Escolar Documentos

Profissional Documentos

Cultura Documentos

Common Rail Fuel System - Odp

Enviado por

Silas F Pimenta93%(14)93% acharam este documento útil (14 votos)

2K visualizações61 páginasTítulo original

Common Rail Fuel System.odp

Direitos autorais

© © All Rights Reserved

Formatos disponíveis

ODP, PDF ou leia online no Scribd

Compartilhar este documento

Compartilhar ou incorporar documento

Você considera este documento útil?

Este conteúdo é inapropriado?

Denunciar este documentoDireitos autorais:

© All Rights Reserved

Formatos disponíveis

Baixe no formato ODP, PDF ou leia online no Scribd

93%(14)93% acharam este documento útil (14 votos)

2K visualizações61 páginasCommon Rail Fuel System - Odp

Enviado por

Silas F PimentaDireitos autorais:

© All Rights Reserved

Formatos disponíveis

Baixe no formato ODP, PDF ou leia online no Scribd

Você está na página 1de 61

Welcome

to a technical overview of

Common Rail

Diesel Fuel Systems

presented by

Tony Kitchen

(AK Training)

Foreword

Tony Kitchen (AK Training) offers professional technical courses for those working in the motor industry

wanting to improve their knowledge and skills and who are serious about personal development. Courses

are based upon 25 years practical experience and extensive hands on technical knowledge of subject

matter (not possible to obtain from reading a book or watching a CD)!

A comprehensive programme of courses is available from AK Training. Courses run from regular venues in

the Milton Keynes, Northampton and Buckingham area. Courses can also be delivered on site at clients

premises anywhere in the UK. Overseas training services are also available. This presentation forms the

basis for a generic common rail diesel course which is now undergoing development and will be available

in the near future

For further information about courses, course dates, fees, venues and all other enquiries including on site

and overseas training, please contact AK Training direct. In the meantime, please enjoy the following

presentation for your technical information.

AK Training

Telephone: 01908 579309 Mobile: 07988 842274

E-mail: info@akautomotivetraining.co.uk www.akautomotivetraining.co.uk

IMI Awards Approved Assessment Centre IRTEC Approved Awards Assessment Centre

Motor industry Professional Training

and Development

Common Rail Diesel Fuel Systems

Aims, objectives and disclaimer:

The aim of this presentation is to give a generic technical overview of the main features and

operating principles of the common rail diesel fuel injection system. The objectives are that

by the end of this presentation, you will have gained a working knowledge and

understanding of the fundamental principles of common rail diesel fuel systems.

Please bear in mind that all facts and figures quoted are intended to show typical examples

only for expianation purposes. Always refer to manufacturer technical data for exact system

specifications and repair procedures.

Finally this slide show does not include speaker notes. If you have any comments or would

like further information, please contact AK Training directly

Common Rail Diesel Fuel Systems

Advantages of common rail:

+ Fuel pressure available on demand.....

+ Higher injection pressures and finer atomization of fuel.

+ Injection pressure created independent of engine speed

+ Multiple injections per cylinder combustion are possible.

Benefits of common rail:

+ Reduction of overall exhaust emissions.

+ Reduction of particulate emissions.

+ Reduction of noise emissions.

+ Improved fuel efficiency.

+ Higher performance.

Common Rail Diesel Fuel Systems

Examples of typical common rail system maximum fuel pressures:

+ Bosch: Generation 1: up to 1350 Bar (19845 psi). Unijet

Generation 2: up to 1600 Bar (23520 psi) EDC 16

Generation 3: up to 2000 Bar + (29400 psi)

+ Denso: 1st generation: up to 1450 Bar (21315 psi) ECD-U2P

24 generation: 1800 Bar + (26460 psi) HP3/HP4

+ Delphi Multec: up to 2000 Bar

Direct acting diesel common rail system: up to 2000 Bar

Various systems differ in design, components layout and specific

functions. However, all operate in a similar way.

Denso

ECD-u2P

Common Rail Diesel Fuel Systems

The fuel system can be divided into three basic circuits

High Hin

otupreagure:tollvery + Low pressure supply circuit

+ High pressure delivery circuit

+ Fuel leak back and return

Fuel leak back and return |

Example: Bosch EDC16

Common Rail Diesel Fuel Systems

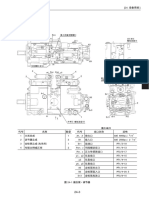

Components overview (example: Bosch EDC 16)

Fuel metering control valve

High pressure Fuel rail pressure control valve

fuel pump —__, 5

Fuel rail pressure sensor

Fuel filter

Electric fuel

pump

=== Low pressure

=== High pressure Injectors

=== Leak back/return

Common Rail Diesel Fuel Systems

High pressure fuel pump

The High pressure pump is the interface between the low pressure

and the high pressure side of the fuel system.

} = }

Bosch CP3 Bosch CP1 Denso HP4

Denso HP3

Basic function:

To ensure that enough fuel is delivered at sufficient pressure across

the engine's entire operating range. This includes delivery of sufficient

fuel for a rapid engine start and pressure increase in the rail.

Common Rail Diesel Fuel Systems

High pressure fuel pump

Fuel return Fuel metering control

Fuel supply inlet i (solenoid)

Example: High pressure

Bosch CP3 i ' FA tuel outiet

Gear type transfer

Pump shaft with pup

eccentric cam

_ Pressure valve

Polygon ring

Suction valve

The pump has several pumping chambers

Common Rail Diesel Fuel Systems

High pressure fuel pump

Pumping _—7

chamber

Fuel metering valve

4: Pressure valve

2: Suction valve

3: Low pressure (yellow)

4: High pressure (red)

Common Rail Diesel Fuel Systems

High pressure fuel pump

Fuel i i

‘uel metering valve Transfer pump

Transfer pump supplies fuel from the fuel tank to the

pumping chambers of the high pressure pump.

Fuel metering valve regulates the fuel intake volume

to the pumping chambers of the high pressure pump.

Common Rail Diesel Fuel Systems

High pressure fuel pump

Pump shaft Polygon ring

Pumping piston

3 pumping pistons are operated by a polygon

ring on an eccentric cam on the pump shaft.

Common Rail Diesel Fuel Systems

High pressure fuel pump

Pump shaft Polygon ring

Pumping piston

As the pump rotates, the polygon ring moves in

a circular motion to operate the pump pistons.

Common Rail Diesel Fuel Systems

Transfer pump

Fuel inlet port

4

Fuel outlet port 4

uerormer pot Trochoidal type (Denso HP3)

Gear type (Bosch cP3)

An electric pre supply pump in fuel tank may be used

instead of a transfer pump. Some systems may use a

combination of electric pump and transfer pump.

Common Rail Diesel Fuel Systems

Fuel metering control valve

Example:

Bosch CP3

+ Located at back of high pressure pump.

+ Controls the fuel intake volume to the pump.

+ Receives battery voltage supply from engine ECM.

Fuel outlet + Energized by ECM via negatively triggered PWM.

* Operating frequency: approximately 180Hz.

Common Rail Diesel Fuel Systems

Fuel metering control valve

_

When solenoid de energized, valve is open

Fuel inlet = LOW fuel volume intake to pump.

a When solenoid energized, valve is closed

= HIGH fuel volume intake to pump.

Fuel outlet

The fuel volume intake is controlled as follows

Common Rail Diesel Fuel Systems

Fuel volume intake control

Pump piston

Pressure valve

to common rail

Suction valve

Return

Safety valve

Feed (from the tank)

Gear pump

Fuel metering control

valve

Throttle bore

Control piston

Lubricating-oil bore

High-pressure pump

Common Rail Diesel Fuel Systems

Fuel volume intake control

Pump piston

Pressure valve

to common rail

Suction valve

Return

Safety valve

Feed (from the tank)

Gear pump

Fuel metering control

valve

Throttle bore

Control piston

Lubricating-oil bore

High-pressure pump

WONOnaeno

Common Rail Diesel Fuel Systems

Advantages of fuel intake volume regulation:

+ Only the required volume of fuel is supplied to the common rail from

the high pressure pump.

+ Reduced fuel flow around system results in lower fuel return flow

temperature

+ Reduced parasitic load on engine from high pressure pump contributes

towards further reductions in exhaust emissions.

High volume

Common Rail Diesel Fuel Systems

Fuel metering control valve failure symptoms and diagnosis

Solenoid circuit monitored by engine ECM

If an open or short circuit is detected:

Engine stops or will not start.

DTC stored and MIL illuminated.

Mechanical faults can cause DTC’s relating to positive

or negative rail pressure deviations.

Common Rail Diesel Fuel Systems

High pressure regulator valve

System variant.

Fitted to back of HP pump.

Controls high pressure fuel High pressure fuel

delivery to common rail. delivery to common tail

Excess fuel returns to

tank.

High pressure

regulator valve

Tr eee

Fuel cooler required to cool

return fuel flow. | [ fon ne

fo fuel tan

Low pressure fuel inlet

(from fuel tank)

Common Rail Diesel Fuel Systems

High pressure accumulator (common rail)

Fuel is supplied to the common rail at high pressure from the high

pressure pump.

The rail stores the fuel and distributes it to the individual injectors.

It also damps pressure vibrations caused by the high pressure pump

and injection processes.

Typical volume of fuel held in common rail: 16 — 20cm’.

Common Rail Diesel Fuel Systems

High pressure accumulator (common rail)

Typical fuel rail pressure with engine idling and at running temperature:

approximately between 300 — 400 Bar (4410 — 5880 psi)

Typical maximum possible fuel rail pressure:

approximately between 1600 — 2000 Bar (23520 — 28400 psi)

Common Rail Diesel Fuel Systems

High pressure accumulator (common rail)

Typical fuel rail pressure with engine idling and at running temperature:

approximately between 300 — 400 Bar (4410 — 5880 psi)

Health and safety

Due to the extremely high working fuel pressures in the common

rail fuel system, NEVER slacken fuel or injector pipes or try to

disconnect components of the fuel system whilst the engine is

running and high pressure is present in the system!

Typical maximum possible fuel rail pressure:

approximately between 1600 — 2000 Bar (23520 — 28400 psi)

Common Rail Diesel Fuel Systems

Fuel rail pressure sensor

S Fuel pressure sensor

A fuel rail pressure sensor is located on the fuel rail.

Common Rail Diesel Fuel Systems

Fuel rail pressure sensor

Monitors the fuel pressure in the common rail.

Typically a piezo resistive type sensor.

Three wires:

+ 5 Volt supply from engine ECM.

+ Sensor ground via engine ECM

+ Linear signal voltage output to ECM.

Signal utilization:

To enable the engine ECM to determine the fuel rail pressure.....

Used by the ECM as part of the calculation for the % duty cycle applied

to the rail pressure contro! solenoid and fuel metering solenoid.

Common Rail Diesel Fuel Systems

Fuel rail pressure sensor Signal voltage

(0 - 5V)

5 Volts supply Sensor ground

from I (<0.2 Volts

Piezo crystal

sensor

Pressure

The engine ECM applies a stabilized 5 Volts supply to the signal wire

of the fuel pressure sensor.

The resistive value of the sensor creates a change in the voltage on the

signal wire relative to the fuel rail pressure.

Common Rail Diesel Fuel Systems

Fuel rail pressure sensor Signal voltage

(0 -5V)

5 Volts supply Sensor ground

from ECM (<0.2 Volts

Piezo crystal

sensor

Pressure

Typical signal voltages from rail pressure sensor:

Engine stationary: approximately 0.5 volts.

Engine idling: approximately 1.32 volts.

Snap acceleration: approximately 3.77 volts +

(Example figures Bosch EDC16).

Common Rail Diesel Fuel Systems

Rail pressure limiter valve

A mechanical pressure limiter valve is fitted to some

systems. It is located at the end of the fuel rail.

a

Its function is to relieve rail pressure if abnormally

Rail pressure limiter high system pressure is generated.

valve (mechanical)

Common Rail Diesel Fuel Systems

Rail pressure limiter valve

If excessive fuel pressure is generated, the valve opens

a fuel return port.

fev Fuel return

Excess fuel is relieved back to the fuel tank.

Rail pressure limiter

valve (mechanical)

Common Rail Diesel Fuel Systems

Rail pressure limiter valve

limiter valve (Denso HP3 system):

valve opens at 230 MPa (2300 Bar)

valve closes at 50 MPa (500 Bar)

Common Rail Diesel Fuel Systems

Fuel rail pressure control valve solenoid

A rail pressure control valve solenoid is fitted to the common rail on

some systems.

Fuel return —____

Rail pressure control

valve (solenoid)

The valve controls fuel pressure by opening and closing a return port

in the rail.

Excess fuel returns to the fuel tank via the fuel return:

Common Rail Diesel Fuel Systems

Rail pressure control valve solenoid

Receives battery voltage supply from engine ECM.

Energized by engine ECM via a negenvely

triggered PWM.

Operating frequency: approximately 1000Hz

Used in conjunction with fuel metering solenoid, the rail pressure solenoid

provides more accurate and faster control of pressure, particularly when

reducing rail pressure during overrun.

Common Rail Diesel Fuel Systems

Rail pressure control valve de energized

More fuel is returned to fuel tank

via return port.

Rail pressure

Decreases.

Fuel return port

Common Rail Diesel Fuel Systems

Rail pressure control valve energized

Less fuel is returned to fuel tank

via return port.

Rail pressure

Increases.

Common Rail Diesel Fuel Systems

Rail pressure control valve failure symptoms and diagnosis

Most likely consequence:

Engine stops or will not start.

Solenoid circuit monitored by engine ECM.

Open or short circuit detected:

DTC stored and MIL illuminated.

(Engine stops or will not start).

Mechanical failure:

Common Rail Diesel Fuel Systems

Rail pressure control valve failure symptoms and diagnosis

Most likely consequence:

Engine stops or will not start.

Solenoid circuit monitored by engine ECM.

Open or short circuit detected:

DTC stored and MIL illuminated.

(Engine stops or will not start).

Mechanical failure:

Valve stuck open = Low rail pressure.

Engine stops or will not start.

Valve stuck closed = High rail pressure.

Engine stops or will not start.

Common Rail Diesel Fuel Systems

Testing rail pressure control valve

Multimeter:

Test internal resistance of valve solenoid winding.

Typical value: approximately 3.6 Ohms.

Diagnostic scan tool:

DTC's and monitoring of rail pressure values.

Oscilloscope:

Test supply voltage and earth switching signal from

engine ECM.

Test stability of waveform.

Common Rail Diesel Fuel Systems

Pressure control valve waveform: engine idling

Green = % duty cycle

Blue = rail pressure

Red = current draw

Common Rail Diesel Fuel Systems

Pressure control valve waveform: snap acceleration

Green = % duty cycle

Blue = rail pressure

Red = current draw

Common Rail Diesel Fuel Systems

Pressure control valve waveform

Common Rail Diesel Fuel Systems

Fuel injectors

The fuel injectors are controlled by either a solenoid or piezo actuator.

They are energized sequentially by the engine ECM.

The ECM simultaneously switches a live voltage supply and an earth for

each injector.

Multiple injection processes per cylinder combustion are possible. &

Common Rail Diesel Fuel Systems

Fuel injectors Fuel leak back (return)

Solenoid actuator

Injector valve Gi Electrical

connection

Valve piston

High pressure fuel inlet

Nozzle spring (from common rail)

Thrust piece

Valve needle

Common Rail Diesel Fuel Systems

Operation of fuel injectors Fuel leak back (return) port

Fuel pressure is supplied to the injector

needle seat area.....

High pressure

fuel inlet

e

__— Injector piston

Injector valve

Injector needle

and also to a small chamber above the

injector piston via a calibrated inlet port.

Common Rail Diesel Fuel Systems

Operation of fuel injectors Fuel leak back (return) port

When the solenoid is energized, "

High pressure

the injector valve opens. (a 2 fuel inlet

Injector valve Injector piston

Injector needle

Fuel pressure is relieved above the injector

piston and returns to the fuel tank via the

injector leak back (return) ports.

Common Rail Diesel Fuel Systems

Operation of fuel injectors Fuel leak back (return) port

This creates a pressure difference above .

High pressure

and below the injector piston. (a 2 fuel inlet

Injector piston

Injector needle

Fuel pressure below the injector needle lifts

the needle.

Common Rail Diesel Fuel Systems

Operation of fuel injectors Fuel leak back (return) port

Fuel is now injected into the .

High pressure

cylinder. ((

p fuel intet

Injector piston

Injector needle

Maximum stroke of solenoid valve:

approximately 50 micrometers (0.05 mm).

Common Rail Diesel Fuel Systems

Piezo injector

Fuel supply

Leak back _ yj \

Piezo stack

Injector piston

Injector valve

Injector needle

Primary advantage:

Quicker response time (up to four times

faster than solenoid controlled injector).

Features

Piezo stack has several hundred wafer

thin slices of Piezo crystal material.

When voltage is applied, the piezo

stack expands and opens the injector

valve.

Mechanical principle of operation is

similar to the solenoid injector.

Common Rail Diesel Fuel Systems

Injector codes

Most injectors have a code that must be programmed into the engine

Bosch injector generation 2 Denso injector

IMA code for injector flow adjustment QR (Quick Response) code

The code relates to the calibrated flow rate of the injector.

It enables the ECM to correct the injection quantity to compensate

for manufacturing tolerances.

Common Rail Diesel Fuel Systems

Oscilloscope waveform: Solenoid injector de energized

““TiBiue = switched +

“| Red = switched -

«| Green = current draw

Common Rail Diesel Fuel Systems

Oscilloscope waveform: Solenoid injector energized

“Tiplue = switched +

“| Red = switched -

«| Green = current draw

Common Rail Diesel Fuel Systems

Oscilloscope waveform: Piezo injector de energized

“Blue = switched +

“| Red = switched -

«| Green = current draw

Common Rail Diesel Fuel Systems

Oscilloscope waveform: Piezo injector energized

“TiBlue = switched +

“| Red = switched -

«| Green = current draw

Common Rail Diesel Fuel Systems

Engine management closed loop control functions:

Rail pressure calculation

Engine Stationary =>, cA

Example:

Comparison:

Actual value

with set value

Closed loop control

Bosch EDC16

(2 point control)

Rail pressure

calculati

(pre set values)

Engine Start

‘% duty cycle:

Fuel metering and

rail pressure

control solenoid

ts

Actual fuel rail

pressure value

Common Rail Diesel Fuel Systems

Engine management closed loop control functions:

Rail pressure calculation Example:

APP Bosch EDC16

— (2 point control)

ECT 3 = —

Common Rail Diesel Fuel Systems

Fuel system diagnosis

Common rail diese! fuel systems operate on a closed loop basis.

The system carries out a great many complex calculations to precisely

control fuel quantity and injection timing.

A range of tools and test equipment is commercially available to assist

with diagnosis of the system.

The following is a brief overview to highlight some of the basic tests that

can be carried out to diagnose faults with the system.

Common Rail Diesel Fuel Systems

Fuel system diagnosis

Basics first!

+ Sufficient diesel in the fuel tank?

+ Fuel contamination (eg from petrol).

+ Fuel leaks and damage to components.

+ Battery state of charge?

+ Adequate low pressure fuel supply from fuel tank?

+ Does engine start or crank and try to start?

+ ls white smoke emitted from exhaust during engine cranking?

(not always easy to see but indicates some fuel is entering cylinders).

+ Are any DTC's stored in fault memory of engine ECM?

Common Rail Diesel Fuel Systems

Fuel system diagnosis

Is the system capable of generating sufficient fuel pressure?

x 1000

Typical minimum ‘manufacturer specified’ value during engine cranking:

approximately between 200 — 300 Bar

In practice, the figure is usually higher for a good system. Above example

shows fuel pressure during engine cranking.

Common Rail Diesel Fuel Systems

Fuel system diagnosis

Injector leak back test

There should not normally be any fuel collected in receptacles during

engine cranking.

Example of acceptable leak back value with engine idling:

approximately 20m per injector over a 2 minute period.

(Always refer to manufacturer data for exact specifications)

Common Rail Diesel Fuel Systems

Fuel system diagnosis

Maximum fuel pressure

er |e > mals I +

MAXIMUM RAIL PRESSURE LAST 10M5_ Crap acceleration

Engine idling (approx 1519 Bar)

(approx 362 Bar)

Engine cranking

(approx 500 Bar) —~___

7 ~ one

Thank you

for attending a technical overview of

Common Rail

Diesel Fuel Systems

presented by

Tony Kitchen

(AK Training)

Você também pode gostar

- Komatsu PC200-7 Error Code On The Monitor, CMP Technology Co., LimitedDocumento5 páginasKomatsu PC200-7 Error Code On The Monitor, CMP Technology Co., Limitedkiagengbrantas heavyequipmentAinda não há avaliações

- Komatsu Manuals Electrical Diagram Pc300Documento6 páginasKomatsu Manuals Electrical Diagram Pc300Seaskyblues76% (25)

- SM Sakai Sv505-1Documento410 páginasSM Sakai Sv505-1LU YO88% (8)

- Manual Hitachi 130Documento20 páginasManual Hitachi 130yoharamyAinda não há avaliações

- Cat 320 GC (Gambar)Documento10 páginasCat 320 GC (Gambar)Budi PrayitnoAinda não há avaliações

- SK130-8 SK140LC-8液压泵分解Documento9 páginasSK130-8 SK140LC-8液压泵分解刘奇雄Ainda não há avaliações

- Omm PC200-7Documento310 páginasOmm PC200-7Budi Waskito89% (9)

- Kobelco SK200-8 Hino J05E Engine Manual - Parts Inspection and Engine Assembly PDFDocumento19 páginasKobelco SK200-8 Hino J05E Engine Manual - Parts Inspection and Engine Assembly PDFEduardo Gamboa100% (1)

- 910f Hydraulic CircuitDocumento2 páginas910f Hydraulic Circuitqwureyquwery100% (4)

- SV510 TechnicalDocumento87 páginasSV510 Technicalferdyak1100% (3)

- 320D2 Troubleshooting2Documento5 páginas320D2 Troubleshooting2evan100% (1)

- Hyundai HydraulicDocumento2 páginasHyundai HydraulicAl Furkhan0% (1)

- Brochure Ec210b Prime t3 en 30 20000465 CDocumento20 páginasBrochure Ec210b Prime t3 en 30 20000465 CJumansyah Hamid100% (2)

- Wheel Loader Hyundai HL960HD-1-30Documento30 páginasWheel Loader Hyundai HL960HD-1-30Sri hartati100% (1)

- Komatsu 7codesDocumento3 páginasKomatsu 7codesSandor Jakab100% (8)

- SK200-8 Super - Fuel SystemDocumento11 páginasSK200-8 Super - Fuel Systemt5442071100% (9)

- D155a 6 PDFDocumento16 páginasD155a 6 PDFJulio A CamposAinda não há avaliações

- Sofware Functions Related To Hydraulic Iecu EqippedDocumento6 páginasSofware Functions Related To Hydraulic Iecu Eqippedqwureyquwery100% (3)

- d65-15 Errors PDFDocumento5 páginasd65-15 Errors PDFjacklyn ade putra100% (1)

- Cat 320Documento32 páginasCat 320mitondho mitondhoAinda não há avaliações

- SK-200 Lodging ManualDocumento162 páginasSK-200 Lodging ManualPat Pat96% (24)

- Service Manual Common Rail System Isuzu 4HK1 6HK1Documento20 páginasService Manual Common Rail System Isuzu 4HK1 6HK1Văn Tuấn NguyễnAinda não há avaliações

- D 65e-8 Acak DemoDocumento11 páginasD 65e-8 Acak Demosonjisahuri33% (3)

- pc130 7Documento16 páginaspc130 7dwahyudiyanto100% (4)

- Code ErrorDocumento3 páginasCode ErrorAndri Wahyudi67% (3)

- Edoc - Pub Sk140sk480lc 8 Service Repairing ManualDocumento292 páginasEdoc - Pub Sk140sk480lc 8 Service Repairing ManualFirman andika100% (1)

- Manual Maintenance Interval Schedule Caterpillar 320d R L Hydraulic ExcavatorsDocumento59 páginasManual Maintenance Interval Schedule Caterpillar 320d R L Hydraulic ExcavatorsDhany Siregar100% (2)

- Event CodeDocumento9 páginasEvent CodeDe Javu100% (1)

- Escaner Ht-8a ExcavadorasDocumento7 páginasEscaner Ht-8a ExcavadorasBrahian Mijael Garrado GonzalesAinda não há avaliações

- Doosan DL450Documento16 páginasDoosan DL450Foromaquinas100% (3)

- Hino J08c Engine ManualDocumento2 páginasHino J08c Engine ManualMichel Mejia durandAinda não há avaliações

- Komatsu Excavadora Pc800Documento181 páginasKomatsu Excavadora Pc800Adal Vera100% (3)

- SH210-5/SH210LC-5 Hydraulic ExcavatorDocumento12 páginasSH210-5/SH210LC-5 Hydraulic ExcavatorpurwadiAinda não há avaliações

- KOBELCO Arm Shock CountermeasureDocumento204 páginasKOBELCO Arm Shock CountermeasurePHÁT NGUYỄN THẾ100% (8)

- Wa5000 3hDocumento986 páginasWa5000 3hEdinson Javier Guevara Garcia100% (1)

- D8R ComplianceDocumento17 páginasD8R ComplianceagegnehutamiratAinda não há avaliações

- 966 Wiring HardnessDocumento2 páginas966 Wiring HardnessandraAinda não há avaliações

- D 7 GDocumento49 páginasD 7 Gmuhammad aliAinda não há avaliações

- SH75X 3BDocumento6 páginasSH75X 3Bdanang100% (1)

- Hydraulic Ver (Eng) Yoshida KaizoDocumento78 páginasHydraulic Ver (Eng) Yoshida KaizoRoyen100% (19)

- Hydraulic Excavators: Working Ranges SpecificationsDocumento2 páginasHydraulic Excavators: Working Ranges SpecificationsLittle AyaAinda não há avaliações

- HITACHI ZAXIS ZX 470LC-5G EXCAVATOR Service Repair Manual PDFDocumento32 páginasHITACHI ZAXIS ZX 470LC-5G EXCAVATOR Service Repair Manual PDFMaulana SaputraAinda não há avaliações

- Isuzu EngineDocumento53 páginasIsuzu EngineSmaileRun78% (18)

- Dokumen - Tips - Kobelco sk200 8 Parts Manual sk200 8sk210lc 8 Shop Manual Hydraulic Excavator SizeDocumento4 páginasDokumen - Tips - Kobelco sk200 8 Parts Manual sk200 8sk210lc 8 Shop Manual Hydraulic Excavator SizeWahyu Yudi100% (1)

- SM D 85 Ess-2 A Demo PDFDocumento33 páginasSM D 85 Ess-2 A Demo PDFArdy091Ainda não há avaliações

- Demo PB GD510R-1Documento7 páginasDemo PB GD510R-1Shop ManualAinda não há avaliações

- Volvo Excavator Ec330blcDocumento3 páginasVolvo Excavator Ec330blcsasikumarcivil1996100% (1)

- 740B Error CodeDocumento6 páginas740B Error CodeRajan Mullappilly100% (2)

- ProductBrochure L150G L180G L220G en 21A1006521Documento32 páginasProductBrochure L150G L180G L220G en 21A1006521jonbzh1Ainda não há avaliações

- ZX 870Documento366 páginasZX 870Dozer Kamil100% (1)

- PC200-8 PC200LC-8 PC200-7 PC200LC-7 Lowres 72326Documento58 páginasPC200-8 PC200LC-8 PC200-7 PC200LC-7 Lowres 72326piteng194592% (24)

- Cat EngineDocumento94 páginasCat Enginejoshuadelapava100% (1)

- Renault Inyección Electrónica Clio 1.4 Ac Delco Monopoint P PDFDocumento2 páginasRenault Inyección Electrónica Clio 1.4 Ac Delco Monopoint P PDFGood CarAinda não há avaliações

- Building ActDocumento136 páginasBuilding ActVeronika RaušováAinda não há avaliações

- UTS ELT MDE S1 Coursebook Evaluation ChecklistDocumento3 páginasUTS ELT MDE S1 Coursebook Evaluation ChecklistHanin Khalishah WaqqasAinda não há avaliações

- GM Inyección Electrónica S10 Blazer 2.2 Efi Delphi Multec emDocumento2 páginasGM Inyección Electrónica S10 Blazer 2.2 Efi Delphi Multec emyayixdfuego131Ainda não há avaliações

- Planes APIDocumento10 páginasPlanes APIManuel FigueroaAinda não há avaliações

- 2020Documento14 páginas2020mintrikpalougoudjoAinda não há avaliações

- Xsara 18 - Berlingo 18 - 18 Xu7jb PDFDocumento2 páginasXsara 18 - Berlingo 18 - 18 Xu7jb PDFJorge Daniel DiazAinda não há avaliações

- Volvo Penta 2001 2002 2003 2003t Engine Unit Workshop ManualDocumento35 páginasVolvo Penta 2001 2002 2003 2003t Engine Unit Workshop Manualso full of HHOAinda não há avaliações

- Caterpillar EMCPDocumento40 páginasCaterpillar EMCPrealwild93% (59)

- Common Rail Fuel SystemDocumento61 páginasCommon Rail Fuel SystemSilas F Pimenta100% (2)

- Daewoo Engine D1146-T-TI Shop ManualDocumento108 páginasDaewoo Engine D1146-T-TI Shop ManualSilas F Pimenta100% (10)

- Multiple Files Are Bound Together in This PDF Package.: Click Here To Download The Latest Version of Adobe ReaderDocumento1 páginaMultiple Files Are Bound Together in This PDF Package.: Click Here To Download The Latest Version of Adobe ReaderSilas F PimentaAinda não há avaliações

- Volvo Penta 2001 2002 2003 2003t Engine Unit Workshop ManualDocumento35 páginasVolvo Penta 2001 2002 2003 2003t Engine Unit Workshop Manualso full of HHOAinda não há avaliações

- Curso Cat 428B Sist Hidraulico Desarmado - Armado Bomba HidraulicaDocumento31 páginasCurso Cat 428B Sist Hidraulico Desarmado - Armado Bomba HidraulicaSilas F Pimenta83% (6)

- Curso Cat d6r III STMGDocumento73 páginasCurso Cat d6r III STMGSilas F Pimenta90% (20)

- MAN D2876 - CR - EngDocumento182 páginasMAN D2876 - CR - EngSilas F Pimenta75% (4)

- Case 580M Serie 3 Trans Specs&TroubleshootingDocumento26 páginasCase 580M Serie 3 Trans Specs&TroubleshootingSilas F Pimenta100% (7)

- MAN D20 Eng PDFDocumento157 páginasMAN D20 Eng PDFjwd83% (54)

- MAN D0836 - CR - enDocumento121 páginasMAN D0836 - CR - enSilas F Pimenta86% (56)

- Delphi DP210 Fuel Injection Pump CatDocumento3 páginasDelphi DP210 Fuel Injection Pump CatSilas F Pimenta90% (20)

- Curso Cat Fan System STMGDocumento79 páginasCurso Cat Fan System STMGSilas F Pimenta100% (14)

- Curso Cat C4.4-6.6 ACERT Technology STMGDocumento153 páginasCurso Cat C4.4-6.6 ACERT Technology STMGSilas F Pimenta100% (31)

- Cat 3406C (PEEC III) Disassembly&Assembly SENR5532Documento130 páginasCat 3406C (PEEC III) Disassembly&Assembly SENR5532Silas F Pimenta94% (17)

- Volvo D12D EspecificacionDocumento42 páginasVolvo D12D EspecificacionSilas F Pimenta92% (72)

- Curso Cat 950-962G Steering Syst STMGDocumento24 páginasCurso Cat 950-962G Steering Syst STMGSilas F Pimenta100% (18)

- Curso Cat 980h STMGDocumento30 páginasCurso Cat 980h STMGSilas F Pimenta100% (14)

- Curso Cat 320-330B Sistema STMG 1Documento20 páginasCurso Cat 320-330B Sistema STMG 1Silas F Pimenta97% (75)

- Curso Cat 966h-972h STMGDocumento63 páginasCurso Cat 966h-972h STMGSilas F Pimenta92% (12)