Escolar Documentos

Profissional Documentos

Cultura Documentos

160.49-PW14york Solid State Starter

Enviado por

Awo Orumila GiraldolegraDireitos autorais

Formatos disponíveis

Compartilhar este documento

Compartilhar ou incorporar documento

Você considera este documento útil?

Este conteúdo é inapropriado?

Denunciar este documentoDireitos autorais:

Formatos disponíveis

160.49-PW14york Solid State Starter

Enviado por

Awo Orumila GiraldolegraDireitos autorais:

Formatos disponíveis

Supersedes: Nothing

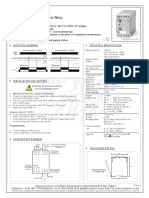

WIRING DIAGRAM

YORK SOLID STATE STARTER

MILLENNIUM MODEL YK

(STYLE C) CHILLERS

PRODUCT DRAWING

YORK INTERNATIONAL CORPORATION

P.O. Box 1592, YORK, PA 17405

CONTRACTOR _______________________

ORDER NO. __________________________

YORK CONTRACT NO. _________________

YORK ORDER NO. _____________________

REFERENCE

DATE ________

FORM 160.49-PW14 (897)

PURCHASER ____________________________________________

JOB NAME _______________________________________________

LOCATION _______________________________________________

ENGINEER ______________________________________________

APPROVAL

DATE ________

CONSTRUCTION

DATE ________

JOB DATA:

CHILLER MODEL NO. ________________________ NO. OF UNITS ________________________

SOLID STATE STARTER, MODEL NO. SSS ________ LK ________ A

MOTOR / STARTER POWER ______ VOLTS, 3-PHASE, ______ HERTZ

OPTIONAL FACTORY INSTALLED DISCONNECT SWITCH _________ AMPS

NOTES:

1. Field Wiring to be in accordance with the latest edition of

the National Electrical Code as well as all other applicable codes and specifications.

2. Numbers along the left side of the elementary diagram

are line identification numbers. The numbers along the

right side indicate the line number location of relay contacts. An underlined contact location signifies a normally

closed contact.

3. Terminal board connection points are indicated by numbers within a square i.e. 1TB

15

Main power connection points are indicated by numbers

within a hexagon i.e. L2

Component terminal markings are indicated by numbers

within a circle i.e. 2

Numbers adjacent to circuit lines are the circuit identification numbers.

4. Terminals L1, L2 & L3 are the main power input terminals

and are field connected (see Note 7). Terminals T1, T2 &

T3 are the compressor motor load power terminals and

are factory connected.

5. The three phase solid state motor overload protection

system provides compressor motor overcurrent protection at 105% Full Load Amps.

6. See YORK Control Center Wiring Diagram Product Drawing Form 160.49-PW8.

7. See Field Connections Wiring Diagram, Product Drawing Form 160.49-PW11 for details on the following items:

main (if applied) wiring location; power wiring ampacity;

line side lug sizes; branch circuit overcurrent protection

device(s) (fuse/breaker) sizing; power and control wiring

harnesses that require field connection (at extra cost) on

units shipped knocked down (see Note 13).

8. Starter incoming power wiring location, Model YK Full

Load Amps (FLA), Locked Rotor Amps (LRA), inrush

amps, and unit dimensions with YORK Solid State Starter

are per Product Drawing 160.49-PA1.

9. Starter approx. overall dimensions are:

26LK / 33LK 35" wide x 25-1/2" high x 12" deep; weight

is approx. 294 lbs. with transformer. See

Notes 7 & 8.

10. The starter will not apply power to the compressor motor

if the ambient air temperature is higher than 110F. The

starter cooling pump will begin to run when the compressor motor is started, and continue to run while the

compressor motor is operating. When the compressor

motor is de-energized, the cooling pump will continue

to run until the SCR temperature is reduced to 110F.

11. The short circuit withstand capacity, as tested per U.L.

Standard 508 (13th Edition), para. 31 at 480 volts, in

RMS (Root mean Square equals .707 x peak current),

symmetrical current are: SSS 26LK and SSS 33LK,

42,000 amps. The short circuit withstand capacity of

the YORK SOLID STATE STARTER with optional disconnect switch, as tested per U.L. standard 508 (13th

Edition), para. 31 at: 200 - 480 volts see above. CSA

approved for 600 volts SSS 26LK, 25,000 amps. Disconnect switch not available for SSS 33LK.

12. The allowable voltage* range for application of the

starter is the same as the compressor motor:

EXTREME

RATED

NAMEPLATE

OPERATING VOLTAGE

VOLTAGE MOTOR VOLTAGE

LOWEST HIGHEST

60

460

460 or 480

414

508

60

575

575 or 600

518

635

50

380

380

342

402

50

400

380

360

423

50

415

415

374

440

* See Form 160.49-PW11, Note 19, for main power transformer.

FREQ.

HZ

13. The YORK Solid State Starter is C.S.A. certified (all 60

Hz models) and U.L. approved (all 60 Hz models, except 575 volts -58) when factory applied to YK units.

Units shipped knocked-down will not have C.S.A. or

U.L. label.

14. A 3-phase undervoltage safety control (80% dropout

voltage, 88% pickup voltage) is furnished as a standard part of the YORK Control Center.

15. If semi-conductor fuses (branch circuit) are furnished

(by others) instead of time delay type (by others) SCR

max. l2t (non-repetitive surge rating at 60 Hz half wave)

for fuse coordination: SSS 26LK, 3,370,000 (amp)2 sec.;

SSS 33LK, 6,845,000 (amp)2 sec.

LD02326

LD02327

CONNECTION DIAGRAM

(NOTES 3 & 4)

LD02328

YORK INTERNATIONAL

FORM 160.49-PW14

ELEMENTARY DIAGRAM

(NOTES 2 & 3)

LD02329

LD02330

YORK INTERNATIONAL

SOLID STATE STARTER

Type Starting Reduced voltage; soft start; controlled inrush maintains the motor current at a constant level throughout the acceleration period, using six silicon controlled rectifiers.

Enclosure NEMA I, ventilated; hinged door with lock and

key latch; for indoor location.

Cooling System Water cooled; unit mounted, factory

wired, inherently protected, 115V, 1/22 HP pump; unit

mounted, cleanable heat exchanger.

Mounting Unit mounted on compressor motor at the factory. Starter factory wired to YORK control center, oil pump

motor starters and compressor motor and cooling pump

motor.

Meters

AMMETER Simultaneous three phase digital readout

via MicroComputer Control Center. Three current transformers provide isolated sensing. Accuracy is typically

3% of full scale. Scales: 26LK 0-2800A, 33LK 0-3500A.

VOLTMETER Simultaneous three phase, digital readout via MicroComputer Control Center. Three phase potential transformer provides isolated sensing. Accuracy

is typically 3% of full scale. Scale: 0 - 700V for 380 - 600V

starters.

ELAPSED TIME METER Digital readout of elapsed running time (0 - 65,535 hours resetable) via MicroComputer

Control Center.

Terminal Lugs Pressure type (solderless), bolted connector, tin plated aluminum lugs for incoming three phase

power line (copper conductors only) connections and system grounding.

Disconnect Switch Optional unit mounted factory wired

disconnects available for SSS 26LK model.

PROTECTIVE DEVICES AND

SERVICE INDICATORS (LED TYPE)

Motor Overcurrent Protection Three-leg sensing solid

state current overloads with indicating light and reset button.

Ambient temperature compensated protection system provides compressor motor overcurrent protection at 105% full

load current and at 150% of Start current setting. Overload light indicates overcurrent condition has stopped the

starter and chiller.

Phase Rotation & Loss Protection circuit and indicator

light. Monitors phase rotation and detects a loss of phase.

This protects the motor from running backwards and from

starting if single phasing is detected (or fuse is blown).

High Temperature SCR heat sink high temperature safety

protection system with three thermistors (one per phase).

High Temp indicating light and reset button. Shuts down

the starter and chiller, if temperature exceeds safe operating

levels. Inhibits startup until temperature falls to an acceptable level.

Transient Overvoltage dv/dt rate of rise protection for the

SCRs is furnished by a snubber resistor - capacitor (R-C)

P.O. Box 1592, YORK, Pennsylvania USA 17405-1592

Copyright by YORK International Corporation 1997

Form 160.49-PW14 (897)

Supersedes: Nothing

network. It prevents false firing of the SCRs and reduces the

repetitive peak transient voltage (from incoming power line).

Out-Of-Phase Re-energization Protection (Power Fault)

Incoming power line momentary interruption (one electrical

cycle duration detected) circuitry to shutdown the starter and

chiller. Disconnects starter within 3-1/2 electrical cycles.

Auto-reset, restarting unit automatically once fault has

cleared. Prevents abnormally high inrush currents, (resulting in high transient motor shaft torque) that can be produced in the motor when it is re-energized soon after a power

interruption. POWER FAULT indicator is lit and maintained

until reset.

Locked Rotor Protection If the motor is stalled and will

not come up to speed, a timer (see below) will shut down the

starter and chiller after approximately 40 seconds.

105% Motor Current Light Indicates the compressor motor

current has exceeded 105% full load amps and the 40 second overload timer has started. If for any reason, the compressor motor does not come up to speed, timer will shutdown the starter and chiller after approximately 40 seconds.

This provides an incomplete start sequence function.

Out-of-Lock Light Indicates excessive input line-to-line

voltage distortion and initiates system shutdown.

Starter Fault Light Indicates the compressor motor current has exceeded 150% of starting current and the one

second overload timer has started; timer shuts down the

starter and chiller.

Undervoltage Safety Prevents startup or causes shutdown if the input line to line voltage (any phase) drops below

80% of the nominal line voltage. Safety is reset when input

voltage rises to 88% of nominal line voltage. Displayed on

MicroComputer Control Center readout.

Phase Current Unbalance Causes system shutdown if

the percent current unbalance exceeds 30% while operating

at or above 80% FLA. Displayed on MicroComputer Control

Center readout.

Fusing Starter three phase control circuit fuse holders

with 500 volt dual element fuses for 380 thru 460 volts or 600

volt single element fuses for 575 volts. Protection for gate

driver voltmeter transformer, oil pump motor supply and

control transformer.

Interlocks A panel shutdown relay provides positive shutdown of the chiller on any starter safety control shutdown;

any chiller safety or operating control shutdown, through the

YORK control center, will stop the starter via starter control

signal. All interlocks between the YORK control center and

starter are furnished completely factory wired.

NOTE: Indicating lights and reset button are on the logic

board inside the MicroComputer Control Center.

CONTROL POWER SUPPLY

2.0 KVA 115 volt, control power transformer (on side of

starter) with 20 amp secondary fuse (located within Solid

State Starter). Provides control power for starter, YORK control center and starter cooling pump power; completely factory installed and wired.

Subject to change without notice. Printed in USA

ALL RIGHTS RESERVED

Você também pode gostar

- De Lux Sistem PartsDocumento58 páginasDe Lux Sistem PartsSaul acostaAinda não há avaliações

- RLC PRC005 E4 - 0110Documento60 páginasRLC PRC005 E4 - 0110jefhdez0% (1)

- BE YK Res SG PDFDocumento12 páginasBE YK Res SG PDFAhmed GamalAinda não há avaliações

- Service Information: GeneralDocumento2 páginasService Information: GeneralAbdulSattarAinda não há avaliações

- TECS Water Cooled ChillerDocumento8 páginasTECS Water Cooled Chillerntt_121987Ainda não há avaliações

- Branch Leaflet TECS-WDocumento12 páginasBranch Leaflet TECS-WAlfin khoeril UmamAinda não há avaliações

- Field Connections Model Yk Chillers (Style F and G) With Variable Speed DriveDocumento10 páginasField Connections Model Yk Chillers (Style F and G) With Variable Speed DriveJose CuevasAinda não há avaliações

- HTTP Cgproducts - Johnsoncontrols.com YorkDoc SI0261.PDF#XML HTTP Cgproducts - Johnsoncontrols.com Search Lit - Aspx CMD Pdfhits& DocId 12037& Index C Inetpub Wwwroot 72.3Documento2 páginasHTTP Cgproducts - Johnsoncontrols.com YorkDoc SI0261.PDF#XML HTTP Cgproducts - Johnsoncontrols.com Search Lit - Aspx CMD Pdfhits& DocId 12037& Index C Inetpub Wwwroot 72.3danyelstoica100% (1)

- Chiller RATINGREPORTDocumento3 páginasChiller RATINGREPORTv6656Ainda não há avaliações

- Rtaa SB 20Documento5 páginasRtaa SB 20kulilin1100% (1)

- Lennox Certified VRF Brochure Spanish V6Documento10 páginasLennox Certified VRF Brochure Spanish V6Ariel Calero0% (1)

- SB0018: Adding Line Inductor to Variable Speed Oil Pump DriveDocumento2 páginasSB0018: Adding Line Inductor to Variable Speed Oil Pump DrivemikenilsonAinda não há avaliações

- ProgramaciAn Tarjeta Simplicity Jhonson ControlsDocumento22 páginasProgramaciAn Tarjeta Simplicity Jhonson ControlsMario CruzAinda não há avaliações

- Multiaqua Products CatalogDocumento418 páginasMultiaqua Products Cataloge-ComfortUSAAinda não há avaliações

- Literature Supplement: Form Number: 160.46-OM3.1 (LS15) 1104 Supersedes: 160.46-OM3.1 (SB9 & SB11)Documento2 páginasLiterature Supplement: Form Number: 160.46-OM3.1 (LS15) 1104 Supersedes: 160.46-OM3.1 (SB9 & SB11)Kannan Krishnamoorthy100% (1)

- HydroBall Operational ManualDocumento12 páginasHydroBall Operational ManualpostboxsgAinda não há avaliações

- Westinghouse R-410A Package Unit Service ManualDocumento118 páginasWestinghouse R-410A Package Unit Service ManualWisam Ankah0% (1)

- YMC Water-Cooled Magnetic Centrifugal Chiller: Cooling Capacities From 800 KW To 3600 KWDocumento2 páginasYMC Water-Cooled Magnetic Centrifugal Chiller: Cooling Capacities From 800 KW To 3600 KWAlessandroAinda não há avaliações

- 201.28-EG1Documento56 páginas201.28-EG1Time To Use BrainAinda não há avaliações

- CTV SLB041 en - 06292020Documento2 páginasCTV SLB041 en - 06292020Nguyen ThuongAinda não há avaliações

- Brochure For York ChillerDocumento8 páginasBrochure For York ChillervenkatearAinda não há avaliações

- Dunham-Bush AFHX-6SR-77-191TRDocumento28 páginasDunham-Bush AFHX-6SR-77-191TRBaltik2672Ainda não há avaliações

- Ge - Electronic - Ice - Maker Maquina de Hielo GEDocumento12 páginasGe - Electronic - Ice - Maker Maquina de Hielo GEEdison EspinalAinda não há avaliações

- YcivDocumento334 páginasYcivrodrigomalvon100% (2)

- BE YCAL Chiller Specs-2Documento106 páginasBE YCAL Chiller Specs-2Diegol ErnestoAinda não há avaliações

- Starters For Centrifugal Chillers: Installation, Operation and Maintenance ManualDocumento56 páginasStarters For Centrifugal Chillers: Installation, Operation and Maintenance ManualMuhammad Javed BhattiAinda não há avaliações

- Active Magnetic BearingDocumento7 páginasActive Magnetic BearingsomendratrivediAinda não há avaliações

- Installation, Operation & Troubleshooting Guide for TI 2ACE Motor Protection ModulesDocumento8 páginasInstallation, Operation & Troubleshooting Guide for TI 2ACE Motor Protection Modulesghiles100% (1)

- Bas SVX08D E4 - 0111Documento80 páginasBas SVX08D E4 - 0111Vinod NairAinda não há avaliações

- Hrol - 19DVG41G43 700RTDocumento5 páginasHrol - 19DVG41G43 700RTGohds100% (1)

- Field Connections Diagram For Ymc Model A Chiller With M1 CompressorDocumento12 páginasField Connections Diagram For Ymc Model A Chiller With M1 CompressorJose CuevasAinda não há avaliações

- Self-Contained Air Conditioners with Water-Cooled CondensersDocumento19 páginasSelf-Contained Air Conditioners with Water-Cooled CondensersFadliAinda não há avaliações

- Carrier S.A. Liste de Pieces Spare Parts List: REF: 30HXC080-A-901 - EE - Standard Unit Date: 11/09/00Documento1 páginaCarrier S.A. Liste de Pieces Spare Parts List: REF: 30HXC080-A-901 - EE - Standard Unit Date: 11/09/00Luciano Lopes SimõesAinda não há avaliações

- Iom Enfriador CgakDocumento32 páginasIom Enfriador CgakDaniel Carretero100% (1)

- 30g, H-8t Carrier ChillerDocumento122 páginas30g, H-8t Carrier ChillerAwo Orumila Giraldolegra100% (1)

- Trane Education Price ListDocumento19 páginasTrane Education Price Listramadan rashad100% (2)

- Product Drawing: MillenniumDocumento13 páginasProduct Drawing: Millenniumjuan991Ainda não há avaliações

- 23xrv 3ssDocumento154 páginas23xrv 3ssLouie DupayaAinda não há avaliações

- Baldor Motor Lubrication RecommendationsDocumento122 páginasBaldor Motor Lubrication RecommendationsjoelAinda não há avaliações

- RLC Svu01b E4 - 06012006Documento60 páginasRLC Svu01b E4 - 06012006YAIR ANDRES BARON PEÑAAinda não há avaliações

- York Models 0157 0267 PDFDocumento308 páginasYork Models 0157 0267 PDFĐặng Phi LongAinda não há avaliações

- Rotary Screw Chillers from 500 to 1100 TonsDocumento24 páginasRotary Screw Chillers from 500 to 1100 TonsWidya PutraAinda não há avaliações

- Turbocor Compressor - Service - HireDocumento4 páginasTurbocor Compressor - Service - Hireinfo3903Ainda não há avaliações

- Progress in Refrigeration Science and Technology: Proceedings of the XIth International Congress of Refrigeration, Munich, 1963No EverandProgress in Refrigeration Science and Technology: Proceedings of the XIth International Congress of Refrigeration, Munich, 1963Ainda não há avaliações

- Structure Maintainer, Group H (Air Conditioning & Heating): Passbooks Study GuideNo EverandStructure Maintainer, Group H (Air Conditioning & Heating): Passbooks Study GuideAinda não há avaliações

- 160 80-PW3Documento5 páginas160 80-PW3juan991Ainda não há avaliações

- Eac 805Documento1 páginaEac 805Charles TineoAinda não há avaliações

- Controlador Bomba Jockey Fta 550fDocumento7 páginasControlador Bomba Jockey Fta 550fRubén VélezAinda não há avaliações

- Standard Submittal PackageDocumento10 páginasStandard Submittal PackageTarek AsfourAinda não há avaliações

- 160 54-PW4Documento5 páginas160 54-PW4Jose CuevasAinda não há avaliações

- Avr 100s IngleseDocumento65 páginasAvr 100s IngleseVedran GaćeAinda não há avaliações

- JPC ManualDocumento6 páginasJPC ManualJaluadi AdiAinda não há avaliações

- SCR Power Controller ManualDocumento28 páginasSCR Power Controller ManualJorge PeraltaAinda não há avaliações

- IM05805023K - XTJP - Op - Manual - RH2 - 06-07-12Documento12 páginasIM05805023K - XTJP - Op - Manual - RH2 - 06-07-12melgarcia829Ainda não há avaliações

- Ramde Motor Protection RelayDocumento8 páginasRamde Motor Protection RelayishhumzpAinda não há avaliações

- Catalogo Tecnico InglesDocumento52 páginasCatalogo Tecnico InglesIngenieria Soporte Técnico SolconAinda não há avaliações

- LT6 CatalogueDocumento24 páginasLT6 CatalogueMohamed Elsayed HasanAinda não há avaliações

- Combined Overcurrent and Earth-fault Relay GuideDocumento12 páginasCombined Overcurrent and Earth-fault Relay GuideNesarkiran BagadeAinda não há avaliações

- Motor Protection ManualDocumento20 páginasMotor Protection ManualNirmal mehtaAinda não há avaliações

- Steps For Android Phones. 1. Enter On The Setting AppDocumento2 páginasSteps For Android Phones. 1. Enter On The Setting AppAwo Orumila GiraldolegraAinda não há avaliações

- Intro To IfaDocumento133 páginasIntro To IfaIfalase Fagbenro95% (154)

- Technician TestDocumento2 páginasTechnician TestAwo Orumila GiraldolegraAinda não há avaliações

- Ogunda Meji 2Documento28 páginasOgunda Meji 2Awo Orumila GiraldolegraAinda não há avaliações

- 160.81-RP3 5-07 YR Style A, B and C Graphic Control CenterDocumento12 páginas160.81-RP3 5-07 YR Style A, B and C Graphic Control CenterAwo Orumila GiraldolegraAinda não há avaliações

- Filter Size Quantity Unit #: 24x24x1 1 17x22x1 1 19 1/2x23 1/2x1 1 16x25x2 4 20x20x1 1Documento74 páginasFilter Size Quantity Unit #: 24x24x1 1 17x22x1 1 19 1/2x23 1/2x1 1 16x25x2 4 20x20x1 1Awo Orumila GiraldolegraAinda não há avaliações

- Customers 2Documento63 páginasCustomers 2Awo Orumila GiraldolegraAinda não há avaliações

- Ogunda Meji 3Documento15 páginasOgunda Meji 3Awo Orumila Giraldolegra100% (1)

- Synopsis The Readings: Ogunda MejiDocumento26 páginasSynopsis The Readings: Ogunda MejiAwo Orumila Giraldolegra89% (9)

- Ogunda Meji 2Documento28 páginasOgunda Meji 2Awo Orumila GiraldolegraAinda não há avaliações

- FirmasDocumento3 páginasFirmasAwo Orumila GiraldolegraAinda não há avaliações

- Horizontal Centrifugal PumpsDocumento22 páginasHorizontal Centrifugal PumpsDenstar Ricardo SilalahiAinda não há avaliações

- 160.47-PW6 Solid State StarterDocumento6 páginas160.47-PW6 Solid State StarterAwo Orumila GiraldolegraAinda não há avaliações

- Model YS Rotary Screw Liquid Chillers Design Level E: FORM 160.80-EG1Documento56 páginasModel YS Rotary Screw Liquid Chillers Design Level E: FORM 160.80-EG1Awo Orumila GiraldolegraAinda não há avaliações

- Cooling Tower FundamentalsDocumento117 páginasCooling Tower FundamentalspadzicAinda não há avaliações

- H0015 EXPEDITED Fax Appbirth CertDocumento3 páginasH0015 EXPEDITED Fax Appbirth CertAwo Orumila GiraldolegraAinda não há avaliações

- Carrier 30g Ecologic Chillers Series 1,2Documento100 páginasCarrier 30g Ecologic Chillers Series 1,2pkumar68Ainda não há avaliações

- 160.80-RP1 10-99 YS Style E 100 To 675 TonsDocumento20 páginas160.80-RP1 10-99 YS Style E 100 To 675 TonsAwo Orumila GiraldolegraAinda não há avaliações

- H0015 EXPEDITED Fax Appbirth CertDocumento3 páginasH0015 EXPEDITED Fax Appbirth CertAwo Orumila GiraldolegraAinda não há avaliações

- 160.81-RP3 5-07 YR Style A, B and C Graphic Control CenterDocumento12 páginas160.81-RP3 5-07 YR Style A, B and C Graphic Control CenterAwo Orumila GiraldolegraAinda não há avaliações

- Model YS Rotary Screw Liquid Chillers Design Level E: FORM 160.80-EG1Documento56 páginasModel YS Rotary Screw Liquid Chillers Design Level E: FORM 160.80-EG1Awo Orumila GiraldolegraAinda não há avaliações

- Type AH Pumps IOMDocumento8 páginasType AH Pumps IOMAwo Orumila GiraldolegraAinda não há avaliações

- Basic Obi Abata DivinationDocumento20 páginasBasic Obi Abata DivinationWilliam Litwaitis100% (20)

- Giraldo Legra ResumeDocumento2 páginasGiraldo Legra ResumeAwo Orumila GiraldolegraAinda não há avaliações

- Giraldo Legra ResumeDocumento2 páginasGiraldo Legra ResumeAwo Orumila GiraldolegraAinda não há avaliações

- H0015 EXPEDITED Fax Appbirth CertDocumento3 páginasH0015 EXPEDITED Fax Appbirth CertAwo Orumila GiraldolegraAinda não há avaliações

- 30g, H-8t Carrier ChillerDocumento122 páginas30g, H-8t Carrier ChillerAwo Orumila Giraldolegra100% (1)

- H0015 EXPEDITED Fax Appbirth CertDocumento3 páginasH0015 EXPEDITED Fax Appbirth CertAwo Orumila GiraldolegraAinda não há avaliações

- 30g, H-8t Carrier ChillerDocumento122 páginas30g, H-8t Carrier ChillerAwo Orumila Giraldolegra100% (1)

- E85010-0099 - EST3 Submittal GuideDocumento64 páginasE85010-0099 - EST3 Submittal GuideCleber Eduardo TodescoAinda não há avaliações

- Sensors & ActuatorsDocumento67 páginasSensors & Actuatorsmahendra naik100% (1)

- XW20LR XW20LRH ManualDocumento5 páginasXW20LR XW20LRH Manualshram444aaAinda não há avaliações

- TRD 24VDC SC Al TtiDocumento2 páginasTRD 24VDC SC Al TtiplwrlvzxaocrejwruoAinda não há avaliações

- DIN 72552 - WikipediaDocumento7 páginasDIN 72552 - Wikipediashalyn matines dabulamanziAinda não há avaliações

- Programación de Control de Temperatura OMRON, Modelo E5CC-E5ECDocumento336 páginasProgramación de Control de Temperatura OMRON, Modelo E5CC-E5ECReinaldo Cordero100% (1)

- Surge Voltage ProtectionDocumento22 páginasSurge Voltage Protectionrajpre1213Ainda não há avaliações

- Electric Solenoid Gear Shifting System 1Documento5 páginasElectric Solenoid Gear Shifting System 1Vos RobertAinda não há avaliações

- Melag Vacu 23-31 - Fault DiagnosisDocumento25 páginasMelag Vacu 23-31 - Fault DiagnosisFrepa_AL100% (3)

- SacoDocumento44 páginasSacorasheed3130% (1)

- JVC TV Power Supply Training GuideDocumento110 páginasJVC TV Power Supply Training GuidePanagiotis Argyropoulos60% (5)

- 7catálogo Magnet Load MonitorDocumento2 páginas7catálogo Magnet Load Monitoredark2009Ainda não há avaliações

- Effect of Inrush Current On Transformer ProtectionDocumento27 páginasEffect of Inrush Current On Transformer ProtectiontusharlilaniAinda não há avaliações

- Meter Relays - Accurate Monitoring and Control in a Compact PackageDocumento7 páginasMeter Relays - Accurate Monitoring and Control in a Compact PackageMok YukAinda não há avaliações

- Abb Acs550 ManualDocumento259 páginasAbb Acs550 ManualSameer Noida100% (1)

- Automatic Reclosing by Basler Electric PDFDocumento35 páginasAutomatic Reclosing by Basler Electric PDFKrishna Venkataraman100% (2)

- Ford Edge 2008-2009 PDFDocumento462 páginasFord Edge 2008-2009 PDFEnedine RamirezAinda não há avaliações

- 11 KV Bay EquipmentDocumento22 páginas11 KV Bay EquipmentSudhir ShindeAinda não há avaliações

- AMX 4+ Error - ListDocumento18 páginasAMX 4+ Error - Listmasroork_293% (15)

- 350ref AqDocumento334 páginas350ref AqSujoy PaulAinda não há avaliações

- General Catalogue 2009-2010Documento181 páginasGeneral Catalogue 2009-2010Leed ENAinda não há avaliações

- How To Read Electronic Circuit Diagrams (1970)Documento225 páginasHow To Read Electronic Circuit Diagrams (1970)smupy_122-1100% (3)

- Manual de Instalacion CrimeStopper SP 500Documento32 páginasManual de Instalacion CrimeStopper SP 500emaffeiAinda não há avaliações

- Rockwell Automation Library of Process Objects Release NotesDocumento33 páginasRockwell Automation Library of Process Objects Release NotesSi Makee KoAinda não há avaliações

- Refrigeration and Air Conditioning Motor Types GuideDocumento10 páginasRefrigeration and Air Conditioning Motor Types GuideRavi Anand PalAinda não há avaliações

- Type: 45TCR: PT100 Temperature Control RelayDocumento1 páginaType: 45TCR: PT100 Temperature Control RelaySunil SanthoshAinda não há avaliações

- Control Relay: NKG3-M Time SwitchDocumento2 páginasControl Relay: NKG3-M Time SwitchRafatAinda não há avaliações

- NV and Vanos DME PinoutsDocumento4 páginasNV and Vanos DME Pinoutsrobertobaggio2009Ainda não há avaliações