Escolar Documentos

Profissional Documentos

Cultura Documentos

Compact PressMaster Control System For Mechanical Stamping Presses

Enviado por

Jorge RushTítulo original

Direitos autorais

Formatos disponíveis

Compartilhar este documento

Compartilhar ou incorporar documento

Você considera este documento útil?

Este conteúdo é inapropriado?

Denunciar este documentoDireitos autorais:

Formatos disponíveis

Compact PressMaster Control System For Mechanical Stamping Presses

Enviado por

Jorge RushDireitos autorais:

Formatos disponíveis

PRODUCT PROFILE

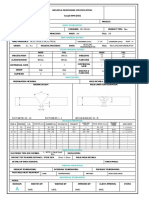

Compact PressMaster Control System for

Mechanical Stamping Presses

Reduce operating costs and downtime with reliable and

flexible programmable press controls.

Compact PressMaster

Functionality

The Compact PressMaster system is a

standard, but expandable, press control

system. The standard/optional

functions include:

Safety Interlocks and Light Curtain

Interface

Clutch/Brake Safety Control with

Inch, Single Stroke, Continuous, Modes

of Operation, including a mode select

key switch

Main Motor Control, including a

25 Hp reversing motor starter and

forward/stop/reverse pushbuttons

Lubrication Control, including a 1 Hp

motor starter and lube verification

monitor

60 Amp / 460V Disconnect

Press Mountable, NEMA 12 Rated

Industrial Enclosure

Operator Fault and Prompt Messages,

Alarm Status Operator Screens on a

PanelView Display

One Industrial Magnetic Absolute

Encoder

Brake Time Monitoring and 90 Degree

Stop Test

Interface for One Run Station with

Anti-Tiedown Protection

Press Stroking Anti-Repeat and Top

Stop Overrun Protection

Clutch/Brake and Counterbalance Air

Pressure Monitoring

User Immediate and Top Stop Control

Interlocks

4 Programmable Limit Switch Outputs

Production counters & maintenance

timers

Overview

The Rockwell Automation Compact PressMaster System is a cost competitive,

programmable controller-based system used for the control and monitoring of

mechanical stamping presses. Reduce cost and risk by purchasing a complete

system, pre-wired and tested, ready for installation. The system is designed to

modernize your press controls, increase control system reliability, and reduce

downtime by providing comprehensive operator diagnostics. Compact

PressMaster provides press users, rebuilders, and OEMS a low cost PLC based

control system to remain competitive and reduce risk.

System Description

The Compact PressMaster System is a pre-engineered press control system based

on standard Rockwell Automation components available locally and supported

worldwide. Compact PressMaster Systems provide press control, operator

interface with comprehensive diagnostics, expandability, and motor controls in a

single integrated package. The system is provided, ready to install, with a

complete set of documentation.

The Compact PressMaster System is based on a Bulletin 6556 clutch/brake

control with dual processors and software designed by Rockwell Automation to

help customers comply with ANSI B11.1, OSHA 1910.217, CSAZ142, and EN

954. Allen-Bradley motor controls and an Allen-Bradley PanelView

monochrome operator interface with keypad is included, to complete the system

and provide maximum reliability.

Compact PressMaster Control System

Results

Legacy Systems

A Compact PressMaster System will help provide the following:

Many systems in the field today are based on relays or "black box"

controls. These systems are often inflexible, difficult to

troubleshoot, limited in features, and expensive to maintain. The

Compact PressMaster solution provides a superior control system

with built-in flexibility, a substantial set of features and low

maintenance costs.

Reduced downtime through advanced diagnostic messages,

helpful operator prompts, and on-line control system

troubleshooting.

Reduced costs and improved system reliability through the use

of standard Rockwell Automation industrial control hardware,

field-proven application software, and a comprehensive

documentation package.

Increased operational flexibility and expandability, while

reducing costs and risk.

Optional Functionality

Manual or Automatic Slide Adjust

8 Channels of Die Protection

8 Programmable Limit Switch Outputs

Hydraulic Overload Control

Other Press Control Systems

Rockwell Automation offers a complete line of standard and

custom press and automation control solutions for the pressroom.

Solutions are available for a mechanical stamping press (gap,

straight side, transfer), tandem line, hydraulic press, forging presses,

die casting, feeder control, servo transfer feed, and other motion

control applications. The AxisPro inter-press automation motion

control systems and TandemPro supervisory systems designed to

provide line control and pressroom production data acquisition,

are also available. StamPro press control systems are also available

to provide customers a custom engineered solution, for total press

and automation control.

Light Curtains with muting

OEM packages

Interface to monitor or up to 4 run stations

Micro Inch Mode

Ethernet Connectivity

Other Options to Complete your Press

Control Requirements, Available from

Rockwell Automation

For More Information

Contact the local Rockwell Automation sales representative or

authorized Rockwell Automation distributor for a StamPro system

quotation worksheet. Complete the worksheet and return it to the

Rockwell Automation MetalForming Automation Control

Solutions team, using the telefax number or e-mail address listed

on the worksheet. The worksheet will be used as the basis for a

proposal for the configuration selected. Further information is also

available on the Internet at

www.rockwellautomation.com/metalforming

Operator Run Stands

CAM Switch Boxes

Field Devices

Professional Installation and Commissioning Services

Allen-Bradley, AxisPro PanelView, StamPro and TandemPro are trademarks of Rockwell Automation.

Trademarks not belonging to Rockwell Automation are property of their respective companies.

Publication EMSE00-AP007A-EN-P April 2007 - Supersedes Publication GMSE00-PP008C-EN-P May 2003 May 2003

Copyright 2007 Rockwell Automation, Inc. All Rights Reserved. Printed in USA.

Você também pode gostar

- Controls and Instrumentation - CompressedDocumento12 páginasControls and Instrumentation - CompressedCricri CriAinda não há avaliações

- Air Miser System Benefits MS129Documento4 páginasAir Miser System Benefits MS129Diego PareschiAinda não há avaliações

- 2016TMC-SchneiderElectricTMCSolutions Services and ExperienceDocumento4 páginas2016TMC-SchneiderElectricTMCSolutions Services and ExperienceIkhtiander IkhtianderAinda não há avaliações

- Technology Working For You.: Approved PrecisionDocumento11 páginasTechnology Working For You.: Approved PrecisionDavid Alejandro TellezAinda não há avaliações

- Form 6 Recloser Control: Maximum Functionality and Ultimate User ConfigurabilityDocumento4 páginasForm 6 Recloser Control: Maximum Functionality and Ultimate User ConfigurabilityJuan CoronelAinda não há avaliações

- DRV Masterdrives MC Catalog Da 65 3Documento224 páginasDRV Masterdrives MC Catalog Da 65 3bajricaAinda não há avaliações

- Rockwell TMC SolutionDocumento8 páginasRockwell TMC SolutionGavinsiauAinda não há avaliações

- Mae-Vbt 2011Documento3 páginasMae-Vbt 2011María Martz De GarcíaAinda não há avaliações

- International Network: The LEROY-SOMER OfferDocumento10 páginasInternational Network: The LEROY-SOMER OfferTibor DanielAinda não há avaliações

- 5939 VM600 Integrated-BrochureDocumento8 páginas5939 VM600 Integrated-BrochurescribdkhatnAinda não há avaliações

- CMCDocumento9 páginasCMCChuma KhanAinda não há avaliações

- Gas Turbine Pump Drive Integrated Control System: Petrotech Home PageDocumento4 páginasGas Turbine Pump Drive Integrated Control System: Petrotech Home Pagescribdkhatn100% (1)

- Turbomachinery Controls (Plantpax)Documento52 páginasTurbomachinery Controls (Plantpax)Ikhtiander Ikhtiander100% (2)

- Catalogo Completo Servomotores SiemensDocumento224 páginasCatalogo Completo Servomotores SiemensFabricioST100% (1)

- Hydro Turbine Speed Governing SystemDocumento12 páginasHydro Turbine Speed Governing SystemPatran ValentinAinda não há avaliações

- Varco SystemsDocumento34 páginasVarco SystemsJesus Oliveros100% (1)

- Receiving Elements: Instrumentation & ControlDocumento47 páginasReceiving Elements: Instrumentation & ControlSka dooshAinda não há avaliações

- Vacon 100 Flow BrochureDocumento12 páginasVacon 100 Flow BrochureZeh Garcia JuniorAinda não há avaliações

- Fal-Dou: (Dough Weight Control Solution)Documento4 páginasFal-Dou: (Dough Weight Control Solution)Rohit MehtaAinda não há avaliações

- Tia11 VPPM enDocumento2 páginasTia11 VPPM enelimecboyAinda não há avaliações

- Simocode ProDocumento34 páginasSimocode ProGregory KingAinda não há avaliações

- Ge Energy Opticomp Integrated Compressor Control SuiteDocumento8 páginasGe Energy Opticomp Integrated Compressor Control SuitemessaoudmasterAinda não há avaliações

- 6SE70 MC Catalog DA65.11 2004Documento241 páginas6SE70 MC Catalog DA65.11 2004chnanduAinda não há avaliações

- 635215952379094386498Documento128 páginas635215952379094386498bajricaAinda não há avaliações

- Hydro Turbine Speed Governing SystemDocumento12 páginasHydro Turbine Speed Governing SystemNaveen Kumar100% (1)

- HM 35-300 enDocumento24 páginasHM 35-300 enairshow19Ainda não há avaliações

- Danfos VFD BrochureDocumento20 páginasDanfos VFD Brochuresas999333Ainda não há avaliações

- B131CDocumento6 páginasB131CMarcelo SánchezAinda não há avaliações

- Danfoss VLT FC300 VLT Automation Drive DKDPB13C102Documento16 páginasDanfoss VLT FC300 VLT Automation Drive DKDPB13C102hoor24332Ainda não há avaliações

- Catálogo de Productos MurphyDocumento28 páginasCatálogo de Productos MurphyRené GPAinda não há avaliações

- Servo Hydraulic CTM 3000knDocumento23 páginasServo Hydraulic CTM 3000knMIGUEL LOPEZAinda não há avaliações

- Integrated Turbine-Compressor ControlDocumento8 páginasIntegrated Turbine-Compressor ControlAbdul RohmanAinda não há avaliações

- Blend MasterDocumento2 páginasBlend MastersaeedhoseiniAinda não há avaliações

- Selection of Instrumentation SystemDocumento39 páginasSelection of Instrumentation System1meander23100% (1)

- Axiomatic BrochureDocumento20 páginasAxiomatic Brochurecorsini999100% (1)

- CNC Controls Product OverviewDocumento9 páginasCNC Controls Product OverviewVikash YadavAinda não há avaliações

- 6P BSG Us PDFDocumento6 páginas6P BSG Us PDFdocrafiAinda não há avaliações

- Hydraulics SolutionsDocumento16 páginasHydraulics Solutionsmarcol705100% (1)

- Omron PLCDocumento17 páginasOmron PLCShahab AhmadaniAinda não há avaliações

- Over View On Section MillDocumento137 páginasOver View On Section MillMustafa Mahmoud AwwadAinda não há avaliações

- Cement Plant Control-FLSDocumento17 páginasCement Plant Control-FLSaizatmaricanAinda não há avaliações

- Ca0312a Test Measurement WebDocumento72 páginasCa0312a Test Measurement WebJohn Melanathy IIAinda não há avaliações

- Injection Molding ControlDocumento15 páginasInjection Molding ControlNalin T BandaraAinda não há avaliações

- BE SG RWF Frick II RotaryDocumento8 páginasBE SG RWF Frick II RotarygamunozdAinda não há avaliações

- Dresser-Rand Control Systems: Easy To Use, Understand and OperateDocumento6 páginasDresser-Rand Control Systems: Easy To Use, Understand and OperateNistha ChakrabortyAinda não há avaliações

- 505 Enhanced: Digital Control For Steam Turbines (With Redundancy)Documento5 páginas505 Enhanced: Digital Control For Steam Turbines (With Redundancy)kazmi81Ainda não há avaliações

- Micro Automation: Logo! Simply Different - Simply IngeniousDocumento16 páginasMicro Automation: Logo! Simply Different - Simply IngeniousJavier FloresAinda não há avaliações

- Pws 002712Documento4 páginasPws 002712Ronnie Hilda Edward SeliAinda não há avaliações

- PMSBDocumento4 páginasPMSBGoran JurisicAinda não há avaliações

- Control Systems Product GUIDE - Ing PDFDocumento2 páginasControl Systems Product GUIDE - Ing PDFtecnigenelecAinda não há avaliações

- Turbine Supervisory InstrumentsationDocumento52 páginasTurbine Supervisory InstrumentsationKarthi KeyanAinda não há avaliações

- Haake Polylab System: Torque Rheometer Haake RheocordDocumento12 páginasHaake Polylab System: Torque Rheometer Haake RheocordJorgeRiascosAinda não há avaliações

- Turbine Supervisory Instrumentation Selection Guide - RockwellDocumento52 páginasTurbine Supervisory Instrumentation Selection Guide - Rockwellhozipek100% (1)

- Pumping Machine Control SolutionsDocumento124 páginasPumping Machine Control SolutionsMihai ConstantinescuAinda não há avaliações

- Altivar 61 Variable Speed DriveDocumento8 páginasAltivar 61 Variable Speed DriveFarid SedekyAinda não há avaliações

- The CNC Handbook: Digital Manufacturing and Automation from CNC to Industry 4.0No EverandThe CNC Handbook: Digital Manufacturing and Automation from CNC to Industry 4.0Nota: 5 de 5 estrelas5/5 (1)

- Practical, Made Easy Guide To Building, Office And Home Automation Systems - Part OneNo EverandPractical, Made Easy Guide To Building, Office And Home Automation Systems - Part OneAinda não há avaliações

- The Modulus of Elasticity of Steel Is It 200 GPaDocumento8 páginasThe Modulus of Elasticity of Steel Is It 200 GPaPratik PatelAinda não há avaliações

- WPS Creation Sample ISODocumento1 páginaWPS Creation Sample ISOmusheerAinda não há avaliações

- Erol Et Al-2007-Developmental Medicine & Child NeurologyDocumento3 páginasErol Et Al-2007-Developmental Medicine & Child NeurologyJorge RushAinda não há avaliações

- Erol Et Al-2007-Developmental Medicine & Child NeurologyDocumento3 páginasErol Et Al-2007-Developmental Medicine & Child NeurologyJorge RushAinda não há avaliações

- LECTURE 2 Bending StressesDocumento11 páginasLECTURE 2 Bending StressesIvana DincicAinda não há avaliações

- B Boehler X 70-IG de en 5Documento1 páginaB Boehler X 70-IG de en 5Jorge RushAinda não há avaliações

- Poland 2025 - Full - Report PDFDocumento96 páginasPoland 2025 - Full - Report PDFJorge RushAinda não há avaliações

- 1 Guide For WPS PQR WPQR PDFDocumento6 páginas1 Guide For WPS PQR WPQR PDFmuhammadazhar100% (1)

- Business Feasibility Study OutlineDocumento14 páginasBusiness Feasibility Study OutlineMohamed AbbasAinda não há avaliações

- Matrix OrganizationsDocumento15 páginasMatrix Organizationsanil_USAinda não há avaliações

- DREHER - Press Linking Line - 1Documento1 páginaDREHER - Press Linking Line - 1Jorge RushAinda não há avaliações

- Design and Fabrication of IC Engine Powered Radio Control CarDocumento35 páginasDesign and Fabrication of IC Engine Powered Radio Control CarearneronAinda não há avaliações

- L740 Series Brochure l730Documento8 páginasL740 Series Brochure l730Jorge RushAinda não há avaliações

- Rexroth PressRexroth Press Automation Intelligent Press Transfer Solutions Automation Intelligent Press Transfer SolutionsDocumento4 páginasRexroth PressRexroth Press Automation Intelligent Press Transfer Solutions Automation Intelligent Press Transfer SolutionsJorge RushAinda não há avaliações

- V ProcessDocumento12 páginasV ProcessJorge RushAinda não há avaliações

- Learning To Solve Non-Routine Mathematical ProblemsDocumento12 páginasLearning To Solve Non-Routine Mathematical ProblemsJorge RushAinda não há avaliações

- MRO Spending, Unit Costs To Rise SharplyDocumento3 páginasMRO Spending, Unit Costs To Rise SharplyJorge RushAinda não há avaliações

- Focus No. 4 White GoodsDocumento68 páginasFocus No. 4 White GoodsJorge RushAinda não há avaliações

- Flyer 250kvaDocumento4 páginasFlyer 250kvaFianHidayat100% (1)

- Sec Murano 2009Documento444 páginasSec Murano 2009alex100% (2)

- Advanced Transportation Engineering... Mcq. Unit-IDocumento7 páginasAdvanced Transportation Engineering... Mcq. Unit-IAbhishek AbAinda não há avaliações

- 04 Information Systems Analysis DesignDocumento43 páginas04 Information Systems Analysis DesignsahrasaqsdAinda não há avaliações

- Guideline To Make and Understand Unit Test Case: 1. OverviewDocumento11 páginasGuideline To Make and Understand Unit Test Case: 1. OverviewDương DũngAinda não há avaliações

- Real-Time Object-Oriented Modeling: Tutorial StructureDocumento27 páginasReal-Time Object-Oriented Modeling: Tutorial StructureSatyender YadavAinda não há avaliações

- Java Applet NotesDocumento4 páginasJava Applet NotesSayani ChandraAinda não há avaliações

- Introduction To UMLDocumento33 páginasIntroduction To UMLsheheryarAinda não há avaliações

- Cruise Control, CVT and Shift Indicator, Engine ControlDocumento25 páginasCruise Control, CVT and Shift Indicator, Engine ControlNhật Đặng100% (1)

- Hino Ha6eti2 Bs II EngineDocumento77 páginasHino Ha6eti2 Bs II EngineMohan CharanchathAinda não há avaliações

- ISO 13849-1 - Anexo K - Representação Numerica MTTFDDocumento2 páginasISO 13849-1 - Anexo K - Representação Numerica MTTFDMarco Manuel Ascensão SilvaAinda não há avaliações

- Use Case Model of Crime Management SystemDocumento15 páginasUse Case Model of Crime Management SystemMuzaffar Salik80% (5)

- Activity #1.3: Advantages of C++ LanguageDocumento2 páginasActivity #1.3: Advantages of C++ Languagesay whhhuuutAinda não há avaliações

- BW ApplicationDeliveryPlatformConfigGuideDocumento82 páginasBW ApplicationDeliveryPlatformConfigGuidedanilo1529Ainda não há avaliações

- 5.1 IT Security Incidents (Computer and Internet Crime)Documento15 páginas5.1 IT Security Incidents (Computer and Internet Crime)Aung Ko Ko ZawAinda não há avaliações

- BTS Automation Approach: Why Automate?Documento8 páginasBTS Automation Approach: Why Automate?Namo SivayaAinda não há avaliações

- Core Components of TransportationDocumento1 páginaCore Components of TransportationJohn Mathew Alday BrionesAinda não há avaliações

- Capybara (Software)Documento4 páginasCapybara (Software)linda976Ainda não há avaliações

- Depth Control of Unmanned Free-Swimming Submersible (UFSS) VehicleDocumento14 páginasDepth Control of Unmanned Free-Swimming Submersible (UFSS) VehicleAsim FarooqAinda não há avaliações

- Computer Networks NoteDocumento38 páginasComputer Networks NoteSimple GuptaAinda não há avaliações

- BRKCLD-1003 (2018)Documento83 páginasBRKCLD-1003 (2018)Paul ZetoAinda não há avaliações

- Test Plan For Online Test GeneratorDocumento9 páginasTest Plan For Online Test GeneratorLucasAinda não há avaliações

- ME6703-CIMS Question BankDocumento9 páginasME6703-CIMS Question BankKanagarajAinda não há avaliações

- Azure Security Benchmark v3.0Documento290 páginasAzure Security Benchmark v3.0Harish DasariAinda não há avaliações

- Gopichand QADocumento4 páginasGopichand QAgopichand.dwhAinda não há avaliações

- How To Integrate Oracle APEX With SubversionDocumento19 páginasHow To Integrate Oracle APEX With SubversionMari MirandaAinda não há avaliações

- 5 Real Project Management Examples For Your Team: Leila CruzDocumento23 páginas5 Real Project Management Examples For Your Team: Leila CruzDieudonné AllaramadjiAinda não há avaliações

- Homogeneous+Charge+Compression+Ignition+ HCCI +enginesDocumento7 páginasHomogeneous+Charge+Compression+Ignition+ HCCI +engineschandruAinda não há avaliações

- CifDocumento4 páginasCifRonit jainAinda não há avaliações

- BNTU IKnezevicNPudarLMrdovicProceedingsDocumento8 páginasBNTU IKnezevicNPudarLMrdovicProceedingsMohamed AssabaaAinda não há avaliações