Escolar Documentos

Profissional Documentos

Cultura Documentos

P

Enviado por

rajpd28Título original

Direitos autorais

Formatos disponíveis

Compartilhar este documento

Compartilhar ou incorporar documento

Você considera este documento útil?

Este conteúdo é inapropriado?

Denunciar este documentoDireitos autorais:

Formatos disponíveis

P

Enviado por

rajpd28Direitos autorais:

Formatos disponíveis

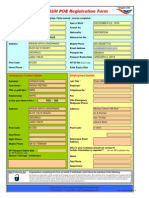

Birla Institute of Technology & Science, Pilani

Distance Learning Programmes Division

First Semester 2008-2009

Comprehensive Examination (EC-2 Regular)

Course No.

Course Title

Nature of Exam

Weightage

Duration

Date of Exam

Note:

1.

2.

3.

4.

5.

: ET ZC432

: QUALITY CONTROL ASSURANCE & RELIABILITY

: Open Book

: 60%

No. of Pages

=2

: 3 Hours

No. of Questions = 7

: 27/09/2008 (FN)

Please follow all the Instructions to Candidates given on the cover page of the answer book.

All parts of a question should be answered consecutively. Each answer should start from a fresh page.

Leave about one inch margin space on all four sides of the answersheet.

Mobile phones and computers of any kind should not be used inside the examination hall.

No need for any graph sheets. All graphs can be drawn roughly in the answer book itself.

Q.1

Sample

Xbar

Automatic machines that fill packages of all-purpose flour to the desired standard weight need to be

closely monitored. A random sample of 4 packages is selected and weighed. The average weight

is then computed. Observations from 15 such samples are shown in the following table.

1

80.2

2

80.0

3

79.6

4

80.3

5

80.1

6

80.4

7

79.5

8

79.4

9

79.7

10

79.5

11

80.3

12

80.5

13

79.8

14

80.4

15

80.2

The desired weight of packages is 80 oz. Historical information on the machine reveals that the

standard deviation of the weights of the individual packages is 0.2 oz. Assume an acceptable Type

I error rate of 0.05. Also assume that it is desired to detect shifts in the process mean of 0.15 oz.

a.

b.

c.

Q.2

Observations are taken from the output of a company making semiconductors. The following table

shows the sample size and the number of non-conforming semiconductors for each sample.

Sample

Inspected items

Non conforming

items

Sample

Inspected items

Non conforming

items

a.

b.

c.

Q.3

Construct and draw a cumulative sum chart and determine whether the machine needs to be

adjusted to meet the target weight.

Determine the parameters of an appropriate V-mask.

Specify the scale factor you use in your cusum plot.

[10]

1

80

2

120

3

60

4

150

5

140

6

150

7

160

8

90

9

100

10

160

11

110

12

100

13

200

14

90

15

160

10

12

14

16

230

17

200

18

150

19

210

20

190

21

160

22

100

23

100

24

90

25

160

12

12

10

Construct and draw a p-chart by setting up the exact control limits for each sample

Are any samples out of control? If so, assuming special causes, revise the centre line and

control limits

Based on the data above, construct a standardized p-chart and discuss your conclusions. [10]

A company named HMIL is investigating two potential vendors on the timeliness of their

deliveries. A random sample of size 10 from the first vendor produced an average delay time of 4.5

days with a standard deviation of 2.3 days. A random sample of size 12 from the second vendor

yielded an average delay time of 3.4 days with a standard deviation of 6.2 days.

a. Find a 90% confidence interval for the ratio of the variances of the delay times for the two

vendors.

b. Find a 95% confidence interval for the differences in the average delay times for the two

vendors.

c. Can we conclude that the first vendor has a smaller variability regarding delay times than the

second? Use a significance level of .05.

[10]

ET ZC432 (EC-2 REGULAR)

Q.4

FIRST SEMESTER 2008-2009

PAGE 2

Consider the assembly of 3 components shown in figure. Tolerances for the three components are

given below:

Gap

Components

Mean Length (in cm)

Tolerances ( in cm)

10

10 +/- 0.5

4 +/- 0.2

5 +/- 0.1

C

A

Assume that the tolerances on the component are independent of each other and that the lengths of

the components are normally distributed.

a. What is the tolerance of the gap?

b. Assuming normality, if specifications of the gap are 0.9 +/- 0.201 cm, what proportion of

assembly will not meet specifications?

c. Suppose the desirable specifications on the gap are 2 +/- 0.02 cm. Assume the mean lengths

of A, B and C to be 11.1, 4.2 and 5.3 cm, respectively. Also assume the natural tolerances to

be +/-0.5, +/-0.2 and +/-0.1 cm for A, B and C, respectively. Find the proportion of

assemblies that will not be acceptable.

[10]

Q.5

A double sampling plan is given as follows: N = 1200, n1 = 50, c1 = 1, r1 = 4, n2 = 110, c2 = 5, r2 =

7. Find the probability of accepting a lot that are 4 % nonconforming? What is the probability of

rejecting a lot on first sample? Use Poissons distribution.

[8]

Q.6

Consider the seven component system shown in the figure. Reliability of components are RA =

0.96, RB = 0.92, RC = 0.94, RD = 0.89, RE = 0.95, RF = 0.88, RG = 0.90.

E

C

D

G

B

a.

b.

Q.7

Find the reliability of the system.

Assuming time to failure for each component has exponential distribution, the failure rate

for each components are A = 0.0005 / hr, B = 0.0005 / hr, C = 0.0003 / hr, D = 0.0008 /

hr, E = 0.0004 / hr, F = 0.006 / hr, G = 0.0064 / hr. Find the reliability of the system

after 1000 hours? What is the mean time to failure of the system?

[8]

Compare and contrast the quality philosophies proposed by Deming, Crosby and Juran. Present

your answer in a tabular format.

[4]

*******

Você também pode gostar

- Stub Axle Design Stub Axle Design Stub Axle Design Stub Axle DesignDocumento1 páginaStub Axle Design Stub Axle Design Stub Axle Design Stub Axle DesignNano NanoAinda não há avaliações

- T.MSD309.8B: Service ManualDocumento16 páginasT.MSD309.8B: Service ManualmirelaAinda não há avaliações

- Biostat To AnswerDocumento3 páginasBiostat To AnswerSamantha ArdaAinda não há avaliações

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeNo EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeNota: 4 de 5 estrelas4/5 (5794)

- Khalifa and Shen, 2005Documento10 páginasKhalifa and Shen, 2005Ali MehmoodAinda não há avaliações

- Appendix GDocumento3 páginasAppendix GYardie TreyBwoy100% (1)

- 06 08 2017 G2a GTDocumento2 páginas06 08 2017 G2a GTNagarajan RajaAinda não há avaliações

- IKEA SB Upholstery 2010 United Kingdom - EnglishDocumento31 páginasIKEA SB Upholstery 2010 United Kingdom - EnglishSam RoldanAinda não há avaliações

- Programming Assignment 2 Udp Pinger VerDocumento7 páginasProgramming Assignment 2 Udp Pinger Verapi-479141525Ainda não há avaliações

- Investigation On Solar Air Dryer by Using Forced Convection With Thermal Storage SystemDocumento8 páginasInvestigation On Solar Air Dryer by Using Forced Convection With Thermal Storage SystemResearch Publish JournalsAinda não há avaliações

- Prioritising Road Safety Commercial Vehicles - GRSPDocumento14 páginasPrioritising Road Safety Commercial Vehicles - GRSPAntalAinda não há avaliações

- 5 6179095781476139217Documento240 páginas5 6179095781476139217Ãã Kā ShAinda não há avaliações

- CUHK Midterm Exam 1st Term 2014-2015 for ACCT 2111 Intro Fin AccountingDocumento11 páginasCUHK Midterm Exam 1st Term 2014-2015 for ACCT 2111 Intro Fin AccountingDonald YumAinda não há avaliações

- Semester Project: COMSATS University Islamabad, Virtual Campus HUM102 Report Writing Skills Assignment # 03 Spring 2020Documento4 páginasSemester Project: COMSATS University Islamabad, Virtual Campus HUM102 Report Writing Skills Assignment # 03 Spring 2020UzairAinda não há avaliações

- i) ii) iii) (Scale) : (SIZE) (Colour) 非1:1Documento19 páginasi) ii) iii) (Scale) : (SIZE) (Colour) 非1:1Filipe ConceiçãoAinda não há avaliações

- IZEVA 2020 Assembly SummaryDocumento15 páginasIZEVA 2020 Assembly SummaryThe International Council on Clean TransportationAinda não há avaliações

- Vantage Syst Form1Documento7 páginasVantage Syst Form1GunawanArpulAinda não há avaliações

- II Cellular4Documento23 páginasII Cellular4Muhammad AfzalAinda não há avaliações

- EE314 Lab 1 FinalDocumento19 páginasEE314 Lab 1 FinalCarlos BabuAinda não há avaliações

- Group 5 BNM & AmlaDocumento32 páginasGroup 5 BNM & AmlaSitiSarahAinda não há avaliações

- OCR Physics A Exam Style QuestionsDocumento2 páginasOCR Physics A Exam Style QuestionsZaman Ali RajaAinda não há avaliações

- FVM SANDWICH BEAMDocumento39 páginasFVM SANDWICH BEAMLaksh ManAinda não há avaliações

- Voltas & Wipro WordDocumento11 páginasVoltas & Wipro WordFaheem YakubAinda não há avaliações

- IELTS Practice Listening Test 2 - Part 3 - Take IELTSDocumento3 páginasIELTS Practice Listening Test 2 - Part 3 - Take IELTSTresor KAOUNODJI KOLADOUMAinda não há avaliações

- Effect Design On Store ImageDocumento13 páginasEffect Design On Store Imagebermand75Ainda não há avaliações

- Instruction Vertyanov JIG Ver3Documento26 páginasInstruction Vertyanov JIG Ver3guvenelktAinda não há avaliações

- OS Electromechanical L4Documento79 páginasOS Electromechanical L4Jeji HirboraAinda não há avaliações

- Institute and Faculty of Actuaries: Subject CT5 - Contingencies Core TechnicalDocumento19 páginasInstitute and Faculty of Actuaries: Subject CT5 - Contingencies Core TechnicalNayaz NMAinda não há avaliações

- 2nd Revision List INDEX Numbers PDFDocumento419 páginas2nd Revision List INDEX Numbers PDFBenard kipchirchirAinda não há avaliações

- Automated Vehicular Identification and Authentication SystemDocumento4 páginasAutomated Vehicular Identification and Authentication SystemInternational Journal of Innovations in Engineering and Technology (IJIET)Ainda não há avaliações

- Software Test Design SpecificationDocumento17 páginasSoftware Test Design SpecificationIoana Augusta PopAinda não há avaliações

- Linfit ForDocumento5 páginasLinfit ForkgrhoadsAinda não há avaliações

- Types of Car Body DamageDocumento2 páginasTypes of Car Body DamagecarbodyrepairsderbyAinda não há avaliações

- Hybrid TopologyDocumento6 páginasHybrid TopologyBuntyAinda não há avaliações

- Employee Pension Scheme Form 10 C PDFDocumento1 páginaEmployee Pension Scheme Form 10 C PDFSuraj BaugAinda não há avaliações

- Student True/False Bond QuizDocumento55 páginasStudent True/False Bond QuizDan DavisAinda não há avaliações

- Cisco 2 Chapter 11 Study GuideDocumento7 páginasCisco 2 Chapter 11 Study GuideGreg MillerAinda não há avaliações

- Installation Manual VS111 Series: Plug-In Amplifier For Proportional ValvesDocumento7 páginasInstallation Manual VS111 Series: Plug-In Amplifier For Proportional Valvesmehdi810Ainda não há avaliações

- Invigilator InstructionDocumento4 páginasInvigilator InstructionbhupenderAinda não há avaliações

- College Student Affairs Committee-ToRDocumento2 páginasCollege Student Affairs Committee-ToRpremnathgopinathanAinda não há avaliações

- Materials Control 12.96 installation manual, 2011 guideDocumento24 páginasMaterials Control 12.96 installation manual, 2011 guideRanko LazeskiAinda não há avaliações

- Asia Pacific University of Technology and Innovation (APU) Page 1 of 3Documento3 páginasAsia Pacific University of Technology and Innovation (APU) Page 1 of 3Kapil Pokhrel50% (2)

- Material Safety Data SheetDocumento14 páginasMaterial Safety Data SheetmelovebeingmeAinda não há avaliações

- Cherie Cosmetics LTDDocumento20 páginasCherie Cosmetics LTDRichell Argones0% (1)

- Click Here and Open in Telegram To Join @truelyengineers For More Answer KeysDocumento10 páginasClick Here and Open in Telegram To Join @truelyengineers For More Answer KeysSankar DeyAinda não há avaliações

- Flavor Potentiators Maga 1983Documento83 páginasFlavor Potentiators Maga 1983FAS AAMU100% (1)

- Pms 5003Documento3 páginasPms 5003LBAinda não há avaliações

- Optimize DC Bias CircuitsDocumento18 páginasOptimize DC Bias CircuitsJawad Ul Hassan Shah100% (1)

- QPJC Registration Form Jan2023Documento2 páginasQPJC Registration Form Jan2023api-271247346Ainda não há avaliações

- Aiza D PharmacyDocumento1 páginaAiza D Pharmacymalik awanAinda não há avaliações

- End Term Examination Sample Paper (PEA305Documento9 páginasEnd Term Examination Sample Paper (PEA305sunnyAinda não há avaliações

- CMPF134 Fundamentals of Data and Information Tutorial 1 Number SystemsDocumento4 páginasCMPF134 Fundamentals of Data and Information Tutorial 1 Number SystemsKei0% (3)

- The Selection of Hyaluronic Acid When Treating With The Nasolabial Fold A Meta-Analysis - Peng, 2021Documento9 páginasThe Selection of Hyaluronic Acid When Treating With The Nasolabial Fold A Meta-Analysis - Peng, 2021Rafael Autran Cavalcante AraújoAinda não há avaliações

- Assign # 1-SPCDocumento9 páginasAssign # 1-SPCNour LyAinda não há avaliações

- 11Documento1 página11chetanursAinda não há avaliações

- Midterm Exam II (20%) : Winter 2007 Date: Monday 2 April Instructor: Dr. Nizar Bouguila Time: 14:45-16:45Documento13 páginasMidterm Exam II (20%) : Winter 2007 Date: Monday 2 April Instructor: Dr. Nizar Bouguila Time: 14:45-16:45sanjay_cssAinda não há avaliações

- IE 423 - HMW 1Documento6 páginasIE 423 - HMW 1Yasemin YücebilgenAinda não há avaliações

- PDocumento2 páginasPrajpd28Ainda não há avaliações

- PDocumento2 páginasPrajpd28Ainda não há avaliações

- Acceptance Sampling Plans and Quality Control ChartsDocumento3 páginasAcceptance Sampling Plans and Quality Control ChartsHassanAinda não há avaliações

- QDocumento49 páginasQrajpd28Ainda não há avaliações

- Is 10398Documento16 páginasIs 10398rajpd28Ainda não há avaliações

- Bitszc423t - Course Handout FileDocumento15 páginasBitszc423t - Course Handout Filerajpd28Ainda não há avaliações

- CDocumento4 páginasCrajpd28Ainda não há avaliações

- Disclosure To Promote The Right To InformationDocumento20 páginasDisclosure To Promote The Right To Informationrajpd28Ainda não há avaliações

- Is 12556Documento6 páginasIs 12556rajpd28Ainda não há avaliações

- Disclosure To Promote The Right To InformationDocumento16 páginasDisclosure To Promote The Right To Informationrajpd28Ainda não há avaliações

- Quality Control Assurance and Reliability (ETZC 432) : BITS PilaniDocumento42 páginasQuality Control Assurance and Reliability (ETZC 432) : BITS Pilanirajpd28Ainda não há avaliações

- Is 13673 4 1998 PDFDocumento17 páginasIs 13673 4 1998 PDFrajpd28Ainda não há avaliações

- Disclosure To Promote The Right To InformationDocumento13 páginasDisclosure To Promote The Right To Informationrajpd28Ainda não há avaliações

- Is 13122 2 1991Documento10 páginasIs 13122 2 1991rajpd28Ainda não há avaliações

- Is 10398Documento16 páginasIs 10398rajpd28Ainda não há avaliações

- Disclosure To Promote The Right To InformationDocumento13 páginasDisclosure To Promote The Right To Informationrajpd28Ainda não há avaliações

- Is 13122 1 1993Documento22 páginasIs 13122 1 1993rajpd28Ainda não há avaliações

- Is 12554 1 1988Documento10 páginasIs 12554 1 1988rajpd28Ainda não há avaliações

- Disclosure To Promote The Right To InformationDocumento9 páginasDisclosure To Promote The Right To Informationrajpd28Ainda não há avaliações

- Disclosure To Promote The Right To InformationDocumento22 páginasDisclosure To Promote The Right To Informationrajpd28Ainda não há avaliações

- Disclosure To Promote The Right To InformationDocumento32 páginasDisclosure To Promote The Right To Informationrajpd28Ainda não há avaliações

- Is 9334 1986Documento20 páginasIs 9334 1986rajpd28Ainda não há avaliações

- Disclosure To Promote The Right To InformationDocumento26 páginasDisclosure To Promote The Right To Informationrajpd28Ainda não há avaliações

- Disclosure To Promote The Right To InformationDocumento20 páginasDisclosure To Promote The Right To Informationrajpd28Ainda não há avaliações

- Disclosure To Promote The Right To InformationDocumento20 páginasDisclosure To Promote The Right To Informationrajpd28Ainda não há avaliações

- Disclosure To Promote The Right To InformationDocumento22 páginasDisclosure To Promote The Right To Informationrajpd28Ainda não há avaliações

- Disclosure To Promote The Right To InformationDocumento26 páginasDisclosure To Promote The Right To Informationrajpd28Ainda não há avaliações

- Disclosure To Promote The Right To InformationDocumento24 páginasDisclosure To Promote The Right To Informationrajpd28Ainda não há avaliações

- Is 9334 1986Documento20 páginasIs 9334 1986rajpd28Ainda não há avaliações

- Is 9334 1986Documento20 páginasIs 9334 1986rajpd28Ainda não há avaliações

- Disclosure To Promote The Right To InformationDocumento15 páginasDisclosure To Promote The Right To Informationrajpd28Ainda não há avaliações

- Disclosure To Promote The Right To InformationDocumento24 páginasDisclosure To Promote The Right To Informationrajpd28Ainda não há avaliações

- Is 8824Documento9 páginasIs 8824rajpd28Ainda não há avaliações