Escolar Documentos

Profissional Documentos

Cultura Documentos

Twisted Magnet Wire TX

Enviado por

Santiago Perez AlvaradoDireitos autorais

Formatos disponíveis

Compartilhar este documento

Compartilhar ou incorporar documento

Você considera este documento útil?

Este conteúdo é inapropriado?

Denunciar este documentoDireitos autorais:

Formatos disponíveis

Twisted Magnet Wire TX

Enviado por

Santiago Perez AlvaradoDireitos autorais:

Formatos disponíveis

148

IEEE TRANSACTIONS

ON PARTS, HYBRIDS, AND PACKAGING,

VOL. PHP-7, NO. 4, DECEMBER 1971

Twisted Magnet Wire Transmission Line

PETER LEFFERSON

Abstract - Transmission line principles are applied to twisted

magnet wire lines made of two wires to establish design limits.

Expressions are developed to predict the effects of wire film insulation

and of twisting. A design procedure is developed to realize a desired

characteristic impedance for the design of radio frequency broad-band

transformers, signal combiners, and pulse transformers.

INTRODUCTION

ROAD-BAND transformers and signal combiners for HF

thru UHF and the digital field using twisted magnet wire

transmission line, have been discussed in the literature and are

widely used. [l]-[3].

The terminal impedances of these

passive devices are a function of: the transmission-line characteristic impedance, line length, core material, and source

impedance at other terminals. If the line impedance can be

controlled, these devices can be built with a wide frequency

range without requiring additional lumped elements. The

terminal reactance can be tailored in the same way to improve

matching into active devices.

This paper will consider only the twisted magnet wire

transmission line and a design procedure will be given as a

function of wire size, wire insulation thickness, insulation

relative dielectric constant, and wire twist.

Twisted magnet wire transmission lines using the wire size

range from 4 to 44 can be realized with characteristic

impedances ranging from 10 to 85 R. More practical examples

would be a 50-a line made with a pair of number 40 wires and

a 25,a line made with a pair of number 15 wires.

Basic Dimension Standard

The United States military specification for magnet wire,

MIL-W-583, will be used for a well-ordered base on which to

build a design procedure. Among other things, this specification defines round magnet wire having film insulation. It lists

American Wire Gage sizes 4-44 in four insulation thickness

groups with their dimensions and tolerances. The minimum

insulation thickness for each wire size in groups 2-4 is

approximately the minimum thickness for the wire size in

group one multiplied by the group number. The maximum

thickness is about equal to the minimum of the next higher

group. These data from MIL-W-583 is repeated in Table I.

Using the dimensions from this table and the expression for

characteristic impedance of two parallel wires [4]

Z1 = pcash-4.

(1)

u

Vt req

The computer calculated characteristic impedances are plotted

in Fig. 1 for a relative dielectric constant of 1.O.D and d are

the wire diameters with and without the insulation film,

respectively. freq is the equivalent relative dielectric constant.

Fig. 1 shows the calculated impedances for the film-thickness

extremes.

WIRE TWIST AND PITCH ANGLE

The effect of twisting the line can be normalized for all

wire sizes if the twist per inch T is equated to the angle

included between each wire and a line drawn down the center

of the transmission line (pitch angle0). For bifilar wire, twist

is given by

tan 0

j-z----(2)

I-iD

The relation of twist and pitch angle is plotted in Fig. 2 for

wire sizes 4-44 and the insulation thicknesses of classes one

and four.

Experimental data suggest that optimum performance is

obtained from lines having pitch angles between 20-45.

When the line twist is loose, it becomes difficult to maintain

continuous line geometry as the line is wound on a form. This

is seen as a large reflection on a time-domain reflectometer.

The transmission line is subjected to excessive stress as the

twist angle approaches 50.5 and in the vicinity of 50.5 it will

break. Equation 2 and. the maximum pitch angle are developed

in the Appendix.

A line impedance rise of 1 or 2 S2can be anticipated when

the line is wound of a ferrite form.

FILM DIELECTRIC

The equivalent dielectric constant that must be considered

in order to give meaning to the theoretical characteristic

impedance of Fig. 1, is a function of the film insulation and

pitch angle. It is common to express a system having two

dielectrics as

freq = (YE~I+ /3Er* CX+ /3 = 1

=Erl

ManuscriptreceivedJune 9, 1971;revisedSeptember13, 1971.

The author is with the Milton Roy Company, St. Petersburg, Fla.

C.L. Ruthroff, Some broad

47, pp. 1337 - 1342, Aug. 1959.

0. Pitzalis, Jr., Practical

transmission line transformers,

Am. 1968.

* 3R.E. Matick, Transmission

application,Proc.

IEEE, vol. 56,

band transformers,

Proc. IEEE, vol.

design information

for braod-band

Proc. IEEE, vol. 56, pp. 738 - 739,

line pulse transformers - Theory and

pp. 47 - 62, Jan. 1968.

(1 -P)+PEr*

= 91 + P (Er2 - frl>,

where erI and er2 are the relative dielectric constants of air (or

some other surrounding material) and the film insulation,

41nternationa1

Telephone and Telegraph Co., Reference Data for

New York: Sames, 1969, ch. 22, p. 22.

Radio Engineers, 5th ed.

Authorized licensed use limited to: Universidad de Antioquia. Downloaded on November 20, 2009 at 11:47 from IEEE Xplore. Restrictions apply.

LEFFERSON:

TWISTED MAGNET WIRE

149

TABLE I

MINIMUM

Wire size

(AWG)

Diameter

nominal

(W

4--5---

6-e7---

8--m

9--lO--ll--12--13--14--15--16--17--18--19--20--21--22--23--24--25--26--27--28--29--30--31--32--33--34--35--36--37--38--39--40--41--42--43--44---

0.2043

. 1819

. 1620

. 1443

. 1285

.!144

. 1019

. 0907

.0808

.0720

.0641

0571

: 0508

.0453

.0403

. 0359

.0320

. 0285

.0253

. 0226

. 0201

. 0179

. 6159

. 0142

. 0126

. 0113

. 0100

. 0089

.0080

. 0071

.0063

. 0056

. 0050

.0045

.0040

.0035

. 0031

. 0028

.0025

.0022

.0020

INCREASE IN DIAMETER OF BARE ROUND WIRE AND THE MAXIMUM

OVERALL DIAMETBR DUE TO FILM INSULATION

CLASS 1

CLASS 2

CLASS 3

CLASS 4

Minimum Maximum

increase in overall

diameter

diameter

Minimum

Maximum

increase in

overall

diameter

diameter

Minimum

Maximum

increase in

overall

diameter

diameter

Minimum Maximbm

increase in

overall

diatieter

diameter

(InI

0.0019

. 0019

.0018

.0017

.0016

.bo16

.0015

.0015

.0014

.0014

. 0014

.0013

.0012

.0012

.OOll

.OOll

. 0010

.OOlO

.OOlO

. 0009

. boo9

. 0009

.0008

.0008

.0007

.0007

.0006

.0006

.0006

.0005

.0005

.0004

.0004

.0003

.0003

.0002

.0002

.0002

.0002

.0002

. 0001

(In)

0.2093

. 1867

. 1665

. 1485

. 1324

. 1181

. 1054

. 0941

.0840

.0750

.0&70

. 0599

.0534

.0478

.0426

-0382

.0341

.0306

.Q273

.0244

.0218

. 0195

. 0174

. 0156

! 0139

. 0126

. 0112

. 0100

. 0091

.0081

.0072

.oo64

.0058

.0052

.0047

.0041

.0037

.0033

.0030

.oO26

.0024

(InI

0.0037

.0036

.0035

.0034

.0033

.0032

.0031

.0030

.0029

.0028

.0027

.0026

.0026

.0025

.0024

t 0023

.0022

.OOZl

.0020

.0019

.0019

.0018

.0017

.0016

.0015

.0014

.0013

.0013

.0012

.OOll

.OOlO

.0009

.0008

.0008

.0007

.0006

.0006

.0005

.0004

,0004

.0004

(In)

0.2111

. 1884

. 1682

. 1502

. 1342

. 1198

. 1071

. 0957

.0855

. 0765

.0684

.0613

.0548

. 0492

.0440

. 0395

.0353

. 0317

. 0284

.0255

. 0229

.0206

.0185

. 0165

. 0148

. 0134

. 0120

. 0108

. 0098

. 0088

. 0078

.0070

.0063

.0057

. 0051

.0045

.0040

. 0036

.0032

. 0029

.0027

(InI

0.0049

.0048

.0047

.0046

.0045

.0044

.0043

. 0042

.004b

.0039

.0038

.0037

.0036

.0035

.0034

.0033

.0031

.0030

.0029

.0028

.0027

.0026

.0025

.0023

.0022

.0021

.0020

.0019

no018

.0017

.0015

. ooi4

.0013

.0012

.OOll

. 0010

.0009

.0008

.0008

.0007

.0006

(InI

(In)

0.2125

. 1897

. 1695

. 1515

.1355

. 1211

: 0969

1084

0.0064

.0062

: 0059

0059

.0058

.0057

.0054

.0056

.0867

. 0776

. 0695

.0624

.0558

.0502

. 0450

.0404

.0362

.0326

. 0292

.0263

. 0237

. 0214

. 0192

. 0172

. 0155

. 0141

. 0127

. 0115

. 0105

. 0095

. 0084

.0076

. 0069

; 0062

.0056

. 0050

.0044

.0040

.0037

.0033

.0030

.0052

.0050

.0049

.0048

.0046

.0045

.0044

:0042

.0040

.0039

.0037

.0036

.0035

.0034

.0032

.0030

.0029

.0028

,0027

.0026

.0025

.0024

.0021

.0020

.0019

.0017

.0016

.0015

.0013

.OOlO

.OOlO

.OOlO

.0009

0.2148

. 1920

.1717

, 1537

. 1377

. 1233

.1106

. 0991

.0888

. 0796

.0715

.0644

.0577

. 0520

.0468

.0422

. 0379

.0342

.0308

. 0279

.0252

.0228

.0206

. 0185

. 0166

. 0152

. 0137

. 0124

.0113

.0102

. 0091

.0082

.0074

.0067

.0060

.0053

.0047

.0043

.0038

.0035

.0032

(InI

Authorized licensed use limited to: Universidad de Antioquia. Downloaded on November 20, 2009 at 11:47 from IEEE Xplore. Restrictions apply.

IEEE TRANSACTIONS

150

ON PARTS, HYBRIDS, AND PACKAGING,

DECEMBER 1971

130120llOLOO

Z_Wc

z

2

E

I

8Q70-

uaE

B soti

24D1

JoM10 I

II

Fig. 1.

Characteristic

10

I,

I1

20

WIRE

15

II

25

(AWG)

SIZE

II

II

1 I

35

30

I1

40

44

impedance for bifilar magnet wire transmission line based on MIL-W-583 dimensions and with relative

dielectric constant of one.

1DODt

loo-

5

E

w

P lot

F

c

1.0 -

I

-

0.1

10

20

PITCH ANGLE

Fig. 2.

30

IN

CLASS 1

CLASS 4

40

DEGREES

50

60

Bifilar transmission line twist per inch versus pitch angle for wire sizes 4-44 having class-l and 4 insulation thickness.

Authorized licensed use limited to: Universidad de Antioquia. Downloaded on November 20, 2009 at 11:47 from IEEE Xplore. Restrictions apply.

LEFFERSON:

151

TWISTED MAGNET WIRE

E

,.q

FROM

C- MEASUREMENTS

10

1;

2b

PITCH

Fig. 3.

Measured equivalent

dielectric

25

ANGLE

;D

3;

4b

i-0

DEGREES

constant versus pitch angle for a sample of no. 29 magnet wire having class-2

insulation thickness.

respectively. erl and er2 are published constants, but 0 is a

function of pitch angle.

The behavior of fi can be seen by observing ereq as the

pitch angle is increased, If one assumes that the internal,

external, and mutual inductance of the line are not changed by

twist, ereq can be calculated from measurements of the actual

characteristics impedance by

calculated Zo for flat parallel wires

with E req = 1

Greq =

IN

measuredZO

(4)

It can also be calculated from capacitance measurements of

the line by

measured capacitance

ereq = calculated capacitance for the same length of

flat parallel wires with ereq =l

(5)

It can be calculated from the electrical line length by

measured electrical length

Greq = measured ph y srcal length of the twisted line . (6)

Laboratory data show agreement among all three of these

within the measurement accuracy of wire dimension, characteristic impedance, and relative dielectric constant of the film.

Five percent random impedance fluctuation along a twisted

line is common. Fig. 3 illustrates an example using number 29

wire having a class-2 thickness of polyester film insulation. The

example shows Ereq calculated from capacitance, electrical

length, and impedance measurements of four line samples

twisted to different pitch angles.

The characteristic impedance and electrical length data

were taken with the Hewlett-Packard model 1415A time

domain reflectometer. The film relative dielectric constants

were calculated from capacitance measurements of wire

samples in a mercury bath.

It was observed that the measured relative dielectric

constant can be greater than the published value for the film

material. This might be expected because as the twist is made

very tight, the wire dimension and the film thickness change SO

that they no longer fit the model for which the theoretical

parameters were calculated.

When the /3 is calculated from the equivalent dielectric

constant measurements, it is found to fit the expression.

p = 0.25 + 4 x 1o-4 8 2.

(7)

In Fig. 4 this expression is used to predict the characteristic

.

impedances

for three magnet wire sizes, as samples. It is seen

to consistently predict the correct impedance sufficiently

closely to yield a voltage standing-wave ratio (VSWR) within

l.l:l.

The slope of fi versus 8 in (7) is a function of the softness

of the wire insulation. Equation (7) holds for most modern

magnet wire insulating films but it will change if the insulation

is very soft. Polytetrafluoroethylene (Teflon) covered hook-up

wire is a good example that shows how far it can change. The

relative dielectric constant versus pitch angle is given in Fig. 5

for a sample of no. 24 19-strand wire. A fit is found by using

p=o.zs+

1 x1o-3 02

03)

DESIGN PROCEDURE

The following steps form a useful outline for designing a

twisted magnet bifilar wire transmission line for a required

characteristic impedance.

Authorized licensed use limited to: Universidad de Antioquia. Downloaded on November 20, 2009 at 11:47 from IEEE Xplore. Restrictions apply.

152

IEEE TRANSACTIONS

Fig. 4.

ON PARTS, HYBRIDS, AND PACKAGING,

DECEMBER 1971

Comparison of measured to estimated characteristic impedance for 3 wire sizes versus pitch angle.

~~

MEASUREhiENTS

t

0

,1

10

20

15

PITCH

Fig. 5.

Measured equivalent

dielectric

25

ANGLE

IN

301

35I

40I,,

45

50

DEGREES

constant versus pitch angle for a sample of Teflon-covered

no. 24 19-strand wire.

Authorized licensed use limited to: Universidad de Antioquia. Downloaded on November 20, 2009 at 11:47 from IEEE Xplore. Restrictions apply.

LEFFERSON:

TWISTED MAGNET WIRE

Fig. 6.

Bifilar wire transmission line twisted to its maximum pitch angle of 50.5.

1) Choose a film insulation thickness group and film

relative dielectric constant. (These are usually limited by their

availability and other physical and electrical considerations.)

2) Calculate the relative dielectric constant assuming pitch

angle of 30 from (3) and (7):

ereq = err + 0.61 (LIZ - err)

where err = 1 for air.

3) Calculate the required characteristic impedance for

relative dielectric constant of 1 from

Zl = N&q;

where

Zl

Z

153

impedance when Ereq = 1;

desired impedance.

4) Use Fig. 1 to choose the correct wire size.

5) Use Fig. 2 to determine the required twist per in.

CONCLUSION

The electrical length of a twisted line is related to the

square root of the equivalent dielectric constant in (6).

Using these basic expressions the following statement can

be made.

1) The impedance increases as the wire dimensions decrease.

2) The impedance decreases as the wire twist is increased.

(The pitch angle increases.)

3) The relative dielectric constant for the line is controlled

more by the film dielectric constant as the pitch angle

increases.

4) For small pitch angles the line impedance can be

reduced by immersing the line in a material other than air.

5) For large pitch angles the line impedance can be

reduced by using a wire insulating film having a high dielectric

constant. The useful pitch angle range is bounded by the

limitation on line uniformity at about 20 and the strength of

copper at about 4.5.

For a film dielectric constant of 3.5 and with air as the

surrounding medium, the useful impedance range for twisted

magnet wire transmission lines is lCM50a.

Over 60 magnet wire transmission lines of many different

forms have verified the conclusions of this paper.

The characteristic impedance of any twisted magnet wire

transmission line can be found if the dimensions and the

dielectric constant are known. Figs. 1 and 6 give the impedance

at the expected tolerance limits for standard wire sizes having

an insulation dielectric constant of 1. This is modified by the

APPENDIX

equivalent dielectric constant, which is a function of the

The

center

lines

of

two

twisted wires form a helix as shown

relative dielectric constant of the film insulation and

in

Fig.

6.

The

helix

diameter

is one wire diameter. It forms a

increases as the line is twisted. The twist for various pitch

sine

wave

in

the

longitudinal

plane.

angles [determined by (2)] is shown in Fig. 2 for wire sizes

4-44. The equivalent relative dielectric constant is related to

the pitch angle by (3) and (7).

A = (D/2) sin (2 71Td)

(9)

Authorized licensed use limited to: Universidad de Antioquia. Downloaded on November 20, 2009 at 11:47 from IEEE Xplore. Restrictions apply.

154

IEEE

TRANSACTIONS

where

ON PARTS,

HYBRIDS,

AND

PACKAGING,

DECEMBER

1971

lines is D and twist can be expressed as

D wire diameter;

T twist per inch;

d distance along the transmission line.

Tmax = (sin 0 )/(2D).

The pitch angle comes out of this as

tan 0 = 71TD

(lo)

where 43 is the pitch angle defined in Fig. 6.

The maximum pitch angle occurs when the line has been

wound to the point where the distance between wire center

00

The maximum pitch angle of 50.5 is found by equating 9 and

11. It is not a function of wire diameter.

The actual wire length can also be seen in Fig. 6 where one

twist is unwrapped. The wire length for one twist is

nDJ1 + l@n 01.

(12)

Peter Lefferson received the B.E.E. and M.E. degrees from the University of Florida, Gainesville, in 1962

and 1965, respectively.

He worked for NASA as an Instrumentation Engineer for one year. He spent five and one half,years with

Electronic Communication Inc., in design of UHF transceivers. Presently, he is with Milton Roy Company,

St. Petersburg, Fla.

Authorized licensed use limited to: Universidad de Antioquia. Downloaded on November 20, 2009 at 11:47 from IEEE Xplore. Restrictions apply.

Você também pode gostar

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeNo EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeNota: 4 de 5 estrelas4/5 (5795)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreNo EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreNota: 4 de 5 estrelas4/5 (1090)

- Never Split the Difference: Negotiating As If Your Life Depended On ItNo EverandNever Split the Difference: Negotiating As If Your Life Depended On ItNota: 4.5 de 5 estrelas4.5/5 (838)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceNo EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceNota: 4 de 5 estrelas4/5 (895)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersNo EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersNota: 4.5 de 5 estrelas4.5/5 (345)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureNo EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureNota: 4.5 de 5 estrelas4.5/5 (474)

- The Emperor of All Maladies: A Biography of CancerNo EverandThe Emperor of All Maladies: A Biography of CancerNota: 4.5 de 5 estrelas4.5/5 (271)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)No EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Nota: 4.5 de 5 estrelas4.5/5 (121)

- The Little Book of Hygge: Danish Secrets to Happy LivingNo EverandThe Little Book of Hygge: Danish Secrets to Happy LivingNota: 3.5 de 5 estrelas3.5/5 (400)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyNo EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyNota: 3.5 de 5 estrelas3.5/5 (2259)

- The Yellow House: A Memoir (2019 National Book Award Winner)No EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Nota: 4 de 5 estrelas4/5 (98)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaNo EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaNota: 4.5 de 5 estrelas4.5/5 (266)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryNo EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryNota: 3.5 de 5 estrelas3.5/5 (231)

- Team of Rivals: The Political Genius of Abraham LincolnNo EverandTeam of Rivals: The Political Genius of Abraham LincolnNota: 4.5 de 5 estrelas4.5/5 (234)

- PLC BitsDocumento10 páginasPLC Bitssivakumar_kalepu555491% (11)

- The Unwinding: An Inner History of the New AmericaNo EverandThe Unwinding: An Inner History of the New AmericaNota: 4 de 5 estrelas4/5 (45)

- A Case Study On SCADA Implementation in 220 KV SubstationDocumento11 páginasA Case Study On SCADA Implementation in 220 KV SubstationAnonymous ggwJDMh8Ainda não há avaliações

- Floor Plan Floor Plan: Schedule of Loads PB1Documento1 páginaFloor Plan Floor Plan: Schedule of Loads PB1Lady Mae BrigoliAinda não há avaliações

- IGCSE Physics Exam Revision NotesDocumento34 páginasIGCSE Physics Exam Revision NotesCoolman Poon88% (17)

- Gel Electrophoresis Power SupplyDocumento9 páginasGel Electrophoresis Power Supplyمحمود صالح محمود عليAinda não há avaliações

- STE Curriculum GuidesDocumento13 páginasSTE Curriculum GuidesJonathanEncomiendaAinda não há avaliações

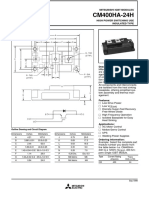

- Igbt Mitsubishi Cm400ha-24hDocumento4 páginasIgbt Mitsubishi Cm400ha-24hELBIN RINCONAinda não há avaliações

- AFE ManualDocumento191 páginasAFE ManualpablodcabreraAinda não há avaliações

- Teori TheveninDocumento6 páginasTeori TheveninAwa StelkAinda não há avaliações

- 7SS52 enDocumento418 páginas7SS52 envsrikala68Ainda não há avaliações

- Ditto Manual File Rev 2Documento2 páginasDitto Manual File Rev 2rkidruAinda não há avaliações

- Engr Josh ReportDocumento85 páginasEngr Josh ReportTEMIDAYOAinda não há avaliações

- 80n02g Mosfet Canal-NDocumento2 páginas80n02g Mosfet Canal-NJuan Carlos ChavezAinda não há avaliações

- Wires, Cables - HT XLPE CablesDocumento4 páginasWires, Cables - HT XLPE CablesSubbuAinda não há avaliações

- Mousa The Soil Ionization GradientDocumento9 páginasMousa The Soil Ionization GradientAjay JayabalanAinda não há avaliações

- Assignment ECEG-4261 Microelectronic Devices and Circuits (MDC)Documento7 páginasAssignment ECEG-4261 Microelectronic Devices and Circuits (MDC)erenaAinda não há avaliações

- Differentiator AmplifierDocumento5 páginasDifferentiator AmplifierAhmed ShaabanAinda não há avaliações

- F2D TutorialTechnical BrushlessIPM MotorDocumento129 páginasF2D TutorialTechnical BrushlessIPM MotorFutureProfaneAinda não há avaliações

- York DXS Compressor DiagnosisDocumento4 páginasYork DXS Compressor DiagnosisDavid Jenkins100% (5)

- Hfe JBL l300 en Alt ScanDocumento13 páginasHfe JBL l300 en Alt ScanthomasAinda não há avaliações

- PSD Course File 2011-12Documento40 páginasPSD Course File 2011-12Sethupathi CmAinda não há avaliações

- Technology 150-170-200Documento12 páginasTechnology 150-170-200andtib100% (1)

- EA747e MZ 4.4Documento28 páginasEA747e MZ 4.4Razvan MaresAinda não há avaliações

- 4064.solving Op Amp Stability 2014 - Part 1Documento52 páginas4064.solving Op Amp Stability 2014 - Part 1paolo_1984Ainda não há avaliações

- Panasonic Gp9de Chassis Th42pv60a-H-M-Mt SM (ET)Documento149 páginasPanasonic Gp9de Chassis Th42pv60a-H-M-Mt SM (ET)bellelibelleAinda não há avaliações

- AMP Regen Clamp SpecsheetDocumento2 páginasAMP Regen Clamp SpecsheetElectromateAinda não há avaliações

- EAW KF750 Processor Settings - Rev1Documento2 páginasEAW KF750 Processor Settings - Rev1Shawn DuncanAinda não há avaliações

- Fiber Optics Trainer KitDocumento3 páginasFiber Optics Trainer KitPriyabrata BiswalAinda não há avaliações

- Insem 1 - PE - Handbook - 2023Documento3 páginasInsem 1 - PE - Handbook - 2023Ananya VAinda não há avaliações

- Sana'A South 30 MW Extension Yemen Diesel Power StationDocumento103 páginasSana'A South 30 MW Extension Yemen Diesel Power StationheemaAinda não há avaliações