Escolar Documentos

Profissional Documentos

Cultura Documentos

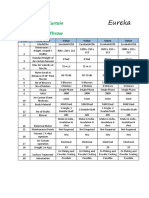

1 Beam Fails Ub305x165x54

Enviado por

Elencheliyan PandeeyanDescrição original:

Direitos autorais

Formatos disponíveis

Compartilhar este documento

Compartilhar ou incorporar documento

Você considera este documento útil?

Este conteúdo é inapropriado?

Denunciar este documentoDireitos autorais:

Formatos disponíveis

1 Beam Fails Ub305x165x54

Enviado por

Elencheliyan PandeeyanDireitos autorais:

Formatos disponíveis

Job No.

Sheet No.

Rev.

00

1

Sultanate of Oman

Job Title

Member/Location

PROPOSED BEAM

Drawing

Made by

SB

Date

09/07/2014

Chd.

STEEL BEAM ANALYSIS & DESIGN (BS5950)

In accordance with BS5950-1:2000 incorporating Corrigendum No.1

TEDDS calculation version 3.0.05

mm

A

Dead

27.200

4300

1

Unfactored Loads

Self weight included

4300

1

Imposed

0.0

mm

A

Load Envelope - Com bination 1

79.621

0.0

mm

A

4300

1

Load Com bination 1 (show n in proportion)

Imposed

Dead

mm

A

4300

1

Bending Mom ent Envelope

kNm

0.0

184.024

mm

A

184.0

4300

1

Job No.

Sheet No.

Rev.

00

2

Sultanate of Oman

Job Title

Member/Location

PROPOSED BEAM

Drawing

Made by

kN

171.185

SB

09/07/2014

Date

Chd.

Shear Force Envelope

171.2

0.0

-171.185

-171.2

mm

4300

1

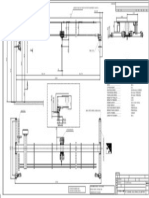

Support conditions

Support A

Vertically restrained

Support B

Vertically restrained

Rotationally free

Rotationally free

Applied loading

Beam loads

Dead self weight of beam 1

Dead full UDL 27.2 kN/m

Imposed full UDL 25.5 kN/m

Load combinations

Load combination 1

Support A

Dead 1.40

Span 1

Dead 1.40

Imposed 1.60

Imposed 1.60

Support B

Dead 1.40

Imposed 1.60

Analysis results

Maximum moment;

Mmax = 184 kNm;

Mmin = 0 kNm

Maximum shear;

Vmax = 171.2 kN;

Vmin = -171.2 kN

Deflection;

max = 4.7 mm;

min = 0 mm

Maximum reaction at support A;

RA_max = 171.2 kN;

RA_min = 171.2 kN

Unfactored dead load reaction at support A;

RA_Dead = 59.6 kN

Unfactored imposed load reaction at support A;

RA_Imposed = 54.8 kN

Maximum reaction at support B;

RB_max = 171.2 kN;

Unfactored dead load reaction at support B;

RB_Dead = 59.6 kN

Unfactored imposed load reaction at support B;

RB_Imposed = 54.8 kN

RB_min = 171.2 kN

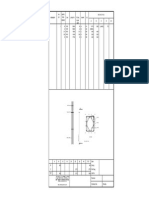

Section details

Section type;

UKB 305x165x54 (Corus Advance)

Steel grade;

S275

From table 9: Design strength py

Thickness of element;

max(T, t) = 13.7 mm

Design strength;

py = 275 N/mm2

Modulus of elasticity;

E = 205000 N/mm2

Job No.

Sheet No.

Rev.

00

3

Sultanate of Oman

Job Title

Member/Location

PROPOSED BEAM

Drawing

SB

Date

09/07/2014

Chd.

310.4

13.7

Made by

13.7

7.9

166.9

Lateral restraint

Span 1 has lateral restraint at supports only

Effective length factors

Effective length factor in major axis;

Kx = 0.85

Effective length factor in minor axis;

Ky = 0.85

Effective length factor for lateral-torsional buckling; KLT.A = 1.00;

Classification of cross sections - Section 3.5

= [275 N/mm2 / py] = 1.00

Internal compression parts - Table 11

Depth of section;

d = 265.2 mm

d / t = 33.6 <= 80 ;

Class 1 plastic

Outstand flanges - Table 11

Width of section;

b = B / 2 = 83.5 mm

b / T = 6.1 <= 9 ;

Class 1 plastic

Section is class 1 plastic

Shear capacity - Section 4.2.3

Design shear force;

Fv = max(abs(Vmax), abs(Vmin)) = 171.2 kN

d / t < 70

Web does not need to be checked for shear buckling

Shear area;

Av = t D = 2452 mm2

Design shear resistance;

Pv = 0.6 py Av = 404.6 kN

PASS - Design shear resistance exceeds design shear force

Moment capacity - Section 4.2.5

Design bending moment;

M = max(abs(Ms1_max), abs(Ms1_min)) = 184 kNm

Moment capacity low shear - cl.4.2.5.2;

Mc = min(py Sxx, 1.2 py Zxx) = 232.7 kNm

Effective length for lateral-torsional buckling - Section 4.3.5

Effective length for lateral torsional buckling;

LE = 1.0 Ls1 = 4300 mm

Job No.

Sheet No.

Rev.

00

4

Sultanate of Oman

Job Title

Member/Location

PROPOSED BEAM

Drawing

Made by

SB

Date

09/07/2014

Chd.

= LE / ryy = 109.371

Slenderness ratio;

Equivalent slenderness - Section 4.3.6.7

Buckling parameter;

u = 0.889

Torsional index;

x = 23.612

Slenderness factor;

v = 1 / [1 + 0.05 ( / x)2]0.25 = 0.833

Ratio - cl.4.3.6.9;

W = 1.000

Equivalent slenderness - cl.4.3.6.7;

LT = u v [W] = 81.056

Limiting slenderness - Annex B.2.2;

L0 = 0.4 (2 E / py)0.5 = 34.310

LT > L0 - Allowance should be made for lateral-torsional buckling

Bending strength - Section 4.3.6.5

Robertson constant;

LT = 7.0

Perry factor;

LT = max(LT (LT - L0) / 1000, 0) = 0.327

Euler stress;

pE = 2 E / LT2 = 307.9 N/mm2

LT = (py + (LT + 1) pE) / 2 = 341.9 N/mm2

pb = pE py / (LT + (LT2 - pE py)0.5) = 162.5 N/mm2

Bending strength - Annex B.2.1;

Equivalent uniform moment factor - Section 4.3.6.6

Moment at quarter point of segment;

M2 = 138 kNm

Moment at centre-line of segment;

M3 = 184 kNm

Moment at three quarter point of segment;

M4 = 138 kNm

Maximum moment in segment;

Mabs = 184 kNm

Maximum moment governing buckling resistance;

MLT = Mabs = 184 kNm

Equivalent uniform moment factor for lateral-torsional buckling;

mLT = max(0.2 + (0.15 M2 + 0.5 M3 + 0.15 M4) / Mabs, 0.44) = 0.925

Buckling resistance moment - Section 4.3.6.4

Buckling resistance moment;

Mb = pb Sxx = 137.5 kNm

Mb / mLT = 148.6 kNm

FAIL - Design bending moment exceeds buckling resistance moment

Check vertical deflection - Section 2.5.2

Consider deflection due to imposed loads

Limiting deflection;;

lim = Ls1 / 250 = 17.2 mm

Maximum deflection span 1;

= max(abs(max), abs(min)) = 4.734 mm

PASS - Maximum deflection does not exceed deflection limit

Você também pode gostar

- Calculation For IPE360Documento12 páginasCalculation For IPE360HaymanAHMEDAinda não há avaliações

- Calculation For IPE200Documento10 páginasCalculation For IPE200HaymanAHMEDAinda não há avaliações

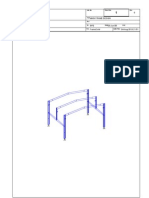

- Another DWG of Vessel No 3Documento1 páginaAnother DWG of Vessel No 3Nomi KhanAinda não há avaliações

- Analysis of Double Howe Steel Truss & Cantilever Truss Using Ansys SoftwareDocumento6 páginasAnalysis of Double Howe Steel Truss & Cantilever Truss Using Ansys SoftwareSRINIVAS DAinda não há avaliações

- Ufgs 33 56 10Documento38 páginasUfgs 33 56 10mohamed fathiAinda não há avaliações

- Perdele Economic B 2VVDocumento4 páginasPerdele Economic B 2VVakitainupufAinda não há avaliações

- Eureka Air Curtains CatalogueDocumento3 páginasEureka Air Curtains CatalogueSumit BhandariAinda não há avaliações

- Selection of An Air Curtain: (See Charts For Numbers)Documento2 páginasSelection of An Air Curtain: (See Charts For Numbers)mechmohsin4745Ainda não há avaliações

- UB5 Steel Beam Analysis & Design (BS5950Documento4 páginasUB5 Steel Beam Analysis & Design (BS5950yambalaoingjrAinda não há avaliações

- I L IL: DS MDXDocumento5 páginasI L IL: DS MDXpmali2Ainda não há avaliações

- Example 1.3 - Monolithic Staircase PDFDocumento5 páginasExample 1.3 - Monolithic Staircase PDFamar aimanAinda não há avaliações

- Client PresentationDocumento29 páginasClient Presentationapi-254207666Ainda não há avaliações

- Air Curtain SpecificationsDocumento1 páginaAir Curtain SpecificationsJames Pitts100% (1)

- PurlinsDocumento6 páginasPurlinsSourabh NegiAinda não há avaliações

- Point Load CalculationsDocumento3 páginasPoint Load Calculationskedar kavathekarAinda não há avaliações

- NDT Calculation: Test Package No: PA-SS08-03 Project: Mead Johnson Nutritional CE370-12Documento7 páginasNDT Calculation: Test Package No: PA-SS08-03 Project: Mead Johnson Nutritional CE370-12ravivarmadatla2011Ainda não há avaliações

- Steel Structure Design CalculationDocumento12 páginasSteel Structure Design CalculationSenthooran MahendranAinda não há avaliações

- Design of Plate GirdersDocumento30 páginasDesign of Plate GirdersTHULASI MAinda não há avaliações

- Arena Print July 26Documento50 páginasArena Print July 26Angelo Gardiola MaglinaoAinda não há avaliações

- Beam 1Documento6 páginasBeam 1Randolph BorgAinda não há avaliações

- How Do Properly Size A FanDocumento4 páginasHow Do Properly Size A Fanmefaisal75Ainda não há avaliações

- EX02. 2D Beam Analysis (Simply Supported Beam)Documento6 páginasEX02. 2D Beam Analysis (Simply Supported Beam)Lisa DiasAinda não há avaliações

- 1 PDFsam PDFsam Duct FittingsDocumento1 página1 PDFsam PDFsam Duct FittingsJosephRusselVizmanosAinda não há avaliações

- 11 RECT TANK 4.0M X 3.0M X 3.3M H - Flocculator PDFDocumento3 páginas11 RECT TANK 4.0M X 3.0M X 3.3M H - Flocculator PDFaaditya chopadeAinda não há avaliações

- Beam DesignDocumento17 páginasBeam Designvaram1Ainda não há avaliações

- Pinned Base Design Calculation: (Aisc 360-05 - LRFD Design Method) GeometryDocumento4 páginasPinned Base Design Calculation: (Aisc 360-05 - LRFD Design Method) GeometryTuanQuachAinda não há avaliações

- Section PropertiesDocumento61 páginasSection Propertiesint8Ainda não há avaliações

- Beam Design CalculationDocumento33 páginasBeam Design CalculationsmijusAinda não há avaliações

- British and European SectionsDocumento89 páginasBritish and European SectionsgenergiaAinda não há avaliações

- Ladder and Self Closing Gate For Storage TankDocumento15 páginasLadder and Self Closing Gate For Storage TankAkshat JainAinda não há avaliações

- Pipefitter/WelderDocumento2 páginasPipefitter/Welderapi-122242190Ainda não há avaliações

- Cryogenic Insulations: Department of BiotechnologyDocumento26 páginasCryogenic Insulations: Department of BiotechnologyBIBLE MALAYALAMAinda não há avaliações

- Project MezzanineDocumento2 páginasProject Mezzaninepujan77Ainda não há avaliações

- Inertia and Elastic Modulus CalculationDocumento14 páginasInertia and Elastic Modulus CalculationBejay BermudezAinda não há avaliações

- Frame Analysis Ver W2Documento14 páginasFrame Analysis Ver W2Sajith RanatungaAinda não há avaliações

- Fink TrussDocumento4 páginasFink TrussJommel GonzalesAinda não há avaliações

- Understanding Oils Fats Processing Aspects Practice KimJongGil POTS Korea 2015 P1 PDFDocumento70 páginasUnderstanding Oils Fats Processing Aspects Practice KimJongGil POTS Korea 2015 P1 PDFMemey LaAinda não há avaliações

- Shear Design of A Hollow Core SlabDocumento17 páginasShear Design of A Hollow Core SlabjrandeepAinda não há avaliações

- Design of Pinned Base Plate:-: Max Axial Case Max Uplift CaseDocumento3 páginasDesign of Pinned Base Plate:-: Max Axial Case Max Uplift CaseYELLAMANDA SANKATIAinda não há avaliações

- Moment of Inertia of Beam Sections - SkyCiv EngineeringDocumento3 páginasMoment of Inertia of Beam Sections - SkyCiv Engineeringv_paramesh131Ainda não há avaliações

- SikaTack Panel System - Sheet 1 Cert 05 - 4218Documento10 páginasSikaTack Panel System - Sheet 1 Cert 05 - 4218Peter DudasAinda não há avaliações

- UKC PropertiesDocumento2 páginasUKC PropertiesytbanAinda não há avaliações

- Analysis and Design of Steel Dome Using Software: Anuj ChandiwalaDocumento5 páginasAnalysis and Design of Steel Dome Using Software: Anuj ChandiwalaSaqlain Awan100% (1)

- Reinf TableDocumento2 páginasReinf TableRigel NapaAinda não há avaliações

- Purlin SoleroDocumento1 páginaPurlin SoleroJoseph Cloyd L. LamberteAinda não há avaliações

- Design Capacity Tables Examples PDFDocumento8 páginasDesign Capacity Tables Examples PDFAS V KameshAinda não há avaliações

- WE-5-2 Fin Plate ConnectionDocumento10 páginasWE-5-2 Fin Plate ConnectionPedro AlmeidaAinda não há avaliações

- Steel Stanchion Design Calcsheet v.0Documento2 páginasSteel Stanchion Design Calcsheet v.0Olusegun S. Ajibola100% (2)

- Crimp PLTDocumento5 páginasCrimp PLTSai SushankAinda não há avaliações

- Lecture 5 Structural Steel Design MuDocumento23 páginasLecture 5 Structural Steel Design MuPenelope MalilweAinda não há avaliações

- Understanding and Classifying Local, Distortional and Global Buckling in Open Thin-Walled MembersDocumento56 páginasUnderstanding and Classifying Local, Distortional and Global Buckling in Open Thin-Walled MembersrahulAinda não há avaliações

- Lifting Lug Weld DesignR1aDocumento1 páginaLifting Lug Weld DesignR1aJohnclaude ChamandiAinda não há avaliações

- Lug CalcionulatDocumento1 páginaLug CalcionulatkurniawanandreasAinda não há avaliações

- Tutorial SolidworksDocumento159 páginasTutorial SolidworksPatrick SnelAinda não há avaliações

- Clevis and Lug DesignDocumento2 páginasClevis and Lug DesignBen ClackAinda não há avaliações

- Worked Example Header PlateDocumento8 páginasWorked Example Header PlateNikola PejatovicAinda não há avaliações

- Ldo Storage Tank Calculation 170Documento6 páginasLdo Storage Tank Calculation 170م.ذكى فضل ذكى100% (1)

- UC100x100x17 Design CalculationDocumento4 páginasUC100x100x17 Design CalculationWin ThanAinda não há avaliações

- Steel Beam Analysis & Design (Bs5950) in Accordance With BS5950-1:2000 Incorporating Corrigendum No.1Documento4 páginasSteel Beam Analysis & Design (Bs5950) in Accordance With BS5950-1:2000 Incorporating Corrigendum No.1NitaiGauranga108Ainda não há avaliações

- Prokon - C12Documento1 páginaProkon - C12Elencheliyan PandeeyanAinda não há avaliações

- 09-MAR-12 19-Apr-2014 09:03 NFR1a.std: Job No Sheet No RevDocumento1 página09-MAR-12 19-Apr-2014 09:03 NFR1a.std: Job No Sheet No RevElencheliyan PandeeyanAinda não há avaliações

- Node Numbers B1Documento1 páginaNode Numbers B1Elencheliyan PandeeyanAinda não há avaliações

- From Either Side Is Not Advisable Because It Is Just Closer To Columns and Please Follow The Old One ItselfDocumento1 páginaFrom Either Side Is Not Advisable Because It Is Just Closer To Columns and Please Follow The Old One ItselfElencheliyan PandeeyanAinda não há avaliações

- Follow The 12000 Dimension As Shown and Don't Do From Other-Side It Will Come Exact To The ColumnDocumento1 páginaFollow The 12000 Dimension As Shown and Don't Do From Other-Side It Will Come Exact To The ColumnElencheliyan PandeeyanAinda não há avaliações

- Frame 2 SKDocumento1 páginaFrame 2 SKElencheliyan PandeeyanAinda não há avaliações

- Pdo HseDocumento33 páginasPdo HseElencheliyan Pandeeyan0% (1)

- 20 MT DG Eot Crane Span 20 MeterDocumento1 página20 MT DG Eot Crane Span 20 MeterElencheliyan PandeeyanAinda não há avaliações

- 5 MT SG Eot Crane Span 30 MeterDocumento1 página5 MT SG Eot Crane Span 30 MeterElencheliyan PandeeyanAinda não há avaliações

- 25 MT DG Eot Crane Span 25 MeterDocumento1 página25 MT DG Eot Crane Span 25 MeterElencheliyan PandeeyanAinda não há avaliações

- 5 MT SG Eot Crane Span 25 MeterDocumento1 página5 MT SG Eot Crane Span 25 MeterElencheliyan PandeeyanAinda não há avaliações

- T-Retaining Wall Design To AS5100.3 Rev BDocumento7 páginasT-Retaining Wall Design To AS5100.3 Rev BKevin FarriesAinda não há avaliações

- Manual Daikin VRVDocumento20 páginasManual Daikin VRVErnesto BonillaAinda não há avaliações

- DM1 315S6 75,0kWDocumento3 páginasDM1 315S6 75,0kWJohnny Diaz VargasAinda não há avaliações

- Japanese Porous AsphaltTechnologyDocumento51 páginasJapanese Porous AsphaltTechnologyAbdillah AhmadAinda não há avaliações

- The Maurer-Cartan EquationDocumento2 páginasThe Maurer-Cartan EquationJohn BirdAinda não há avaliações

- CT Analyzer User Manual ESPDocumento178 páginasCT Analyzer User Manual ESPmendezhanda100% (1)

- Air Cooled CondensersDocumento13 páginasAir Cooled CondensersSyed ShoebAinda não há avaliações

- Methylene Blue Index of Clay: Standard Test Method ForDocumento2 páginasMethylene Blue Index of Clay: Standard Test Method ForPedjaAinda não há avaliações

- 02january 18 2019 Exam H&GDocumento2 páginas02january 18 2019 Exam H>ullao Mark Carlo100% (1)

- Jovian Atmosphere Case Study WriteupDocumento7 páginasJovian Atmosphere Case Study Writeupapi-480372762Ainda não há avaliações

- Loading To Box CulvertsDocumento20 páginasLoading To Box CulvertsPaddie MwangiAinda não há avaliações

- NikkuDocumento36 páginasNikkuNishkarsh AroraAinda não há avaliações

- Mechanical Engineering - Final PDFDocumento248 páginasMechanical Engineering - Final PDFRubal SharmaAinda não há avaliações

- Pharmaceutical Emulsions by Haroon RahimDocumento49 páginasPharmaceutical Emulsions by Haroon RahimHaroon Rahim67% (3)

- F1 Flow Measurement in Closed ConduitDocumento5 páginasF1 Flow Measurement in Closed ConduitSzeQiLungAinda não há avaliações

- Case Studies On Nonlinear Control Theory of The Inverted PendulumDocumento28 páginasCase Studies On Nonlinear Control Theory of The Inverted PendulumDragan ErcegAinda não há avaliações

- Dsme h5375s Ane FDDocumento29 páginasDsme h5375s Ane FDtosveAinda não há avaliações

- Abaqus Tutorial 1Documento11 páginasAbaqus Tutorial 1Dg IRfan100% (1)

- Solid Conveying in Vane Extruder For Polymer Processing: Effects On Pressure EstablishmentDocumento10 páginasSolid Conveying in Vane Extruder For Polymer Processing: Effects On Pressure EstablishmentИгорь БезукладниковAinda não há avaliações

- Geologic Processes On EarthDocumento38 páginasGeologic Processes On EarthTrisha May Flores100% (2)

- Lift Shear Walls Individual Compression Shear WallsDocumento19 páginasLift Shear Walls Individual Compression Shear Wallssaurabh singhAinda não há avaliações

- UH-60 L BookletDocumento18 páginasUH-60 L Bookletcho kang ho100% (1)

- Design of ConcreteDocumento3 páginasDesign of Concretesachin balyanAinda não há avaliações

- Matigo Mocks Uace Phy 2 GuideDocumento22 páginasMatigo Mocks Uace Phy 2 Guidebuuleivan8Ainda não há avaliações

- Work Analysis of Compliant Leg Mechanisms For Bipedal Walking RobotsDocumento8 páginasWork Analysis of Compliant Leg Mechanisms For Bipedal Walking RobotsAurel GSAinda não há avaliações

- 1 Outrigger and Belt Wall SystemDocumento24 páginas1 Outrigger and Belt Wall SystemBurhan NasutionAinda não há avaliações

- The Physical Properties of The Hot Fluid Have Been Extrapolated Beyond The Valid Temperature RangeDocumento3 páginasThe Physical Properties of The Hot Fluid Have Been Extrapolated Beyond The Valid Temperature RangeSrihari KodimelaAinda não há avaliações

- A Review of Pile Set-UpDocumento20 páginasA Review of Pile Set-UpFernando SmithAinda não há avaliações

- Influence of Silica Fume On High Strength Lightweight ConcreteDocumento8 páginasInfluence of Silica Fume On High Strength Lightweight ConcretePhanHathamAinda não há avaliações

- Microfiltration (MF), Ultrafiltration (UF)Documento52 páginasMicrofiltration (MF), Ultrafiltration (UF)WONG TS80% (5)