Escolar Documentos

Profissional Documentos

Cultura Documentos

Gail Case Study - Pata

Enviado por

hezron77Título original

Direitos autorais

Formatos disponíveis

Compartilhar este documento

Compartilhar ou incorporar documento

Você considera este documento útil?

Este conteúdo é inapropriado?

Denunciar este documentoDireitos autorais:

Formatos disponíveis

Gail Case Study - Pata

Enviado por

hezron77Direitos autorais:

Formatos disponíveis

CIMCON iRTU

OIL & GAS

APPLICATION NOTE

CIMCON PROTECTS PIPELINES

FROM CORROSION AT ONE OF

THE LARGEST PETROCHEMICAL

COMPLEX OF ASIA

Result: Predictable maintenance schedule and better pipe health management through

GPS guided true off potential measurement.

Introduction

The Project

The Customer: GAIL (INDIA) Limited is Indias flagship

Natural Gas company, integrating all aspects of Natural

Gas value chain.

In This SCADA System covers monitoring of around 80 TR

Units with 854 reference cells on CIMCON make Remote

Terminals. These TR units and RTUs comprise the

petrochemical Plant CP monitoring system.

GAIL's business portfolio includes:

5,800 km of Natural Gas high pressure trunk

pipeline with a capacity to carry 130 MMSCMD of

natural gas across the country,

7 LPG Gas Processing Units to produce 1.2

MMTPA of LPG and other liquid hydrocarbons,

north India's only gas based integrated

Petrochemical complex at Pata, India with a

capacity of producing 3,10,000 TPA of Polymers,

1922 km of LPG Transmission pipeline network

with a capacity to transport 3.8 MMTPA of LPG

30 oil and gas Exploration blocks and 3 Coal Bed

Methane Blocks

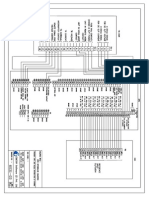

A SCADA network on a telephonic communication based

backbone was envisaged as a solution. A schematic

diagram of the system is attached herewith.

The Work

Design, execution and customization of the SCADA

system for cathodic protection of plant and hooking up of

the system with the Central CP monitoring system at GAIL

Petrochemical Complex located near PATA in Uttar

Pradesh, India.

The challenge

The Consultant: EILs (Engineers India Limited) field of

interest includes Petroleum Refineries, Pipeline, Oil & Gas

processing, petrochemicals, Oil & Gas Platforms etc.

The cathodic protection system with 854 reference cells

monitored more than 600 parameters and the data

collected from RTUs were distributed all over the plant.

EIL has 4300 assignments including 320 major projects,

successfully completed and operating smoothly. EIL has

45 petroleum refinery projects in different stages of

execution.

The proposed system was supposed to synchronize all the

TRUs through GPS technology. The interruption cycle of

all the 80 TRUs in the 5 Sq. KM plant area could be

programmed remotely. All the TRs built in GPS &

MODEMs could be used to acquire & control TRU data

and Off-Potential. The system had to undergo rigorous

testing

for

certification

from

EIL.

The turn over of the company in 2005 06 was $178

million and the profit was $ 32 million approximately.

This paper is produced for internal use at CIMCON.

www.cimconautomation.com

OIL & GAS

APPLICATION NOTE

The Solution

CIMCON offered CPSCANET software and telephone

communication (PSTN) enabled Remote Terminal Units to

ensure seamless data integration for monitoring.

CIMCON having its own development based in India,

Ahmedabad customized the CPSCANET software to suit

GAILs requirement. The software had mimics to represent

the transformer rectifier unit readings.

The Remote Terminal unit (RTU) should call back

central Monitoring computer station to report if at

least one of the monitored signals is outside set

limits. It shall be the report abnormal output

current, voltage, if those are the input signals

being monitored.

The RTU should dial three alternate numbers in

case a number is busy.

RTU should generate visual alarm and e-mail as

and when the parameters go outside

programmable limits,

Reference cell integrity check for all 814 cells,

Include GPS hardware for time synchronization,

Historical data availability and multiple spreadsheet based

reports improved the data analysis process.

The RTU can be specified by the following attributes:

The RTU should be able to record input voltage

and current in real time.

The data memory should be 64 KB

It It should have auto reporting features to make

periodically calling back the Central Control

Room Computer to report operating parameters

as per user defined call back schedule

programmable from one call back every of 2

Hours to 24 Hours.

This paper is produced for internal use at CIMCON.

www.cimconautomation.com

In HDPE plant, RTU for TRs is be capable of

handling 96AI, 56DI & 32 DO.

Modification of scheduling information,

Log & store data with time stamping, and retain it

even in case of power failure,

OIL & GAS

The SCANET software can be specified like as described

below:

Windows XP operating system,

APPLICATION NOTE

Benefits

The benefits of installation of the system can be listed as

follows:

Scalable to respond growing network need,

Communication capability includes manual calls

to Remote Monitoring System, Standard

Scheduled Monitoring calls, Calls from RTUs in

report-by- exception mode,

Real time database accommodates 500

measurands, 500 status indications, 5000

computed values,

High Availability

Alarm log generation based on defined limits

All PSP and TR Unit current & voltage data for

different 854 cells are available at MCS.

Data integrity improved and custom information

searching becomes easy due to use of SQL

server,

Results in Predictable maintenance schedule.

Corrosion of pipe can be monitored for best

results,

Exceptional events recorded in the system gives

an indication of maintenance requirement of the

system.

Remote monitoring of off-potential through GPS

based system.

As the SCADA software talks to existing as well

as the new RTUs, GAIL has more options in case

of augmentation / upgradation of plant pipeline

network.

Easy data maintenance

Access control

Performs logical operations,

Allows remote programming of control logic ,

Customized detailed data acquisition screen,

Customized report generation based on customer

requirements,

This paper is produced for internal use at CIMCON.

www.cimconautomation.com

Less maintenance cost due to better

maintenance planning and less unscheduled

shutdowns,

OIL & GAS

Worldwide Headquarters

234 Littleton Road, Westford

MA 01886, USA

Tel: (978) 692 9868

Fax: (978) 392 9869

E-mail: info@cimcon.com

APPLICATION NOTE

Asia Pacific Division

Global Support Center

Ahmedabad

801 SAKAR IV,

Ellisbridge,

Ahmedabad - 380 006

Tel : +91-79-657 8639

Fax: +91-79-657 8659

Pune

3rd Floor, OZ Plaza,

TASMAC Road,

Vimannagar,

Pune - 411 014.

Tel: +91-20-4002 7475

www.cimconautomation.com

2007 CIMCON Software, Inc. All rights reserved.

Você também pode gostar

- Caterpillar Common RailDocumento6 páginasCaterpillar Common Rail08088338100% (2)

- Mark VieDocumento4 páginasMark VieWalid Bahi100% (1)

- Practical, Made Easy Guide To Building, Office And Home Automation Systems - Part OneNo EverandPractical, Made Easy Guide To Building, Office And Home Automation Systems - Part OneAinda não há avaliações

- SCADAPack Product BrochureDocumento16 páginasSCADAPack Product BrochureAqua Technology Group100% (1)

- Practical Data Acquisition for Instrumentation and Control SystemsNo EverandPractical Data Acquisition for Instrumentation and Control SystemsAinda não há avaliações

- Standard Technical Features of BTG System for Supercritical Thermal UnitsDocumento222 páginasStandard Technical Features of BTG System for Supercritical Thermal Unitsshanmars007100% (2)

- Scada Systems in Tneb 221213Documento103 páginasScada Systems in Tneb 221213Neelakandan Masilamani100% (1)

- Gea S1004 PDFDocumento8 páginasGea S1004 PDFmeirangongAinda não há avaliações

- Specification For Cathodic Protection DesignDocumento39 páginasSpecification For Cathodic Protection Designhezron7771% (7)

- Introduction to PLC Automation and ProgrammingDocumento140 páginasIntroduction to PLC Automation and ProgrammingAbrhamAinda não há avaliações

- Amadeus QueuesDocumento27 páginasAmadeus QueuesSamuel Hernández0% (1)

- SPC-0804.02-60.05 Rev D2 DCS SpecificationDocumento31 páginasSPC-0804.02-60.05 Rev D2 DCS SpecificationharmlesdragonAinda não há avaliações

- 5 Ways I Bypassed Your Web Application Firewall (WAF)Documento18 páginas5 Ways I Bypassed Your Web Application Firewall (WAF)JOSÉ IGNACIO PARRA VALENZUELA100% (1)

- SCADA and Central Applications: An IntroductionDocumento53 páginasSCADA and Central Applications: An IntroductionBADRI VENKATESH100% (1)

- Day 1 OperationsDocumento62 páginasDay 1 OperationsRiyadh SalehAinda não há avaliações

- Coker UnitDocumento15 páginasCoker UnitAhmed YousryAinda não há avaliações

- Pipeline Scada SystemDocumento64 páginasPipeline Scada SystemMayank VishnoiAinda não há avaliações

- Scada Dms Tech SpecDocumento36 páginasScada Dms Tech SpecNad EemAinda não há avaliações

- Hydro Turbine Speed Governing SystemDocumento12 páginasHydro Turbine Speed Governing SystemNaveen Kumar100% (1)

- Dcs SystemDocumento29 páginasDcs SystemSandeep Sachan100% (3)

- Company Profile PT - Smartadeco IndonesiaDocumento20 páginasCompany Profile PT - Smartadeco IndonesiarositasurosoAinda não há avaliações

- IEC60870-5-104 RTU Monitoring over GPRSDocumento8 páginasIEC60870-5-104 RTU Monitoring over GPRSSGQAinda não há avaliações

- Final Presentation 1Documento42 páginasFinal Presentation 1Yashas Yashu100% (2)

- Vanguard Product BrochureDocumento6 páginasVanguard Product BrochurescribdkhatnAinda não há avaliações

- Optilift-GL: Gas Lift Monitoring and OptimizationDocumento2 páginasOptilift-GL: Gas Lift Monitoring and OptimizationFabro CoronelAinda não há avaliações

- Ibp1545 12Documento11 páginasIbp1545 12Marcelo Varejão CasarinAinda não há avaliações

- Innovations Improve LNG: Terminal Efficiency and SafetyDocumento3 páginasInnovations Improve LNG: Terminal Efficiency and SafetyL0NE DruidAinda não há avaliações

- Research Designs and Standards Organisation Manak Nagar, Lucknow - 226 011, IndiaDocumento41 páginasResearch Designs and Standards Organisation Manak Nagar, Lucknow - 226 011, IndiaChandra Mohan RawatAinda não há avaliações

- Tmo Berland South Pipeline Jupiter Tie in SpecificationsDocumento16 páginasTmo Berland South Pipeline Jupiter Tie in SpecificationsharryAinda não há avaliações

- Fuel Farm & Hydrant System Case Study for Salalah AirportDocumento1 páginaFuel Farm & Hydrant System Case Study for Salalah AirportDuane RaymondAinda não há avaliações

- ScadaDocumento47 páginasScadajas90192100% (1)

- RCS-9698GHn+ìGATEWAY 2010catalog-13Documento3 páginasRCS-9698GHn+ìGATEWAY 2010catalog-13Rinda_RaynaAinda não há avaliações

- Mini TransDocumento2 páginasMini TransAhmedRaafatAinda não há avaliações

- Ge DGCM Field Rtu CatalogDocumento12 páginasGe DGCM Field Rtu CatalogyogacruiseAinda não há avaliações

- Paper 26-Review of Remote Terminal Unit (RTU) and Gateways For Digital Oilfield DelpoymentsDocumento4 páginasPaper 26-Review of Remote Terminal Unit (RTU) and Gateways For Digital Oilfield DelpoymentssmejiagonzalesAinda não há avaliações

- Case Studies en Oil-And-gasDocumento12 páginasCase Studies en Oil-And-gasnagymateAinda não há avaliações

- Application of PLC's For Automation of Processes in IndustriesDocumento7 páginasApplication of PLC's For Automation of Processes in IndustriesMHMDAinda não há avaliações

- Comfort Controller 6400 (Outdoor Duty Rated) : Product DataDocumento4 páginasComfort Controller 6400 (Outdoor Duty Rated) : Product Datalecau50cdlAinda não há avaliações

- 239 Motor Protection RelayDocumento8 páginas239 Motor Protection Relaydes1982Ainda não há avaliações

- RLMSDocumento7 páginasRLMSSatish VenkatanarayanaAinda não há avaliações

- Technical Requirements of RtuDocumento34 páginasTechnical Requirements of RtuJoshua GarbinAinda não há avaliações

- PLG C 3 Natural Gas ChromatographDocumento4 páginasPLG C 3 Natural Gas ChromatographYuli_PribadiAinda não há avaliações

- SCADA and HMI Unit 3Documento43 páginasSCADA and HMI Unit 3Daniel VasanthanAinda não há avaliações

- 4.2 - Diseno Del Componente ComputacionalDocumento13 páginas4.2 - Diseno Del Componente ComputacionalJosueAinda não há avaliações

- Diseño Mecatrónico: PLC Fundamentos y AplicacionesDocumento13 páginasDiseño Mecatrónico: PLC Fundamentos y AplicacionesJosueAinda não há avaliações

- Boiler Control Using SCADADocumento9 páginasBoiler Control Using SCADAAdarsh Sunkad0% (1)

- Wireless ATMS Solution Case Studies 1680108601Documento6 páginasWireless ATMS Solution Case Studies 1680108601Rajbir YadavAinda não há avaliações

- Pub059 030 00 - 0812 PDFDocumento32 páginasPub059 030 00 - 0812 PDFCzar PrepoAinda não há avaliações

- SCADA Applications in Power SystemsDocumento5 páginasSCADA Applications in Power SystemsTeju NookalaAinda não há avaliações

- Manual-Motor de Gasolina Cm11 MkiiDocumento4 páginasManual-Motor de Gasolina Cm11 MkiiNallely MassoAinda não há avaliações

- MVI69 AFC DatasheetDocumento3 páginasMVI69 AFC Datasheet김윤식Ainda não há avaliações

- Cat 3500 Upg - Aig - 8 11Documento11 páginasCat 3500 Upg - Aig - 8 11Camilo Andres TabaresAinda não há avaliações

- Introduction to SCADA Systems FundamentalsDocumento20 páginasIntroduction to SCADA Systems FundamentalsНурсултан БекзулдаAinda não há avaliações

- Use of SCADA Systems in Power System AutomationDocumento10 páginasUse of SCADA Systems in Power System AutomationKamlesh KumarAinda não há avaliações

- Plant Automation and Telecontrol in One System: Simatic Pcs 7Documento8 páginasPlant Automation and Telecontrol in One System: Simatic Pcs 7alainAinda não há avaliações

- Task 1: Understanding Selection of Hardware and SoftwareDocumento3 páginasTask 1: Understanding Selection of Hardware and SoftwareBrendan Burr50% (8)

- BR Isk Mt375Documento2 páginasBR Isk Mt375Javed HashmiAinda não há avaliações

- Bently Nevada 3500 22Documento9 páginasBently Nevada 3500 22papashoAinda não há avaliações

- PLC: Programmable Logic Controller – Arktika.: EXPERIMENTAL PRODUCT BASED ON CPLD.No EverandPLC: Programmable Logic Controller – Arktika.: EXPERIMENTAL PRODUCT BASED ON CPLD.Ainda não há avaliações

- TT13 - Cpinterferenceaucsc2012Documento16 páginasTT13 - Cpinterferenceaucsc2012hezron77Ainda não há avaliações

- A Mathematical Model For The Cathodic Protection of Tank BottomsDocumento20 páginasA Mathematical Model For The Cathodic Protection of Tank Bottomshezron77Ainda não há avaliações

- CIMCON Proposal CP Remote Monitoring - IRTUDocumento2 páginasCIMCON Proposal CP Remote Monitoring - IRTUhezron77Ainda não há avaliações

- Interface DrawingDocumento1 páginaInterface Drawinghezron77Ainda não há avaliações

- CurrentRatings PDFDocumento0 páginaCurrentRatings PDFVirajitha MaddumabandaraAinda não há avaliações

- CP Training2 - GCC - CPTraining2Documento13 páginasCP Training2 - GCC - CPTraining2hezron77Ainda não há avaliações

- Shore Hardness Testers Measure Material RigidityDocumento1 páginaShore Hardness Testers Measure Material Rigidityhezron77Ainda não há avaliações

- Surge ArrestorDocumento3 páginasSurge Arrestorhezron77Ainda não há avaliações

- AP2610-20 - Install 9034544-01Documento2 páginasAP2610-20 - Install 9034544-01CartoonXAinda não há avaliações

- MicrophoneDocumento11 páginasMicrophoneChew Kah MengAinda não há avaliações

- Dhruv Sap CVDocumento3 páginasDhruv Sap CVarpangupta007Ainda não há avaliações

- Cpsu Hinigaran Campus: Central Philippines State UniversityDocumento3 páginasCpsu Hinigaran Campus: Central Philippines State UniversityChristian anthony SerfinoAinda não há avaliações

- Webedition UserguideDocumento310 páginasWebedition Userguideumpff100% (3)

- IP5407 InjoinicDocumento13 páginasIP5407 InjoinicWillyPVAinda não há avaliações

- ECE 6130/4130: Advance VLSI Systems: Combinational Logic Styles: Part-II Dynamic Logic Other StylesDocumento26 páginasECE 6130/4130: Advance VLSI Systems: Combinational Logic Styles: Part-II Dynamic Logic Other StylesRupesh ParabAinda não há avaliações

- Low-Profile Wideband Four-Corner-Fed Square Patch Antenna For 5G MIMO Mobile Antenna ApplicationDocumento5 páginasLow-Profile Wideband Four-Corner-Fed Square Patch Antenna For 5G MIMO Mobile Antenna Applicationrajesh yadavAinda não há avaliações

- M190PW01 V0Documento28 páginasM190PW01 V0Tomescu MarianAinda não há avaliações

- Resume Allison VincentDocumento3 páginasResume Allison Vincentapi-351166570Ainda não há avaliações

- UmerkotDocumento154 páginasUmerkotAakif HussainAinda não há avaliações

- Promocion Tiendas Te-Ka Bodega 2021-9Documento22 páginasPromocion Tiendas Te-Ka Bodega 2021-9Beiker Jose Palencia SarmientoAinda não há avaliações

- UADSystem ProfileDocumento4 páginasUADSystem ProfileJohn WangAinda não há avaliações

- FoxitPDFEditor20 ManualDocumento204 páginasFoxitPDFEditor20 Manuallavius_mAinda não há avaliações

- Question Bank Microwave 2013Documento6 páginasQuestion Bank Microwave 2013LakshmanaKumarAinda não há avaliações

- Piaggio Mp3 400 I.E Service Station Manual-7Documento20 páginasPiaggio Mp3 400 I.E Service Station Manual-7H. KeithAinda não há avaliações

- ZXR10 5900E Configuration Guide (Basic Configuration)Documento174 páginasZXR10 5900E Configuration Guide (Basic Configuration)HectorAinda não há avaliações

- LJQHelp PaletteDocumento2 páginasLJQHelp PaletteMuhammad AwaisAinda não há avaliações

- FM Global Property Loss Prevention Data Sheets: List of FiguresDocumento25 páginasFM Global Property Loss Prevention Data Sheets: List of Figureskw teoAinda não há avaliações

- Tapping The World's Innovation Hot Spots Presented by Naval BhushaniaDocumento8 páginasTapping The World's Innovation Hot Spots Presented by Naval BhushaniaNaval BhushaniaAinda não há avaliações

- Dokumen - Tips Cardioline Ar 1200 Service Manual (07!05!2020)Documento38 páginasDokumen - Tips Cardioline Ar 1200 Service Manual (07!05!2020)juniorAinda não há avaliações

- University Competency Model PDFDocumento8 páginasUniversity Competency Model PDFodescribdAinda não há avaliações

- SUP-01-Document ControlDocumento2 páginasSUP-01-Document ControlSALAH HELLARAAinda não há avaliações

- Microsoft GP 10 (VSTDGPProgrammersGuide)Documento120 páginasMicrosoft GP 10 (VSTDGPProgrammersGuide)Atif RehmanAinda não há avaliações

- ITGS Paper 2 Question Booklet HLSLDocumento8 páginasITGS Paper 2 Question Booklet HLSLMohammad HamdanAinda não há avaliações

- Comptia A+ (2009 Edition) Bridge Exam Objectives Exam Number: Br0-003Documento17 páginasComptia A+ (2009 Edition) Bridge Exam Objectives Exam Number: Br0-003Ray ConferAinda não há avaliações

- T-Rex Installation ManualDocumento2 páginasT-Rex Installation ManualVictor Bitar100% (2)

- Experiment 9 Pulse Width and Pulse Position ModulationDocumento3 páginasExperiment 9 Pulse Width and Pulse Position ModulationVaibhav ZadeAinda não há avaliações