Escolar Documentos

Profissional Documentos

Cultura Documentos

Dry Cooling of Coke - Ispatguru

Enviado por

knsaravanaTítulo original

Direitos autorais

Formatos disponíveis

Compartilhar este documento

Compartilhar ou incorporar documento

Você considera este documento útil?

Este conteúdo é inapropriado?

Denunciar este documentoDireitos autorais:

Formatos disponíveis

Dry Cooling of Coke - Ispatguru

Enviado por

knsaravanaDireitos autorais:

Formatos disponíveis

12/25/2014

DryCoolingofCoke|ispatguru.com

Home

Aboutme

ConsultingServices

ContactMe

Sitemap

Articles

IspatDigest

Searchthiswebsite...

HomeArticlesDryCoolingofCoke

Articles

Apr25

Tags

CDCP

CDQ

cokerate

CSR

Micum

RelatedPosts

FactorsaffectingCokerateinaBlastFurnace

CorporateSocialResponsibility

TechnologiesforimprovementinCokingprocessinByproductCokeOvens

Metallurgicalcoke

ShareThis

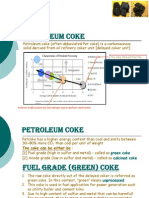

DryCoolingofCoke

PostedbySatyendraonApr25,2013inArticles|8comments

http://ispatguru.com/drycoolingofcoke/

1/7

12/25/2014

DryCoolingofCoke|ispatguru.com

DryCoolingofCoke

Drycoolingofcokeisknownascokedryquenching(CDQ)andisanalternativetothetraditionalwet

quenching.Duringwetquenchingofrunofovencoke,sensibleheatofthehotcokeisdissipatedintothe

atmosphereandislost.Inadditionthereareairborneemissions(0.5tonofsteampertonofcokeladenwith

phenol,cyanide,sulfideanddust)andalargequantityofwater(around0.6Cumpertonofcoke)isneededfor

wetquenching.Thecontaminantsinwaterarealsodischargedintheenvironment.InaCokeDryCoolingPlant

(CDCP)redhotcokeiscooledbyinertgases.Theheatenergyfromtheredhotcokeisrecoveredinawaste

heatboilerforuseassteam,resultinginenergyconservationaswellasareductionincokeparticleemissions.

Around80%ofsensibleheatisrecovered.TheCDCPprocessflowisinFig1.

Fig1ProcessflowinCDCP

History

Afterpilotandpilot/commercialtrialsthefirstfullscaleCDCPinstallationwascommissionedin1965atthe

CherepovetsIronandSteelWorksinthenUSSR.By1978around50CDCPmodulesof56tonsperhourwere

inoperationinthenUSSR.JapanpurchasedlicensefromUSSRandthreeJapaneseinstallationswere

commissionedin197677.InIndiaMECONpurchasedlicenseforGiprokoksdesignCDCPfromUSSRand

thefirst12chamberswereinstalledatVisakhapatnamSteelPlant.ThefirstCDCPplantwascommissionedin

September1989.Presently19chambersofthisdesignareinoperation.

ConceptofCokeDryCooling

HotcokeisbroughtfromthebatterytotheCDCPinbottomopeningbucketkeptonthequenchingcar.This

bucketisliftedattheCDCPbyahoisting/chargingdevicetothetopoftheCDCPchamberandredhotcokeis

dischargedinthechamberforcooling.Hotcoke(temperaturearound10001100degC)iscooledinthe

chamberbytheinertgas.TheinertgasinacontinuousrunningCDCPplantisamixgaswhichconsistsof

mainlynitrogen(70%75%)alongwithsmallamountsofCO2(0%15%),CO(8%10%),andH2(2%

3%).Inthechamberinertgasmovesupwardswhilethecokemovesdownwardbythegravity.Thecokeis

dischargedatthebottom.Thepassagetimeofthecokethroughthechamberisaround56hoursandtheflow

rateofinertgasisaround82,000NCumperhour.Thetemperatureofthecokeatthetimeofdischargefrom

thechamberisbelow200degC.Thehotinertgas,afterpickingheatfromthehotcoke,comesoutfromthetop

ataround800degCandisconveyedtothewasteheatrecoveryboiler(WHRB)wherethesensibleheatofthe

inertgasisusedtoproducehighpressure(around40Kgf/Sqcm)andtemperature(around440degC)steam

(25tons/hour).Thissteamproducespowerinabackpressureturbine.Thelowtemperaturecirculatinginertgas

attheWHRBexitispressurizedbyabloweranditscompositioniscorrectedbyadditionofnitrogengasand

thenthecoolinggasisinjectedatthebottomoftheCDCPchamber.Thetemperatureofthecoolinggasis

around170degC.OtherimportantequipmentinCDCParecutoffdeviceforcuttingoutthecokefromthe

chamber,dustremovingsystemforremovingthedustinthecirculatinginertgasandgasblower.

Primaryandsecondarydustcollectionsystemsareinstalledatthecokechargingandthedischargingareaas

wellasintheboilersection.Dustemissionsarereducedto50mg/NCuminabagfilterhousewhichisless

http://ispatguru.com/drycoolingofcoke/

2/7

12/25/2014

DryCoolingofCoke|ispatguru.com

than0.09Kgofdustpertonofdrycooledcoke.Sinecoolinggasisrecirculatedinaclosedsystemthereisno

airbornecokeemissionsfromgascooling.AlsonodustladensteamcloudsarereleasedbytheCDCP.This

helpsintheimprovementintheworkingenvironmentinthearea.

InamodernthreechamberCDCP,anominalcapacityof50tonsperhourisachievedperchamber.Normally

twochambersareinfulloperationandoneisinhotstandbystatus.CDCPisusuallyoperatedinsuchaway

thattwochambersandboilerworkatfullcapacityandthethirdiskeptinhotconditionbychargingat10%of

itscoolingcapacity.Thisstandbychamberisthusreadytoassumefulloperationincaseaproblemariseswith

eitheroftheoperatingtwochambers.Acokedrycoolingplantmoduleofcapacity56tonsperhourof

GiprokoksdesignisshowninFig2

Fig2Cokedrycoolingplantmodule.

Advantagesofcokedrycooling

1. MicumvalueM40ofthecokeisimprovedby3%to8%.MicumvalueM10ofthecokeisimproved

by0.3%to0.8%

2. CSRvalueofcokeimprovesbyaround2%.

3. Incokeproducedbydrycooling,thequalityofcokeismorestablebecauseoflowstandarddeviation

(usuallyaround1.25%).Auniformqualityofcokehelpsinblastfurnaceoperation.

4. Useofdrycooledcokereducesthecokerateintheblastfurnacebyaround2%2.5%.

5. Sincethehotcokeiscooledgraduallybytheinertgas,itisfreefromsurfaceporeandinternalcracks

normallypresentinthewetquenchedcoke.

6. Cokedrycoolingisenvironmentfriendlyascomparedtowetquenchingsincetheredcokeisquenched

byinertgasinaclosedsystemandisequippedwithefficientdustremovingfacilitiesandsuchavoidsthe

pollutionoftheatmosphere.

7. Cokedrycoolinggeneratesenergyfromwasteheat.Around1518MWofpowercanbegeneratedfrom

aCDCPhavingacapacityof100tonsperhour.

8. Sinceitrecoverssensibleheatofthecokethereisnetenergysaving.Energysavingisaround0.25G

cal/tonofcoke.

9. Sincethepowerisgeneratedbysteamfromwasteenergyinsteadofsteamfromfuelburningboiler,

emissionoftheequivalentamountofgreenhousegas(CO2)totheatmosphereissaved.Co2emissions

reductionisaround130Kg/tonofcoke.

10. Sincethemoisturecontentofcokeproducedbydrycoolingisaround0.2%ascomparedtothatof

around5%inwetquenchedcoke,ithelpsinreducingthecokerateinblastfurnace.Moistureinthecoke

needsadditionalheatintheblastfurnaceforevaporation.

11. CDCPhasbetterreliabilityandlowermaintenance.

12. Thereisconservationofwater.

http://ispatguru.com/drycoolingofcoke/

3/7

12/25/2014

DryCoolingofCoke|ispatguru.com

Recommend 264peoplerecommend

this.SignUptoseewhat

yourfriendsrecommend.

8Comments

1.

Apr26

brijeshkumardwivedi

Goodliteratureforcdqunderstanding.

Reply

2.

Apr26

SubhenduKumarDalai

Theoverallthermalefficiencyis8085%whichisaverygoodvalue.Thankyousirforthisuseful

article.

Reply

3.

Apr28

MilindThosar

DearSir,

GoodtechnicalliteratureforIndiaindustry.Keepitup.Ithelpseverybodystudent,engineersand

managers.

Yoursfaithfully,

MilindThosar

Reply

Apr30

KKGhosh

VisakhapatnamSteelPlant(VSP)underRashtriyaIspatNigamLimited(RINL)aNavaratnaPSU

isopeartingdryquenchingsuccessfullysinceearly90s.

Reply

4.

Apr30

KKGhosh

DearSir

Doyouhavedataofothersteelplantsgloballyregardinggenerationofcokedustpertonneofdrycoke?

Reply

http://ispatguru.com/drycoolingofcoke/

4/7

12/25/2014

5.

DryCoolingofCoke|ispatguru.com

Apr30

subodhkumar

Veryinformativereport.

Maintenanceofconventionalcokeovensparticularlyinefficientcleaningofthecokeovendoorshad

beenthecauseofverypoorlifeofIndiancokeovenbatteries.Whatarethemaintenanceproblemsand

experienceinIndiawithdrycokequenching?

Reply

6.

Feb15

GCSharma

Veryinformativeanduseful.SailIspBurnpurhasinstalledthisplant.Thanksforsuchgoodwriteup

Reply

7.

May13

jai

Kindlyexplainthepotentialhazards.

Reply

Trackbacks/Pingbacks

1. TechnologiesforimprovementinCokingprocessinByproductCokeOvens|ispatguru.com[...]Dry

CoolingofCoke[...]

LeaveaReply

Youremailaddresswillnotbepublished.Requiredfieldsaremarked*

Name*

Email*

Website

Comment

YoumayusetheseHTMLtagsandattributes:<ahref=""title=""><abbrtitle=""><acronymtitle="">

<b><blockquotecite=""><cite><code><deldatetime=""><em><i><qcite=""><strike><strong>

SubmitComment

http://ispatguru.com/drycoolingofcoke/

5/7

12/25/2014

DryCoolingofCoke|ispatguru.com

Like 264peoplelikethis.SignUptosee

whatyourfriendslike.

RecentPosts

LimeandCalcinedDolomiteforUseinSteelPlant

BuildingOrganizationalCapabilitiesforExcellence

RefractoryLiningofaContinuousCastingTundish

CalciuminSteels

PeopleStrategyforExcellence

RecentComments

SubrataChakrabortyonIronorepelletsandPelletizingprocesses

Arupkr.HalderonRollingMillsRolls

Arupkr.HalderonRollingMillsRolls

KashivishwanathonIronorepelletsandPelletizingprocesses

AmrutSwainonTheSinteringProcessofIronOreFines

Archives

December2014

November2014

October2014

September2014

August2014

July2014

June2014

May2014

April2014

March2014

February2014

January2014

December2013

November2013

October2013

September2013

August2013

July2013

June2013

May2013

April2013

March2013

February2013

Categories

Articles

IspatDigest

Uncategorized

Meta

Login

EntriesRSS

CommentsRSS

WordPress.org

http://ispatguru.com/drycoolingofcoke/

6/7

12/25/2014

DryCoolingofCoke|ispatguru.com

DesignedbyElegantThemes|PoweredbyWordpress

http://ispatguru.com/drycoolingofcoke/

7/7

Você também pode gostar

- Carbon Capture and Storage: The Legal Landscape of Climate Change Mitigation TechnologyNo EverandCarbon Capture and Storage: The Legal Landscape of Climate Change Mitigation TechnologyAinda não há avaliações

- Dry Quenching of Hot Coke - IspatGuruDocumento10 páginasDry Quenching of Hot Coke - IspatGurukaustavAinda não há avaliações

- 2004 CHLORIDE AND POTASSIUM REMOVAL PROCESSES FOR KRAFT PULP MILLS - A ReviewDocumento13 páginas2004 CHLORIDE AND POTASSIUM REMOVAL PROCESSES FOR KRAFT PULP MILLS - A ReviewHenrique CostaAinda não há avaliações

- NCBMPaper 2007Documento10 páginasNCBMPaper 2007Mazhar choudharyAinda não há avaliações

- CO2 Recovery MHIDocumento44 páginasCO2 Recovery MHIAl HattanAinda não há avaliações

- Coke Prevention During Steam Cracking For Ethylene Production. - Kurita ENDocumento2 páginasCoke Prevention During Steam Cracking For Ethylene Production. - Kurita ENvaraduAinda não há avaliações

- Chemical RecoveryDocumento28 páginasChemical RecoveryAditya Raj100% (1)

- Presentations 15Documento44 páginasPresentations 15thirumalaiAinda não há avaliações

- Carbon Capture and StorageDocumento24 páginasCarbon Capture and StorageShashwat OmarAinda não há avaliações

- Processes For Recycling: 4.4.1.2.1 Conventional Kroll ProcessDocumento14 páginasProcesses For Recycling: 4.4.1.2.1 Conventional Kroll Processelma watAinda não há avaliações

- Carbon Curing PDFDocumento5 páginasCarbon Curing PDFSyed Yameen AndrabiAinda não há avaliações

- Sodium Chlorite Handbook PDFDocumento27 páginasSodium Chlorite Handbook PDFDiksha rejaAinda não há avaliações

- Vinyl Chloride Production-PowerpointDocumento69 páginasVinyl Chloride Production-PowerpointRounak Choudhary100% (3)

- CEresearch 123Documento59 páginasCEresearch 123jhay thegreatAinda não há avaliações

- Chlor Alkali TechnologyDocumento19 páginasChlor Alkali TechnologyRamakrishna ReddyAinda não há avaliações

- Pre CombustionDocumento62 páginasPre CombustionigrjaaAinda não há avaliações

- Chlorine Production and UsesDocumento81 páginasChlorine Production and Usesmuhammad_asim_10Ainda não há avaliações

- 01 Chlorine Production eDocumento10 páginas01 Chlorine Production ekajaiquAinda não há avaliações

- A Life Cycle Assessment of Portland Cement ManufacturingDocumento2 páginasA Life Cycle Assessment of Portland Cement Manufacturing1gargirajawatAinda não há avaliações

- Questions and Answers: Chlorine DioxideDocumento6 páginasQuestions and Answers: Chlorine DioxideChanBoonChewAinda não há avaliações

- Sodium HydroxideDocumento1 páginaSodium HydroxideEmmily NyatichiAinda não há avaliações

- Chloro AlkalisDocumento20 páginasChloro AlkalisPrabhdeep Singh VirdiAinda não há avaliações

- Carbon Dioxide (CO) Is Composed of TwoDocumento19 páginasCarbon Dioxide (CO) Is Composed of TwoFurqan YousafzaiAinda não há avaliações

- Coursework B Science 2014 ChemistryDocumento5 páginasCoursework B Science 2014 Chemistryafaybjktm100% (2)

- Petroleum DaDocumento17 páginasPetroleum DaPavneet KaurAinda não há avaliações

- CFB Refractory Repair: Power January 2006Documento10 páginasCFB Refractory Repair: Power January 2006num0067Ainda não há avaliações

- A Clean Production Process of Sodium Chlorite From Sodium ChlorateDocumento7 páginasA Clean Production Process of Sodium Chlorite From Sodium ChlorateArbhy Indera IkhwansyahAinda não há avaliações

- Dry Quenched Coke - Enabler To Enhance BF PerformanceDocumento26 páginasDry Quenched Coke - Enabler To Enhance BF PerformanceSatyamKumarAinda não há avaliações

- A Vital Element of Our Low-Carbon Energy Future: Carbon Capture and StorageDocumento42 páginasA Vital Element of Our Low-Carbon Energy Future: Carbon Capture and StorageAsad KhanAinda não há avaliações

- Carbon EngineeringDocumento5 páginasCarbon EngineeringYashasvi DhankharAinda não há avaliações

- Carbon EngineeringDocumento5 páginasCarbon EngineeringYashasvi DhankharAinda não há avaliações

- Objective 6.4Documento2 páginasObjective 6.4Rodrigo WrightAinda não há avaliações

- Zeeshan Ashraf (044) Assignment Chem-453Documento12 páginasZeeshan Ashraf (044) Assignment Chem-453Zeeshan AshrafAinda não há avaliações

- FAQ Chlorine Dioxide - European Version April 2017Documento16 páginasFAQ Chlorine Dioxide - European Version April 2017Long Thuận100% (1)

- Manufacturing Fine TiO2 Particles by Chloride ProcessDocumento2 páginasManufacturing Fine TiO2 Particles by Chloride ProcessDiahAyuSafitriAinda não há avaliações

- Coking TechnologyDocumento32 páginasCoking TechnologyzamijakaAinda não há avaliações

- Carbon Capture and StorageDocumento25 páginasCarbon Capture and StorageRajeev Garg100% (1)

- "Carbon Capture and Sequestration: in The Canadian Context": Sura Abdul-Razzak April 14 2008Documento25 páginas"Carbon Capture and Sequestration: in The Canadian Context": Sura Abdul-Razzak April 14 2008karamnia100% (1)

- Glass Manufacturing PDFDocumento4 páginasGlass Manufacturing PDFwakasensei9950% (2)

- Ilovepdf MergedDocumento341 páginasIlovepdf MergedIndresh BharadwajAinda não há avaliações

- NewItem 91 NewItem 91 Sulphuric Acid Plants CoindsDocumento51 páginasNewItem 91 NewItem 91 Sulphuric Acid Plants CoindsJadeja PradyumansinhAinda não há avaliações

- (PDF) CFB Refractory RepairDocumento1 página(PDF) CFB Refractory RepairManuel CampuzanoAinda não há avaliações

- L7 PDFDocumento24 páginasL7 PDFAnil KumarAinda não há avaliações

- United States Patent (191: Yamamoto, Shibukawa SyukiDocumento6 páginasUnited States Patent (191: Yamamoto, Shibukawa SyukiUntung SetiawanAinda não há avaliações

- Paper Accepted For Publication at Chemical Engineering Research and DesignDocumento58 páginasPaper Accepted For Publication at Chemical Engineering Research and Designjhay thegreatAinda não há avaliações

- Pirolisis de PolipropilenoDocumento9 páginasPirolisis de PolipropilenoNena Jessi LoveAinda não há avaliações

- Measuring Product Carbon FootprintDocumento6 páginasMeasuring Product Carbon FootprintmercurybkkAinda não há avaliações

- British Solid Carbon Dioxide: Dry Ice, Sometimes Referred To As "Cardice" (ChieflyDocumento4 páginasBritish Solid Carbon Dioxide: Dry Ice, Sometimes Referred To As "Cardice" (ChieflyjonanaAinda não há avaliações

- Chem EngineeringDocumento61 páginasChem EngineeringVIMALAinda não há avaliações

- Explain What Happens During The Following Stages of Bleaching Chemical PulpsDocumento8 páginasExplain What Happens During The Following Stages of Bleaching Chemical PulpszacksAinda não há avaliações

- Carbon Capture and Storage - WikipediaDocumento53 páginasCarbon Capture and Storage - WikipediaMOHAN RAVICHANDRANAinda não há avaliações

- An Introduction To Low Carbon FuelsDocumento29 páginasAn Introduction To Low Carbon FuelsRamesh-NairAinda não há avaliações

- Dry Ice PDFDocumento18 páginasDry Ice PDFAli AtwaAinda não há avaliações

- Vinyl Chloride MonomerDocumento22 páginasVinyl Chloride MonomerShoaib RathoreAinda não há avaliações

- CO Capture and Storage: Options and Challenges For The Cement IndustryDocumento49 páginasCO Capture and Storage: Options and Challenges For The Cement IndustryMohamedRaahimAinda não há avaliações

- Exhaust Gas Treatment - Dec15r1Documento19 páginasExhaust Gas Treatment - Dec15r1Emanuel FusinatoAinda não há avaliações

- Homework 4 Climate Change Solution ResearchDocumento1 páginaHomework 4 Climate Change Solution ResearchmartirezdawncelineAinda não há avaliações

- Chlor-Alkali IndustryDocumento57 páginasChlor-Alkali IndustryKhansa GulshadAinda não há avaliações

- Steam Turbine Q&ADocumento8 páginasSteam Turbine Q&AknsaravanaAinda não há avaliações

- Nithya Kalyana Perumal TempleDocumento2 páginasNithya Kalyana Perumal TempleknsaravanaAinda não há avaliações

- Monitor Feedwater Heater PerformanceDocumento1 páginaMonitor Feedwater Heater PerformanceknsaravanaAinda não há avaliações

- Boiler-Questions - AnswersDocumento38 páginasBoiler-Questions - AnswersKapil_1983100% (3)

- Economizer Recirculation For Low-Load Stability in Heat Recovery Steam GeneratorDocumento10 páginasEconomizer Recirculation For Low-Load Stability in Heat Recovery Steam GeneratorknsaravanaAinda não há avaliações

- Nithya Kalyana Perumal TempleDocumento2 páginasNithya Kalyana Perumal TempleknsaravanaAinda não há avaliações

- Brochure Sticky Traps V 10.223102555Documento5 páginasBrochure Sticky Traps V 10.223102555knsaravanaAinda não há avaliações

- ERW PipesDocumento2 páginasERW PipesknsaravanaAinda não há avaliações

- CDM RDF 12MW Karimnagar APDocumento112 páginasCDM RDF 12MW Karimnagar APknsaravana100% (1)

- Union Cement Company, UAE, 15MW WHRBDocumento1 páginaUnion Cement Company, UAE, 15MW WHRBknsaravana0% (1)

- Client Server Application For Echo Command: Ex No Date Experiment Name Page No Marks SignDocumento6 páginasClient Server Application For Echo Command: Ex No Date Experiment Name Page No Marks SignknsaravanaAinda não há avaliações

- Zerodha Stock Market PDFDocumento108 páginasZerodha Stock Market PDFAnshu GauravAinda não há avaliações

- STD Spec For Piping WeldingDocumento14 páginasSTD Spec For Piping WeldingknsaravanaAinda não há avaliações

- Crompton Greaves Domestic Pumps Price ListDocumento12 páginasCrompton Greaves Domestic Pumps Price Listknsaravana100% (1)

- Bagasse Weight CalculationDocumento2 páginasBagasse Weight Calculationjibyk100% (11)

- Steam Turbine DesignDocumento14 páginasSteam Turbine DesignFaiz de PorrasAinda não há avaliações

- Heat RateDocumento3 páginasHeat RatenbvltrainingAinda não há avaliações

- Name TransferDocumento4 páginasName TransferrbspAinda não há avaliações

- Sliding Pressure OperationDocumento5 páginasSliding Pressure Operationknsaravana100% (1)

- USC BoilerDocumento31 páginasUSC Boilerscribd.123Ainda não há avaliações

- Case Studies of Transportation Public-Private Partnerships Around The WorldDocumento158 páginasCase Studies of Transportation Public-Private Partnerships Around The WorldzhenhuaruiAinda não há avaliações

- Column, Slab, Footing and Wall Footing Foundations: Class A MixingDocumento47 páginasColumn, Slab, Footing and Wall Footing Foundations: Class A MixingGioharry Nul PanambulanAinda não há avaliações

- Sat Vocabulary Lesson and Practice Lesson 5Documento3 páginasSat Vocabulary Lesson and Practice Lesson 5api-430952728Ainda não há avaliações

- Assignment 1Documento3 páginasAssignment 1farhang_tAinda não há avaliações

- World's Standard Model G6A!: Low Signal RelayDocumento9 páginasWorld's Standard Model G6A!: Low Signal RelayEgiAinda não há avaliações

- Sika - Bitumen: Bitumen Emulsion Waterproof & Protective CoatingDocumento3 páginasSika - Bitumen: Bitumen Emulsion Waterproof & Protective Coatingdinu69inAinda não há avaliações

- 02-Building Cooling LoadsDocumento3 páginas02-Building Cooling LoadspratheeshAinda não há avaliações

- PEH Q3 Long QuizDocumento1 páginaPEH Q3 Long QuizBenedict LumagueAinda não há avaliações

- 外贸专业术语Documento13 páginas外贸专业术语邱建华Ainda não há avaliações

- Gypsum Plasterboard: National Standard of The People'S Republic of ChinaDocumento15 páginasGypsum Plasterboard: National Standard of The People'S Republic of ChinaGarry100% (2)

- Electric ScootorDocumento40 páginasElectric Scootor01fe19bme079Ainda não há avaliações

- Determination of Drop-Impact Resistance of Plastic BottlesDocumento11 páginasDetermination of Drop-Impact Resistance of Plastic BottlesAndres BrañaAinda não há avaliações

- VBAC MCQsDocumento3 páginasVBAC MCQsHanaAinda não há avaliações

- Effects of Climate ChangeDocumento3 páginasEffects of Climate Changejiofjij100% (1)

- TreesDocumento69 páginasTreesADITYA GEHLAWATAinda não há avaliações

- Drilling & GroutingDocumento18 páginasDrilling & GroutingSantosh Laxman PatilAinda não há avaliações

- Dawn of Solar PV CookingDocumento5 páginasDawn of Solar PV CookingAbhinav AgrawalAinda não há avaliações

- Keiilf: Training ManualDocumento53 páginasKeiilf: Training ManualGary GouveiaAinda não há avaliações

- Socialized HousingDocumento48 páginasSocialized HousingJessieReiVicedoAinda não há avaliações

- Poly 103Documento20 páginasPoly 103Sharifah Zulaikha BenYahyaAinda não há avaliações

- Tree Growth CharacteristicsDocumento9 páginasTree Growth CharacteristicsMunganAinda não há avaliações

- Hydrodynamic Calculation Butterfly Valve (Double Disc)Documento31 páginasHydrodynamic Calculation Butterfly Valve (Double Disc)met-calcAinda não há avaliações

- Schneider Pressure Switch XMLDocumento2 páginasSchneider Pressure Switch XMLhaoAinda não há avaliações

- Sales 20: Years Advertising Expense (Millions) X Sales (Thousands) yDocumento8 páginasSales 20: Years Advertising Expense (Millions) X Sales (Thousands) ybangAinda não há avaliações

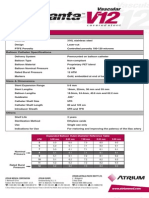

- Advanta V12 Data SheetDocumento2 páginasAdvanta V12 Data SheetJuliana MiyagiAinda não há avaliações

- Module-4 (PDFDrive)Documento67 páginasModule-4 (PDFDrive)Divya priya KAinda não há avaliações

- PIX4D Simply PowerfulDocumento43 páginasPIX4D Simply PowerfulJUAN BAQUEROAinda não há avaliações

- Math COT 3Documento18 páginasMath COT 3Icy Mae SenadosAinda não há avaliações

- Passenger Lift Alert - Health and Safety AuthorityDocumento4 páginasPassenger Lift Alert - Health and Safety AuthorityReginald MaswanganyiAinda não há avaliações

- Murata High Voltage CeramicDocumento38 páginasMurata High Voltage CeramictycristinaAinda não há avaliações

- Arizona, Utah & New Mexico: A Guide to the State & National ParksNo EverandArizona, Utah & New Mexico: A Guide to the State & National ParksNota: 4 de 5 estrelas4/5 (1)

- Naples, Sorrento & the Amalfi Coast Adventure Guide: Capri, Ischia, Pompeii & PositanoNo EverandNaples, Sorrento & the Amalfi Coast Adventure Guide: Capri, Ischia, Pompeii & PositanoNota: 5 de 5 estrelas5/5 (1)

- South Central Alaska a Guide to the Hiking & Canoeing Trails ExcerptNo EverandSouth Central Alaska a Guide to the Hiking & Canoeing Trails ExcerptNota: 5 de 5 estrelas5/5 (1)

- Japanese Gardens Revealed and Explained: Things To Know About The Worlds Most Beautiful GardensNo EverandJapanese Gardens Revealed and Explained: Things To Know About The Worlds Most Beautiful GardensAinda não há avaliações

- New York & New Jersey: A Guide to the State & National ParksNo EverandNew York & New Jersey: A Guide to the State & National ParksAinda não há avaliações