Escolar Documentos

Profissional Documentos

Cultura Documentos

CC Civil Brochure

Enviado por

Abdul AzizDireitos autorais

Formatos disponíveis

Compartilhar este documento

Compartilhar ou incorporar documento

Você considera este documento útil?

Este conteúdo é inapropriado?

Denunciar este documentoDireitos autorais:

Formatos disponíveis

CC Civil Brochure

Enviado por

Abdul AzizDireitos autorais:

Formatos disponíveis

12.02.

UK

MADE IN UK

Concrete Impregnated Fabric...

NATIONAL WINNER

National Winner

Chambers of Commerce

Award 2011

AGRO

OTHER

POWER

Knowledge

Transfer

Network

Modern Built

Environment

Top Innovation

BRE Insite 2011

most INNOVATIVE product

AT

TE

OIL & GAS DESIGN

RNAT

I

AL FAIR

ON

CHAMBER

AWARDS

2011

RAIL

ZNAN I

PO

ROAD

WORLD OF CONCRETE

2011 Experts Choice Winner

Most Innovative Product

MTP Gold Medal Award

BUDMA 2011

www.concretecanvas.co.uk

2009 Winner

Material Connexion Medium Award

Material of the Year

2011 Nominee,

2007 Finalist

Design to Improve Life Award

For further information or technical support contact:

TM

+ 44 (0) 845 680 1908

info@concretecanvas.co.uk

www www.concretecanvas.co.uk

Concrete Impregnated Fabric...

Concrete CanvasTM

What is it?

Concrete Canvas (CC), is a flexible, cement impregnated fabric that

hardens when hydrated to form a thin, durable, water proof and fire

resistant concrete layer. CC allows concrete construction without the

need for plant or mixing equipment. Simply position the Canvas and

just add water.

CC consists of a 3-dimensional fibre matrix containing a specially

formulated dry concrete mix. A PVC backing on one surface of the

Canvas ensures the material is completely water proof. The material

can be hydrated either by spraying or by being fully immersed in

water. Once set, the fibres reinforce the concrete, preventing crack

propagation and providing a safe plastic failure mode. CC is available

in 3 thicknesses: CC5, CC8 and CC13, which are 5, 8 and 13mm thick

respectively.

Concrete Canvas section

Fibrous top surface (surface to hydrate)

3D fibre matrix

Dry concrete mix

PVC backing (water proof layer)

CC Key Facts

Easy To Use

CC is available in man portable rolls for applications with limited access

or where heavy plant equipment is not available. There is no need for

mixing or measuring, the concrete is premixed and cannot be over

hydrated. It will set underwater and in sea water.

Rapid

Once hydrated, CC remains workable for 2 hours and hardens to 80%

strength within 24 hours. Accelerated or retarded formulations can be

produced to meet specific customer requirements.

Environmentally Friendly

CC is a low mass, low carbon technology which uses up to 95% less

material than conventional concrete for many applications. It has

minimal impact on the local ecology due to its limited alkaline reserve

and very low wash rate. The impact on the environment is further

decreased by reducing the need for plant equipment.

Flexible

Batched rolls

CC has good drape characteristics allowing it to take up the shape of

complex surfaces including those with a double curvature. Unset

Canvas can be cut or tailored using basic hand tools.

Strong

The fibre reinforcement prevents cracking, absorbs energy from

impacts and provides a stable failure mode.

Durable

CC is chemically resistant, has good weathering performance and will

not degrade in UV.

Water Proof

The PVC backing on one surface of the Canvas ensures that the

material is completely water proof and chemically resistant.

Fire Resistant

CC is fire-safe, does not contribute to the surface spread of flames,

has a low level of smoke development and minimal hazardous gas

emissions. CC has achieved Euroclass classification B-s1, d0.

Bulk rolls

For further information or technical support contact:

TM

+ 44 (0) 845 680 1908

info@concretecanvas.co.uk

www www.concretecanvas.co.uk

Concrete Impregnated Fabric...

CC Applications

Ditch Lining

Slope Protection

CC can be rapidly unrolled to form ditch or channel lining. It is

significantly quicker and less expensive to install than conventional

concrete ditch lining and requires no specialist plant equipment. The

30m ditch shown above was lined in 45min.

CC can be used as slope stabilisation and other erosion control

applications such as temporary and permanent slope protection,

retaining walls, boulder fences, low level bunds and river bank and

dam revetments.

Bund Lining

Cable Protective Covering

Secondary containment bunds can be quickly lined with CC to provide

an efficient, chemically resistant alternative to concrete walling.

CC can be installed in-line with existing cable laying equipment to

provide protection against impact damage at a rate of 1000m/day.

200mm wide CC13 has been tested to BS 2484:1985 (Appendix A)

Impact Resistance for Straight concrete and clayware cable covers.

Pipeline Protection

Mining Applications

CC can be used as a coating for overland or underwater pipeline

protection, providing a superior tough rock shield. In remote areas it

can be used to coat steel pipe on site without expensive wet concrete

application plants. CC will set underwater and provide negative

buoyancy. CC13 meets the requirements of ASTM G13 .

CC can be used as an alternative to poured or sprayed concrete or as

a quick way of erecting strong permanent or temporary blast and vent

structures and spall lining.

Ground Resurfacing

Other Applications

CC can be secured with ground anchors to rapidly create a concrete

surface for flooring, pedestrian walk-ways or dust suppression. CC8

and CC13 have been tested to EN 1991-1-1:2002 (Resistance to

Imposed Loads on Vehicle Traffic Areas)

Other applications include use as a general replacement for shotcrete,

retaining walls, scour protection, culverts, blinding layers, weed

inhibiting, basement lining, water tanks, flood defences, tunnel lining

architectural and design applications...

For further information or technical support contact:

TM

+ 44 (0) 845 680 1908

info@concretecanvas.co.uk

www www.concretecanvas.co.uk

Concrete Impregnated Fabric...

Strength

Concrete Canvas Material Data

Very high early strength is a fundamental characteristic of CC.

Typical strengths and physical characteristics are as follows:

Compressive tests based on ASTM C109 02

- 10 day compressive failure stress (MPa)

40

Bending tests based on BS EN 12467:2004

- 10 day bending failure stress (MPa)

- 10 day bending Youngs modulus (MPa)

3.4

180

Tensile data

Physical Properties*

CC

Tensile strength (kN/m)

Thickness

(mm)

Batch Roll

Size (sqm)

Bulk Roll

Size (sqm)

Roll Width

(m)

Length direction

Width direction

CC5

6.7

3.8

CC5

10

200

1.0

CC8

8.6

6.6

CC8

125

1.1

CC13

19.5

12.8

CC13

13

N/A

80

1.1

CC

Mass (unset)

(kg/m2)

Density (unset)

(kg/m3)

Density (set)

(kg/m3)

CC5

7.0

1500

+30-35%

CC8

12.0

1500

+30-35%

CC13

19.0

1500

+30-35%

Setting

Abrasion Resistance (DIN 52108)

- Similar to twice that of OPC

Max 0.10 gm/cm2

4-5

MOHS hardness

CBR Puncture Resistance EN ISO 12236: 2007 (CC8 & CC13 only)

2.69kN

- Min. Push-through force

38mm

- Max. Deflection at Peak

Method of Hydration

Resistance to Imposed Loads on Vehicle Traffic Areas

EN 1991-1-1:2002 (CC8 & CC13 only)

- Category G compliant

- Gross weight of 2 axle vehicle 30 to 160kN

- Uniformly distributed load not exceeding 5kN/sqm

Spray the fibre surface with water until it feels wet to touch

for several minutes after spraying.

Standard Test Method for Impact Resistance of Pipeline Coatings

ASTM G13 (CC13 only)

Passed

Working Time

1-2 hours subject to ambient temperature

CC will achieve 80% strength at 24 hours after hydration.

Other

Re-spray the CC again after 1 hour if:

- Installing CC5

- Installing CC on a steep or vertical surface

- Installing in warm climates

Notes:

- CC cannot be over hydrated and an excess of water is always

recommended.

- Minimum ratio of water:CC is 1:2 by weight.

- Do not jet high pressure water directly onto the CC as this may wash

a channel in the material.

- CC can be hydrated using saline or non-saline water.

- CC will hydrate and set underwater.

- CC has a working time of 1-2 hours after hydration. Do not move CC

once it has begun to set.

- Working time will be reduced in hot climates.

- CC will set hard in 24 hours but will continue to gain strength for

years.

- If CC is not fully saturated, the set may be delayed and strength

reduced. If the set is delayed, re-wet with a large excess of water.

Passed

Soak-Dry testing (BS EN 12467:2004 part 5.5.5)

Passed

Water impermeability (BS EN 12467:2004 part 5.4.4)

Moisture vapour transmission rate

PVC Thickness

PVC MVTR range

0.42 mm

0.836 - 0.924 g.mm / (m.day)

< 3000mm

CC Static Head

Patent Information

Patent Protected

Pat Pend/Granted: AE (932/2006), AU (2005254788), BR (PI 0511408-0), CA (2570532),

CA (2655054), EP (1766162), EP (2027319), GB (2455008), IN (20/DELNP/2007),

JP (2007-516049), NO (20070245), RU (2386767), SA (12/303,864), US (7721749),

US (US-2010-0233417-A1), WO 2010/086618, ZA (2007/0471), ZA (2009/00222)

and other patents pending.

* Indicative values

B-s1, d0

Concrete Canvas Ltd.

CF37 5SP, United Kingdom

Contact Concrete Canvas Ltd. (UK)

Address

Unit 3, Block A22,

Treforest Ind. Estate,

CF37 5SP, UK

Passed**

** For tanking applications where a 100% waterproof seal is required, it is

recommended to use CC as a protective overlay in combination with an

appropriate sealed membrane liner. CC is not recommended as the sole

barrier layer where 100% impermeability is critical.

Reaction to Fire

CC has achieved Euroclass B certification:

BS EN 13501-1:2007+A1:2009

Freeze-thaw testing (BS EN 12467:2004 part 5.5.2)

E-mail: info@concretecanvas.co.uk

Phone: +44 (0) 845 680 1908

Web: www.concretecanvas.co.uk

11

The information contained herein is offered free of charge and is, to the best of our

knowledge, accurate. However, since the circumstances and conditions in which such

information and the products discussed therein can be used may vary and are beyond our

control, we make no warranty, express or implied, of merchantability, fitness or otherwise,

or against patent infringement, and we accept no liability, with respect to or arising from

use of such information or any such product.

EN12467:2004

Concrete Canvas:

Fibre cement sheet

NT

Oversize sheets

Class 1, Category A

Reaction to Fire B-s1,d0

Concrete Canvas 2012

Você também pode gostar

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeNo EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeNota: 4 de 5 estrelas4/5 (5794)

- The Little Book of Hygge: Danish Secrets to Happy LivingNo EverandThe Little Book of Hygge: Danish Secrets to Happy LivingNota: 3.5 de 5 estrelas3.5/5 (399)

- Lay Out AwalDocumento1 páginaLay Out AwalJennifer BakerAinda não há avaliações

- Hotel Bisnis Terintegrasi Ka Lebak Bulus Arsitektur HijauDocumento1 páginaHotel Bisnis Terintegrasi Ka Lebak Bulus Arsitektur HijauJennifer BakerAinda não há avaliações

- Skyscape Brochure 1299Documento8 páginasSkyscape Brochure 1299Jennifer BakerAinda não há avaliações

- Absensi Security Tebet8:008:008:008:008:0012:008:008:008:008:008:008:008:0012:00Documento4 páginasAbsensi Security Tebet8:008:008:008:008:0012:008:008:008:008:008:008:008:0012:00Jennifer BakerAinda não há avaliações

- Aluminium Composite Panel and Building Materials SupplierDocumento2 páginasAluminium Composite Panel and Building Materials SupplierJennifer BakerAinda não há avaliações

- 3D Shapes and Objects For PowerPoint SlidesDocumento27 páginas3D Shapes and Objects For PowerPoint SlidesDeepak OlaAinda não há avaliações

- PT Ecotekno. Jababeka. Cubicle ToiletDocumento4 páginasPT Ecotekno. Jababeka. Cubicle ToiletJennifer Baker100% (1)

- 0.drawing ListDocumento1 página0.drawing ListJennifer BakerAinda não há avaliações

- RabDocumento2 páginasRabJennifer BakerAinda não há avaliações

- Material ReceivedDocumento5 páginasMaterial ReceivedJennifer BakerAinda não há avaliações

- Combined Picture and Text Effects For Powerpoint SlidesDocumento25 páginasCombined Picture and Text Effects For Powerpoint SlidesJennifer BakerAinda não há avaliações

- Absensi tenaga kerja struktur mandorDocumento10 páginasAbsensi tenaga kerja struktur mandorJennifer BakerAinda não há avaliações

- DB1 (1 Unit)Documento1 páginaDB1 (1 Unit)Jennifer BakerAinda não há avaliações

- Material ReceivedDocumento88 páginasMaterial ReceivedJennifer BakerAinda não há avaliações

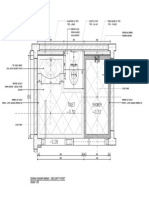

- Denah Kamar Mandi - Security PostDocumento1 páginaDenah Kamar Mandi - Security PostJennifer BakerAinda não há avaliações

- 01Documento1 página01Jennifer BakerAinda não há avaliações

- Area Service DenahDocumento1 páginaArea Service DenahJennifer BakerAinda não há avaliações

- W2C (4 Unit)Documento1 páginaW2C (4 Unit)Jennifer BakerAinda não há avaliações

- Brosur Woven GeotextileDocumento12 páginasBrosur Woven GeotextileJennifer Baker100% (1)

- S Umber Jay A CatalogueDocumento0 páginaS Umber Jay A CatalogueJennifer BakerAinda não há avaliações

- Tabel Kta NiagaDocumento1 páginaTabel Kta NiagaJennifer BakerAinda não há avaliações

- F'Hovinsi Jawa Barat Kabupaten Kara Wang: - KarawangDocumento1 páginaF'Hovinsi Jawa Barat Kabupaten Kara Wang: - KarawangJennifer BakerAinda não há avaliações

- AAAAAAAADocumento5 páginasAAAAAAAAKom SIfuAinda não há avaliações

- PRECONDocumento48 páginasPRECONakisAinda não há avaliações

- Life HouseDocumento3 páginasLife HouseJennifer BakerAinda não há avaliações

- What Will I Do (Tam-Tam)Documento1 páginaWhat Will I Do (Tam-Tam)Jennifer BakerAinda não há avaliações

- 1202 CC User GuideDocumento12 páginas1202 CC User GuideJennifer BakerAinda não há avaliações

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryNo EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryNota: 3.5 de 5 estrelas3.5/5 (231)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceNo EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceNota: 4 de 5 estrelas4/5 (894)

- The Yellow House: A Memoir (2019 National Book Award Winner)No EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Nota: 4 de 5 estrelas4/5 (98)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureNo EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureNota: 4.5 de 5 estrelas4.5/5 (474)

- Never Split the Difference: Negotiating As If Your Life Depended On ItNo EverandNever Split the Difference: Negotiating As If Your Life Depended On ItNota: 4.5 de 5 estrelas4.5/5 (838)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaNo EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaNota: 4.5 de 5 estrelas4.5/5 (265)

- The Emperor of All Maladies: A Biography of CancerNo EverandThe Emperor of All Maladies: A Biography of CancerNota: 4.5 de 5 estrelas4.5/5 (271)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersNo EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersNota: 4.5 de 5 estrelas4.5/5 (344)

- Team of Rivals: The Political Genius of Abraham LincolnNo EverandTeam of Rivals: The Political Genius of Abraham LincolnNota: 4.5 de 5 estrelas4.5/5 (234)

- The Unwinding: An Inner History of the New AmericaNo EverandThe Unwinding: An Inner History of the New AmericaNota: 4 de 5 estrelas4/5 (45)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyNo EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyNota: 3.5 de 5 estrelas3.5/5 (2219)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreNo EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreNota: 4 de 5 estrelas4/5 (1090)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)No EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Nota: 4.5 de 5 estrelas4.5/5 (119)