Escolar Documentos

Profissional Documentos

Cultura Documentos

BCM 524 Lecture 1 PDF

Enviado por

Anonymous wTTx1LDescrição original:

Título original

Direitos autorais

Formatos disponíveis

Compartilhar este documento

Compartilhar ou incorporar documento

Você considera este documento útil?

Este conteúdo é inapropriado?

Denunciar este documentoDireitos autorais:

Formatos disponíveis

BCM 524 Lecture 1 PDF

Enviado por

Anonymous wTTx1LDireitos autorais:

Formatos disponíveis

11/7/2014

07/11/2014

BCM524

CONSTRUCTION

SYSTEM ANALYSIS

INTRODUCTION TO PRODUCTION

MANAGEMENT

NOR ZAILAH ABDULLAH

ANI MASLINA SALEH

1

INTRODUCTION

o

Production/operations management is

the process which combines and

transforms various resources into value

added product/services in a controlled

manner as per the policies of the

organization.

It is that part of an organization which is

concerned with the transformation of a

range of inputs into the required

products/services having the requisite

quality level.

11/7/2014

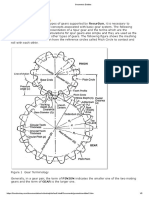

Functional Subsystems of Organisations

Supporting function

Communicate

PERSONNEL

MARKETING

Figure 1 Subsystem

in organisation

Authorization & control

FINANCE

PRODUCTION

The set of interrelated management

activities,

which

are

involved

in

manufacturing certain products, is

called production management.

If the same concept is extended to

services

management,

then

the

corresponding set of management

activities

is

called

operations

management.

11/7/2014

Production and Operation Management

Production and

Operations

Management

("POM") is about the

transformation of

production and

operational inputs

into "outputs" that,

when distributed,

meet the needs of

customers.

Output

Figure 2 Conversion Process

PRODUCTION MANAGEMENT

Activities which are involved in manufacturing

certain products is called as PRODUCTION

MANAGEMENT

Examples of productions are : manufacturing

custom-made products like, boilers with a

specific capacity, constructing flats, some

structural fabrication works for selected

customers.

Manufacturing standardized products like ;

car, bus, motor cycle, radio, television etc.

11/7/2014

OPERATIONS MANAGEMENT

Management activities which extended to

services is called as OPERATIONS MANAGEMENT

Examples of services custom made services

like medical facilities and clinical tests,

arranging food for parties, travel booking

services etc.

Standardised services like, developing standard

computer soft wares, providing standard

insurance policies etc

POM 5 Main Headings

Product

Plant

Programmes

Processes

People

11/7/2014

Matrix of Functional Subsystems and Management Activities

SYSTEMS CONCEPT OF PRODUCTION

System is a collection of interrelated entities

Figure 4 explains the systems aspects of

production/operations function of an organisation

The organisation receives several inputs as indicated on the

left hand side and converts them into useful products

and/or services using its facilities (manufacturing facilities)

In the process of conversion, definitely. There will be some

deviations in the products attributes like quality, size, shape

and number of units produced.

The feedback mechanism is a continuous exercise to

monitor the status of the system.

10

11/7/2014

Figure 4 - Systems aspect of production / operations function

11

The system operates in an environment. So,

the system has to take feedback from its

environment and adjust its parameters

accordingly.

The environment can be classified into ;

Internal environment (e.g. top management)

External environment (e.g. legal, political, social

or economic conditions considers the

feedback and adjust its parameter accordingly)

Figure 5 shown the detailed schematic

diagram of production/operations subsystem.

12

11/7/2014

Figure 5 - Schematic representation of production/operations

subsystem

13

Matrix of Functional Subsystems

and Management Activities

Figure 3 - Relative frequency of decisions at different levels of

management

14

11/7/2014

TYPES OF PRODUCTION SYSTEM

The production system of a company mainly

uses facilities, equipment, and operating

methods (called the production system) to

produce goods that satisfy customers

demand.

The requirements of a production system

depend on the of product that the company

offers and the strategy that it employs to serve

its customers.

The classification of production system is

summarised in the Table 1 below.

15

Table 1 Classification of Production System

Basic

Classifications

Examples

Types of

output

Products

Consumer goods like furniture, TV, radio,

etc. Producer goods like, lathe, milling ,

etc

Transportation, health, entertainment,

banking services, education system, etc.

Types of flow

Projects

Job shop

Services

Flow Shop

Continuous

process

Types of

Customized

specification Standardized

under service

type

Construction of bridge, dam, road, etc.

Hospital, auto repair, machine shop,

furniture company, etc.

High volume TV factory, auto factory,

etc.

Postal services, telephone company,

power corporation, oil refinery, chemical

plant

Medical care, legal services

Insurance, wholesale stores

16

11/7/2014

i) Flow Shop

Conversion process in which successive units of

output undergo the same sequence of

operations, using specialised equipment usually

positioned along a production line: example

auto assembly, assembly of television sets,

assembly of electric motors, assembly of

computer keyboards, etc.

Extreme form of flow shop is sometimes treated

as a continuous process in which there is a

constant flow of materials, as in oil refining,

chemical processing and other in which there is

no way to identify successive units of output.

17

Flow Shop (contd)

Ordinary flow shop can be classified into;

Continuous flow shop

Will produce the same type of output

like cigarettes, fertilizer, cement, etc.

Intermittent flow shop

The process is interrupted to set it up to

handle different specifications of the

same basic design. (e.g. bottling

factories, mass production of clothing,

television sets, etc.)

18

11/7/2014

ii) Job Shop

This is a conversion process in which units of

different types of products follow different

sequences through different shops.

This type of system has more flexibility. But

this system results into more set-up time,

more in-process inventory, complex

scheduling, varying quality and so forth.

Example furniture company, Hospital,

machine shop etc.

19

iii) The Project

project refers to refers to process of creating a

complex one-of-a-kind product or service with a

set of well-defined tasks in terms of resources

required and time phasing.

Some

examples of projects are : dam

constructions, starting new industries, fabricating

boilers, and so on.

20

10

11/7/2014

DISCUSSION

Services can pose a variety of managerial challenges

for managers challenges that in manufacturing are

either much less or nonexistent. And because services

represent an increasing share of the economy, this

places added importance to understanding and

dealing with challenges of managing services.

QUESTIONS

What managerial challenges do services present that

manufacturing does not?

Why does service management present more

challenges than manufacturing?

21

11

Você também pode gostar

- Coastal Ocean Observing SystemsNo EverandCoastal Ocean Observing SystemsYonggang LiuAinda não há avaliações

- Lecture Arch 513 Construction ManagementDocumento45 páginasLecture Arch 513 Construction ManagementJanine Abuyan ObligadoAinda não há avaliações

- 04 Machine Design & DesignDocumento22 páginas04 Machine Design & DesignCholan PillaiAinda não há avaliações

- Problem Statement PDFDocumento10 páginasProblem Statement PDFDana Al-YafeiAinda não há avaliações

- Project Integration Management: Initiation Planning Executing Monitoring and Controlling ClosingDocumento5 páginasProject Integration Management: Initiation Planning Executing Monitoring and Controlling Closingvikram122Ainda não há avaliações

- T0455-11-16 Rev.0 John - Proposal of Solar Roof Mounting Structure For 5 M...Documento8 páginasT0455-11-16 Rev.0 John - Proposal of Solar Roof Mounting Structure For 5 M...Thai chheanghourtAinda não há avaliações

- Title: Construction Technology Ii Course Work Report: Siti Nadiah Binti Mokhtar Noor Safika Faezan Binti AzahariDocumento107 páginasTitle: Construction Technology Ii Course Work Report: Siti Nadiah Binti Mokhtar Noor Safika Faezan Binti AzahariSeid HodzicAinda não há avaliações

- IRC Draft Specification For Cold Milling 14 April 2011Documento3 páginasIRC Draft Specification For Cold Milling 14 April 2011Sunil BoseAinda não há avaliações

- Monthly Progress Report On Road Safety ActivitiesDocumento17 páginasMonthly Progress Report On Road Safety ActivitiesAkshay Kumar SahooAinda não há avaliações

- Basic Industrial Training Mercedes Benz Company Building ProjectDocumento8 páginasBasic Industrial Training Mercedes Benz Company Building ProjectSachitra Priyashan GovinnaAinda não há avaliações

- BASF MasterSeal M 790 TdsDocumento9 páginasBASF MasterSeal M 790 TdsAmar WadoodAinda não há avaliações

- Indian RailwayDocumento22 páginasIndian RailwayHarish Girdhar100% (1)

- Sydney Water Meter InstallationDocumento31 páginasSydney Water Meter InstallationAnnahuynhAinda não há avaliações

- Nicmar Nicmar Institute of Construction Management and Research School of Distance EducationDocumento13 páginasNicmar Nicmar Institute of Construction Management and Research School of Distance Educationrahulchauhan7869Ainda não há avaliações

- 3 BConstruction Stormwater Erosion Control PlansDocumento4 páginas3 BConstruction Stormwater Erosion Control Plans许爱文Ainda não há avaliações

- Silt CurtainDocumento8 páginasSilt Curtainwilliam pasamonteAinda não há avaliações

- Metro Project SummariesDocumento42 páginasMetro Project SummariesMetro Los Angeles100% (1)

- BoqDocumento12 páginasBoqpavlovicrs100% (1)

- ITT - Statement of ComplianceDocumento3 páginasITT - Statement of ComplianceAtif RizviAinda não há avaliações

- Ethiopian Building Proclamation No. 624 - 2009ethiopian Legal BriefDocumento38 páginasEthiopian Building Proclamation No. 624 - 2009ethiopian Legal Briefbereket gAinda não há avaliações

- Construction Technology AssignmentDocumento5 páginasConstruction Technology AssignmentAbubakar DanmashiAinda não há avaliações

- Method Statement of Potable Water and Firefighting Network ConstructionDocumento51 páginasMethod Statement of Potable Water and Firefighting Network Constructionmohdshahul543Ainda não há avaliações

- Turbo Air VentilatorsDocumento13 páginasTurbo Air VentilatorsmishrasujitAinda não há avaliações

- 3.7 Method StatementDocumento3 páginas3.7 Method StatementHenryAinda não há avaliações

- Technical Proposal GuidelinesDocumento2 páginasTechnical Proposal GuidelinesashleesuchiAinda não há avaliações

- Government Gazette Staatskoerant: Republic of South Africa Republiek Van Suid AfrikaDocumento16 páginasGovernment Gazette Staatskoerant: Republic of South Africa Republiek Van Suid AfrikaDocumentsZAAinda não há avaliações

- Study of Factors Affecting Construction Cost Performance in Nigerian Construction Sites. Amusan.L.M E-Mail: Worldalternativeamusan@yahoo AbstractDocumento18 páginasStudy of Factors Affecting Construction Cost Performance in Nigerian Construction Sites. Amusan.L.M E-Mail: Worldalternativeamusan@yahoo AbstractAfeez MayowaAinda não há avaliações

- Var Api P3Documento7 páginasVar Api P3Francisco CentenoAinda não há avaliações

- Bending Moment Capacity of PipesDocumento13 páginasBending Moment Capacity of Pipess3201696Ainda não há avaliações

- Smart Highway KSCE PDFDocumento1 páginaSmart Highway KSCE PDFMuhammadSaadAinda não há avaliações

- Site Layout Plan For ConstructionDocumento5 páginasSite Layout Plan For Construction95 - MichaelAinda não há avaliações

- Emerging Technologies A Suggested Design Method For Curved Jacked Steel PipeDocumento11 páginasEmerging Technologies A Suggested Design Method For Curved Jacked Steel PipefalokunAinda não há avaliações

- Unit 5: Quality Sysyems Organizing and ImplementationDocumento23 páginasUnit 5: Quality Sysyems Organizing and ImplementationVinitgaAinda não há avaliações

- Managing & Controlling Airport Construction Projects - Jan 2001Documento10 páginasManaging & Controlling Airport Construction Projects - Jan 2001TATATAHERAinda não há avaliações

- Work Methodology For Installation of Service Water Piping Under GroundDocumento2 páginasWork Methodology For Installation of Service Water Piping Under GroundKomputershengalAinda não há avaliações

- Site Management and OrganizationDocumento8 páginasSite Management and OrganizationCarlos Ramos GuerraAinda não há avaliações

- Decision Theory & Decision Tree PDFDocumento5 páginasDecision Theory & Decision Tree PDFAfiq FuadAinda não há avaliações

- Business PlanDocumento36 páginasBusiness PlanSiare AntoneAinda não há avaliações

- Assignment Title Sustainable Materials For ConstructionDocumento25 páginasAssignment Title Sustainable Materials For ConstructionSajjad HassanAinda não há avaliações

- Sinewave Biomass Power - Assessment Report PDFDocumento20 páginasSinewave Biomass Power - Assessment Report PDFPranab SinhaAinda não há avaliações

- HSBEI-1294-0314 Piling Rigs Overturning On Construction SitesDocumento4 páginasHSBEI-1294-0314 Piling Rigs Overturning On Construction SitestsuakAinda não há avaliações

- KarnatakaDocumento379 páginasKarnatakab_csrAinda não há avaliações

- SCHEDULING AND PLANING COTM IntroductionnDocumento5 páginasSCHEDULING AND PLANING COTM Introductionnnahom antenehAinda não há avaliações

- KHNKJH NCP 30 1Documento31 páginasKHNKJH NCP 30 1djsouravAinda não há avaliações

- Pag-IBIG Housing Loan CalculatorDocumento2 páginasPag-IBIG Housing Loan CalculatorkiraAinda não há avaliações

- Compressor: Reciprocating Compressors (Edit) Main Article: Reciprocating CompressorDocumento17 páginasCompressor: Reciprocating Compressors (Edit) Main Article: Reciprocating Compressorraymart caluag0% (1)

- Module 4 (3) Collection, Transport, TransferDocumento32 páginasModule 4 (3) Collection, Transport, TransfervanilivaniliAinda não há avaliações

- Authority Requirement and DocumentationDocumento9 páginasAuthority Requirement and DocumentationRomeo CorneliezAinda não há avaliações

- Water Supply Distribution: On Completion of This Module You Should Be Able ToDocumento18 páginasWater Supply Distribution: On Completion of This Module You Should Be Able ToAnmol JassalAinda não há avaliações

- Request For Quotation - Temporary Bridge On Kabul River (Final 11feb11) PDFDocumento14 páginasRequest For Quotation - Temporary Bridge On Kabul River (Final 11feb11) PDFsubbaraoAinda não há avaliações

- Manual Aircond Rumah PDFDocumento115 páginasManual Aircond Rumah PDFazizmcp2Ainda não há avaliações

- Programme of Works 2008-2009Documento189 páginasProgramme of Works 2008-2009rbr100% (2)

- Punggol: From Farmland To Smart Eco-TownDocumento70 páginasPunggol: From Farmland To Smart Eco-TownMr Lokovettor100% (1)

- Unit 4Documento40 páginasUnit 4luthfil100% (1)

- Project Execution PlanDocumento56 páginasProject Execution PlanAîda hajriAinda não há avaliações

- Assignment 1-Pre Contract Planning and ControlDocumento2 páginasAssignment 1-Pre Contract Planning and ControlWisdom Kwame Agbozo0% (1)

- Quotation Container Office 20 Feet 2Documento1 páginaQuotation Container Office 20 Feet 2Rezza Octova GochirAinda não há avaliações

- Bedding & Back Filling SpecificationDocumento3 páginasBedding & Back Filling SpecificationMohammed Asimuddin Farooqui100% (1)

- Teaa Case Study-JzDocumento85 páginasTeaa Case Study-JzKota BalaAinda não há avaliações

- CV - Mohamad Azreen Shah Bin Aziz ShahDocumento3 páginasCV - Mohamad Azreen Shah Bin Aziz ShahAnonymous wTTx1LAinda não há avaliações

- Method Statement CoringDocumento1 páginaMethod Statement CoringAnonymous wTTx1L100% (1)

- Installation of Aluminium WorkDocumento18 páginasInstallation of Aluminium WorkAnonymous wTTx1LAinda não há avaliações

- MOS Open CutDocumento3 páginasMOS Open CutAnonymous wTTx1LAinda não há avaliações

- MOS Electrical WorksDocumento1 páginaMOS Electrical WorksAnonymous wTTx1LAinda não há avaliações

- MOS Plumbing WorksDocumento1 páginaMOS Plumbing WorksAnonymous wTTx1LAinda não há avaliações

- MOS-Relocation of Floor TrapDocumento1 páginaMOS-Relocation of Floor TrapAnonymous wTTx1LAinda não há avaliações

- Ubbl 1984 PDFDocumento196 páginasUbbl 1984 PDFAnonymous wTTx1LAinda não há avaliações

- Method Statement For Excavation and Backfilling WorksDocumento2 páginasMethod Statement For Excavation and Backfilling WorksAnonymous wTTx1L86% (22)

- M&E IntegrationDocumento18 páginasM&E IntegrationAnonymous wTTx1LAinda não há avaliações

- Lesson For SpreadsheetsDocumento69 páginasLesson For SpreadsheetsCrisna Rivera PundanoAinda não há avaliações

- Guest AccountingDocumento8 páginasGuest Accountingjhen01gongonAinda não há avaliações

- JQuery Interview Questions and AnswersDocumento5 páginasJQuery Interview Questions and AnswersShailesh M SassAinda não há avaliações

- Octopus 900 Instructions For UseDocumento18 páginasOctopus 900 Instructions For UseAli FadhilAinda não há avaliações

- Exchange Rates JBDocumento9 páginasExchange Rates JBboss9921Ainda não há avaliações

- Financial Analysis of OGDCLDocumento16 páginasFinancial Analysis of OGDCLsehrish_sadaqat7873100% (1)

- Lecture Notes (Financial Economics)Documento136 páginasLecture Notes (Financial Economics)americus_smile7474100% (2)

- Modeling Cover Letter No ExperienceDocumento7 páginasModeling Cover Letter No Experienceimpalayhf100% (1)

- D.E.I Technical College, Dayalbagh Agra 5 III Semester Electrical Engg. Electrical Circuits and Measurements Question Bank Unit 1Documento5 páginasD.E.I Technical College, Dayalbagh Agra 5 III Semester Electrical Engg. Electrical Circuits and Measurements Question Bank Unit 1Pritam Kumar Singh100% (1)

- Foreclosure of REMDocumento10 páginasForeclosure of REMShanelle NapolesAinda não há avaliações

- Profile Romblon IslandDocumento10 páginasProfile Romblon Islandderella starsAinda não há avaliações

- Chapter IDocumento38 páginasChapter ITuyền PhạmAinda não há avaliações

- Guidance - Third Party Human Capital Providers - January 2024Documento3 páginasGuidance - Third Party Human Capital Providers - January 2024rahmed78625Ainda não há avaliações

- Invidis Yearbook 2019Documento51 páginasInvidis Yearbook 2019Luis SanchezAinda não há avaliações

- LOVDocumento43 páginasLOVMei FadillahAinda não há avaliações

- Sampling PowerpointDocumento21 páginasSampling PowerpointMuhammad Furqan Aslam AwanAinda não há avaliações

- Data Loss PreventionDocumento20 páginasData Loss Preventiondeepak4315Ainda não há avaliações

- Digirig Mobile 1 - 9 SchematicDocumento1 páginaDigirig Mobile 1 - 9 SchematicKiki SolihinAinda não há avaliações

- Trahar (2013) - Internationalization of The CurriculumDocumento13 páginasTrahar (2013) - Internationalization of The CurriculumUriel TorresAinda não há avaliações

- FGD MetallurgyDocumento5 páginasFGD MetallurgyrajivashishAinda não há avaliações

- Electrical NTPCDocumento24 páginasElectrical NTPCSenthil KumarAinda não há avaliações

- Inkt Cables CabinetsDocumento52 páginasInkt Cables CabinetsvliegenkristofAinda não há avaliações

- JKR SPJ 1988 Standard Specification of Road Works - Section 1 - GeneralDocumento270 páginasJKR SPJ 1988 Standard Specification of Road Works - Section 1 - GeneralYamie Rozman100% (1)

- Geometric Entities: Basic Gear TerminologyDocumento5 páginasGeometric Entities: Basic Gear TerminologyMatija RepincAinda não há avaliações

- Tech Bee JavaDocumento57 páginasTech Bee JavaA KarthikAinda não há avaliações

- Pivacare Preventive-ServiceDocumento1 páginaPivacare Preventive-ServiceSadeq NeiroukhAinda não há avaliações

- Chapter 3: Classical Production Models: News Vendor ModelDocumento85 páginasChapter 3: Classical Production Models: News Vendor ModelmauriciovendraminAinda não há avaliações

- Wi-Fi Planning and Design Questionnaire 2.0Documento12 páginasWi-Fi Planning and Design Questionnaire 2.0Free Space67% (3)

- Title To The ProjectDocumento14 páginasTitle To The ProjectJatinChadhaAinda não há avaliações

- Piccadilly Circus BusDocumento1 páginaPiccadilly Circus Busmeylota2Ainda não há avaliações