

of slip rings connected on same shaft as that of rotor. The three ends of three phase windings are permanently

connected to these slip rings. The external resistance can be easily connected through the brushes and slip rings

and hence used for speed control and improving the starting torque of three phase induction motor. The

brushes are used to carry electric current to and from the rotor winding. These brushes are further connected to

three phase star connected resistances. At starting, the resistance are connected in rotor circuit and is gradually

cut out as the rotor pick up its speed. When the motor is running the slip ring are shorted by connecting a metal

collar, which connect all slip ring together and the brushes are also removed. This reduces wear and tear of the

brushes. Due to presence of slip rings and brushes the rotor construction becomes somewhat complicated

therefore it is less used as compare to squirrel cage induction motor.

http://www.electrical4u.com/construction-of-three-phase-induction-motor/

4/6

8/9/2014

Construction of Three Phase Induction Motor | Electrical4u

Advantages of slip

ring

induction

motor 1. It

has high

starting

torque

low

and

starting

current.

2. Possibility of

adding

additional

resistance to

Slip Ring Three Phase Induction Motor

control

speed.

Application:

Slip ring induction motor are used where high starting torque is required i.e in hoists, cranes, elevator etc.

Difference between Slip Ring and Squirrel Cage Induction Motor

SLIP RING OR PHASE WOUND INDUCTION SQUIRREL CAGE INDUCTION MOTOR

MOTOR

Construction is complicated due to presence of slip ring and

Construction is very simple

brushes

The rotor winding is similar to the stator winding

The rotor consists of rotor bars which are permanently

shorted with the help of end rings

We can easily add rotor resistance by using slip ring and

Since the rotor bars are permanently shorted, its not

brushes

possible to add external resistance

Due to presence of external resistance high starting torque can Staring torque is low and cannot be improved

be obtained

Slip ring and brushes are present

Slip ring and brushes are absent

Frequent maintenance is required due to presence of brushes

Less maintenance is required

The construction is complicated and the presence of brushes

The construction is simple and robust and it is cheap as

and slip ring makes the motor more costly

compared to slip ring induction motor

This motor is rarely used only 10 % industry uses slip ring

Due to its simple construction and low cost. The squirrel

induction motor

cage induction motor is widely used

http://www.electrical4u.com/construction-of-three-phase-induction-motor/

5/6

8/9/2014

Construction of Three Phase Induction Motor | Electrical4u

Rotor copper losses are high and hence less efficiency

Less rotor copper losses and hence high efficiency

Speed control by rotor resistance method is possible

Speed control by rotor resistance method is not possible

Slip ring induction motor are used where high starting torque is

Squirrel cage induction motor is used in lathes, drilling

required i.e in hoists, cranes, elevator etc

machine, fan, blower printing machines etc

Search

http://www.electrical4u.com/construction-of-three-phase-induction-motor/

6/6

Você também pode gostar

- 6th Central Pay Commission Salary CalculatorDocumento15 páginas6th Central Pay Commission Salary Calculatorrakhonde100% (436)

- Effects of Harmonics On Induction MotorsDocumento5 páginasEffects of Harmonics On Induction Motorsrbargallo0Ainda não há avaliações

- A Presentation On Shaded Pole Induction Motor: Prepared By: Salunkhe KalpeshDocumento20 páginasA Presentation On Shaded Pole Induction Motor: Prepared By: Salunkhe KalpeshKalpesh SalunkheAinda não há avaliações

- Is 6665-1985Documento33 páginasIs 6665-1985t_syamprasadAinda não há avaliações

- 2017 Chen3009 Chapter 1 Compressible Flow-StudentDocumento38 páginas2017 Chen3009 Chapter 1 Compressible Flow-StudentApple EmiratessAinda não há avaliações

- Final Exam 2012Documento12 páginasFinal Exam 2012Mat MorashAinda não há avaliações

- Induction MotorDocumento43 páginasInduction MotorAshvani ShuklaAinda não há avaliações

- Three-Phase Induction Motor - LongDocumento63 páginasThree-Phase Induction Motor - LongTuhin techAinda não há avaliações

- Electrical Machines: Lecture Notes for Electrical Machines CourseNo EverandElectrical Machines: Lecture Notes for Electrical Machines CourseAinda não há avaliações

- Single Phase Induction MotorDocumento7 páginasSingle Phase Induction MotorReeta Dutta100% (1)

- M.Tech Power System PDFDocumento30 páginasM.Tech Power System PDFRaja RamachandranAinda não há avaliações

- Construction and Working of 3 Phase Induction MotorDocumento3 páginasConstruction and Working of 3 Phase Induction MotorArdyas Wisnu BaskoroAinda não há avaliações

- Module3 - Induction MotorDocumento45 páginasModule3 - Induction MotorRevki 'Exiit'Ainda não há avaliações

- 3phase Induction Motor (Sukhpreet)Documento17 páginas3phase Induction Motor (Sukhpreet)Ankesh KunwarAinda não há avaliações

- 01 Transformer ConstructionDocumento32 páginas01 Transformer Constructionedin_huseinbegovicAinda não há avaliações

- PCEG 403 Lab No. 1 Title: Simulation of Single Phase Half Wave Converter DC DriveDocumento5 páginasPCEG 403 Lab No. 1 Title: Simulation of Single Phase Half Wave Converter DC DriveJanup PokharelAinda não há avaliações

- EquivalEquivalent Circuit of Single-Phase Induction Motorent Circuit of Single-Phase Induction MotorDocumento13 páginasEquivalEquivalent Circuit of Single-Phase Induction Motorent Circuit of Single-Phase Induction Motoraili_avinashAinda não há avaliações

- Construction of Three Phase Induction MotorDocumento18 páginasConstruction of Three Phase Induction MotorRajeev ValunjkarAinda não há avaliações

- Unit-4-Electrical Machines: Lecture-3 Starting methods of 3-Φ Induction MotorDocumento13 páginasUnit-4-Electrical Machines: Lecture-3 Starting methods of 3-Φ Induction MotorPratik SarkarAinda não há avaliações

- Starting Method of 3-Phase Induction MotorDocumento4 páginasStarting Method of 3-Phase Induction MotorRajith Gamage100% (2)

- MOTORING AND GENERATING MODE OF 3-Φ INDUCTION MACHINE - A COMPARATIVE EVALUATION FOR ENERGY EFFICIENCY PDFDocumento64 páginasMOTORING AND GENERATING MODE OF 3-Φ INDUCTION MACHINE - A COMPARATIVE EVALUATION FOR ENERGY EFFICIENCY PDFIjabi0% (1)

- Generator Design StepsDocumento40 páginasGenerator Design StepsrajfabAinda não há avaliações

- Transformer FaultsDocumento11 páginasTransformer FaultsMusembiAinda não há avaliações

- Single Phase TransformerDocumento37 páginasSingle Phase TransformerMohamed Rezza Mohd NohAinda não há avaliações

- Induction MotorDocumento14 páginasInduction Motoraryans143sAinda não há avaliações

- (4-2) Synchronous GeneratorDocumento35 páginas(4-2) Synchronous Generatorfarah haniAinda não há avaliações

- Single Phase Induction MotorDocumento5 páginasSingle Phase Induction MotorSridhar SridharAinda não há avaliações

- VVVF DrivesDocumento16 páginasVVVF DrivesIsradani MjAinda não há avaliações

- Brushed DC Electric Motor - WikipediaDocumento63 páginasBrushed DC Electric Motor - WikipediaKISHORE PERUMALLAAinda não há avaliações

- No Load Test On Single Phase Induction MotorDocumento1 páginaNo Load Test On Single Phase Induction Motorg3v5Ainda não há avaliações

- EE 442 642 IntroductionDocumento14 páginasEE 442 642 IntroductionUSERNAME12340987Ainda não há avaliações

- Ch7 Induction MotorDocumento82 páginasCh7 Induction MotorMuhammad R ShihadehAinda não há avaliações

- Introduction: The Induction Motor Is A Three Phase AC Motor and Is The Most WidelyDocumento13 páginasIntroduction: The Induction Motor Is A Three Phase AC Motor and Is The Most WidelyAsimAinda não há avaliações

- Reluctance MotorDocumento16 páginasReluctance Motorapi-382713280% (5)

- Synchronous MotorsDocumento25 páginasSynchronous MotorsParvesh NainAinda não há avaliações

- Development of Electric Drives in Light Rail Transit (LRT) SystemDocumento31 páginasDevelopment of Electric Drives in Light Rail Transit (LRT) SystemArjun Pratap Singh100% (1)

- Linear Induction MotorDocumento18 páginasLinear Induction Motorapi-3827132100% (5)

- Induction Motor Braking Regenerative Dynamic Braking of Induction Motor - Electrical4u PDFDocumento7 páginasInduction Motor Braking Regenerative Dynamic Braking of Induction Motor - Electrical4u PDFbalajiAinda não há avaliações

- Three Phase Induction - MotorDocumento52 páginasThree Phase Induction - MotorAdityaAinda não há avaliações

- PX7203-Special Electrical Machines PDFDocumento11 páginasPX7203-Special Electrical Machines PDFvaishnavisriAinda não há avaliações

- Unit-7 8 Electric Traction - II IIIDocumento24 páginasUnit-7 8 Electric Traction - II IIIShreyaAinda não há avaliações

- Smartplant ElectricalDocumento1 páginaSmartplant ElectricalGEETHA PUSHKARANAinda não há avaliações

- Electrical Engineering QUESTION BANKDocumento7 páginasElectrical Engineering QUESTION BANKMATHANKUMAR.S100% (1)

- Induction Machine ReportDocumento24 páginasInduction Machine ReportSiddharth NandhanAinda não há avaliações

- Switched Reluctance Motor (SRM)Documento8 páginasSwitched Reluctance Motor (SRM)Ömer Faruk AbdullahAinda não há avaliações

- PMBLDC Motor DriveDocumento55 páginasPMBLDC Motor DriveSushant SinghAinda não há avaliações

- Lecture14 - Stator Phase Circuits & Coil Design, Part 1Documento21 páginasLecture14 - Stator Phase Circuits & Coil Design, Part 1ramaswamykama786Ainda não há avaliações

- (Single+Three) Phase Induction Motors Interview Questions SetDocumento18 páginas(Single+Three) Phase Induction Motors Interview Questions SetrajshahieeeAinda não há avaliações

- EXPERIMENT Induction MotorDocumento10 páginasEXPERIMENT Induction MotorMohamed Meeran100% (1)

- 3 Phase Induction Motor ReportDocumento5 páginas3 Phase Induction Motor ReportOPIYO ONYANGO100% (3)

- Chap1 Special MachinesDocumento23 páginasChap1 Special MachinesHell Maax100% (2)

- DC Motor S: Anand 08338958770Documento79 páginasDC Motor S: Anand 08338958770Rohit AvasthiAinda não há avaliações

- Induction GeneratorDocumento12 páginasInduction GeneratorSumaira SaifAinda não há avaliações

- Unit 3Documento5 páginasUnit 3Narasimman DonAinda não há avaliações

- Construction of Machine PDFDocumento110 páginasConstruction of Machine PDFAvinash SinghAinda não há avaliações

- Improved Indirect Power Control (IDPC) of Wind Energy Conversion Systems (WECS)No EverandImproved Indirect Power Control (IDPC) of Wind Energy Conversion Systems (WECS)Ainda não há avaliações

- Electrical Load-Curve Coverage: Proceedings of the Symposium on Load-Curve Coverage in Future Electric Power Generating Systems, Organized by the Committee on Electric Power, United Nations Economic Commission for Europe, Rome, Italy, 24 – 28 October 1977No EverandElectrical Load-Curve Coverage: Proceedings of the Symposium on Load-Curve Coverage in Future Electric Power Generating Systems, Organized by the Committee on Electric Power, United Nations Economic Commission for Europe, Rome, Italy, 24 – 28 October 1977Ainda não há avaliações

- Investigation of the Usefulness of the PowerWorld Simulator Program: Developed by "Glover, Overbye & Sarma" in the Solution of Power System ProblemsNo EverandInvestigation of the Usefulness of the PowerWorld Simulator Program: Developed by "Glover, Overbye & Sarma" in the Solution of Power System ProblemsAinda não há avaliações

- Arabic Study GuideDocumento7 páginasArabic Study GuideMuhammadZaydArattKhanAinda não há avaliações

- Optimal P-Q Control of Grid-Connected InvertersDocumento19 páginasOptimal P-Q Control of Grid-Connected InvertersMuhammadZaydArattKhanAinda não há avaliações

- Coal Used in Thermal Power PlantsDocumento3 páginasCoal Used in Thermal Power PlantsMuhammadZaydArattKhanAinda não há avaliações

- AliahDocumento4 páginasAliahMuhammadZaydArattKhanAinda não há avaliações

- Control Design Guidelines For Single-Phase Grid-Connected Photovoltaic Inverters With Damped Resonant Harmonic CompensatorsDocumento10 páginasControl Design Guidelines For Single-Phase Grid-Connected Photovoltaic Inverters With Damped Resonant Harmonic CompensatorsMuhammadZaydArattKhanAinda não há avaliações

- Lighting Design Students Guide - CIBSE PDFDocumento133 páginasLighting Design Students Guide - CIBSE PDFsameerray12100% (1)

- Control Design Guidelines For Single-Phase Grid-Connected Photovoltaic Inverters With Damped Resonant Harmonic CompensatorsDocumento10 páginasControl Design Guidelines For Single-Phase Grid-Connected Photovoltaic Inverters With Damped Resonant Harmonic CompensatorsMuhammadZaydArattKhanAinda não há avaliações

- APPLICATION FOR THE POST OF: - DEPARTMENT: - Recent Passport Size Photograph To Be Affixed HereDocumento3 páginasAPPLICATION FOR THE POST OF: - DEPARTMENT: - Recent Passport Size Photograph To Be Affixed HereMuhammadZaydArattKhanAinda não há avaliações

- IBM Chatbot TutorialDocumento29 páginasIBM Chatbot TutorialMuhammadZaydArattKhanAinda não há avaliações

- The Economics of Halal IndustryDocumento16 páginasThe Economics of Halal IndustryMuhammadZaydArattKhanAinda não há avaliações

- Temperature Controller PDFDocumento3 páginasTemperature Controller PDFMuhammadZaydArattKhanAinda não há avaliações

- The Letters of Maulana Saeed Ahmad Khan Saheb PDFDocumento44 páginasThe Letters of Maulana Saeed Ahmad Khan Saheb PDFMuhammadZaydArattKhanAinda não há avaliações

- Basic Electricity PDFDocumento16 páginasBasic Electricity PDFMuhammadZaydArattKhanAinda não há avaliações

- Al Adab Al Mufrad Al BukhariDocumento148 páginasAl Adab Al Mufrad Al BukhariNazar Jo50% (2)

- HIT ChecklistDocumento1 páginaHIT ChecklistMuhammadZaydArattKhanAinda não há avaliações

- Sample Job Offer Letter: (Company Information or On Letterhead)Documento1 páginaSample Job Offer Letter: (Company Information or On Letterhead)Ridwan KingdomAinda não há avaliações

- Ahsan Al QasasDocumento54 páginasAhsan Al QasasLuisa de CesareAinda não há avaliações

- Et 8Documento3 páginasEt 8MuhammadZaydArattKhanAinda não há avaliações

- A.C. FundamentalsDocumento11 páginasA.C. FundamentalsMuhammadZaydArattKhanAinda não há avaliações

- CNC MaterialDocumento1 páginaCNC MaterialMuhammadZaydArattKhanAinda não há avaliações

- Et 6Documento3 páginasEt 6MuhammadZaydArattKhanAinda não há avaliações

- Et 3Documento2 páginasEt 3MuhammadZaydArattKhanAinda não há avaliações

- Electrical MachinesDocumento403 páginasElectrical Machinessasikumar100% (9)

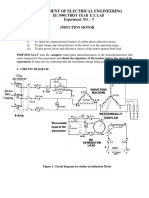

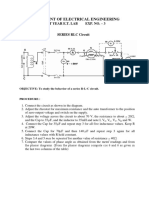

- Expt 1Documento4 páginasExpt 1MuhammadZaydArattKhanAinda não há avaliações

- Facebook Paid Marketing SecretsDocumento22 páginasFacebook Paid Marketing SecretsMuhammadZaydArattKhan100% (1)

- Shredded Club Workout Log PDFDocumento5 páginasShredded Club Workout Log PDFMuhammadZaydArattKhanAinda não há avaliações

- Muslim Entrepreneurship in IrelandDocumento99 páginasMuslim Entrepreneurship in IrelandMuhammadZaydArattKhanAinda não há avaliações

- University of Auckland ProspectusDocumento52 páginasUniversity of Auckland ProspectusMuhammadZaydArattKhanAinda não há avaliações

- HDE 153.CT.07.a DistribucionesParametrosGeotecnicosDocumento144 páginasHDE 153.CT.07.a DistribucionesParametrosGeotecnicosIngrid Irreño PalomoAinda não há avaliações

- JotterPad - JotterPad - FinalDocumento26 páginasJotterPad - JotterPad - FinalOlajide HeritageAinda não há avaliações

- 02 Rob SwiftDocumento16 páginas02 Rob Swiftjitendra2786Ainda não há avaliações

- Secondary Test Physics DynamicsDocumento5 páginasSecondary Test Physics DynamicsApril NgAinda não há avaliações

- Thrust BearingsDocumento3 páginasThrust BearingsorokoroAinda não há avaliações

- The Physics of Anti-Gravity Systems: © 2018 Brent Jarvis All Rights ReservedDocumento7 páginasThe Physics of Anti-Gravity Systems: © 2018 Brent Jarvis All Rights Reservedsheraz ahmadAinda não há avaliações

- ASTM D790 2010.flexionDocumento11 páginasASTM D790 2010.flexionaletapia100% (1)

- S o M - Definitions CompleteDocumento25 páginasS o M - Definitions CompleteHema SubramanianAinda não há avaliações

- Powder Technology Lecture SlidesDocumento12 páginasPowder Technology Lecture Slidesruano25Ainda não há avaliações

- 01261132Documento32 páginas01261132namithdevadigaAinda não há avaliações

- Advanced Surveying and GIS MCQSDocumento51 páginasAdvanced Surveying and GIS MCQSRITUPARNA ACHARYYA0% (2)

- Sample Papers SolvedDocumento185 páginasSample Papers Solvedjovanbhaskaran10Ainda não há avaliações

- Microstrip AntennaDocumento56 páginasMicrostrip AntennaPrajakta MoreAinda não há avaliações

- Pumping Tests: R R T Q S S H HDocumento6 páginasPumping Tests: R R T Q S S H HGonzalo Salazar PanequeAinda não há avaliações

- Module 2-Lesson 6 Mech 101Documento8 páginasModule 2-Lesson 6 Mech 101PJ MaskAinda não há avaliações

- 6325 05 PDFDocumento33 páginas6325 05 PDFMatias Montenegro MancillaAinda não há avaliações

- MIT8 01SC Problems11 SolnDocumento13 páginasMIT8 01SC Problems11 Solnडॉ. कनिष्क शर्माAinda não há avaliações

- DC To DC Mobile Charging Using DDocumento12 páginasDC To DC Mobile Charging Using DanmolAinda não há avaliações

- Matlab Code For Solution by Torsional Equivalence MethodDocumento6 páginasMatlab Code For Solution by Torsional Equivalence MethodmishtinilAinda não há avaliações

- Complex Analysis Complex Numbers and Functions PDFDocumento48 páginasComplex Analysis Complex Numbers and Functions PDFJohn Lloyd ComiaAinda não há avaliações

- Diode RectifiersDocumento64 páginasDiode RectifiersAmineAinda não há avaliações

- Appendix 1 PHY094 - QuizDocumento2 páginasAppendix 1 PHY094 - QuizIzzatiAinda não há avaliações

- Chemical Reactions: Reactants ProductsDocumento16 páginasChemical Reactions: Reactants ProductsRSLAinda não há avaliações

- Chemistry 12 PDFDocumento83 páginasChemistry 12 PDFAnonymous 8V2iHxBAinda não há avaliações

- Voltage TransformerDocumento20 páginasVoltage TransformerRK K100% (3)

- Fundamentals of Molecular CatalysisDocumento537 páginasFundamentals of Molecular CatalysisSandeep SaiAinda não há avaliações

- Class Test 1 (Light) - AnswersDocumento7 páginasClass Test 1 (Light) - Answerskeyur.gala0% (1)