Escolar Documentos

Profissional Documentos

Cultura Documentos

Dynamic Var Compensation: An Accusine Pcs Solution

Enviado por

jacojhamesTítulo original

Direitos autorais

Formatos disponíveis

Compartilhar este documento

Compartilhar ou incorporar documento

Você considera este documento útil?

Este conteúdo é inapropriado?

Denunciar este documentoDireitos autorais:

Formatos disponíveis

Dynamic Var Compensation: An Accusine Pcs Solution

Enviado por

jacojhamesDireitos autorais:

Formatos disponíveis

Dynamic Var Compensation1.

qxp

03/30/2007

11:40 AM

Page 1

technical paper

Dynamic Var Compensation

An AccuSine PCS Solution

Summary

Several types of loads, such as electric arc welders and arc furnaces,

cause high levels of inrush current during their operating cycle,

which is often only several seconds in duration. These high cycle-tocycle currents cause the flux (magnetizing current) of the upstream

transformer to saturate. Flux saturation causes the transformer output

voltage to drop precipitously and results in failure or poor performance

of the load.

Additionally, when the above occurs, the source sees the voltage

drop and attempts to provide the needed current to maintain the

faulting transformer voltage, thus creating an additional component to

the current surge within the electrical system. This current surge

accentuates the voltage drop of the source on an intermittent basis.

If the voltage cycling is repetitive, it might appear to humans as

lighting flicker.

Key benefits of dynamic VAR compensation:

Improvement of the quality of the output product

Improvement of poor power factor

Improvement of electrical system stability

Correction of phase imbalances

How AccuSine PCS Works

AccuSine PCS is designed to inject current to support the current

requirements of the load to reduce demands upon the upstream

electrical system. With AccuSine PCS the system transformer does

not see the massive demand for inrush current and does not

experience flux saturation. Therefore, the voltage remains stable at

the load and in the upstream electrical system. All of the primary

problems, like flicker, are eliminated.

Current before AccuSine

Current after AccuSine

03/30/2007

11:40 AM

Comparing Alternatives

Static VAR Compensation

One method of mitigation employed is the

static VAR compensator. This device

employs fixed banks of power factor

capacitors, controlled with thyristors, which

can switch them on and off rapidly. In

many instances, there are also thyristorswitched inductors to prevent

system resonance.

Static VAR compensation maintain voltage

levels, reduce voltage flicker, improve

power factor, correct phase imbalance and

improve system stability. However, static

VAR compensators are usually applied

upstream of the system transformer, thus

failing to correct the problem at the load

and improving product quality. In addition,

they are relatively slow compared to the

welding phenomenon and

thus not very effective.

Dynamic VAR Compensation

A power correction system like AccuSine

PCS is a smart solution for VAR

compensation. It is a scalable bus-applied

device that delivers flexibility in placement

and precision control. The extraordinary

speed of AccuSine PCS makes it an

effective solution.

Remember, dynamic VAR compensation is

just one of the benefits of a power

correction system.

For more information, contact the

Schneider Electric Power Quality

Correction Group at (905) 678-6699 or

pqc@squared.com.

Please visit our website at

www.reactivar.com.

Page 2

AccuSine PCS employs an analog current control algorithm for ultra

rapid response. This permits AccuSine PCS instant-on feature to

inject current during

rapid load transitions,

such as a first strike

of an arc welder. It

does not matter to

AccuSine PCS

whether this is a large

harmonic or reactive

load change.

AccuSine PCS sees it

through the current

transducers

monitoring the load

and instantly

responds by injecting

as many cycles of

peak injection current

as required to support

the load.

As a result of this instant-on system, AccuSine PCS maintains voltage

levels, reduce voltage flicker, improve power factor and improve

product quality and employee performance and, thus, improve overall

plant efficiency.

Special Application Notes

Electric Arc Welder

Electric arc welders operate intermittently for short intervals of time.

When the weld is first struck, the welder requires essentially infinite

current for a few cycles. During this period, the electrical system

providing the power cannot provide all of the current demanded. The

result is voltage sag at the welder and a poor quality weld.

In an automated manufacturing plant, such as an automobile body

plant, there are several welders on an electrical system fed from one

power system. Simultaneous operation of multiple welders compounds

the voltage sag problem and the incidence of poor product welds is

greatly increased.

Effects of Harmonic Current

Electric arc welders are unpredictable because of the cycle-to-cycle

variation of the arc, especially upon first strike of the welder. This

results in a difficulty to define harmonic spectra. As the weld begins

to flow, the harmonic spectra are more predictable with less

amplitude of the peak current. However, the harmonic current still

cannot be predicted.

This unpredictabity, in addition to the very high cycle-to-cycle

peak currents at first strike, make selection of a mitigation method

extremely difficult.

Schneider Electric

Power Quality Correction Group

3220 Caravelle Drive

Mississauga ON L4V 1K9

Tel.: (905) 678-6699

www.reactivar.com

Head Office

295 Techpark Drive

Suite 100

LaVergne, TN 37086

Tel.: (615) 287-3500

www.us.schneider-electric.com

Document Number 5820HO0705

2007 Schneider Electric. All rights reserved.

Dynamic Var Compensation1.qxp

Você também pode gostar

- UDAYDocumento52 páginasUDAYShravan KumarAinda não há avaliações

- Pensation of Voltage - FullDocumento21 páginasPensation of Voltage - FullTJPRC PublicationsAinda não há avaliações

- Voltage Support Control Strategies For Static Synchronous Compensators Under Unbalanced Voltage SagsDocumento4 páginasVoltage Support Control Strategies For Static Synchronous Compensators Under Unbalanced Voltage SagschikatisivashankarAinda não há avaliações

- Grebe - Capacitor Switching and Its Impact On Power Quality Draft Paper 0000 PDFDocumento7 páginasGrebe - Capacitor Switching and Its Impact On Power Quality Draft Paper 0000 PDFrmendozaing100% (1)

- RXPE's SVC Solutions Improve Power Quality and Grid StabilityDocumento17 páginasRXPE's SVC Solutions Improve Power Quality and Grid StabilitySteven Leif EsselAinda não há avaliações

- Power Factor Correction by Pulse Width Modulated Switched Single CapacitorDocumento26 páginasPower Factor Correction by Pulse Width Modulated Switched Single CapacitorDevendra SharmaAinda não há avaliações

- Introduction To Power Factor Correction PDFDocumento8 páginasIntroduction To Power Factor Correction PDFErlangga SatyawanAinda não há avaliações

- Improve Power System Voltage Stability Using SVCDocumento19 páginasImprove Power System Voltage Stability Using SVCvictor100% (1)

- Static Var Compensator (SVC)Documento9 páginasStatic Var Compensator (SVC)KrishnanAinda não há avaliações

- 29-04-2021-1619695048-6-Ijeee-2. Ijeee - Power Quality Improvement Using Fuzzy Based StatcomDocumento10 páginas29-04-2021-1619695048-6-Ijeee-2. Ijeee - Power Quality Improvement Using Fuzzy Based Statcomiaset123Ainda não há avaliações

- Power Quality Seminar ReportDocumento26 páginasPower Quality Seminar ReportPinax Patel HereAinda não há avaliações

- Power OscillationsDocumento54 páginasPower OscillationsVijay RohillaAinda não há avaliações

- D StatcomDocumento29 páginasD StatcomSai Pranahita Bhaskarapantulu100% (1)

- 1.AC DC InteractionDocumento26 páginas1.AC DC Interactionpvenky_kkdAinda não há avaliações

- Reactive Power Compensation SeminarDocumento19 páginasReactive Power Compensation SeminarShivam TayadeAinda não há avaliações

- Accusine: Harmonic Filtering and Reactive Power CompensationDocumento20 páginasAccusine: Harmonic Filtering and Reactive Power CompensationlcatelaniAinda não há avaliações

- AC-DC Interaction: Key Considerations for Voltage Stability, Resonances, and Torsional EffectsDocumento26 páginasAC-DC Interaction: Key Considerations for Voltage Stability, Resonances, and Torsional EffectsChetan KotwalAinda não há avaliações

- Mitigation of Power Quality Problems Using Custom Power DeviceDocumento5 páginasMitigation of Power Quality Problems Using Custom Power DeviceOscar Fernando Chevarria MezaAinda não há avaliações

- Accusine Harmonics FilterDocumento16 páginasAccusine Harmonics FilterMarwan DabbousAinda não há avaliações

- Statcom + SSSCDocumento18 páginasStatcom + SSSCRahul Chauhan M.Tech., Electronics Engineering, IIT(BHU)Ainda não há avaliações

- Reactive Power Compensation: BY M.Sethu Madhavan EPE 15011D4914Documento25 páginasReactive Power Compensation: BY M.Sethu Madhavan EPE 15011D4914chandra 798Ainda não há avaliações

- Power System2Documento15 páginasPower System2Aayush PatidarAinda não há avaliações

- Power Factor Correction ThesisDocumento7 páginasPower Factor Correction Thesisfc4qgsp7100% (1)

- Sivaram PDFDocumento15 páginasSivaram PDFLava KumarAinda não há avaliações

- A Presentation On Reactive Power Compensation: BY K.S.S Venkata Satya Naveen S.Manoj KumarDocumento26 páginasA Presentation On Reactive Power Compensation: BY K.S.S Venkata Satya Naveen S.Manoj KumarFuh ValleryAinda não há avaliações

- 1.AC DC InteractionDocumento26 páginas1.AC DC InteractionDr.K.Krishna Veni ProfessorAinda não há avaliações

- 17th International Conference On Electrical, Electronics and Systems Engineering December 21 - 22, 2015 Istanbul, TurkeyDocumento47 páginas17th International Conference On Electrical, Electronics and Systems Engineering December 21 - 22, 2015 Istanbul, TurkeyPraveen Nayak BhukyaAinda não há avaliações

- Performance Analysis of 48-Pulse VSC-Based STATCOM in Mitigation of Voltage Dip Caused by The Starting of A High Power Induction-MotorDocumento5 páginasPerformance Analysis of 48-Pulse VSC-Based STATCOM in Mitigation of Voltage Dip Caused by The Starting of A High Power Induction-MotorIJERDAinda não há avaliações

- Voltage Icker Mitigation by FACTS Devices: March 2015Documento7 páginasVoltage Icker Mitigation by FACTS Devices: March 2015shehan.defonsekaAinda não há avaliações

- Automatic Power Factor Controlling PanelDocumento15 páginasAutomatic Power Factor Controlling PanelheruvalaAinda não há avaliações

- Reliability-Enhancing Technologies for Wind Power IntegrationDocumento11 páginasReliability-Enhancing Technologies for Wind Power IntegrationDimas_pradethaAinda não há avaliações

- Synchronous CondensersDocumento15 páginasSynchronous Condenserspawan ranaAinda não há avaliações

- Power Line Disturbance PDFDocumento63 páginasPower Line Disturbance PDFs31314100% (1)

- Comparison of shunt capacitor, SVC, and STATCOM for static voltage stabilityDocumento15 páginasComparison of shunt capacitor, SVC, and STATCOM for static voltage stabilityJayaprakash DasAinda não há avaliações

- 1.1.OVERVIEW: Modelling of Dstatcom For Power Quality ProblemsDocumento21 páginas1.1.OVERVIEW: Modelling of Dstatcom For Power Quality ProblemsAnjali RaiAinda não há avaliações

- Power Quality Issues and SolutionsDocumento26 páginasPower Quality Issues and SolutionsAbhishek Dasari100% (2)

- Power Quality AssignmentDocumento6 páginasPower Quality Assignmentazzam_aliAinda não há avaliações

- VSC Based DSTATCOM & Pulse-Width Modulation For Power Quality ImprovementDocumento4 páginasVSC Based DSTATCOM & Pulse-Width Modulation For Power Quality Improvementsurendiran123Ainda não há avaliações

- Voltage FlickerDocumento7 páginasVoltage FlickerAnonymous xaeuoo4Ainda não há avaliações

- By:-S.Shivaprasad N.Swathireddy T.Ramu RanjankumarDocumento36 páginasBy:-S.Shivaprasad N.Swathireddy T.Ramu RanjankumarShiva Prasad SankojuAinda não há avaliações

- Power System ContingenciesDocumento31 páginasPower System ContingenciesSal ExcelAinda não há avaliações

- 3 Voltage Level Improving by Using Static VARDocumento7 páginas3 Voltage Level Improving by Using Static VAREngr Muhammad Imran KhanAinda não há avaliações

- Adaptive VAR CompensatorDocumento8 páginasAdaptive VAR CompensatorHillary McgowanAinda não há avaliações

- Some Power Electronics Case Studies Using Matlab Simpowersystem BlocksetNo EverandSome Power Electronics Case Studies Using Matlab Simpowersystem BlocksetAinda não há avaliações

- Brochure AccuSine 5820BR0901Documento16 páginasBrochure AccuSine 5820BR0901Szabolcs SzabolcsAinda não há avaliações

- Power Quality Solutions Using Power ElectronicsDocumento12 páginasPower Quality Solutions Using Power ElectronicscheshankarAinda não há avaliações

- Enhancement of Power Quality in Grid Connected Wind Energy System Using STATCOMDocumento9 páginasEnhancement of Power Quality in Grid Connected Wind Energy System Using STATCOMShaik Muhammad ImranAinda não há avaliações

- POWER QUALITY IMPROVEMENT USING STATCOMDocumento6 páginasPOWER QUALITY IMPROVEMENT USING STATCOMjoAinda não há avaliações

- Dual P-Q Theory based energy Optimized Dynamic Voltage RestorerDocumento19 páginasDual P-Q Theory based energy Optimized Dynamic Voltage RestorerPenukulapadu kalyani kumari0% (1)

- Presented By: Sibaram Padhy Konark Institute of Science and Technology (Kist) REGD NO:-0801214280Documento16 páginasPresented By: Sibaram Padhy Konark Institute of Science and Technology (Kist) REGD NO:-0801214280Dev KumarAinda não há avaliações

- Damping of Sub synchronous Resonance Using SSSC Based PWM Hysteresis ControllerDocumento9 páginasDamping of Sub synchronous Resonance Using SSSC Based PWM Hysteresis ControllerrajapandiyaAinda não há avaliações

- SVC and STATCOM Application in Electric ArcDocumento7 páginasSVC and STATCOM Application in Electric ArcGolfkung PairojAinda não há avaliações

- Synchronous Condensers for Power Factor CorrectionDocumento15 páginasSynchronous Condensers for Power Factor CorrectionPawan Rana100% (1)

- Thesis Power Factor CorrectionDocumento5 páginasThesis Power Factor CorrectionYolanda Ivey100% (2)

- Unit 1 Reactive Power ManagementDocumento14 páginasUnit 1 Reactive Power Managementmanishakadam221284Ainda não há avaliações

- Power QualityDocumento9 páginasPower QualitySharmila ManokaranAinda não há avaliações

- Solutions For Static Var Compensator: SVC - Brings Reliabe and High-Quality Power To ConsumersDocumento16 páginasSolutions For Static Var Compensator: SVC - Brings Reliabe and High-Quality Power To ConsumersSalih YolluAinda não há avaliações

- Electrical Power Systems Quality Lecture 2Documento43 páginasElectrical Power Systems Quality Lecture 2Carlnagum 123456789Ainda não há avaliações

- Improvement of Transient Stability of Two Machine System Using Static VAR Compensator and Power System StabilizerDocumento4 páginasImprovement of Transient Stability of Two Machine System Using Static VAR Compensator and Power System StabilizereditorijsaaAinda não há avaliações

- Cap & Fuse Failure Analysis 04Documento12 páginasCap & Fuse Failure Analysis 04GMCaselAinda não há avaliações

- High Bay LedDocumento18 páginasHigh Bay LedkerenAinda não há avaliações

- SE CertificationDocumento1 páginaSE CertificationjacojhamesAinda não há avaliações

- PDFDocumento8 páginasPDFjacojhamesAinda não há avaliações

- Catalogo Interruptores HVX PIX COMPACDocumento2 páginasCatalogo Interruptores HVX PIX COMPACjacojhamesAinda não há avaliações

- The Death Car: Reading Comprehension (Intermediate)Documento19 páginasThe Death Car: Reading Comprehension (Intermediate)miy500_542116704Ainda não há avaliações

- Etap Network AnalysisDocumento16 páginasEtap Network AnalysisJaime David Jr.Ainda não há avaliações

- WSOS5 Release Note Version 03Documento14 páginasWSOS5 Release Note Version 03aelebestAinda não há avaliações

- Brochure Pm5560Documento4 páginasBrochure Pm5560jacojhamesAinda não há avaliações

- Insulated Portable Food ContainerDocumento3 páginasInsulated Portable Food ContainerjacojhamesAinda não há avaliações

- Reading I06Documento7 páginasReading I06jacojhamesAinda não há avaliações

- Writing Letters1Documento14 páginasWriting Letters1AgnesAinda não há avaliações

- "Empresa Microsin E.I.R.Ltda": Apellido Nombre F - Nac Seccion SueldoDocumento2 páginas"Empresa Microsin E.I.R.Ltda": Apellido Nombre F - Nac Seccion SueldojacojhamesAinda não há avaliações

- Bases Beca IdiomasDocumento30 páginasBases Beca IdiomasjacojhamesAinda não há avaliações

- Spkout I5 InformationDocumento12 páginasSpkout I5 InformationjacojhamesAinda não há avaliações

- Var Plus CanDocumento2 páginasVar Plus CanlucdrgAinda não há avaliações

- Project The Ant Ranch Ponzi Scheme JDDocumento7 páginasProject The Ant Ranch Ponzi Scheme JDmorraz360Ainda não há avaliações

- Digital Booklet - Bach ConcertosDocumento14 páginasDigital Booklet - Bach Concertosppopgod33% (3)

- Shoib CV Scaffold EngineerDocumento3 páginasShoib CV Scaffold EngineerMohd Shoib100% (1)

- SD Electrolux LT 4 Partisi 21082023Documento3 páginasSD Electrolux LT 4 Partisi 21082023hanifahAinda não há avaliações

- Gary Mole and Glacial Energy FraudDocumento18 páginasGary Mole and Glacial Energy Fraudskyy22990% (1)

- ABS Rules for Steel Vessels Under 90mDocumento91 páginasABS Rules for Steel Vessels Under 90mGean Antonny Gamarra DamianAinda não há avaliações

- AHP for Car SelectionDocumento41 páginasAHP for Car SelectionNguyên BùiAinda não há avaliações

- Spouses Mariano Z. Velarde and Avelina D. VELARDE, Petitioners, vs. COURT OF Appeals, David A. RAYMUNDO and GEORGE RAYMUNDO, RespondentsDocumento11 páginasSpouses Mariano Z. Velarde and Avelina D. VELARDE, Petitioners, vs. COURT OF Appeals, David A. RAYMUNDO and GEORGE RAYMUNDO, RespondentsRobyn JonesAinda não há avaliações

- Proposed Delivery For PAU/AHU Method Statement SEC/MS/3-25Documento4 páginasProposed Delivery For PAU/AHU Method Statement SEC/MS/3-25Zin Ko NaingAinda não há avaliações

- Dell 1000W UPS Spec SheetDocumento1 páginaDell 1000W UPS Spec SheetbobAinda não há avaliações

- SDNY - Girl Scouts V Boy Scouts ComplaintDocumento50 páginasSDNY - Girl Scouts V Boy Scouts Complaintjan.wolfe5356Ainda não há avaliações

- Sapkale Sandspit 2020Documento5 páginasSapkale Sandspit 2020jbs_geoAinda não há avaliações

- Insulators and Circuit BreakersDocumento29 páginasInsulators and Circuit Breakersdilja aravindanAinda não há avaliações

- Computers As Components 2nd Edi - Wayne WolfDocumento815 páginasComputers As Components 2nd Edi - Wayne WolfShubham RajAinda não há avaliações

- EDI810Documento11 páginasEDI810ramcheran2020Ainda não há avaliações

- Lista Precio Septiembre 0609Documento75 páginasLista Precio Septiembre 0609gAinda não há avaliações

- Hardened Concrete - Methods of Test: Indian StandardDocumento16 páginasHardened Concrete - Methods of Test: Indian StandardjitendraAinda não há avaliações

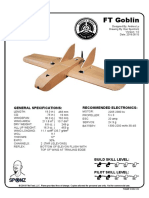

- FT Goblin Full SizeDocumento7 páginasFT Goblin Full SizeDeakon Frost100% (1)

- Discursive Closure and Discursive Openings in SustainabilityDocumento10 páginasDiscursive Closure and Discursive Openings in SustainabilityRenn MAinda não há avaliações

- Customer Satisfaction and Brand Loyalty in Big BasketDocumento73 páginasCustomer Satisfaction and Brand Loyalty in Big BasketUpadhayayAnkurAinda não há avaliações

- PTAS-11 Stump - All About Learning CurvesDocumento43 páginasPTAS-11 Stump - All About Learning CurvesinSowaeAinda não há avaliações

- Flare Finance Ecosystem MapDocumento1 páginaFlare Finance Ecosystem MapEssence of ChaAinda não há avaliações

- LPM 52 Compar Ref GuideDocumento54 páginasLPM 52 Compar Ref GuideJimmy GilcesAinda não há avaliações

- De Thi Chuyen Hai Duong 2014 2015 Tieng AnhDocumento4 páginasDe Thi Chuyen Hai Duong 2014 2015 Tieng AnhHuong NguyenAinda não há avaliações

- ATOMIC GAMING Technical Tutorial 1 - Drawing Game Statistics From Diversity Multigame StatisticsDocumento4 páginasATOMIC GAMING Technical Tutorial 1 - Drawing Game Statistics From Diversity Multigame StatisticsmiltoncgAinda não há avaliações

- Taxation of interest income paid to foreign corporationsDocumento1 páginaTaxation of interest income paid to foreign corporationsCass CataloAinda não há avaliações

- Leg Wri FInal ExamDocumento15 páginasLeg Wri FInal ExamGillian CalpitoAinda não há avaliações

- Arizona Supreme CT Order Dismisses Special ActionDocumento3 páginasArizona Supreme CT Order Dismisses Special Actionpaul weichAinda não há avaliações

- Dairy DevelopmentDocumento39 páginasDairy DevelopmentHemanth Kumar RamachandranAinda não há avaliações

- Backup and Recovery ScenariosDocumento8 páginasBackup and Recovery ScenariosAmit JhaAinda não há avaliações