Escolar Documentos

Profissional Documentos

Cultura Documentos

WPS Translarail

Enviado por

wpsssamsungDireitos autorais

Formatos disponíveis

Compartilhar este documento

Compartilhar ou incorporar documento

Você considera este documento útil?

Este conteúdo é inapropriado?

Denunciar este documentoDireitos autorais:

Formatos disponíveis

WPS Translarail

Enviado por

wpsssamsungDireitos autorais:

Formatos disponíveis

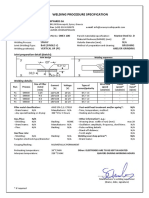

Socit J.

SAURON

S.A.

DMS Description de la Mthode de Soudage

WPS Welding Procedure Specification

19, rue Pierre JOSSE ZI- Les Bordes

C.E. 24131 91924 BONDOUFLE Cedex

Tel. : + 33 1 69 91 48 00

Fax : + 33 1 69 91 48 19

contact@sauron.com

TRANSLARAIL

Records

Location :

Bondoufle

JS-05-01-A

DMS / WPS No. :

Examined by :

J. L. MATHIEU

Date :

03/04/2006

Written by :

P. GUYET

Date :

28/07/2006

Applications

Refilling and repairing of the tread of railroad rails

Procedures

Welding process :

114 (filler wire)

Depositing procedure :

TRANSLAMATIC

Preparation details :

03JS014C Chap. : 4

Preparatory procedure :

Grinding

Max. preparation depth :

15 (mm)

Cleaning procedure :

Grinding

Welding position :

PA

Base material diameter (mm) :

Not applicable.

Reference standard :

NF EN 288-2

Date :

1992/1997

Base metal

Base material specification :

Rail STEEL 50 E6 / 60 E1

Grade :

200 / 260

Refilling type :

Solid bar

Inspection :

Sweating

Preparation drawing

Layout of the layers

L5P

Ground

area

20 mm

Slope

20 mm

Scraped

area

1st layer refilling

Ground

area

Slope

Deposit area

nd

layer refilling

Filler metal

Designation :

TRANSLARAIL

Reference :

TAC2000 8008

Classification :

DIN 8555 : MF1-GF-300

Drying or special drying :

Not applicable

Presentation :

Filler wire

Filler metal diameter :

1.6 mm

Protection gas :

Without

Packaging :

DIN8559 (K300)

Analysis report :

No. 43616

Reference organization : Institut de Soudure (Welding Institute)

06 JS 009

1/2

01/05/2006

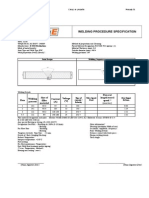

Socit J.SAURON

S.A.

DMS Description de la Mthode de Soudage

WPS Welding Procedure Specification

19, rue Pierre JOSSE ZI- Les Bordes

C.E. 24131 91924 BONDOUFLE Cedex

Tel. : + 33 1 69 91 48 00

Fax : + 33 1 69 91 48 19

contact@sauron.com

Filler metal (continued)

Applications

Selection criteria

Average

Good

Very Good

Shock

*********************************

Abrasion

*******************

Excellent

Behavior to heat *****

TRANSLARAIL

Filler metal analysis

MECHANICAL

Hardness

Typical Values

320

HV

(outside

dilution)

Typical Values

0.11

0.3

1.4

1.5

0.4

2.8

0.5

0.002

0.005

CHEMICAL

Conditions

Rough welding

%

C

Cr

Al

Mn

Si

Ni

Mo

S

P

EN 10 204-3.1B

EN 1597-1

Welding

Preheating type :

Side of refilling

Preheating procedure :

500 mm ramp

Preheating gas :

Propane C3 H8

Preheating temperature :

350C

Welding current type :

D.C.

Characteristic type :

C.V.

Polarity :

Positive (+)

Stick Out :

30 mm

Translation speed :

30 cm / min

Deposit mode :

Straight / continuous

Angle position :

90

Deposit direction :

Front / rear

Welding current :

160 / 170 A

Welding voltage :

25 / 26 v

Welding parameters

Layer

no.

Process

Filler metal

dimension

Current

A

Voltage

V

Slag cleaning

Wire feed

advance speed

Temperature at

end of layer

114

1.6 mm

170 A 10

26 V 1

End of layer

5,2 / 5,7 m /min

450C/500C

114

1.6 mm

170 A 10

26 V 1

End of layer

5,2 / 5,7 m /min

450C/500C

Comments :

Signature

06 JS 009

2/2

01/05/2006

Você também pode gostar

- Chem Consulting: Specification SheetDocumento1 páginaChem Consulting: Specification SheetYaqoob AliAinda não há avaliações

- PQR-WPS-WPQR XXX Rev 0Documento6 páginasPQR-WPS-WPQR XXX Rev 0Brett Gosselin100% (1)

- Cajon-001 WPSDocumento2 páginasCajon-001 WPSDanem HalasAinda não há avaliações

- Ami-003 WPSDocumento2 páginasAmi-003 WPSBenjamin BrownAinda não há avaliações

- WPS - 006Documento13 páginasWPS - 006MAT-LIONAinda não há avaliações

- Cape WPSDocumento1 páginaCape WPSKeneth Del CarmenAinda não há avaliações

- WPS - D1.1Documento1 páginaWPS - D1.1Nam_HitechAinda não há avaliações

- Onex-Wps-100 - Single V - 27-Smaw-Vertical UpDocumento1 páginaOnex-Wps-100 - Single V - 27-Smaw-Vertical Upteopan PanAinda não há avaliações

- WPS - 008Documento11 páginasWPS - 008MAT-LIONAinda não há avaliações

- p22MNVMB MN Gtaw+Smaw (Pipe)Documento2 páginasp22MNVMB MN Gtaw+Smaw (Pipe)abidaliabid1Ainda não há avaliações

- WPS - Welding Instruction - FUCHSDocumento23 páginasWPS - Welding Instruction - FUCHSShanoor AS100% (1)

- Company Name Key Information Questions Answers File Reference Test Conducted On Reviews & ApprovalsDocumento11 páginasCompany Name Key Information Questions Answers File Reference Test Conducted On Reviews & ApprovalsMAT-LIONAinda não há avaliações

- Ami-001 WPSDocumento2 páginasAmi-001 WPSPramod Athiyarathu100% (1)

- Wps Vosl-Pl-1 Pipeline Rev.2 XDocumento11 páginasWps Vosl-Pl-1 Pipeline Rev.2 XVijo Jose100% (1)

- Product CertificateDocumento1 páginaProduct CertificateMURSHID MUHAMMEDAinda não há avaliações

- Preliminary Welding Procedure Specification: Code: EN ISO 15609-1Documento2 páginasPreliminary Welding Procedure Specification: Code: EN ISO 15609-1wentropremAinda não há avaliações

- Welding Procedure Specification-1Documento8 páginasWelding Procedure Specification-1Suresh Rathod100% (1)

- Geecy Industrial Services Pvt. LTDDocumento4 páginasGeecy Industrial Services Pvt. LTDbirthinonceAinda não há avaliações

- Fabshield Offshore 71ni-1Documento2 páginasFabshield Offshore 71ni-1Anonymous ejnktktkY7Ainda não há avaliações

- Fab-Wps-002sfasf Asfh Fhjsafgjha Sfsa FSDocumento2 páginasFab-Wps-002sfasf Asfh Fhjsafgjha Sfsa FSabidaliabid1100% (1)

- WPS - 015Documento11 páginasWPS - 015MAT-LIONAinda não há avaliações

- 304HCu 310NDocumento40 páginas304HCu 310NmalsttarAinda não há avaliações

- WPS Batch 1Documento12 páginasWPS Batch 1sutrimoAinda não há avaliações

- Page 2 of 6: Test Certificate No. 0000052877Documento1 páginaPage 2 of 6: Test Certificate No. 0000052877pranesh kadam100% (2)

- Wps ExampleDocumento2 páginasWps ExampleAnonymous stV08Js44VAinda não há avaliações

- Angle Bar 130x130x9mm Mill CertificateDocumento1 páginaAngle Bar 130x130x9mm Mill Certificatepstechnical_43312697100% (2)

- 355 Jr+Ar: Weldi NG Procedure Data SheetDocumento2 páginas355 Jr+Ar: Weldi NG Procedure Data SheetKawser HossainAinda não há avaliações

- Chromecore-430-G Er430Documento1 páginaChromecore-430-G Er430peymanAinda não há avaliações

- MCX Connector SeriesDocumento15 páginasMCX Connector SeriesCmpterRFAinda não há avaliações

- WPS 0250Documento1 páginaWPS 0250igorspirkoskiAinda não há avaliações

- WPS FormatDocumento1 páginaWPS FormatAbdullah AnsariAinda não há avaliações

- Welding Procedure B69AWDocumento2 páginasWelding Procedure B69AWMastram HatheshAinda não há avaliações

- Welding Presentation by NoreastDocumento78 páginasWelding Presentation by Noreastravi00098Ainda não há avaliações

- WpsDocumento2 páginasWpsnaseema1100% (1)

- WPS Sitelca S002Documento2 páginasWPS Sitelca S002Jose Antonio GomezAinda não há avaliações

- SK Tool Alloy C-S (Up 23-Gf-200-Ckz)Documento1 páginaSK Tool Alloy C-S (Up 23-Gf-200-Ckz)brunizzaAinda não há avaliações

- A1X3R1 - 2d - EPI-08-WP5-TW PDFDocumento10 páginasA1X3R1 - 2d - EPI-08-WP5-TW PDFJose Anisio SilvaAinda não há avaliações

- Indrani Technocrafts: Metallurgical Test CertificateDocumento1 páginaIndrani Technocrafts: Metallurgical Test CertificateAditya ChouguleAinda não há avaliações

- WPS - 014Documento11 páginasWPS - 014MAT-LIONAinda não há avaliações

- Selected Welding Application in Offshore IndustryDocumento38 páginasSelected Welding Application in Offshore IndustryzuudeeAinda não há avaliações

- WPS-6 Doc Rev00 On 17 Sept 2018 Final FormatDocumento3 páginasWPS-6 Doc Rev00 On 17 Sept 2018 Final FormatSWARUP CHUGUGLEAinda não há avaliações

- Stani Memorial College of Engg. & Technology, Jaipur Session PlanDocumento2 páginasStani Memorial College of Engg. & Technology, Jaipur Session PlanYudhisthar SainiAinda não há avaliações

- Welding ManualDocumento9 páginasWelding Manualkawsar98Ainda não há avaliações

- Wps - 09 Mt-Imecol Asme304 Gtaw Sheet-Tubesheet Rev 0Documento5 páginasWps - 09 Mt-Imecol Asme304 Gtaw Sheet-Tubesheet Rev 0Oscar Iván Duque DíazAinda não há avaliações

- PQR Gmaw3gDocumento4 páginasPQR Gmaw3gdevendrasingh2021100% (3)

- WPS - 019Documento11 páginasWPS - 019MAT-LIONAinda não há avaliações

- 375 - 50WT Cat 3Documento2 páginas375 - 50WT Cat 3ATF PrécisionAinda não há avaliações

- Spherical BearingsDocumento3 páginasSpherical BearingsGMT Rubber-Metal-TechnicAinda não há avaliações

- Welding Procedure Specification SampleDocumento5 páginasWelding Procedure Specification SampleAdiAinda não há avaliações

- Product Range DN 32+: Standard or CustomizedDocumento2 páginasProduct Range DN 32+: Standard or CustomizedViale ElvioAinda não há avaliações

- 2005-05 - WPS & PQR C5Documento6 páginas2005-05 - WPS & PQR C5misthahAinda não há avaliações

- Metrode Cryogenic 308lcf B-37Documento5 páginasMetrode Cryogenic 308lcf B-37Claudia MmsAinda não há avaliações

- 6 MM TCDocumento1 página6 MM TCpranesh kadamAinda não há avaliações

- List 1 Approved Steelmakers and Manufacturers of Rolled Steel Plates, Strip, Sections & BarsDocumento75 páginasList 1 Approved Steelmakers and Manufacturers of Rolled Steel Plates, Strip, Sections & Barswyvren88Ainda não há avaliações

- Is For Ms Pipe Fe 330Documento5 páginasIs For Ms Pipe Fe 330cieindoreAinda não há avaliações

- Brittle Fracture in Steel StructuresNo EverandBrittle Fracture in Steel StructuresG.M. BoydAinda não há avaliações

- How to prepare Welding Procedures for Oil & Gas PipelinesNo EverandHow to prepare Welding Procedures for Oil & Gas PipelinesNota: 5 de 5 estrelas5/5 (1)

- Spot Welding Interview Success: An Introduction to Spot WeldingNo EverandSpot Welding Interview Success: An Introduction to Spot WeldingAinda não há avaliações

- Method Statement: Long Carbon EuropeDocumento4 páginasMethod Statement: Long Carbon EuropewpsssamsungAinda não há avaliações

- Repair of Rails On Site by Welding XA00127720Documento20 páginasRepair of Rails On Site by Welding XA00127720wpsssamsungAinda não há avaliações

- EN 1090 White Paper17 119019 PDFDocumento24 páginasEN 1090 White Paper17 119019 PDFZaza PokumbaAinda não há avaliações

- 24UTP Railway GBDocumento8 páginas24UTP Railway GBwpsssamsungAinda não há avaliações

- CastingDocumento48 páginasCastingwpsssamsungAinda não há avaliações

- Sets of Rule For Fuzzy Logic Control of Washing MachineDocumento1 páginaSets of Rule For Fuzzy Logic Control of Washing MachineKHAIRUNISAAinda não há avaliações

- Introduction To PythonDocumento0 páginaIntroduction To PythonLokesh BhatiaAinda não há avaliações

- Fabric Conveyor Belts Installation and Maintenance Guide: Habasit - Solutions in MotionDocumento16 páginasFabric Conveyor Belts Installation and Maintenance Guide: Habasit - Solutions in MotionAbdul Kani Ahamed MAinda não há avaliações

- Orbinox Ex PDFDocumento2 páginasOrbinox Ex PDFRio PurnamaAinda não há avaliações

- Urban Transport Guidelines - Geometric Design of Urban Colloctor RoadsDocumento26 páginasUrban Transport Guidelines - Geometric Design of Urban Colloctor RoadsCharl de Reuck100% (1)

- 142 Manual Final Fall 2003 Body OnlyDocumento118 páginas142 Manual Final Fall 2003 Body Onlyjlehman100% (1)

- Brushless ExcitationDocumento4 páginasBrushless Excitationmsovais6792100% (2)

- Calculations of Elastic Moduli of Polymer Crystals." II. TeryleneDocumento11 páginasCalculations of Elastic Moduli of Polymer Crystals." II. Teryleneapi-3733260Ainda não há avaliações

- MA WAFLInternals V2.0Documento20 páginasMA WAFLInternals V2.0Vimal PalanisamyAinda não há avaliações

- ML3 USB Adapter 76-50214-02 Instructions: Container RefrigerationDocumento24 páginasML3 USB Adapter 76-50214-02 Instructions: Container RefrigerationHussain ShahAinda não há avaliações

- Soalan Fizik Chapter 9Documento10 páginasSoalan Fizik Chapter 9Yusfalina Mohd YusoffAinda não há avaliações

- Argo-hyto-High Pressure Filter Kits 40.95 EN US PDFDocumento10 páginasArgo-hyto-High Pressure Filter Kits 40.95 EN US PDFhydrola 2021Ainda não há avaliações

- Namuli Maxine Tamale Research Proposal 2Documento38 páginasNamuli Maxine Tamale Research Proposal 2mpairwe cliffortAinda não há avaliações

- Sample Soil Report 1Documento27 páginasSample Soil Report 1prince francisAinda não há avaliações

- You're Reading An Excerpt. Click Here To Read Official FURUNO MD-550 User GuideDocumento3 páginasYou're Reading An Excerpt. Click Here To Read Official FURUNO MD-550 User GuideSugeng HariadiAinda não há avaliações

- Montague Gold MineDocumento6 páginasMontague Gold MineChrispen MachipisaAinda não há avaliações

- IEEE PES - Tutorial Course On Power System Stabilization Via Excitation ControlDocumento74 páginasIEEE PES - Tutorial Course On Power System Stabilization Via Excitation Controlsulemankhalid100% (2)

- Steinmetz CP - On The Law of Hysteresis Part 3Documento47 páginasSteinmetz CP - On The Law of Hysteresis Part 3Rahul GaurAinda não há avaliações

- Insulated Gate Bipolar Transistor With Ultrafast Soft Recovery DiodeDocumento16 páginasInsulated Gate Bipolar Transistor With Ultrafast Soft Recovery DiodeLucía MitchellAinda não há avaliações

- SAP SRM TutorialDocumento33 páginasSAP SRM TutorialNawed AnjumAinda não há avaliações

- Classification of MissileDocumento4 páginasClassification of MissileMoaz Hussain100% (1)

- Change Sequence's Current Value (CURRVAL) Without Dropping It OraExplorerDocumento6 páginasChange Sequence's Current Value (CURRVAL) Without Dropping It OraExplorerIan HughesAinda não há avaliações

- Rod Lock CylindersDocumento7 páginasRod Lock CylindersmaciasrobAinda não há avaliações

- THHN TC FuerzaDocumento2 páginasTHHN TC Fuerzajuan pablo castro gallegoAinda não há avaliações

- CKD Sab SVB Catalogue en Cc770a PDFDocumento58 páginasCKD Sab SVB Catalogue en Cc770a PDFvanAinda não há avaliações

- Pavan Tools Catalog 2012Documento76 páginasPavan Tools Catalog 2012Pavan ToolsAinda não há avaliações

- General CatalogueDocumento19 páginasGeneral Cataloguedbristow21Ainda não há avaliações

- Fluke T3 Voltage and Continuity TesterDocumento2 páginasFluke T3 Voltage and Continuity Testerkoko MeAinda não há avaliações

- 90 XLBrochureDocumento2 páginas90 XLBrochureraynelyAinda não há avaliações

- Vacuum Dewatering FlooringDocumento4 páginasVacuum Dewatering FlooringArunava Das100% (1)