Escolar Documentos

Profissional Documentos

Cultura Documentos

1021

Enviado por

VenkiBollaDireitos autorais

Formatos disponíveis

Compartilhar este documento

Compartilhar ou incorporar documento

Você considera este documento útil?

Este conteúdo é inapropriado?

Denunciar este documentoDireitos autorais:

Formatos disponíveis

1021

Enviado por

VenkiBollaDireitos autorais:

Formatos disponíveis

Instruction for replacement

of components in UNISAB II

- for compressors

Set

I

R

UNISAB II

This instruction is a description of how to

- EPROM from version 1.12 incl.

replace the following parts in UNISAB II:

and higher version no. . . . . . . . . . . . p. 7

- the door . . . . . . . . . . . . . . . . . . . . . . . p. 2

- EPROM from version 1.10 incl.

and lower version no . . . . . . . . . . . . p. 9

- the CPU print . . . . . . . . . . . . . . . . . . p. 2

- CPU print and EPROM . . . . . . . . . . p. 3

- EPROM (programme) . . . . . . . . . . . p. 3

- EEPROM (diagnosis) . . . . . . . . . . . . p. 6

- Languages for EPROM version

1.13 A and B dated 990128 . . . . . . p. 10

- Languages for EPROM version

1.13 A, B and C dated 990831 . . . . p. 11

- EPROM from version 2.01 incl.

- the relay print . . . . . . . . . . . . . . . . . . p. 6

and higher version no . . . . . . . . . . . p. 12

- the battery . . . . . . . . . . . . . . . . . . . . . p. 6

0171-948

01.07.01

Before replacing any of the above parts,

bent a little backwards). Remove the two

make sure that the UNISAB II system is

safety straps as well as the earth connec-

completely switched off.

tions.

Notice:

Take the new door and mount in reverse

Other control voltage may be connected to

order to the dismounting.

the UNISAB II system.

Connect the supply voltage.

Also make sure that the main current to the

- The relay print with all the wiring

compressor motor is disconnected. This can

connections

be done by removing the fuses so that the

motor does not start up inadvertently.

- The CPU print, which is fitted on the relay

print.

Replacing the door

- The transformer.

Take out the blue and white plugs leading to

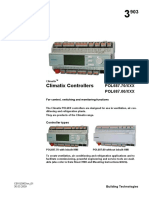

The parts are shown in fig. 1.

the relay print (both securing lugs must be

Fig. 1

Connection for display

Connection for keyboard

Battery

EPROM

Cooling plate

Serial EEPROM

CPU print

Fuse

Transformer

Dig. inputs

Digital outputs

Terminals

Replacement of CPU print

fixed as it is placed in to plugs with

connection to the relay print. It is important

Dismantle the door completely in order to

that you pull at the side of the print in which

provide free access to the printed circuit

the plugs are positioned to avoid pulling it out

board.

askew, hereby damaging the print.

Remove the screws by which the print is

fixed. Get hold of the bottom of the print and

Move both EPROM and EEPROM from the

pull it out carefully. It may be rather firmly

old CPU print to the new one.

01.07.01

0171-948

Important

print, the following procedure must be

See also Replacing the EPROM.

observed:

Mount a new CPU print and door in reverse

Important

See also Replacing the EPROM.

order.

Once this has been done and the control is

Mount the new parts and switch on the

switched on, the following picture will appear

control and the following picture appears in

in the display shortly:

the display:

COPY EEPROM

SERIAL NO.

NO

Answer with YES and press the A key.

Write the serial no of the compressor in this

UNISAB II will now be reconfigured and the

area and press the A key. Shortly all three

contents of the EEPROM, corresponding to

the setup of the compressor, is now copied

into the CPU memory.

The settting is now the same as before the

CPU print was changed, except for the

light diode on the front will start flashing and

the display now shows the CONFIG picture.

It is also necessary to enter the original setup

and all alarm and warning limits as well as

the setpoints, which must be different from

calibration of the pressure transducers,

possibly the brine temperature as well as the

hour counter which is now zero. The lan-

the factory setting. Remember also to

calibrate the pressure transducers.

guage is now English. If you want another

All these values you should also be able to

language, select this. Enter the values from

find in the Starting-up Manual. Remember to

the table in the Starting-up Manual which is

set time and date. The language is now

delivered with the compressor. Remember to

English. In case another language is wanted,

set time and date.

select this.

Replacing CPU print and

EPROM

Replacing the EPROM

(programme)

If, as an exception to the rule, it proves

EPROM is a programmable module, mounted

necessary to insert a new EPROM in

on a socket in the microelectronic part of the

connection with the replacement of a CPU

UNISAB.

0171-948

01.07.01

S The EPROM module is loosened from its

EPROM and electronics on the

whole can be damaged by static

electricity. In order to avoid this

damage you must make sure that

static electricity is discharged without the current passing through the

electronics. I.e. touch the part upon

which EPROM is placed both before and while you pick it up. And

touch the box of the apparatus, in

which EPROM is going to be positioned both before and while fitting

it. Naurally, you must use the same

hand that holds (or is going to get

hold of) the EPROM.

socket by an authorized EPROM puller.

Take care not to damage the pins on the

EPROM module.

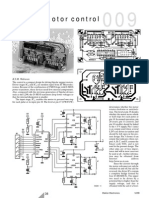

Fig. 2

EPROM

On replacing the EPROM or by transfer

from one UNISAB II to another, apply the

following procedure:

S Note the value of the hour counter as well

Mount the EPROM using your fingers, while

paying attention to the following:

S Position the EPROM with the notch in the

module turning right -- see fig. 2.

as the calibration values for pressure

S Take care that all pins are fitted in the

transducers and brine temperature.

socket and carry out the mounting with

S Switch off the power supply to UNISAB.

S Switch off the compressor motor starter

great care.

S Refit the door.

and keep all safety measures in

Once this has been done and the control is

accordance with the instruction manual

switched on, the following picture will appear

and local rules and regulations.

in the display shortly:

S Place the door in service position as

described in Operating UNISAB II.

COPY EEPROM

NO

S The EPROM MODULE is positioned in the

top left corner of the printed board as

shown in fig. 15.

EPROM hs a white label on its surface.

4

Answer with YES and press the A key. The

UNISAB II will now be re--configured and the

contents of the EEPROM, corresponding to

01.07.01

0171-948

the setup of the compressor, is now copied

into the CPU store.

- Timers, P--band factors

- Capacity limits

The setting is now the same as before the

EPROM was changed, except for the

See the table on UNISAB II settings for a

complete review.

calibration of the pressure transducers,

possibly the brine temperature as well as the

hour counter which is now zero.

See chapter: Operating the UNISAB II,

sub--section: Factory settings, in order to

carry out the factory reset.

The language is now English. If another

language is wanted, select this. Enter the

Once the FACTORY RESET has been

values from the table in the Starting-- up

completed, enter all the settings noted down

Manual which is delivered with the

compressor. Remember to set time and date.

in the table for UNISAB II settings and which

differ from the factory values of UNISAB II.

On changing the EPROM in connection with

an upgrading to an up--dated programme

version, it is recommended to carry out a

FACTORY RESET.

Before a FACTORY RESET is carried out,

write down all the UNISAB II settings in the

table on UNISAB II settings, especially the

parameters that are changed back to factory

setting by a factory reset. This applies to the

following parameters:

- Alarm and warning limits, set points,

neutral zone, proportional band

0171-948

01.07.01

Replacing the EEPROM

(diagnosis)

The control is now ready for operation with

the same setup as before the EEPROM was

removed.

In this EEPROM you will find information

about:

Replacing the relay print

- Compressor serial no.

Dismantle the door completely in order to

provide free access to the printed circuit

- The date of the initial start-up.

board.

- Compressor configuration.

All connected wires on the relay print must be

- The total number of alarm and warning

that correct remounting is possible.

dismounted, but first they must be marked so

limits as well as all other setting values.

Remove the screws that fix the print and tilt

the print out of the plastic holders at the

- Status for up to 30 old alarms.

terminal row on the long side of the print.

- Total number of alarms.

Pull the print off the guide opposite the

terminal row and out of the cabinet.

This EEPROM can be removed from the

Move the CPU print with the EPROM and

UNISAB II (placed in a socket) while the

same precautions are being taken as during

Serial EEPROM onto the new relay print.

the replacement of the EPROM.

Mount the new relay print in the reverse order

of the dismounting and connect the marked

Normally, the EEPROM must stay in the

control as this cannot function without it, but

in case the contents of the EEPROM, due to

special circumstances, should be desired

examined by YORK Refrigeration, Denmark,

wires in the correct order.

Replacing the battery

The battery is primarily used in order to

it can be removed for inspection.

ensure that the internal watch runs accurately

During the removal, first switch off the control

RAM-store is supplied during power cuts.

after a power cut. Besides, the so-called

and have an empty EEPROM ready for

The battery has an expected life of 10 years

insertion.

and is of the Lithium type. It is not charged by

the electronic circuit of the UNISAB II.

Once the new EEPROM has been fitted,

switch on the control again, and all

If the following picture appears in the display

information will now be copied into the new

after a power cut, this is a sign that the

EEPROM.

battery should be replaced:

01.07.01

0171-948

COPY EEPROM

UNISAB II. Before the power supply is

NO

switched off, write down all available

settings in the before-mentioned table. In

particular the settings of: alarms,

If a new battery is at disposal, switch off the

warnings, timers and running time, set

control and change the battery. Dispose of

points, configuration, calibration values

the old battery in conformity with the

for pressure transducers etc. To ease

environmental rules in force.

the job, ask the customer if the settings

Mount a new battery and switch on the con-

have already been recorded.

trol. The above picture now appears once

2: Switch the power supply to the UNISAB II

more in the display. Answer with YES and

off and dismount the cabinet plastic cover

press the A key.

by removing the five screws. The EPROM

The setup of the compressor is now the same

puller. Place the old EPROM in the

as before the power cut, except for the

EPROM box and unpack the new one.

can now be pulled out using an EPROM

calibration values for the pressure

Before mounting the new EPROM, make

transducers and the brine temperature as

well as the hour counter which is now zero.

These values you should be able to find in

the compressor Starting-up Manual. In case

no new battery is at disposal, answer YES to

the above picture, and repeat the same

operation as when the battery was replaced.

sure that the pins are bent slightly and like

this exactly fitted into the EPROM socket.

Mount the EPROM using manually.

Position it in the socket and make sure

that all pins are correctly fitted into the

socket and that the notch in the module is

turning right.

Remember to set time and date as well as

Now push the EPROM in place applying a

the language required, and the compressor is

firm and even pressure.

now operational.

3: Mount the plastic cover using the five

Please notice that at the next power cut,

screws; refit the door and switch on the

the problem will be exactly the same.

current supply to UNISAB II.

4: The UNISAB II will now display the

Replacement of EPROM from

version 1.12 (incl.) and higher

version no.

following picture:

1: Use the table Settings for UNISAB II which

COPY EEPROM

NO

can be found in the Starting-up Manual for

0171-948

01.07.01

By pressing the Set key for 2-3 seconds

to setup menu. Now press the Y key

the following picture will appear in the

twice until cursor is at config. Press the

display:

" key for the configuration picture. Now

press the B key as far down as possible

to the factory reset line. Press the Set

PASSWORD

1 2 3 4

SET FOR ACCEPT/QUIT

key for 2-3 seconds until the display

shows the following picture:

By pressing the " A Y B keys, the

PASSWORD

1 2 3 4

SET FOR ACCEPT/QUIT

password can be changed to 1266 and the

new password is confirmed by pressing

Set .

By using the arrow keys, " A Y B ,

The cursor will now be positioned at no.

change the password to 1266 and press

Use the Y B keys to switch from no to

Set . The cursor will now be positioned at

yes and confirm by pressing Set .

no. Now press the Y key or the B key to

The display will now display the following

switch from no to yes and press Set

picture:

again. The display will now show the

following picture:

COPY EEPROM YES

FACTORY RESET

YES

Press the A key to restart the UNISAB II.

Now press the A key to restart the

5: UNISAB II will now restart with the original

UNISAB II.

settings before the EPROM was changed.

A new factory reset must be performed to

The UNISAB II will now restart with the

enable the UNISAB II to work with the new

factory settings. The settings from the

features of the new EPROM. To do this the

UNISAB II settings table must now be

following procedure must be followed:

re-entered.

Go to main menu by pressing the " key,

6 When all settings have been re-entered

and then press the Y key once. Cursor is

into the UNISAB II, the compressor is

now positioned at setup. Press the " key

operational and the procedure is complete.

01.07.01

0171-948

Replacement of EPROM from

version 1.10 (incl.) and lower

version no. in UNISAB II

the socket and that the notch in the chip is

turning right.

Now push the chip in place applying a firm

When replacing an EPROM version 1.10 or

and even pressure.

3: Remount the plastic cover with the five

lower, three chips must be replaced: 1

screws and close the door. Switch on the

EPROM, 1 EEPROM and 1 PAL chip.

current to the UNISAB II.

Please note that if the PAL chip carries the

code CPU 196 2.1, it is not to be replaced.

4: When the current is switched on again the

following picture will appear in the display:

1: Use the table Settings for UNISAB II

which can be found in the starting-up

manual for UNISAB II. Before switching

SERIAL NUMBER

000000000

the current supply off, write down all

settings in the table. The settings include

alarms, warnings, timers and running

hours, set points, configuration,

calibration values for pressure

transducers etc. To ease the job, ask the

customer if the settings have already been

Now press Set for 2-3 seconds until the

display shows the following picture:

PASSWORD

1 2 3 4

SET FOR ACCEPT/QUIT

recorded.

Use the arrow keys, " A Y B , to

2: Disconnect the power supply to the

change the password to 1266 and press

UNISAB II and dismount the cabinet

plastic cover by loosening the five screws.

Set . The cursor will now be situated at:

Pull out the three chips using an EPROM

puller.

SERIAL NUMBER

000000000

Place the old chips in the EPROM box and

take out the new ones.

By using the arrow keys, " A Y

Before mounting the new chips, bend the

B ,enter the compressors serial

pins to fit the socket.

number which was written down before

the replacement of the chips.

To mount a chip, hold it between two

fingers and place it carefully in the socket.

Now press Set and the cursor will be

Before pushing the chip in place, make

positioned at serial number. Press the A

sure that the pins are correctly fitted into

key to restart the UNISAB II.

0171-948

01.07.01

5: When the UNISAB II is restarted, the

7: When all settings have been entered into

menu will show the configuration picture

the UNISAB II, the compressor is

and the yellow, red and green diodes on

operational and the procedure is complete.

the door will be flashing.

EPROM version 1.13 A and B marked

6: Enter the configuration settings that were

written down before the replacement. It is

with date 990128 feature the following

languages in this order:

particularly important to configure the

following:

EPROM A:

Compressor type

German

Refrigerant

Danish

DK

Autostart=yes (normal)

French

Finnish

FIN

Autostop=yes (normal)

English

GB

Pre-lubrication, yes , if

Italian

Norwegian

Dutch

NL

S

screwpressor with oil pump

Compressor number

Swedish

Baud rate= 9600 (normal)

EPROM B:

If UNISAB--Chiller is present:

Czech

CZ

Spanish

Greek

GR

English

GB

After entering the configuration data, re-

Hungarian

start the UNISAB II by pressing the A

Portuguese

Key. When the main picture appears after

Polish

PL

the restart, enter the rest of the settings

Russian

RUS

that were written down in the UNISAB II

English

GB

With chiller = yes

Without chiller = no

settings table.

10

01.07.01

0171-948

EPROM version 1.13 A, B and C marked

EPROM C:

with date 990831 feature the following

languages in this order:

EPROM A:

Danish

DK

Finnish

FIN

English

GB

Italian

Norwegian

Swedish

Czech

CZ

Spanish

English

GB

Greek

GR

Portuguese

Polish

PL

EPROM B:

German

French

English

GB

Hungarian

Dutch

NL

Russian

RUS

Mounting of EPROM from version 2.01 instead of earlyer versions

PLEASE READ THE HOLE CHAPTER BEFORE STARTING THE PROCESS !

Fig. 3

Connection

for keyboard

PAL

U17 EPROM U17

U18 EPROM U18

CPU print

Empty socket!

NEVER use this

socket together

with sockets pos.

U17 and U18

Connection

for display

EEPROM

Battery

Cooling

plate

Fuse

Trans-former

Dig. inputs

Digital outputs

Terminals

0171-948

01.07.01

11

When mounting e--prom set version 2.01 all

the chips has to be removed and you must

ensure that the cpu print is the new revision

C with sockets for 3 eproms see above picture.

that the notch in the chip is turning right. For

the e--prom U17 and U18 the text on the label

are facing up--side down.

The new Eprom set consist of 4 chips :

eprom U17 and eprom U18, one eeprom

printet 24C32 and one PAL chip with

label=CPU196 16b V3.0. See above picture

where to fit the chips.

3: Remount the plastic cover with the five

screws and close the front cover. Switch on

the current to the UNISAB II.

1: Use the table Settings for UNISAB II

which can be found in the starting--up manual

for UNISAB II. Before switching the current

supply off, write down all settings in the table.

The settings include alarms, warnings,

timers and running hours, set points, configuration, calibration values for pressure

transducers etc. To ease the job, ask the

customer if the settings have already been

recorded.

2: Disconnect the power supply to the UNISAB II and dismount the cabinet plastic cover

by loosening the five screws. Disconnect the

battery plug from the relay print and ensure

that the electronics has been Discharged for

at least 5 minutes before inserting the new

chips.

Pull out all the chips using an EPROM puller.

Place the old chips in the EPROM box and

take out the new ones.

Before mounting the new chips, If needed

bend the pins to fit the socket.

To mount a chip, hold it between two fingers

and place it carefully in the socket. Before

pushing the chip in place, make sure that the

pins are correctly fitted into the socket and

12

Now push the chip in place applying a firm

and even pressure.

4: When the power is switched on again the

following picture will appear in the display:

SERIAL NUMBER

000000000

Now press Set for 2-3 seconds until the display shows the following picture:

PASSWORD

1 2 3 4

SET FOR ACCEPT/QUIT

Use the arrow keys, " A Y B , to change

the password to 1266 and press Set . The

cursor will now be situated at:

SERIAL NUMBER

000000000

By using the arrow keys, " A Y B ,enter

the compressors serial number which was

written down before the replacement of the

chips.

Now press Set and the cursor will be positioned at serial number. Press the A key to

restart the UNISAB II.

5: When the UNISAB II is restarted, the menu

will show the configuration picture and the

01.07.01

0171-948

yellow, red and green diodes on the front

cover will be flashing. See the changed

menu tree in the instruction manual ver. 2.01

a compressor driv en by a frequency con-

6: Enter the configuration settings that were

written down before the replacement. It is

particularly important to configure the following:

with standard motor without frequency

verter and at the same timeshould run in

sequence with one or more compressors

converter.

S Compressor number

S Baud rate=19200 (normal, 9600 for

older UNISAB II)

S Compressor type

S Refrigerant

S Port 1 in communication are used in connection with evolution PLC

S Autostart=yes (normal)

S Port 2 in communication are used when

S Autostop=yes (normal)

S Pre--lubrication=yes , if screw compressor

with electric driven oil pump

S Press --1/9-- 1/25

- 1/25-- 1/59

Choose - 1/9-- 1/25 for standard cooling

compressors

Choose - 1/25-- 1/59 for heating pumps or

when running with R744 (CO2)

S ROTATUNE

communicating with Quantum panels

Set always Chiller = No

After entering the configuration data, end the

process by entering factory reset=Yes and

re--start the UNISAB II by pressing the Key. <

twice

When the main picture appears after the restart, enter the rest of the settings that were

written down in the UNISAB II settings table.

It is essentially to reinsert the values for

Note: This item will only work correctly

system number and start number in the

from eprom version 2.01 ROTA or later

menu Multisab State, otherwise the kom-

versions

pressor will not be able to start in auto-

Choose YES if the Unisab II is mounted on

matic or remote control mode.

0171-948

01.07.01

13

7: When all settings have been entered into

the UNISAB II, the compressor is operational

and the procedure is complete.

Greek GR

EPROM version 2.01 feature the following

languages in this order:

Italian I

Czech CZ

German D

Danish DK

Spanish E

Hungarian H

Norwegian N

Dutch NL

Portuguese P

Polish PL

French F

Russian RUS

Finnish FIN

Swedish S

English GB

Turkish TR

YORK REFRIGERATION

Chr. Xs Vej 201 P.O. Box 1810 DK-8270 Hjbjerg Denmark

Phone +45 87 36 70 00 Fax +45 87 36 77 05

14

01.07.01

0171-948

Você também pode gostar

- UNISAB II Spare Parts and Part Numbers PDFDocumento2 páginasUNISAB II Spare Parts and Part Numbers PDFmahmoud487150% (2)

- Unisab II Ver 202.04 - Engineering Manual - 0178-511 - ENGDocumento230 páginasUnisab II Ver 202.04 - Engineering Manual - 0178-511 - ENGjuan leyyon88% (8)

- UNISAB II Spare Parts and Part NumbersDocumento2 páginasUNISAB II Spare Parts and Part NumbersMahmoud MohamedAinda não há avaliações

- Advanced Direct Digital Controller ManualDocumento50 páginasAdvanced Direct Digital Controller Manualcraponzel0% (1)

- ODMEDocumento12 páginasODMEAntonio Antonio100% (1)

- Data Sheet Epn-110dn,-2Documento5 páginasData Sheet Epn-110dn,-2roy fadliAinda não há avaliações

- AE CC 01 - ManualDocumento18 páginasAE CC 01 - ManualRey-an A. Moreno60% (5)

- LZ Series: 1 POLE-1, 3, 5, 10 ADocumento10 páginasLZ Series: 1 POLE-1, 3, 5, 10 ALucian SinpetruAinda não há avaliações

- Samsung PepaDocumento99 páginasSamsung PepaLuis VeraAinda não há avaliações

- Catalog Hyundai HGCDocumento92 páginasCatalog Hyundai HGCBảo ChâuAinda não há avaliações

- Servomex 1800 1900 Manual PDFDocumento122 páginasServomex 1800 1900 Manual PDFbrunolacerdajrAinda não há avaliações

- GM150 Commissioning ManualDocumento358 páginasGM150 Commissioning ManualLeandro MedeirosAinda não há avaliações

- AF-60 Programming (FR)Documento71 páginasAF-60 Programming (FR)Zouhair IguerhzifenAinda não há avaliações

- Introducing Unisab II Version 2.05.1 and 2.05.2Documento4 páginasIntroducing Unisab II Version 2.05.1 and 2.05.2Mahmoud Mohamed100% (1)

- UT-2506 User ManualDocumento22 páginasUT-2506 User ManualBayanaka TehnikAinda não há avaliações

- UmsDocumento0 páginaUmsrolley5909Ainda não há avaliações

- Siemens POL68X DDC - CleanedDocumento17 páginasSiemens POL68X DDC - CleanedMAinda não há avaliações

- Instruction Manual For Screw Compressor Unit Controller Mypro Touch Type-SDocumento167 páginasInstruction Manual For Screw Compressor Unit Controller Mypro Touch Type-SJuad GA SAAinda não há avaliações

- Manual FMS3000-Eng Software 1.7Documento43 páginasManual FMS3000-Eng Software 1.7Rahat AliAinda não há avaliações

- Finder Temperizadores 87 PDFDocumento8 páginasFinder Temperizadores 87 PDFflywheel2006Ainda não há avaliações

- EPN-110DN, Installation Instructions 4189340132 UKDocumento4 páginasEPN-110DN, Installation Instructions 4189340132 UKWilliam WijayaAinda não há avaliações

- Panel Consilium 5100195-20A: Attached AttachedDocumento2 páginasPanel Consilium 5100195-20A: Attached AttachedDenisAinda não há avaliações

- Electrolux Clarus Error CodesDocumento42 páginasElectrolux Clarus Error CodesRudy prastamaAinda não há avaliações

- Trouble ShootingDocumento16 páginasTrouble ShootingVinay Singh100% (1)

- PC ManualDocumento34 páginasPC ManualminpyitAinda não há avaliações

- Fig. 182 - Motormaster V P50 Fault Code Display: Manual ControlDocumento2 páginasFig. 182 - Motormaster V P50 Fault Code Display: Manual ControlVelmar diseño y construccionAinda não há avaliações

- Dics 6100 PDFDocumento97 páginasDics 6100 PDFBf Ipanema100% (1)

- UNISAB II ProtocolosDocumento15 páginasUNISAB II ProtocolosRouberioRolim100% (2)

- Boiler Safety PurgeDocumento2 páginasBoiler Safety PurgeŞansal Dikmener100% (1)

- Logiturn II: Installation Manual For 3-Arm, 2-Arm and Open Gate Turnstiles Und Vario Vertical TurnstilesDocumento48 páginasLogiturn II: Installation Manual For 3-Arm, 2-Arm and Open Gate Turnstiles Und Vario Vertical TurnstilesCarlos RibeiroAinda não há avaliações

- JOWA Seaguard Bilge AlarmDocumento2 páginasJOWA Seaguard Bilge AlarmPrinceBabuAinda não há avaliações

- BJB3C 3fi Motor-DriveDocumento5 páginasBJB3C 3fi Motor-Drivethorsharp67% (6)

- Lenze 8200 Vector-25Documento25 páginasLenze 8200 Vector-25poaguiAinda não há avaliações

- DanBuss DNIPDocumento26 páginasDanBuss DNIPAnwar CordovaAinda não há avaliações

- Dics 6100 PDFDocumento97 páginasDics 6100 PDFGonzalo Villalobos SanchezAinda não há avaliações

- Boiler Setting ProceduresDocumento19 páginasBoiler Setting Proceduressumit100% (1)

- Finetek SP200Documento2 páginasFinetek SP200adavit73Ainda não há avaliações

- Salwico 2020 Manual-130524Documento141 páginasSalwico 2020 Manual-130524Mayan De la CruzAinda não há avaliações

- Service Manual Damcos Local Power Unit en 60632 1 PDFDocumento144 páginasService Manual Damcos Local Power Unit en 60632 1 PDFpapaki2100% (1)

- Hyundai UAN Cradle Retrofit ManualDocumento11 páginasHyundai UAN Cradle Retrofit Manualauto etrustAinda não há avaliações

- Manuel Service LG ARIA SOHO LDK100 PDFDocumento51 páginasManuel Service LG ARIA SOHO LDK100 PDFAtabji SamirAinda não há avaliações

- INV Trouble Shootguide (Engver.)Documento108 páginasINV Trouble Shootguide (Engver.)Yohanes Triatmojo100% (1)

- Manual Mypro Touch - EspañolDocumento16 páginasManual Mypro Touch - EspañolDi MartinAinda não há avaliações

- Rse-P Ii Short Manual: W X +12.0 Bar +12.0 BarDocumento81 páginasRse-P Ii Short Manual: W X +12.0 Bar +12.0 Bar徐玉坤100% (2)

- Unisab III 1.08 Operating en 2010 10Documento48 páginasUnisab III 1.08 Operating en 2010 10Fabio Splendor0% (5)

- AutroSafe - SHI PILS - Work-Doc - Auramarine PDFDocumento88 páginasAutroSafe - SHI PILS - Work-Doc - Auramarine PDFBui Duy ThanhAinda não há avaliações

- Driver L297 + L6203Documento2 páginasDriver L297 + L6203TatiiieleeeAinda não há avaliações

- How To Check Radar Error On GLK-100A 1Documento4 páginasHow To Check Radar Error On GLK-100A 1tralalaAinda não há avaliações

- Kemppi Master Mastertig 1400 1500 2200 2800 3500Documento31 páginasKemppi Master Mastertig 1400 1500 2200 2800 3500Acubas0% (1)

- Matrix Instruction Manual 1-25-07 REV-1.70 PDFDocumento100 páginasMatrix Instruction Manual 1-25-07 REV-1.70 PDFJuaperez Edmag100% (1)

- OdmeDocumento10 páginasOdmeHarshit Nanda100% (1)

- Navigation Light Control Panel PDF Download PandeltaDocumento3 páginasNavigation Light Control Panel PDF Download Pandeltaricky100% (1)

- BF10 T1000 CV SysDocumento16 páginasBF10 T1000 CV SysNguyen Phuoc HoAinda não há avaliações

- 2006101921011453187392Documento6 páginas2006101921011453187392Roman RufoAinda não há avaliações

- Ultrasonic Cleaner S 700 HM PDFDocumento109 páginasUltrasonic Cleaner S 700 HM PDFJulian Andrés FajardoAinda não há avaliações

- Preline RTA 421: ContactorDocumento6 páginasPreline RTA 421: ContactorMarco Antonio Esquivel BarretoAinda não há avaliações

- Rtaa SB 21Documento4 páginasRtaa SB 21kulilin1100% (1)

- Replacing An ECM PCBDocumento5 páginasReplacing An ECM PCBkarbaran1391Ainda não há avaliações

- 330 PDFsam Puritan-Bennett-700 PDFDocumento139 páginas330 PDFsam Puritan-Bennett-700 PDFBruna MechiAinda não há avaliações

- Service Manual Europa BDocumento68 páginasService Manual Europa BMarco Orlandi69% (16)

- DistDocumento63 páginasDistVenkiBollaAinda não há avaliações

- Install Google DriveDocumento1 páginaInstall Google DriveVenkiBollaAinda não há avaliações

- Yokogawa's Comprehensive Lifecycle Approach To Process Control System Cyber-SecurityDocumento20 páginasYokogawa's Comprehensive Lifecycle Approach To Process Control System Cyber-SecurityVenkiBollaAinda não há avaliações

- Adjustment of Position Transmitter - 3448.004 PDFDocumento3 páginasAdjustment of Position Transmitter - 3448.004 PDFVenkiBollaAinda não há avaliações

- Unisab II (0178-445-ENG-logo)Documento228 páginasUnisab II (0178-445-ENG-logo)kenny__8454% (13)

- 1021Documento14 páginas1021VenkiBolla50% (2)

- Emerson DeltaV Version 11 White Paper 9-24-10Documento19 páginasEmerson DeltaV Version 11 White Paper 9-24-10negrinAinda não há avaliações

- 1021Documento14 páginas1021VenkiBolla50% (2)

- Adjustment of Position Transmitter - 3448.004 PDFDocumento3 páginasAdjustment of Position Transmitter - 3448.004 PDFVenkiBollaAinda não há avaliações

- Yager200i Gy6 Scooter ManualDocumento76 páginasYager200i Gy6 Scooter ManualBob GinelAinda não há avaliações

- HS2016 HS2032 HS2064 HS2128 - V1.3 - Installation Guide - Eng - International - R001Documento28 páginasHS2016 HS2032 HS2064 HS2128 - V1.3 - Installation Guide - Eng - International - R001Roberto MnedezAinda não há avaliações

- Legrand Price List-01 ST April-2014Documento144 páginasLegrand Price List-01 ST April-2014Umesh SutharAinda não há avaliações

- AHS Ing Rev2Documento50 páginasAHS Ing Rev2Ahmed Iraqiabdelnaby100% (1)

- Safety: Operation and Maintenance Manual ExcerptDocumento30 páginasSafety: Operation and Maintenance Manual ExcerptIuri BragaAinda não há avaliações

- SUCO Catalog Pressure Switches 1 PDFDocumento149 páginasSUCO Catalog Pressure Switches 1 PDFrenankeybAinda não há avaliações

- Wiring Diagram Outdoor Emergency Lighting Units: Installation Instructions Model: Wgc42FeDocumento2 páginasWiring Diagram Outdoor Emergency Lighting Units: Installation Instructions Model: Wgc42FeMario WiryaAinda não há avaliações

- Aristel Av20 InstallationDocumento40 páginasAristel Av20 InstallationZoltan MarosanAinda não há avaliações

- PPG 1622A ManualDocumento38 páginasPPG 1622A Manualk_ndres841Ainda não há avaliações

- Nx100 Maintenance eDocumento240 páginasNx100 Maintenance eszpieg1200% (1)

- Safety Handles P-KUBE Krome: AN S1B000ADocumento2 páginasSafety Handles P-KUBE Krome: AN S1B000Ajavivi_75Ainda não há avaliações

- Electrical Workshop EE-113: Prepared By: Engr. Shafaq EjazDocumento53 páginasElectrical Workshop EE-113: Prepared By: Engr. Shafaq Ejazshafaq ejazAinda não há avaliações

- Mircom CR135MP Data SheetDocumento2 páginasMircom CR135MP Data SheetJMAC SupplyAinda não há avaliações

- Price ScheduleDocumento12 páginasPrice ScheduleAkd DeshmukhAinda não há avaliações

- Honeywell Sensing Micro Switch BZ Large Basic Product Sheet 004955 5 en PDFDocumento23 páginasHoneywell Sensing Micro Switch BZ Large Basic Product Sheet 004955 5 en PDFGus LopezAinda não há avaliações

- OLRDocumento3 páginasOLRMazhar SaqlainAinda não há avaliações

- Calibration Howden LPI SystemDocumento5 páginasCalibration Howden LPI Systemanyelit2021Ainda não há avaliações

- Skycrane Operation ManualDocumento36 páginasSkycrane Operation Manualpaulo_1_2_333% (3)

- XYZ 200 ManualDocumento95 páginasXYZ 200 ManualMShoibAinda não há avaliações

- Owner'S Manual: Read This Manual Carefully Before Operating This VehicleDocumento84 páginasOwner'S Manual: Read This Manual Carefully Before Operating This VehicleAminullah MuhammadAinda não há avaliações

- AUMADocumento24 páginasAUMAVenkatesh GangadharAinda não há avaliações

- Steam O&MDocumento28 páginasSteam O&MmadiAinda não há avaliações

- V-300 10 - 20 V-300 Max 10 - 20 Maintenance Manual (TK 50978-1-MS USA 06 - 01)Documento10 páginasV-300 10 - 20 V-300 Max 10 - 20 Maintenance Manual (TK 50978-1-MS USA 06 - 01)Juan Miguel Marin Quintero0% (1)

- 012710-0e-1000 Electrical Drawing (TQC)Documento412 páginas012710-0e-1000 Electrical Drawing (TQC)Илья ПоловинкоAinda não há avaliações

- Messko Product Catalogue Transformer SolutionsDocumento28 páginasMessko Product Catalogue Transformer SolutionsVahidAinda não há avaliações

- Tadano Rough Terrain Cranes Spec D5cac6Documento13 páginasTadano Rough Terrain Cranes Spec D5cac6michael_mic99Ainda não há avaliações

- Prilog 191Documento4 páginasPrilog 191Kristijan HorvatAinda não há avaliações

- RH Console Wiring Ride Control Wiring: 416F2, 422F2, 428F2 and 434F2 Electrical System Backhoe LoaderDocumento4 páginasRH Console Wiring Ride Control Wiring: 416F2, 422F2, 428F2 and 434F2 Electrical System Backhoe LoaderPaul HernandezAinda não há avaliações

- XINDAK PA-1 Instructions ManualDocumento11 páginasXINDAK PA-1 Instructions ManualmilexconsultAinda não há avaliações

- iPhone 14 Guide for Seniors: Unlocking Seamless Simplicity for the Golden Generation with Step-by-Step ScreenshotsNo EverandiPhone 14 Guide for Seniors: Unlocking Seamless Simplicity for the Golden Generation with Step-by-Step ScreenshotsNota: 5 de 5 estrelas5/5 (2)

- Chip War: The Fight for the World's Most Critical TechnologyNo EverandChip War: The Fight for the World's Most Critical TechnologyNota: 4.5 de 5 estrelas4.5/5 (82)

- Chip War: The Quest to Dominate the World's Most Critical TechnologyNo EverandChip War: The Quest to Dominate the World's Most Critical TechnologyNota: 4.5 de 5 estrelas4.5/5 (227)

- iPhone Unlocked for the Non-Tech Savvy: Color Images & Illustrated Instructions to Simplify the Smartphone Use for Beginners & Seniors [COLOR EDITION]No EverandiPhone Unlocked for the Non-Tech Savvy: Color Images & Illustrated Instructions to Simplify the Smartphone Use for Beginners & Seniors [COLOR EDITION]Nota: 5 de 5 estrelas5/5 (2)

- Amazon Web Services (AWS) Interview Questions and AnswersNo EverandAmazon Web Services (AWS) Interview Questions and AnswersNota: 4.5 de 5 estrelas4.5/5 (3)

- Raspberry Pi for Python Programmers Cookbook - Second EditionNo EverandRaspberry Pi for Python Programmers Cookbook - Second EditionAinda não há avaliações

- Unlock Any Roku Device: Watch Shows, TV, & Download AppsNo EverandUnlock Any Roku Device: Watch Shows, TV, & Download AppsAinda não há avaliações

- CompTIA A+ Complete Review Guide: Core 1 Exam 220-1101 and Core 2 Exam 220-1102No EverandCompTIA A+ Complete Review Guide: Core 1 Exam 220-1101 and Core 2 Exam 220-1102Nota: 5 de 5 estrelas5/5 (2)

- CompTIA Security+ All-in-One Exam Guide, Sixth Edition (Exam SY0-601)No EverandCompTIA Security+ All-in-One Exam Guide, Sixth Edition (Exam SY0-601)Nota: 5 de 5 estrelas5/5 (1)

- CompTIA A+ Certification All-in-One Exam Guide, Eleventh Edition (Exams 220-1101 & 220-1102)No EverandCompTIA A+ Certification All-in-One Exam Guide, Eleventh Edition (Exams 220-1101 & 220-1102)Nota: 5 de 5 estrelas5/5 (2)

- iPhone X Hacks, Tips and Tricks: Discover 101 Awesome Tips and Tricks for iPhone XS, XS Max and iPhone XNo EverandiPhone X Hacks, Tips and Tricks: Discover 101 Awesome Tips and Tricks for iPhone XS, XS Max and iPhone XNota: 3 de 5 estrelas3/5 (2)

- CompTIA A+ Complete Review Guide: Exam Core 1 220-1001 and Exam Core 2 220-1002No EverandCompTIA A+ Complete Review Guide: Exam Core 1 220-1001 and Exam Core 2 220-1002Nota: 5 de 5 estrelas5/5 (1)

- How to Jailbreak Roku: Unlock Roku, Roku Stick, Roku Ultra, Roku Express, Roku TV with Kodi Step by Step GuideNo EverandHow to Jailbreak Roku: Unlock Roku, Roku Stick, Roku Ultra, Roku Express, Roku TV with Kodi Step by Step GuideNota: 1 de 5 estrelas1/5 (1)

- Mastering IoT For Industrial Environments: Unlock the IoT Landscape for Industrial Environments with Industry 4.0, Covering Architecture, Protocols like MQTT, and Advancements with ESP-IDFNo EverandMastering IoT For Industrial Environments: Unlock the IoT Landscape for Industrial Environments with Industry 4.0, Covering Architecture, Protocols like MQTT, and Advancements with ESP-IDFAinda não há avaliações

- Essential iPhone X iOS 12 Edition: The Illustrated Guide to Using iPhone XNo EverandEssential iPhone X iOS 12 Edition: The Illustrated Guide to Using iPhone XNota: 5 de 5 estrelas5/5 (1)

- Exploring Apple Mac - Sonoma Edition: The Illustrated, Practical Guide to Using MacOSNo EverandExploring Apple Mac - Sonoma Edition: The Illustrated, Practical Guide to Using MacOSAinda não há avaliações

- Amazon Echo Manual Guide : Top 30 Hacks And Secrets To Master Amazon Echo & Alexa For Beginners: The Blokehead Success SeriesNo EverandAmazon Echo Manual Guide : Top 30 Hacks And Secrets To Master Amazon Echo & Alexa For Beginners: The Blokehead Success SeriesAinda não há avaliações

- Windows 10 Mastery: The Complete User Guide to Learn Windows 10 from Beginner to ExpertNo EverandWindows 10 Mastery: The Complete User Guide to Learn Windows 10 from Beginner to ExpertNota: 3.5 de 5 estrelas3.5/5 (6)

- Raspberry Pi Retro Gaming: Build Consoles and Arcade Cabinets to Play Your Favorite Classic GamesNo EverandRaspberry Pi Retro Gaming: Build Consoles and Arcade Cabinets to Play Your Favorite Classic GamesAinda não há avaliações

- How To Market Mobile Apps: Your Step By Step Guide To Marketing Mobile AppsNo EverandHow To Market Mobile Apps: Your Step By Step Guide To Marketing Mobile AppsAinda não há avaliações

![iPhone Unlocked for the Non-Tech Savvy: Color Images & Illustrated Instructions to Simplify the Smartphone Use for Beginners & Seniors [COLOR EDITION]](https://imgv2-2-f.scribdassets.com/img/audiobook_square_badge/728318688/198x198/f3385cbfef/1714829744?v=1)