Escolar Documentos

Profissional Documentos

Cultura Documentos

Making Your Own Rivets - The AK Files Forums

Enviado por

scout50Direitos autorais

Formatos disponíveis

Compartilhar este documento

Compartilhar ou incorporar documento

Você considera este documento útil?

Este conteúdo é inapropriado?

Denunciar este documentoDireitos autorais:

Formatos disponíveis

Making Your Own Rivets - The AK Files Forums

Enviado por

scout50Direitos autorais:

Formatos disponíveis

Making Your Own Rivets - The AK Files Forums

. 1 7

http://www.akfiles.com/forums/showthread.php?t=110867

User Name

The AK Files Forums > General Forums > Gunsmithing & Build It Yourself

Making Your Own Rivets

Remember Me?

Password

Register

FAQ

Calendar

Thread Tools

05-14-2012, 03:22 PM

akma

Veteran Member

AKaholic #: 159266

Join Date: Nov 2011

Location: Not where I want to

be!

Posts: 1,003

#1

Making Your Own Rivets

I would like to show how to convert standard rivets into European AK style rivets. This is by no means an all inclusive tutorial but some ideas that have worked for me. I hope to further refine my methods and techniques to produce

an accurate cost effective alternative to store bought rivet kits.

Some factory rivet specs. These are averages. One thing I have noticed is heads vary in size on one rifle.

Romanian front and rear trunnion rivets are .250 dia. x. 073 high

Romanian front trigger guard rivets are .270 dia. x .083 high

Romanian rear trigger guard rivet is .282 dia. x .086 high

Chinese factory rivets are slightly larger at .292 dia. x .110 high.

Tools used

Drill press

Files

Swaging plate

Head forming plate

12 ton hydraulic press

Oil or grease

Hammer

Punch

Here is a list of rivets and where they are used. I bought them from McMaster-Carr.

http://www.mcmaster.com/#standard-rivets/=fpe66s

Large Diameter:

Rear Trunnion Long Swell neck 47/74 3/16 x 2 97300A677

Front Trunnion Swell neck 74 3/16 x 3/8 97300A663

Small Diameter:

Rear Trunnion Short Swell neck 74 5/32 x 3/8 97300A105

Trigger Guard Front 47/74 5/32 x 3/8 97300A105

Trigger Guard Rear 47/74 5/32 x 97300A100

Front Trunnion 47/74 Swell neck 5/32 x 3/8 97300A105

The first thing is to make your swaging plate. This is central to converting your rivets. I started with a piece of 3/8 scrap mild steel plate.

Small Rivets

To form the small dia. rivets drill two #21 or 0.159 dia. holes. One countersink with a HF 45 degree countersink http://www.harborfreight.com/1-2-hal...ink-93342.html and the other leave flat. The countersink is used to put the

swell neck on and form the head at the same time. The swell necks are easy to do and look right. The other one is used to form the head on the non swell neck rivets. Simply lube and place the rivet in swaging plate hole and back

with the head forming plate and press. Drive it out with the punch. Now chuck it in the drill press and turn the head to size.

Large Rivets

The large dia. rivets are a little more work. You need to reduce the body size and swage the head. To do this drill three holes a #14, #15 and #16 then relieve the back to make removal easier. You only need to countersink the #16

hole after back relieving. The #16 is used only to form and size the head and swell neck on the 2 long rivets because they dont reduce well with a hammer.

To form the short rivets moderately hammer the rivets into each progressively smaller hole using lubricant. When its in the #16 put it into the press with the head forming plate and swage the head. Now it's ready to shape in the

drill press.

The long rivets need to be turned in the drill press to size the body. They dont reduce well in the swaging plate. They start to look like fish hooks. With my drill press chuck I found I can put the head in first and tighten the chuck to

reduce the tip. I didnt think that would work but it does with the 2 rivet. This also helps when test fitting it in the trunnion. Your final diameter should be .177 or a little less. Next put the swell neck on. Lube and swage in the #16

hole. Now shape the head in the drill press.

*Note be careful when swaging the rivet head making sure the bottom of the rivet doesnt get compressed against the backer plate otherwise you will have to pound it back out. Ask me how I know. He, He, He.

You will have to trim the rivets length to suit your needs based on the size of your head forming die.

Swaging plate and Head forming plate

Swaging the head

Before and after swaging

10/12/2014 4:37 PM

Making Your Own Rivets - The AK Files Forums

. 2 7

http://www.akfiles.com/forums/showthread.php?t=110867

Swell neck

Reducing body diameter on the short 3/16 dia. Rivet.

Turning the body on the long 3/16 dia rivet.

Turning the head.

10/12/2014 4:37 PM

Making Your Own Rivets - The AK Files Forums

. 3 7

http://www.akfiles.com/forums/showthread.php?t=110867

Finished large rivet body diameter is .177.

Last edited by akma; 05-19-2012 at 11:44 AM. Reason: Additional information

05-19-2012, 02:46 AM

#2

Utga Schleigle

Veteran Member

Thank You for posting this. I will work on this this weekend. This will help greatly.

I just bought some steel blocks to do this.

AKaholic #: 8480

Join Date: Jun 2007

Location: LB Peoples Republik

Kalifornicators

Posts: 1,780

Got this from another site - witch copied from another file. NOT SURE WHO WAS ORIGINAL AUTHOR

repost

"Bulk rivets (from McMaster or others) can easily be converted to swell head if you don't want to buy the one's advertised at $8-10 set. I made the jig in about 5 minutes. Take a piece of 1/4 mild steel and with a countersink (I

used 5/8) drill down about 1/16 inch. The outside diameter of the countersink hole will be the greater diameter of the swell neck. Then drill a 5/32 hole in the center of the countersink hole and through the 1/4 steel. Looking down

at the steel you will have a 5/32 countersunk hole. The amount of countersink represents the amount of swell neck which will be impressed onto the rivet. Place a 5/32 rivet (AK rivets work also) into the countersunk hole so the

underside of the rivet head rests on the countersunk 5/32 hole. Place a piece of 1/4 steel (either flat or slightly relieved) on the rivet head and likewise support the steel from the underside(I drilled a 1/4 hole in this steel to allow

for the protruding rivet). Place the three pieces of 1/4 steel in a bench vice so when the vice is closed pressure will force the underside of the rivet head into the countersunk hole. After the vice is tightened and released, the rivet

can be tapped out. If you want more swell, simply deepen the countersink. With a little modification this should also work with rear trunnion rivets.

If this method is already known I apologize but I haven't come across this while reading the various threads. I also have hundreds of regular (non swell head rivets) which I bought for practice with a bolt cutter/rivet tool."

__________________

PLEASE WEAR EYE PROTECT & PROTECTIVE GEAR IN SHOP!!!!!! You can order another part from from manufacturer, but you can't order another finger or eye from your mother & father.

***This DOES NOT constitute GOOD or SANE legal - professional gunsmithing - psychiatric - CPA - MD - gardening advice. Please contactact qualified professional in their respective specialties.*** Go ahead mix and match

professionals with what ever problem you have??? That would be funney!!!!!

Last edited by Utga Schleigle; 05-19-2012 at 05:42 PM.

05-19-2012, 07:36 AM

#3

akma

Veteran Member

AKaholic #: 159266

Join Date: Nov 2011

Location: Not where I want to

be!

Posts: 1,003

I use the hydraulic press instead of the vise and two sizes of holes for the different diameter rivets needed. The angle of the drill bit is not steep enough and does not match the trunnions. I used a HF 45 degree to match the

original. Relieving or back drilling the back side of the hole it makes rivet removal a lot easier after the the head is formed. You can use the same technique to make gas piston rivets by squishing the head flat.

BTW thank you for your extensive write up on making your own rivets.

05-19-2012, 08:37 AM

#4

69Mach1

Member

tag

AKaholic #: 48505

Join Date: Jul 2009

Location: USA

Posts: 140

05-19-2012, 10:20 AM

#5

6526

Curio & Relic

good info,,,,,,,,,,,,,,,,,,,,,I do something similar to mod sinker nails for the long rivits

AKaholic #: 3433

Join Date: Jan 2005

Location: southwest WI

Posts: 6,288

05-19-2012, 11:12 AM

#6

ohmysac

Senior Member

That's an excellent idea. Will be trying this.

AKaholic #: 3544

Join Date: Feb 2005

Posts: 852

05-19-2012, 04:19 PM

#7

Utga Schleigle

Veteran Member

AKaholic #: 8480

Join Date: Jun 2007

Quote:

Originally Posted by akma

I use the hydraulic press instead of the vise and two sizes of holes for the different diameter rivets needed. The angle of the drill bit is not steep enough and does not match the trunnions. I used a HF 45 degree to match the

original. Relieving or back drilling the back side of the hole it makes rivet removal a lot easier after the the head is formed. You can use the same technique to make gas piston rivets by squishing the head flat.

10/12/2014 4:37 PM

Making Your Own Rivets - The AK Files Forums

. 4 7

Location: LB Peoples Republik

Kalifornicators

Posts: 1,780

http://www.akfiles.com/forums/showthread.php?t=110867

BTW thank you for your extensive write up on making your own rivets.

I agree on the low angle of most driill bitts - 110 degrees - I was also going to use the 45 degree counter sink from HF.

Also was going to make the swage / swedge block do double duty as a drill out guide.

AK BIULDER SELLS THESE 5/32 ONLY drill bitt ONLY - BUTT notice hole on side is smaller bevell - interesting.

drill out guide block only has to center and hold bit on the round of rivit head - does not have to be full ball end dimple.

I wanted 1/8 and 5/32 and 3/16 rivit head drill out hole.

Also was thinking of dimple-ling the buck plate and taping through rivit throught the swage bolck to expand the rivit into the 45 degree counter sink. FOR (1) to get a swell neck that did use the rivit head for metal. AND (2) Hanson

sold sold me some rivits with LOW UNIVERSAL HEADS not FULL ROUND HEADS. I wanted to fix that.

__________________

PLEASE WEAR EYE PROTECT & PROTECTIVE GEAR IN SHOP!!!!!! You can order another part from from manufacturer, but you can't order another finger or eye from your mother & father.

***This DOES NOT constitute GOOD or SANE legal - professional gunsmithing - psychiatric - CPA - MD - gardening advice. Please contactact qualified professional in their respective specialties.*** Go ahead mix and match

professionals with what ever problem you have??? That would be funney!!!!!

Last edited by Utga Schleigle; 05-19-2012 at 05:45 PM.

05-19-2012, 05:42 PM

#8

akma

Veteran Member

I think it would be to complicated making your swage plate do double duty. The swage plate is thick and kind of bulky and a drill out guide doesen't need to be that big. Just my opinion.

AKaholic #: 159266

Join Date: Nov 2011

Location: Not where I want to

be!

Posts: 1,003

I put the bucking plate on top of the rivet and just swage the head and swell neck at the same time as there is no need for an extra step. The heads and swell neck squish real easy in the press. Also the low dome rivets will

probably leave less work finishing after you form the head and put the swell neck on. BTW do you have the link for the Hanson rivets?

05-20-2012,

01:11 PM

Utga

Schleigle

Veteran

Member

AKaholic #:

8480

Join Date: Jun

2007

Location: LB

Peoples

Republik

Kalifornicators

Posts: 1,780

#9

Quote:

Originally Posted by akma

I think it would be to complicated making your swage plate do double duty. The swage plate is thick and kind of bulky and a drill out guide doesen't need to be that big. Just my opinion.

I put the bucking plate on top of the rivet and just swage the head and swell neck at the same time as there is no need for an extra step. The heads and swell neck squish real easy in the press. Also the low dome rivets will probably leave

less work finishing after you form the head and put the swell neck on. BTW do you have the link for the Hanson rivets?

http://www.hansonrivet.com/w08.htm

http://www.hansonrivet.com/

I liked Hanson Rivet because they have many lengths - there pan head rivits are a better diameter and head hieght than the flat / nail head rivits of the links below.

Each has some rivits - HANSON RIVET seems to have it all.

http://www.mcmaster.com/?orderview=n...essors/=d7gmpz

Mc Master

Centaur Forge only has 5/32 by 1 & 3/4 length.

Be specific and ask for FULL ROUND HEAD RIVITS / RIVETS --- not low head universal rivits.

use HANSON Rivet chart to compare and base purchase accordingly.

10/12/2014 4:37 PM

Making Your Own Rivets - The AK Files Forums

. 5 7

http://www.akfiles.com/forums/showthread.php?t=110867

10/12/2014 4:37 PM

Making Your Own Rivets - The AK Files Forums

. 6 7

http://www.akfiles.com/forums/showthread.php?t=110867

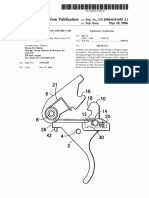

This is the drawing submitted to HANsON Rivet to get a custom order of swell nech rivets - $899.oo in tooling that factory would keep - minimum run of 20,000 rivits at APROX $1,700.oo. Too much $$$$ for ROI for a hobby.

Will work on tonight and report back.

__________________

PLEASE WEAR EYE PROTECT & PROTECTIVE GEAR IN SHOP!!!!!! You can order another part from from manufacturer, but you can't order another finger or eye from your mother & father.

***This DOES NOT constitute GOOD or SANE legal - professional gunsmithing - psychiatric - CPA - MD - gardening advice. Please contactact qualified professional in their respective specialties.*** Go ahead mix and match professionals with what

ever problem you have??? That would be funney!!!!!

05-22-2013, 04:51 PM

#10

Andrew4

Senior Member

That there is some man MATH arr arr!

AKaholic #: 169077

Join Date: Apr 2013

Location: Flint Town, Mi

Posts: 598

08-29-2013, 04:33 PM

#11

56type

Member

AKaholic #: 15047

Join Date: Sep 2008

Location: IN.

Posts: 227

For the Chinese rivets I ordered some from the seller on GB and came up with these measurements......

Shaft dia. = .196

Head dia. = .296

Head height = .079

In looking at the Hanson chart above it would seem that the 5/32 or 3/16 would work best for the Chinese builds. The 3/16 list the shaft dia. as being closer to the ideal 5mm but will require more swaging work on the head of the

rivet. The 5/32 is closer to ideal 4.5mm found on the four smaller front trunnion rivets. When I compared the supposedly Chinese sourced rivets I found the fit to be almost a friction fit in the trunnions as there was considerable

drag when taking the rivet in or out for test fitting the rivet to the trunnion holes The Chinese rivets are definitely TIGHT, though only one out of the ten or so I ordered would fit the four smaller front trunnion holes, and it came in

at .175 on the shaft dia. and fit the holes closely. Hope this helps for those building up Chinese kits.

10/12/2014 4:37 PM

Making Your Own Rivets - The AK Files Forums

. 7 7

http://www.akfiles.com/forums/showthread.php?t=110867

ETA: I did some further digging and came up with these drill sizes for making the tooling to form the Chinese rivets. All the part numbers are from Enco but the manufacturer is listed as Hertel......

Drill bit size #9 (.196) - 4.98mm PN:337-2653 $3.14 ea.

Drill bit size "M" (.295) - 7.49mm PN:337-2674 $6.93 ea.

Drill bit size #16 (.177) - 4.50mm PN:337-2646 $3.03 ea.

All bits listed above are 135 degree split-point cobalt so they shouldn't have any trouble with any scrap metal whether hardened or not.

Last edited by 56type; 08-29-2013 at 04:48 PM.

08-30-2013, 11:18 AM

#12

3 weelin geezer

Senior Member

How can it be cost effective for a blacksmith to make each one individually instead of having an automatic hydraulic press make hundreds at a time and sell them in bulk? Not to mention having different kinds available too?

http://www.rivetsinstock.com/

AKaholic #: 6252

Join Date: Jul 2006

Location: El Paso Tx

Posts: 514

Previous Thread | Next Thread

Currently Active Users Viewing This Thread: 3 (0 members and 3 guests)

Posting Rules

You

You

You

You

may

may

may

may

not

not

not

not

post new threads

post replies

post attachments

edit your posts

BB code is On

Smilies are On

[IMG] code is On

HTML code is On

Forum Jump

Forum Rules

All times are GMT -5. The time now is 07:35 AM.

Contact Us - The AK Files - Archive - Top

Powered by vBulletin Version 3.8.7

Copyright 2000 - 2014, vBulletin Solutions, Inc.

10/12/2014 4:37 PM

Você também pode gostar

- Do-It-Yourself Gun Repair: Gunsmithing at HomeNo EverandDo-It-Yourself Gun Repair: Gunsmithing at HomeNota: 2 de 5 estrelas2/5 (1)

- Hunting with Muzzleloading Revolvers: New powders and bullets have made these guns capable game killers.No EverandHunting with Muzzleloading Revolvers: New powders and bullets have made these guns capable game killers.Nota: 5 de 5 estrelas5/5 (1)

- Punching Holes: Buying Ammunition, Gun Accessories, Knives and Tactical Gear at Wholesale PricesNo EverandPunching Holes: Buying Ammunition, Gun Accessories, Knives and Tactical Gear at Wholesale PricesAinda não há avaliações

- Gun Digest American Arms ATI GSG-5 Assembly/Disassembly InstructionsNo EverandGun Digest American Arms ATI GSG-5 Assembly/Disassembly InstructionsAinda não há avaliações

- Professional Gunsmithing - A Textbook on the Repair and Alteration of Firearms - With Detailed Notes and Suggestions Relative to the Equipment and Operation of a Commercial Gun ShopNo EverandProfessional Gunsmithing - A Textbook on the Repair and Alteration of Firearms - With Detailed Notes and Suggestions Relative to the Equipment and Operation of a Commercial Gun ShopNota: 5 de 5 estrelas5/5 (3)

- GG2 Operator's ManualDocumento30 páginasGG2 Operator's ManualWerner Patric WengAinda não há avaliações

- Jewel 2-Stage TriggerDocumento13 páginasJewel 2-Stage TriggerAdam BallAinda não há avaliações

- The Gun Digest Book of Firearms Assembly/Disassembly Part V - ShotgunsNo EverandThe Gun Digest Book of Firearms Assembly/Disassembly Part V - ShotgunsNota: 5 de 5 estrelas5/5 (3)

- Gun Digest's Customize Your Revolver Concealed Carry Collection eShort: From regular pistol maintenance to sights, action, barrel and finish upgrades for your custom revolver.No EverandGun Digest's Customize Your Revolver Concealed Carry Collection eShort: From regular pistol maintenance to sights, action, barrel and finish upgrades for your custom revolver.Ainda não há avaliações

- Building or Restoring Your Muzzleloader: Making Muzzleloaders from Kits and Damaged GunsNo EverandBuilding or Restoring Your Muzzleloader: Making Muzzleloaders from Kits and Damaged GunsAinda não há avaliações

- Making The Extractor Cut On A Virgin Barrel - The AK Files ForumsDocumento4 páginasMaking The Extractor Cut On A Virgin Barrel - The AK Files Forumsscout50Ainda não há avaliações

- Practical Guide to the Operational Use of the PPS-43 Submachine GunNo EverandPractical Guide to the Operational Use of the PPS-43 Submachine GunAinda não há avaliações

- Elementary Gunsmithing: A Manual of Instruction for Amateurs in the Alteration and Repair of FirearmsNo EverandElementary Gunsmithing: A Manual of Instruction for Amateurs in the Alteration and Repair of FirearmsAinda não há avaliações

- Hunting with Muzzleloading Shotguns and Smoothbore Muskets: Smoothbores Let You Hunt Small Game, Big Game and Fowl with the Same GunNo EverandHunting with Muzzleloading Shotguns and Smoothbore Muskets: Smoothbores Let You Hunt Small Game, Big Game and Fowl with the Same GunAinda não há avaliações

- Installing An External Bolt Stop/Release On A Remington 700Documento10 páginasInstalling An External Bolt Stop/Release On A Remington 700M Poveda0% (1)

- The Gunsmith's Manual: Practical Guide to All Branches of the TradeNo EverandThe Gunsmith's Manual: Practical Guide to All Branches of the TradeAinda não há avaliações

- Ti25 Advanced Composite Steel Lip Magazine For Ruger 10 - 22 byDocumento3 páginasTi25 Advanced Composite Steel Lip Magazine For Ruger 10 - 22 byarizona212Ainda não há avaliações

- The Handloader's Manual of Cartridge ConversionsNo EverandThe Handloader's Manual of Cartridge ConversionsNota: 5 de 5 estrelas5/5 (1)

- Functional Composite Materials: Manufacturing Technology and Experimental ApplicationNo EverandFunctional Composite Materials: Manufacturing Technology and Experimental ApplicationAinda não há avaliações

- TM-9-1005-301-30 Repair Wood Fibre Plastic Components of Weapons Part1Documento19 páginasTM-9-1005-301-30 Repair Wood Fibre Plastic Components of Weapons Part1browar444Ainda não há avaliações

- The Gun Workshop June 2019 FinalDocumento2 páginasThe Gun Workshop June 2019 Finalpeter3972Ainda não há avaliações

- Custom Rifles - Mastery of Wood & Metal: David Miller Co.No EverandCustom Rifles - Mastery of Wood & Metal: David Miller Co.Ainda não há avaliações

- The Practical Guide to Man-Powered Weapons and Ammunition: Experiments with Catapults, Musketballs, Stonebows, Blowpipes, Big Airguns, and Bullet BowsNo EverandThe Practical Guide to Man-Powered Weapons and Ammunition: Experiments with Catapults, Musketballs, Stonebows, Blowpipes, Big Airguns, and Bullet BowsNota: 5 de 5 estrelas5/5 (1)

- Practical Guide to the Operational Use of the M79 Grenade LauncherNo EverandPractical Guide to the Operational Use of the M79 Grenade LauncherAinda não há avaliações

- Advanced Gunsmithing: A Manual of Instruction in the Manufacture, Alteration, and Repair of Firearms (75th Anniversary Edition)No EverandAdvanced Gunsmithing: A Manual of Instruction in the Manufacture, Alteration, and Repair of Firearms (75th Anniversary Edition)Nota: 3.5 de 5 estrelas3.5/5 (2)

- AK Accurizing TipsDocumento27 páginasAK Accurizing TipsEmilio Torres EsguerraAinda não há avaliações

- Building a Home Defense Remington 870 ShotgunNo EverandBuilding a Home Defense Remington 870 ShotgunNota: 3.5 de 5 estrelas3.5/5 (5)

- FE Analysis of Firearm Locking Systems: Lorenzo CastiglioniDocumento15 páginasFE Analysis of Firearm Locking Systems: Lorenzo CastiglionijkruiseAinda não há avaliações

- Gun Digest's Revolver Malfunction Clearing Concealed Carry eShort: Learn how to clear trigger jams, gun misfires and case-under-extractor malfunctions.No EverandGun Digest's Revolver Malfunction Clearing Concealed Carry eShort: Learn how to clear trigger jams, gun misfires and case-under-extractor malfunctions.Ainda não há avaliações

- Winchester Model 1885Documento0 páginaWinchester Model 1885carlosfanjul1Ainda não há avaliações

- Churchills Mauser C96: Notes on -The blow-up in Sydney Street- from the London DecameroneNo EverandChurchills Mauser C96: Notes on -The blow-up in Sydney Street- from the London DecameroneAinda não há avaliações

- Gun Vises For Almost Nothin..Documento4 páginasGun Vises For Almost Nothin..bulkmail5784Ainda não há avaliações

- The Crack Shot: or Young Rifleman's Complete Guide: Being a Treatise on the Use of the RifleNo EverandThe Crack Shot: or Young Rifleman's Complete Guide: Being a Treatise on the Use of the RifleAinda não há avaliações

- Handloader's Manual - A Treatise on Modern Cartridge Components and Their Assembly by the Individual Shooter Into Accurate Ammunition to Best Suit his Various PurposesNo EverandHandloader's Manual - A Treatise on Modern Cartridge Components and Their Assembly by the Individual Shooter Into Accurate Ammunition to Best Suit his Various PurposesAinda não há avaliações

- Us 20060101695Documento11 páginasUs 20060101695galak12001100% (1)

- The 1903 Colt 'Hammerless' Pocket ModelDocumento8 páginasThe 1903 Colt 'Hammerless' Pocket Modelblowmeasshole1911Ainda não há avaliações

- Product Instructions - Flat Bending Jig InstructionsDocumento34 páginasProduct Instructions - Flat Bending Jig InstructionsDale WadeAinda não há avaliações

- Spanish MauserDocumento21 páginasSpanish Mauserscout50100% (3)

- Smith and Wesson Revolver RepairsDocumento25 páginasSmith and Wesson Revolver Repairsscout50100% (3)

- Forming 223 Rem Brass For The Nagant RevolverDocumento19 páginasForming 223 Rem Brass For The Nagant Revolverscout50Ainda não há avaliações

- M70 Owner ManualDocumento16 páginasM70 Owner Manualscout50100% (1)

- AKM Poster - AKM 1Documento1 páginaAKM Poster - AKM 1scout50100% (1)

- Type 2 & Type 3 AK-47Documento6 páginasType 2 & Type 3 AK-47scout50100% (1)

- 6ZF57 Berdan II M1870 Rifle Blueprints Pages 1 To 16Documento16 páginas6ZF57 Berdan II M1870 Rifle Blueprints Pages 1 To 16scout50Ainda não há avaliações

- Making The Extractor Cut On A Virgin Barrel - The AK Files ForumsDocumento4 páginasMaking The Extractor Cut On A Virgin Barrel - The AK Files Forumsscout50Ainda não há avaliações

- Virgin Build AK-47 Yugoslavian M70AB2 Stamped Receiver Yugo M70 AB2Documento50 páginasVirgin Build AK-47 Yugoslavian M70AB2 Stamped Receiver Yugo M70 AB2scout50100% (1)

- 2C3FD Berdan II M1870 Rifle Blueprints Pages 32 To 49Documento17 páginas2C3FD Berdan II M1870 Rifle Blueprints Pages 32 To 49scout50Ainda não há avaliações

- MG 42 Semi ManualDocumento50 páginasMG 42 Semi Manualscout50100% (7)

- Declassified Rocket LaunchersDocumento123 páginasDeclassified Rocket Launcherskgrhoads100% (1)

- Ari Saka Type 38 BoltDocumento7 páginasAri Saka Type 38 Boltscout50100% (1)

- 3 ф.пушка.Documento2 páginas3 ф.пушка.scout50Ainda não há avaliações

- Ari Saka Type 38 BoltDocumento7 páginasAri Saka Type 38 Boltscout50100% (1)

- P08 BlueprintsDocumento31 páginasP08 BlueprintsLonxx83% (12)

- Food NutritionDocumento21 páginasFood NutritionLaine AcainAinda não há avaliações

- Meditation For AddictionDocumento2 páginasMeditation For AddictionharryAinda não há avaliações

- 978-1119504306 Financial Accounting - 4thDocumento4 páginas978-1119504306 Financial Accounting - 4thtaupaypayAinda não há avaliações

- PropertycasesforfinalsDocumento40 páginasPropertycasesforfinalsRyan Christian LuposAinda não há avaliações

- Quiz 07Documento15 páginasQuiz 07Ije Love100% (1)

- Stress Corrosion Cracking Behavior of X80 PipelineDocumento13 páginasStress Corrosion Cracking Behavior of X80 Pipelineaashima sharmaAinda não há avaliações

- Marriot CaseDocumento15 páginasMarriot CaseArsh00100% (7)

- Prof. Monzer KahfDocumento15 páginasProf. Monzer KahfAbdulAinda não há avaliações

- FCAPSDocumento5 páginasFCAPSPablo ParreñoAinda não há avaliações

- TOURISM AND HOSPITALITY ORGANIZATIONS Di Pa TapooosDocumento97 páginasTOURISM AND HOSPITALITY ORGANIZATIONS Di Pa TapooosDianne EvangelistaAinda não há avaliações

- Durst Caldera: Application GuideDocumento70 páginasDurst Caldera: Application GuideClaudio BasconiAinda não há avaliações

- Lesson 17 Be MoneySmart Module 1 Student WorkbookDocumento14 páginasLesson 17 Be MoneySmart Module 1 Student WorkbookAry “Icky”100% (1)

- Placement TestDocumento6 páginasPlacement TestNovia YunitazamiAinda não há avaliações

- Zoonotic Diseases From HorsesDocumento12 páginasZoonotic Diseases From HorsesSandra Ximena Herreño MikánAinda não há avaliações

- PsychometricsDocumento4 páginasPsychometricsCor Villanueva33% (3)

- Final Test General English TM 2021Documento2 páginasFinal Test General English TM 2021Nenden FernandesAinda não há avaliações

- Manalili v. CA PDFDocumento3 páginasManalili v. CA PDFKJPL_1987100% (1)

- Verb To Be ExerciseDocumento6 páginasVerb To Be Exercisejhon jairo tarapues cuaycalAinda não há avaliações

- A Practical Guide To Transfer Pricing Policy Design and ImplementationDocumento11 páginasA Practical Guide To Transfer Pricing Policy Design and ImplementationQiujun LiAinda não há avaliações

- DE1734859 Central Maharashtra Feb'18Documento39 páginasDE1734859 Central Maharashtra Feb'18Adesh NaharAinda não há avaliações

- Wastewater Treatment: Sudha Goel, Ph.D. Department of Civil Engineering, IIT KharagpurDocumento33 páginasWastewater Treatment: Sudha Goel, Ph.D. Department of Civil Engineering, IIT KharagpurSubhajit BagAinda não há avaliações

- Dye-Sensitized Solar CellDocumento7 páginasDye-Sensitized Solar CellFaez Ahammad MazumderAinda não há avaliações

- Delegated Legislation in India: Submitted ToDocumento15 páginasDelegated Legislation in India: Submitted ToRuqaiyaAinda não há avaliações

- Executive SummaryDocumento3 páginasExecutive SummarySofia ArissaAinda não há avaliações

- Community Service Learning IdeasDocumento4 páginasCommunity Service Learning IdeasMuneeb ZafarAinda não há avaliações

- Qafqaz UniversityDocumento3 páginasQafqaz UniversityQafqazlife QUAinda não há avaliações

- Literatures of The World: Readings For Week 4 in LIT 121Documento11 páginasLiteratures of The World: Readings For Week 4 in LIT 121April AcompaniadoAinda não há avaliações

- Journal Entry EnrepDocumento37 páginasJournal Entry Enreptherese lamelaAinda não há avaliações

- Spice Processing UnitDocumento3 páginasSpice Processing UnitKSHETRIMAYUM MONIKA DEVIAinda não há avaliações

- Past Simple of BeDocumento2 páginasPast Simple of BeRoxana ClepeAinda não há avaliações