Escolar Documentos

Profissional Documentos

Cultura Documentos

E08

Enviado por

abuahnfDescrição original:

Título original

Direitos autorais

Formatos disponíveis

Compartilhar este documento

Compartilhar ou incorporar documento

Você considera este documento útil?

Este conteúdo é inapropriado?

Denunciar este documentoDireitos autorais:

Formatos disponíveis

E08

Enviado por

abuahnfDireitos autorais:

Formatos disponíveis

APPENDIX E8

MISCELLANEOUS MATERIALS

AND THEIR PROPERTIES

Akhil Prakash, P.E.

Senior Engineer

Wolf Creek Nuclear Operating Corporation

Burlington, Kansas

E.101

E.102

APPENDIXES

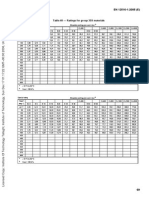

TABLE E8.1 Nominal Coefficients of Thermal Expansion for Ferrous Materials

Temperature, F

Coefficient

70

100

150

200

250

300

350

Material Group A

[Note (1)]

A

B

C

6.41

...

0

6.53

6.50

0.0023

6.73

6.57

0.0063

6.93

6.67

0.0104

7.12

6.77

0.0146

7.30

6.87

0.0190

7.49

6.98

0.0235

Material Group B

[Note (2)]

A

B

C

5.60

...

0

5.83

5.73

0.0021

6.20

5.91

0.0057

6.55

6.09

0.0095

6.88

6.27

0.0135

7.18

6.43

0.0177

7.47

6.59

0.0221

Material Group C

[Note (3)]

A

B

C

5.42

...

0

5.65

5.53

0.0020

6.03

5.71

0.0055

6.39

5.89

0.0092

6.73

6.09

0.0132

7.04

6.26

0.0173

7.33

6.43

0.0216

Material Group D

[Note (4)]

A

B

C

7.02

...

0

7.13

7.06

0.0025

7.29

7.16

0.0069

7.45

7.25

0.0113

7.60

7.34

0.0158

7.74

7.43

0.0205

7.88

7.50

0.0252

Material Group E

[Note (5)]

A

B

C

6.20

...

0

6.37

6.27

0.0023

6.62

6.41

0.0062

6.85

6.54

0.0102

7.05

6.65

0.0144

7.25

6.78

0.0187

7.43

6.88

0.0231

2Cr1Mo

A

B

C

6.45

...

0

6.60

6.50

0.0023

6.80

6.60

0.0063

6.90

6.70

0.0105

7.16

6.80

0.0147

7.35

6.90

0.0190

7.48

6.98

0.0235

5CrMo,

5CrMoSi, and

5CrMoTi

A

B

C

6.52

...

0

6.59

6.50

0.0026

6.71

6.65

0.0066

6.83

6.73

0.0107

6.94

6.80

0.0149

7.04

6.87

0.0190

7.15

6.93

0.0233

7CrMo and

9Cr-1Mo

A

B

C

5.82

...

0

5.90

5.85

0.0021

6.03

5.93

0.0057

6.16

6.02

0.0094

6.29

6.10

0.0132

6.41

6.15

0.0170

6.53

6.23

0.0209

MnV

A

B

C

6.60

...

0

6.79

6.68

0.0024

7.00

6.80

0.0065

7.20

6.90

0.0108

7.40

7.05

0.0152

7.58

7.15

0.0197

7.75

7.25

0.0244

5NiMo

A

B

C

6.20

...

0

6.34

6.27

0.0023

6.55

6.41

0.0062

6.74

6.50

0.0101

6.90

6.59

0.0142

7.06

6.68

0.0184

7.21

6.76

0.0227

8Ni and 9Ni

A

B

C

5.50

...

0

5.70

5.63

0.0020

6.00

5.80

0.0056

6.25

5.94

0.0093

6.45

6.06

0.0131

6.60

6.17

0.0170

6.75

6.28

0.0211

12Cr, 12Cr1Al,

13Cr, and 13Cr4Ni

A

B

C

5.92

...

0

6.03

5.98

0.0022

6.18

6.08

0.0058

6.30

6.15

0.0096

6.41

6.23

0.0135

6.50

6.30

0.0174

6.59

6.35

0.0213

15Cr and 17Cr

A

B

C

5.33

...

0

5.41

5.37

0.0019

5.54

5.45

0.0052

5.66

5.52

0.0086

5.77

5.59

0.0121

5.88

5.65

0.0156

5.99

5.70

0.0192

Materials

Carbon and low

alloy steels

High chrome steels

E.103

MISCELLANEOUS MATERIALS AND THEIR PROPERTIES

TABLE E8.1 Nominal Coefficients of Thermal Expansion for Ferrous Materials

(Continued )

Temperature, F

400

450

500

550

600

650

700

750

800

7.66

7.07

0.0280

7.84

7.15

0.0326

8.03

7.25

0.0374

8.21

7.34

0.0423

8.35

7.42

0.0472

8.51

7.52

0.0523

8.64

7.59

0.0574

8.78

7.68

0.0627

8.90

7.76

0.0680

7.73

6.74

0.0267

7.97

6.89

0.0314

8.18

7.06

0.0364

8.38

7.18

0.0414

8.55

7.28

0.0463

8.70

7.40

0.0515

8.83

7.51

0.0568

8.94

7.61

0.0621

9.02

7.71

0.0675

7.60

6.61

0.0262

7.85

6.77

0.0309

8.07

6.91

0.0357

8.28

7.06

0.0407

8.46

7.17

0.0456

8.62

7.30

0.0508

8.75

7.41

0.0560

8.87

7.50

0.0612

8.96

7.59

0.0665

8.01

7.58

0.0300

8.13

7.63

0.0348

8.25

7.70

0.0397

8.36

7.77

0.0448

8.46

7.83

0.0498

8.55

7.90

0.0550

8.63

7.94

0.0600

8.71

8.00

0.0653

8.78

8.05

0.0706

7.59

6.98

0.0276

7.75

7.07

0.0322

7.90

7.16

0.0369

8.04

7.24

0.0417

8.16

7.32

0.0466

8.28

7.41

0.0516

8.39

7.47

0.0565

8.49

7.55

0.0616

8.57

7.61

0.0667

7.65

7.07

0.0280

7.76

7.15

0.0326

7.90

7.23

0.0373

7.99

7.31

0.0421

8.10

7.38

0.0469

8.17

7.45

0.0519

8.25

7.50

0.0567

8.32

7.56

0.0617

8.40

7.62

0.0668

7.25

6.97

0.0276

7.35

7.00

0.0319

7.44

7.05

0.0364

7.53

7.10

0.0409

7.62

7.15

0.0455

7.71

7.19

0.0500

7.79

7.24

0.0547

7.87

7.28

0.0594

7.95

7.32

0.0641

6.64

6.29

0.0249

6.75

6.34

0.0289

6.87

6.40

0.0330

6.97

6.46

0.0372

7.07

6.51

0.0414

7.17

6.57

0.0457

7.27

6.62

0.0500

7.36

6.66

0.0544

7.44

6.71

0.0588

7.90

7.33

0.0290

8.05

7.40

0.0337

8.17

7.50

0.0388

8.30

7.58

0.0437

8.40

7.65

0.0486

8.50

7.74

0.0539

8.60

7.80

0.0590

8.70

7.87

0.0642

8.78

7.93

0.0695

7.35

6.84

0.0271

7.50

6.92

0.0315

7.63

6.99

0.0361

7.76

7.06

0.0407

7.89

7.14

0.0454

8.00

7.21

0.0501

8.12

7.27

0.0549

8.23

7.34

0.0599

8.33

7.40

0.0649

6.90

6.39

0.0253

7.04

6.47

0.0295

7.16

6.56

0.0338

7.27

6.63

0.0382

7.37

6.70

0.0426

7.45

6.72

0.0468

7.52

6.78

0.0513

7.57

6.84

0.0558

7.64

6.89

0.0604

Carbon and low alloy steels

High chrome steels

6.66

6.40

0.0253

6.72

6.44

0.0294

6.77

6.48

0.0334

6.83

6.51

0.0375

6.88

6.53

0.0415

6.94

6.57

0.0457

6.99

6.60

0.0499

7.05

6.64

0.0542

7.11

6.67

0.0584

6.09

5.75

0.0228

6.19

5.80

0.0264

6.28

5.85

0.0302

6.37

5.90

0.0340

6.46

5.95

0.0378

6.54

6.00

0.0418

6.62

6.05

0.0457

6.70

6.09

0.0497

6.77

6.13

0.0537

E.104

APPENDIXES

TABLE E8.1 Nominal Coefficients of Thermal Expansion for Ferrous Materials

(Continued )

Materials

Coefficient

Temperature, F

70

100

150

200

250

300

350

A

B

C

5.02

...

0

5.07

5.06

0.0018

5.14

5.12

0.0049

5.22

5.15

0.0080

5.29

5.20

0.0112

5.36

5.23

0.0144

5.44

5.26

0.0177

18Cr13Ni3Mo

and 16Cr12Ni

2Mo [Note (6)]

A

B

C

8.42

...

0

8.59

8.54

0.0031

8.84

8.64

0.0083

9.09

8.76

0.0137

9.33

8.88

0.0192

9.56

8.97

0.0248

9.76

9.11

0.0306

17Cr4Ni4Cu

A

B

C

5.89

...

0

5.89

5.89

0.0021

5.89

5.89

0.0057

5.90

5.90

0.0092

5.90

5.90

0.0127

5.90

5.90

0.0163

5.91

5.91

0.0199

18Cr5Ni3Mo

A

B

C

7.94

...

0

8.06

8.03

0.0029

8.26

8.17

0.0078

8.43

8.25

0.0129

8.61

8.35

0.0180

8.78

8.45

0.0233

8.94

8.54

0.0287

18Cr8Ni [Note (6)]

and 18Cr11Ni

A

B

C

8.46

...

0

8.63

8.55

0.0031

8.87

8.67

0.0083

9.08

8.79

0.0137

9.27

8.90

0.0192

9.46

9.00

0.0248

9.64

9.10

0.0306

18Cr10NiTi

A

B

C

8.97

...

0

9.03

9.02

0.0033

9.13

9.10

0.0088

9.23

9.16

0.0143

9.33

9.22

0.0199

9.41

9.26

0.0256

9.49

9.30

0.0312

18Cr10NiCb

A

B

C

8.53

...

0

8.70

8.62

0.0031

9.00

8.75

0.0084

9.29

8.92

0.0139

9.55

9.07

0.0196

9.78

9.22

0.0254

9.98

9.32

0.0313

19Cr9NiMoW

A

B

C

9.10

...

0

9.21

9.17

0.0033

9.38

9.27

0.0089

9.54

9.37

0.0146

9.70

9.46

0.0204

9.85

9.54

0.0263

9.99

9.63

0.0324

22Cr13Ni5Mn

A

B

C

8.24

...

0

8.35

8.30

0.0030

8.51

8.40

0.0081

8.67

8.48

0.0132

8.81

8.57

0.0185

8.95

8.65

0.0239

9.08

8.73

0.0293

25Cr12Ni,

23Cr12Ni, and

25Cr20Ni

A

B

C

8.81

...

0

8.89

8.87

0.0032

8.99

8.95

0.0086

9.06

9.02

0.0141

9.11

9.06

0.0196

9.17

9.10

0.0251

9.22

9.12

0.0306

25Ni15Cr2Ti

A

B

C

8.22

...

0

8.31

8.24

0.0030

8.46

8.32

0.0080

8.61

8.39

0.0131

8.75

8.47

0.0183

8.89

8.54

0.0236

9.02

8.62

0.0290

28Ni19CrCuMo

A

B

C

8.72

...

0

8.84

8.75

0.0032

8.93

8.85

0.0085

9.02

8.90

0.0139

9.11

8.99

0.0194

9.20

9.04

0.0250

9.29

9.09

0.0305

High chrome steels (Contd )

27Cr

High alloy steels

Source: Reproduced from 1995 ASME Section II, Part D, with permission from American Society

of Mechanical Engineers, 345 East 47th St., New York, NY.

GENERAL NOTE:

Coefficient A is the instantaneous coefficient of thermal expansion 106 (in./in./F). Coefficient B

is the mean coefficient of thermal expansion 106 (in./in./F) in going from 70F to indicated temperature.

Coefficient C is the linear thermal expansion (in./ft) in going from 70F to indicated temperature.

E.105

MISCELLANEOUS MATERIALS AND THEIR PROPERTIES

TABLE E8.1 Nominal Coefficients of Thermal Expansion for Ferrous Materials

(Continued )

Temperature, F

400

450

500

550

600

650

700

750

800

5.51

5.30

0.0210

5.58

5.33

0.0243

5.66

5.37

0.0277

5.73

5.40

0.0311

5.80

5.43

0.0345

5.88

5.47

0.0381

5.94

5.50

0.0416

9.95

9.21

0.0365

10.10

9.32

0.0425

10.25

9.42

0.0486

10.38

9.50

0.0547

10.51

9.60

0.0611

10.64

9.69

0.0674

10.76

9.76

0.0738

10.87

9.81

0.0800

10.98

9.90

0.0867

5.91

5.91

0.0234

5.91

5.91

0.0269

5.91

5.91

0.0305

5.93

5.93

0.0342

5.96

5.93

0.0377

5.99

5.93

0.0413

6.03

5.94

0.0449

6.08

5.95

0.0486

6.14

5.96

0.0522

9.09

8.61

0.0341

9.24

8.69

0.0396

9.38

8.76

0.0452

9.52

8.83

0.0509

9.64

8.90

0.0566

9.76

8.97

0.0624

9.87

9.04

0.0683

9.96

9.10

0.0743

10.06

9.16

0.0802

9.80

9.19

0.0364

9.95

9.28

0.0423

10.10

9.37

0.0483

10.25

9.45

0.0544

10.38

9.53

0.0606

10.50

9.61

0.0669

10.60

9.69

0.0733

10.70

9.76

0.0796

10.79

9.82

0.0860

9.57

9.34

0.0370

9.64

9.38

0.0427

9.72

9.42

0.0486

9.78

9.45

0.0545

9.85

9.48

0.0602

9.92

9.52

0.0662

9.98

9.55

0.0722

10.04

9.58

0.0787

10.10

9.61

0.0842

10.16

9.45

0.0374

10.30

9.55

0.0435

10.44

9.65

0.0498

10.55

9.75

0.0562

10.66

9.83

0.0625

10.76

9.90

0.0689

10.86

9.97

0.0754

10.96

10.03

0.0818

11.05

10.08

0.0883

10.13

9.69

0.0384

10.26

9.76

0.0445

10.38

9.83

0.0507

10.50

9.89

0.0570

10.61

9.95

0.0633

10.72

10.01

0.0697

10.81

10.07

0.0761

10.91

10.13

0.0827

10.99

10.18

0.0892

9.21

8.79

0.0348

9.33

8.86

0.0404

9.44

8.92

0.0460

9.54

8.98

0.0517

9.64

9.03

0.0574

9.73

9.09

0.0633

9.82

9.15

0.0692

9.89

9.20

0.0751

9.97

9.25

0.0810

9.27

9.14

0.0362

9.29

9.16

0.0418

9.33

9.18

0.0474

9.37

9.20

0.0530

9.39

9.21

0.0586

9.44

9.23

0.0642

9.47

9.25

0.0699

9.52

9.27

0.0756

9.56

9.28

0.0813

9.14

8.69

0.0344

9.26

8.76

0.0399

9.37

8.82

0.0455

9.48

8.88

0.0512

9.58

8.94

0.0569

9.68

9.00

0.0627

9.77

9.06

0.0685

9.85

9.11

0.0744

9.93

9.17

0.0803

9.38

9.14

0.0362

9.48

9.18

0.0419

9.57

9.22

0.0476

9.66

9.26

0.0533

9.76

9.30

0.0591

9.86

9.35

0.0651

9.95

9.39

0.0710

10.04

9.44

0.0770

10.14

9.48

0.0830

High chrome steels (Contd)

6.02

5.54

0.0452

6.09

5.57

0.0488

High alloy steels

Notes continue on next page.

E.106

APPENDIXES

TABLE E8.1 Nominal Coefficients of Thermal Expansion for Ferrous Materials

(Continued )

Notes:

(1) Material Group A consists of:

Plain carbon steels

Carbonmanganese steel

NiMoV

NiMoCrV

(2) Material Group B consists of:

Carbonsilicon steels

CMo

CrNiMo

(3) Material Group C consists of:

CMnSi steels

CrMoSi

1CrMoV

(4) Material Group D consists of:

MnMo

MnMo

(5) Material Group E consists of:

1Ni1CrMo

1NiCrMo

2NiCrMo

(6) Includes N grades also

NiMoCrV

Ni1MoCr

NiCrMoV

1NiCrMo

NiCrMoV

NiCuMo

CrNiCuAl

CrNiCu

CrMo

CrMoV

1CrMo

1CrMo

1CrMoSi

1CrMoCu

CrMo

1CrMoSi

2CrMo

3Cr1Mo

MnMoNi

MnMoNi

MnMoNi

2NiCrMo

2Ni1Cu

2Ni and 3Ni

3Ni1CrMoV

E.107

MISCELLANEOUS MATERIALS AND THEIR PROPERTIES

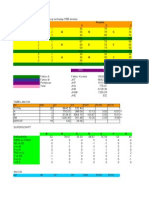

TABLE E8.2 Moduli of Elasticity E of Ferrous Materials for Given Temperatures

Modulus of Elasticity E Value Given 106 psi, for Temp., F, of

Materials

325

200

100

70o

200

300

400

500

600

700

800

900

Carbon steels with

C 0.30%

Carbon steels with

C 0.30%

Material Group A1

Material Group B2

Material Group C 3

Material Group D4

Material Group E5

Material Group F 6

Material Group G7

31.4

30.8

30.2

29.5

28.8

28.3

27.7

27.3

26.7

25.5

24.2

22.4

31.2

30.6

30.0

29.3

28.6

28.1

27.5

27.1

26.5

25.3

24.0

22.3

31.1

29.6

31.6

32.6

32.9

31.2

30.3

30.5

29.1

31.0

32.0

32.3

30.7

29.7

29.9

28.5

30.4

31.4

31.7

30.1

29.1

29.2

27.8

29.7

30.6

30.9

29.2

28.3

28.5

27.1

29.0

29.8

30.1

28.5

27.6

28.0

26.7

28.5

29.4

29.7

27.9

27.0

27.4

26.1

27.9

28.8

29.0

27.3

26.5

27.0

25.7

27.5

28.3

28.6

26.7

25.8

26.4

25.2

26.9

27.7

28.0

26.1

25.3

25.3

24.6

26.3

27.1

27.3

25.6

24.8

23.9

23.0

25.5

26.3

26.1

24.7

24.1

22.2

...

24.8

25.6

24.7

23.2

23.5

Notes:

(1) Material Group A consists of the following carbonmolybdenum steels:

CMo

MnMo

MnMo

MnV

(2) Material Group B consists of the following Ni steels:

NiMoCrV

1NiCrMo

NiMoV

Ni1MoCr

NiMoCrV

NiCrMoV

CrNiCuAl

2Ni1Cu

CrNiCu

2Ni

NiCuMo

3Ni

(3) Material Group C consists of the following 2Cr steels:

CrMo

1CrMo

1CrMoSi

1CrMo

2CrMo

(4) Material Group D consists of the following 23Cr steels:

2Cr1Mo

3Cr1Mo

(5) Material Group E consists of the following 59Cr steels:

5CrMo

5CrMoSi

5CrMoTi

7CrMo

9CrMo

(6) Material Group F consists of the following chromium steels:

12CrAl

13Cr

15Cr

17Cr

(7) Material Group G consists of the following austenitic steels:

18Cr8Ni

18Cr10NiCb

18Cr8NiN

18Cr18Ni2Si

16Cr12Ni

20Cr6Ni9Mn

18Cr13Ni3Mo

22Cr13Ni5Mn

16Cr12Ni2MoN

23Cr12Ni

18Cr3Ni13Mn

25Cr20Ni

18Cr10NiTi

Source: Reproduced from 1995 ASME Section II, Part D, with permission from American Society

of Mechanical Engineers, 345 East 47th St., New York, NY.

Você também pode gostar

- Chne 101 Fall 2013, Chemical Engineering Lab Fuel Cell Demo: Ayham MaadiDocumento2 páginasChne 101 Fall 2013, Chemical Engineering Lab Fuel Cell Demo: Ayham MaadiAyham MaadiAinda não há avaliações

- Ageing and Life Extension of Offshore Structures: The Challenge of Managing Structural IntegrityNo EverandAgeing and Life Extension of Offshore Structures: The Challenge of Managing Structural IntegrityAinda não há avaliações

- Specific ActivitiesDocumento15 páginasSpecific Activitiess3dbwAinda não há avaliações

- FAA 2020 0493 0006 - Attachment - 2Documento83 páginasFAA 2020 0493 0006 - Attachment - 2engine wangAinda não há avaliações

- Case Studies in Mechanical Engineering: Decision Making, Thermodynamics, Fluid Mechanics and Heat TransferNo EverandCase Studies in Mechanical Engineering: Decision Making, Thermodynamics, Fluid Mechanics and Heat TransferNota: 5 de 5 estrelas5/5 (2)

- Table 40 - Ratings For Group 3E0 MaterialsDocumento1 páginaTable 40 - Ratings For Group 3E0 MaterialsMaverikbjAinda não há avaliações

- Combustion Engines: An Introduction to Their Design, Performance, and SelectionNo EverandCombustion Engines: An Introduction to Their Design, Performance, and SelectionAinda não há avaliações

- Machine Design Chapter 8 SolutionsDocumento26 páginasMachine Design Chapter 8 SolutionsSubhash KorumilliAinda não há avaliações

- BPC 3053Documento9 páginasBPC 3053Shafiqa ZulkefliAinda não há avaliações

- Next Generation HALT and HASS: Robust Design of Electronics and SystemsNo EverandNext Generation HALT and HASS: Robust Design of Electronics and SystemsAinda não há avaliações

- Critical Values Of: T T T T T T T T T TDocumento1 páginaCritical Values Of: T T T T T T T T T Tzain6461Ainda não há avaliações

- Fani Fakrotial DoneDocumento6 páginasFani Fakrotial DoneFani Karina AstriniAinda não há avaliações

- EASC404 Past QuestionDocumento3 páginasEASC404 Past QuestionHerman KwamebourAinda não há avaliações

- Table A9-2. Discharge of Fully Contracted Standard Submerged RectangularDocumento2 páginasTable A9-2. Discharge of Fully Contracted Standard Submerged RectangularoctatheweelAinda não há avaliações

- Class Routine CseDocumento20 páginasClass Routine CseMishal IslamAinda não há avaliações

- 1.3. - Conga Capex Reconciliation - area.RevCDocumento1 página1.3. - Conga Capex Reconciliation - area.RevCvisnupadaAinda não há avaliações

- PDF Card - Fe - 00-006-0696 PDFDocumento1 páginaPDF Card - Fe - 00-006-0696 PDFmohammed sabeehAinda não há avaliações

- Labor Subcontracts: Offshore Estimating 465Documento1 páginaLabor Subcontracts: Offshore Estimating 465sivavalaiAinda não há avaliações

- Well Fluids Sample PropertiesDocumento12 páginasWell Fluids Sample PropertiesgregAinda não há avaliações

- Lampiran: Universitas Sumatera UtaraDocumento24 páginasLampiran: Universitas Sumatera UtaraAbidNasiroAinda não há avaliações

- Table Chapman EnskogDocumento2 páginasTable Chapman EnskogNajmuddin Bin Mohd RamliAinda não há avaliações

- Steel Industry Update #269Documento8 páginasSteel Industry Update #269Michael LockerAinda não há avaliações

- PDF Card - (Fe, Ni) - 00-037-0474Documento1 páginaPDF Card - (Fe, Ni) - 00-037-0474mohammed sabeehAinda não há avaliações

- Preleminary Report Cm2 Rev01Documento28 páginasPreleminary Report Cm2 Rev01RakaAinda não há avaliações

- Lampiran 4data Hasil PerhitunganDocumento10 páginasLampiran 4data Hasil PerhitunganArie FajrinAinda não há avaliações

- 8 EE A 3 ScientificNotationPRDocumento2 páginas8 EE A 3 ScientificNotationPRkolawoleAinda não há avaliações

- PMRE 6006 Final Oct 2023 - TakehomeDocumento6 páginasPMRE 6006 Final Oct 2023 - TakehomeHelter SkelterAinda não há avaliações

- Astm E647Documento18 páginasAstm E647lanforex90522100% (1)

- CEPCIDocumento1 páginaCEPCIhendrablast67% (3)

- Five Hundred Forty (540) Calendar DaysDocumento1 páginaFive Hundred Forty (540) Calendar DaysRodolfo Jr PestanoAinda não há avaliações

- United States Patent: Chang Et Al. (10) Patent No.: US 8,026,567 B2Documento6 páginasUnited States Patent: Chang Et Al. (10) Patent No.: US 8,026,567 B2Burak PalaAinda não há avaliações

- Revision QuestionsDocumento9 páginasRevision QuestionsBurGer HamAinda não há avaliações

- Satefy Valve Test Bench For SteamDocumento17 páginasSatefy Valve Test Bench For SteamamojodiAinda não há avaliações

- Table 2-3.1 Pressure-Temperature Ratings For Group 3.1 MaterialsDocumento1 páginaTable 2-3.1 Pressure-Temperature Ratings For Group 3.1 MaterialsPanchal ShaileshAinda não há avaliações

- A2as Biol Revised Support 2044Documento123 páginasA2as Biol Revised Support 2044Meagan MahangooAinda não há avaliações

- Deformation and Stress Analysis of Sheet Hydroforming in Car Frame T-JointDocumento8 páginasDeformation and Stress Analysis of Sheet Hydroforming in Car Frame T-JointIJRASETPublicationsAinda não há avaliações

- Table 1: Composition of Ethyl Cellulose Microspheres SN Ingredient F1 F2 F3 F4 F5 F6Documento2 páginasTable 1: Composition of Ethyl Cellulose Microspheres SN Ingredient F1 F2 F3 F4 F5 F6Maulik PatelAinda não há avaliações

- HDBK172F 06Documento45 páginasHDBK172F 06xolraxAinda não há avaliações

- SimulationMolec AdsPropane - PropylenOn13X 2007Documento7 páginasSimulationMolec AdsPropane - PropylenOn13X 2007TouatiAinda não há avaliações

- Analysis and Redesign of Failed Jacket IDocumento10 páginasAnalysis and Redesign of Failed Jacket Iabryant633777Ainda não há avaliações

- United States Patent (10) Patent No.: US 8,076,507 B2Documento12 páginasUnited States Patent (10) Patent No.: US 8,076,507 B2Manuel Gonzalez GalvezAinda não há avaliações

- API-510 Exam # 3 2008 Answer GuideDocumento6 páginasAPI-510 Exam # 3 2008 Answer Guidechowhk100% (2)

- AnswersDocumento9 páginasAnswersTan Yoke YenAinda não há avaliações

- LJ Parameters For Propane PropeneDocumento5 páginasLJ Parameters For Propane Propenesridhar pallaAinda não há avaliações

- Appendix Felder DikonversiDocumento26 páginasAppendix Felder DikonversilonglastingloveAinda não há avaliações

- 405 - Report HA +0.5Documento2 páginas405 - Report HA +0.5Nazar JabbarAinda não há avaliações

- School of Chemistry and Physics, University of Kwazulu-Natal, Private Bag X01, Scottsville, Pietermaritzburg, 3209 South AfricaDocumento5 páginasSchool of Chemistry and Physics, University of Kwazulu-Natal, Private Bag X01, Scottsville, Pietermaritzburg, 3209 South AfricaLol BlahAinda não há avaliações

- Critical Values For The Student's T Distribution: Appendix ADocumento2 páginasCritical Values For The Student's T Distribution: Appendix Aandres_hernandez_30Ainda não há avaliações

- Case StudyDocumento20 páginasCase StudySubramanyam VemulaAinda não há avaliações

- US8792257Documento16 páginasUS8792257Muhammad Saqib AliAinda não há avaliações

- InstantaneousDocumento1 páginaInstantaneousrishikeshmandawadAinda não há avaliações

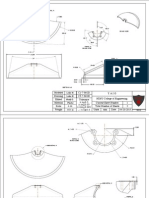

- Y.A.I.G Modeled Drawing Edited Scale Material Weight Current Sheet Number 1 Total Number of Sheets 2 C1-7-MOD C1-7-MOD NDSU College of EngineeringDocumento2 páginasY.A.I.G Modeled Drawing Edited Scale Material Weight Current Sheet Number 1 Total Number of Sheets 2 C1-7-MOD C1-7-MOD NDSU College of Engineeringapi-302059651Ainda não há avaliações

- FactorDocumento2 páginasFactorRajalingam ArumugamAinda não há avaliações

- Amet University: Grade Statement DetailsDocumento2 páginasAmet University: Grade Statement DetailsSiddharth Narayanan ChidambareswaranAinda não há avaliações

- Paper 3 SPM 2011 Mastery PracticesDocumento30 páginasPaper 3 SPM 2011 Mastery Practicesaganbasm100% (1)

- Project Report SimulationDocumento17 páginasProject Report SimulationVamsi KrishnaAinda não há avaliações

- Paper 3 SPM 2011 Mastery PracticesDocumento30 páginasPaper 3 SPM 2011 Mastery PracticesaganbasmAinda não há avaliações

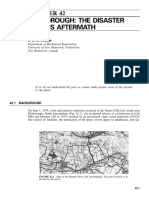

- Flixborough: The Disaster and Its Aftermath: J. E. S. VenartDocumento31 páginasFlixborough: The Disaster and Its Aftermath: J. E. S. VenartabuahnfAinda não há avaliações

- FHFDocumento4 páginasFHFabuahnfAinda não há avaliações

- VPOP Centum VP Operation and MonitoringDocumento1 páginaVPOP Centum VP Operation and MonitoringabuahnfAinda não há avaliações

- Gateway Book 3 PDFDocumento69 páginasGateway Book 3 PDFabuahnf100% (1)

- IMCS Versus Conventional MCC - PCIC - 2009Documento6 páginasIMCS Versus Conventional MCC - PCIC - 2009abuahnfAinda não há avaliações

- 0700 BengkuluDocumento14 páginas0700 BengkuluabuahnfAinda não há avaliações

- MsdsDocumento5 páginasMsdsabuahnfAinda não há avaliações

- Well ControlDocumento187 páginasWell Controlabuahnf100% (1)

- Solar Centaur 40 DSDocumento2 páginasSolar Centaur 40 DSabuahnfAinda não há avaliações

- Donaldson CoolerDocumento4 páginasDonaldson CoolerabuahnfAinda não há avaliações

- E09Documento10 páginasE09vasucristalAinda não há avaliações

- Tutorial On Cryogenic Turboexpanders: by Jigger JumonvilleDocumento8 páginasTutorial On Cryogenic Turboexpanders: by Jigger JumonvilleabuahnfAinda não há avaliações

- Optimization of Shell-and-Tube Intercooler in Multistage Compressor SystemDocumento11 páginasOptimization of Shell-and-Tube Intercooler in Multistage Compressor SystemabuahnfAinda não há avaliações

- Exercise Redox Chemistry Grade 10: Matematika Fisika Dan Kimia Jadi Mudah Dan MenyenangkanDocumento3 páginasExercise Redox Chemistry Grade 10: Matematika Fisika Dan Kimia Jadi Mudah Dan MenyenangkanArda RahmainiAinda não há avaliações

- Science: Quarter 1 - Module 3Documento14 páginasScience: Quarter 1 - Module 3Matt Louge MaglaquiAinda não há avaliações

- Formula Writing and Naming of CompoundsDocumento24 páginasFormula Writing and Naming of CompoundsKentCastro100% (2)

- HL P2 Exam Chem2020Documento12 páginasHL P2 Exam Chem2020rania samirAinda não há avaliações

- Transition Metal ChemistryDocumento223 páginasTransition Metal Chemistryelgendy12040% (1)

- ACTIVITY: Element RapDocumento2 páginasACTIVITY: Element RapMobiAinda não há avaliações

- 862 Chemistry Paper 1Documento9 páginas862 Chemistry Paper 1Aryan SinghAinda não há avaliações

- FormDocumento6 páginasFormesmeralda melendezAinda não há avaliações

- Boiler Water ConditioningDocumento3 páginasBoiler Water ConditioningShahin AfrozAinda não há avaliações

- Module 3 Electrons in AtomsDocumento23 páginasModule 3 Electrons in AtomsJulie Anne Manggurit (Grade-10 Tesla)Ainda não há avaliações

- Silo - Tips Answer Key Build An Atom Part I Atom Screen Build An Atom Simulation An AtomDocumento6 páginasSilo - Tips Answer Key Build An Atom Part I Atom Screen Build An Atom Simulation An AtomFilip SalekAinda não há avaliações

- Model Answer: The Following Questions Answer Choose The Correct Answer: (20Documento4 páginasModel Answer: The Following Questions Answer Choose The Correct Answer: (20Khalid AbeedAinda não há avaliações

- Chapter 3. Study of Acids, Bases and Salts: Page No: 62Documento14 páginasChapter 3. Study of Acids, Bases and Salts: Page No: 62Sucheta DasAinda não há avaliações

- Chemistry Project Term 2 PDFDocumento30 páginasChemistry Project Term 2 PDFChryssa EconomouAinda não há avaliações

- Sulfuric Acid (H2so4)Documento3 páginasSulfuric Acid (H2so4)Muhammad Juanda Teknik KimiaAinda não há avaliações

- Pratical Organic Chemistry (12th)Documento4 páginasPratical Organic Chemistry (12th)Raju SinghAinda não há avaliações

- Basic Chemistry 5th Edition Timberlake Test BankDocumento28 páginasBasic Chemistry 5th Edition Timberlake Test Banksamuelfintanult1jj100% (32)

- Chemistry Perfect Score Module Form 4 Set 1Documento27 páginasChemistry Perfect Score Module Form 4 Set 1ZekZanaAinda não há avaliações

- Unsaturated Hydrocarbons,: Olefins Becauæ ArsDocumento9 páginasUnsaturated Hydrocarbons,: Olefins Becauæ ArsClaire Angelie RuayaAinda não há avaliações

- SDFSFDocumento3 páginasSDFSFAmyAinda não há avaliações

- Polymetron 8810 Analyser Ammonia and Nitrate MonitoringDocumento5 páginasPolymetron 8810 Analyser Ammonia and Nitrate Monitoringqasim_maqboolAinda não há avaliações

- SCNC 1112 Fundamentals of Modern Science: Important Reactions For The Physical and Living WorldDocumento15 páginasSCNC 1112 Fundamentals of Modern Science: Important Reactions For The Physical and Living WorldLai EdmondAinda não há avaliações

- AP Chemistry Formula SheetDocumento3 páginasAP Chemistry Formula SheetCeliciaAinda não há avaliações

- 1 - Chemical Foundations: Practice TestDocumento3 páginas1 - Chemical Foundations: Practice TestAshrafAL-ajouri / اشرف العجوريAinda não há avaliações

- 0653 w16 QP 11Documento20 páginas0653 w16 QP 11yuke kristinaAinda não há avaliações

- Lesson Plan: Lesson: Uses of AmmoniaDocumento3 páginasLesson Plan: Lesson: Uses of AmmoniaMarcTnn100% (1)

- Tantalum (V) and Niobium (V) Extraction by Octanol: V.G. Mayorov, A.I. NikolaevDocumento7 páginasTantalum (V) and Niobium (V) Extraction by Octanol: V.G. Mayorov, A.I. NikolaevDilip100% (1)

- Hev - Chim.acta.200588523 545. DikonversiDocumento24 páginasHev - Chim.acta.200588523 545. Dikonversiasmaul mashadAinda não há avaliações

- Module BDocumento6 páginasModule BDaniellhy 10Ainda não há avaliações

- Unit Test 2 (Acids Bases and Salts)Documento3 páginasUnit Test 2 (Acids Bases and Salts)Bhatt AcademyAinda não há avaliações

- Troubleshooting Process Plant Control: A Practical Guide to Avoiding and Correcting MistakesNo EverandTroubleshooting Process Plant Control: A Practical Guide to Avoiding and Correcting MistakesNota: 1 de 5 estrelas1/5 (2)

- Guidelines for the Management of Change for Process SafetyNo EverandGuidelines for the Management of Change for Process SafetyAinda não há avaliações

- Process Plant Equipment: Operation, Control, and ReliabilityNo EverandProcess Plant Equipment: Operation, Control, and ReliabilityNota: 5 de 5 estrelas5/5 (1)

- Case Studies of Material Corrosion Prevention for Oil and Gas ValvesNo EverandCase Studies of Material Corrosion Prevention for Oil and Gas ValvesAinda não há avaliações

- Piping Engineering Leadership for Process Plant ProjectsNo EverandPiping Engineering Leadership for Process Plant ProjectsNota: 5 de 5 estrelas5/5 (1)

- Mastering Biochemistry: A Comprehensive Guide to ExcellenceNo EverandMastering Biochemistry: A Comprehensive Guide to ExcellenceAinda não há avaliações

- Sodium Bicarbonate: Nature's Unique First Aid RemedyNo EverandSodium Bicarbonate: Nature's Unique First Aid RemedyNota: 5 de 5 estrelas5/5 (21)

- Well Control for Completions and InterventionsNo EverandWell Control for Completions and InterventionsNota: 4 de 5 estrelas4/5 (10)

- An Applied Guide to Water and Effluent Treatment Plant DesignNo EverandAn Applied Guide to Water and Effluent Treatment Plant DesignNota: 5 de 5 estrelas5/5 (4)

- Troubleshooting Vacuum Systems: Steam Turbine Surface Condensers and Refinery Vacuum TowersNo EverandTroubleshooting Vacuum Systems: Steam Turbine Surface Condensers and Refinery Vacuum TowersNota: 4.5 de 5 estrelas4.5/5 (2)

- Functional Safety from Scratch: A Practical Guide to Process Industry ApplicationsNo EverandFunctional Safety from Scratch: A Practical Guide to Process Industry ApplicationsAinda não há avaliações

- Bow Ties in Risk Management: A Concept Book for Process SafetyNo EverandBow Ties in Risk Management: A Concept Book for Process SafetyAinda não há avaliações

- Guidelines for Chemical Process Quantitative Risk AnalysisNo EverandGuidelines for Chemical Process Quantitative Risk AnalysisNota: 5 de 5 estrelas5/5 (1)

- The HAZOP Leader's Handbook: How to Plan and Conduct Successful HAZOP StudiesNo EverandThe HAZOP Leader's Handbook: How to Plan and Conduct Successful HAZOP StudiesAinda não há avaliações

- Lees' Process Safety Essentials: Hazard Identification, Assessment and ControlNo EverandLees' Process Safety Essentials: Hazard Identification, Assessment and ControlNota: 4 de 5 estrelas4/5 (4)

- An Introduction to the Periodic Table of Elements : Chemistry Textbook Grade 8 | Children's Chemistry BooksNo EverandAn Introduction to the Periodic Table of Elements : Chemistry Textbook Grade 8 | Children's Chemistry BooksNota: 5 de 5 estrelas5/5 (1)

- The Perfumed Pages of History: A Textbook on Fragrance CreationNo EverandThe Perfumed Pages of History: A Textbook on Fragrance CreationNota: 4 de 5 estrelas4/5 (1)

- Pulp and Paper Industry: Emerging Waste Water Treatment TechnologiesNo EverandPulp and Paper Industry: Emerging Waste Water Treatment TechnologiesNota: 5 de 5 estrelas5/5 (1)

- Process Steam Systems: A Practical Guide for Operators, Maintainers, and DesignersNo EverandProcess Steam Systems: A Practical Guide for Operators, Maintainers, and DesignersAinda não há avaliações