Escolar Documentos

Profissional Documentos

Cultura Documentos

Condenser

Enviado por

atulbhogare7Direitos autorais

Formatos disponíveis

Compartilhar este documento

Compartilhar ou incorporar documento

Você considera este documento útil?

Este conteúdo é inapropriado?

Denunciar este documentoDireitos autorais:

Formatos disponíveis

Condenser

Enviado por

atulbhogare7Direitos autorais:

Formatos disponíveis

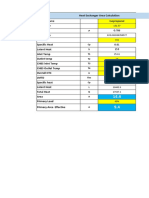

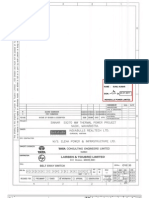

Doc no.

-10265-16010-D

Sheet 1 of 4

HEAT EXCHANGER ENGG.

BHEL,HARIDWAR

APPROVED

NAME :

CAT-A

A. K. TANDON

5X270 MW AMRAVATI TPP

Dt. 05.10.2010

SIGN.:

CUSTOMERS NAME:

INDIA BULLS POWER LTD

CONSULTANTS NAME:

TATA CONSULTING ENGINNERS LTD.

INDIABULLS POWER LIMITED.

DATA SHEET FOR STEAM SURFACE CONDENSER

SL.

NO.

DESCRIPTION

UNIT

01

Manufacturer

BHEL

02

Type & number of pass

SURFACE TYPE /2-PASS

03

Design Standard

HEI

04

Design condition

(HBD NO.PE-DC-352-100-N157)

[ VWO, 3% mu, 0.1033 ata,

CW inlet temp. 32.0 deg C ]

05

Cooling Water Flow

M3/hr

34500.00

06

Water velocity

M/sec

2.1

07

Pressure drop across condenser

terminals on CW side

MWC

5.0

08

Heat rejected

water

Kcal/

hr

303.15 x 106

09

Temperature rise of circulating water

considering design cooling water

flow.

Deg C

~ 9

10

Condenser back pressure

Ata

0.1033

to

circulating

Rashmi Gupta

(Worked/Chkd)

DATA

M. K. Lahoti

(Approved)

Doc no. -10265-16010-D

Sheet 2 of 4

11

Design Particulars

(a)

No

(b)

Arrangement with respect to turbine

axis

(c)

Condensing

(d)

Cleanliness

12

Corrosion allowance

(a)

Water box and Tube plates,

(b)

Shell, hotwell & condenser neck

of passes

surface,

PERPENDICULAR

M2

0.85

factor

support

15468

MM

3.2

MM

1.6

13

Tube

plates

(a)

No. of

(b)

Spacing

MM

730

(c)

Thickness

MM

16

14

Tube

(a)

Numbers

(b)

Size (OD x TK)

MMxMM

28.575 x 0.7112

(c)

Length between tube plates

MM

11000.00

(d)

Material

15

Tube

16

Tube sheet thickness

17

Hot well

(a)

Material

(b)

Capacity

19

Total weight of tubes,

tube

support plates

28

15664

Welded SS 304

holes

size

& chamfer

AS

MM

40

thickness

MM

16

at normal operating level,

M3

35

Tonnes

~87

Rashmi Gupta

(Worked/Chkd)

PER

HEI

M. K. Lahoti

(Approved)

Doc no. -10265-16010-D

Sheet 3 of 4

20

Weight of heaviest pieces to be

handled during transportation and

erection,

Tonnes

21

Method of protection of top tube rows

of tube bundle from high velocity

steam erosion

Thicker tubes provided

in top 2 rows(0.889 mm

thk)

22

Vibration Analysis of Tubes

By HEI method

23

Deaeration level achieved

24

Features to enable one condenser section

to be isolated on the cooling water side

for maintenance.

Divided type water box

provided

25

Type of connection with LP Turbine

Welded

26

Method of Installation/Condenser Supporting

Arrangement

Spring Supported

27

Design Pressure - Shell/Steam Side

kg/cm2g

Full vacuum & 1.08

28

Design Pressure - Tube/C.W. Side

kg/cm2g

29

Steam Temperature on top of tube bundle

As per HBD

30

Temperature of air vapour mixture at

air cooling section

4.17 degree subcooled from

steam saturation temp.

31

Design Cooling water Outlet Temperature

32

No. of Tubes in Impingement Section

296

33

No. of Tubes in remaining condensing section

15368

34

Tube thickness

35

Tube Material

SA249 WELDED SS304 AUSTENITIC

36

Method of attaching Tube Sheet with Shell

Welded

37

Material of construction of tube support

plates

CARBON STEEL IS 2062 Gr.B

38

Material of construction of Hotwell

CARBON STEEL IS 2062 Gr.B

CC/litre

Deg C

MM

Rashmi Gupta

(Worked/Chkd)

~15

0.015

41

0.7112

M. K. Lahoti

(Approved)

Doc no. -10265-16010-D

Sheet 4 of 4

39

Type of Water Boxes

40

Shape of Water Boxes

41

Thickness of Water Boxes

42

Material Of construction of Water Boxes

CARBON STEEL IS 2062 Gr.B

43

Material Of construction of Shell and

Neck Walls

CARBON STEEL IS 2062 Gr.B

44

Wall Thickness of Shell & Neck Walls

45

Dry/Empty Weight of condenser

TONNES

385

46

Weight of Condenser filled with water

up to LP Turbine Blade Tip

TONNES

1240

Rashmi Gupta

(Worked/Chkd)

BOLTED

Dome Shaped

MM

MM

32

16

M. K. Lahoti

(Approved)

Você também pode gostar

- p101516-010 Rev.1 Gland Steam Condenser Specification Stg62Documento2 páginasp101516-010 Rev.1 Gland Steam Condenser Specification Stg62Rais RijalAinda não há avaliações

- Air Cooled Steam Condenser-Design Method PDFDocumento8 páginasAir Cooled Steam Condenser-Design Method PDFLTE0020% (1)

- Asme2b sb-234Documento10 páginasAsme2b sb-234fdfsdfsdfsdfAinda não há avaliações

- SH, RH DesignDocumento8 páginasSH, RH DesignJKKAinda não há avaliações

- Ejma7r2 Bellows Worksheet 1Documento8 páginasEjma7r2 Bellows Worksheet 1NamıkAinda não há avaliações

- ACC - Offer 000984 Rev PDFDocumento31 páginasACC - Offer 000984 Rev PDFMohamed SaaDAinda não há avaliações

- Design Calc - Cooling Tower Sizing - R1 - 15.10.2011Documento1 páginaDesign Calc - Cooling Tower Sizing - R1 - 15.10.2011AliAliAinda não há avaliações

- Acc Vs Heller CTDocumento37 páginasAcc Vs Heller CTkiddjoe1470Ainda não há avaliações

- Data Sheet EjectorDocumento4 páginasData Sheet EjectorGunturMudaAliAkbarAinda não há avaliações

- 236-76-12 Welding Jiont Selections For Pipes & TubesDocumento7 páginas236-76-12 Welding Jiont Selections For Pipes & TubesJKKAinda não há avaliações

- HMBD Review Check ListDocumento4 páginasHMBD Review Check Listctraminst_81Ainda não há avaliações

- 26-72-02 Splicing Fins That Are Welded To Pr. PartsDocumento5 páginas26-72-02 Splicing Fins That Are Welded To Pr. PartsJKKAinda não há avaliações

- Optional Integral With Hub Type Body Flange CalculationDocumento13 páginasOptional Integral With Hub Type Body Flange Calculation9913489806Ainda não há avaliações

- CN - Heat Tracing Calcualtion: Calculation Note D3-NGD PRO 024 NG-018Documento1 páginaCN - Heat Tracing Calcualtion: Calculation Note D3-NGD PRO 024 NG-018EmamokeAinda não há avaliações

- Tubesheet Calculation: Step 1Documento2 páginasTubesheet Calculation: Step 1Bintang LazuardiAinda não há avaliações

- Insul & RefractoryDocumento8 páginasInsul & RefractoryJKK0% (1)

- 13 Internal Walkway and PerformanceDocumento24 páginas13 Internal Walkway and PerformanceDSGAinda não há avaliações

- Heat Exchanger Area & Boilup Rate CalculationDocumento19 páginasHeat Exchanger Area & Boilup Rate CalculationNitin KurupAinda não há avaliações

- Steam Boiler Spec.Documento17 páginasSteam Boiler Spec.bandithaguru6338100% (1)

- Az - Zour R&M Furnace Dimensions - ADocumento1 páginaAz - Zour R&M Furnace Dimensions - AShameer MajeedAinda não há avaliações

- DBR 2x18MWDocumento107 páginasDBR 2x18MWErin WardAinda não há avaliações

- TQ - Air Fin Cooler (CS) - ModificationDocumento6 páginasTQ - Air Fin Cooler (CS) - ModificationAvinash ShuklaAinda não há avaliações

- 53-75-09 Butt Welded Joints Details & AssemblyDocumento3 páginas53-75-09 Butt Welded Joints Details & AssemblyJKKAinda não há avaliações

- Center Vent & Peripheral Vent CalDocumento1 páginaCenter Vent & Peripheral Vent CalrichardchiamAinda não há avaliações

- 8-65-19 ''Pulsed Arc '' MIG Welding Stright Tubes in ChattanoogaDocumento9 páginas8-65-19 ''Pulsed Arc '' MIG Welding Stright Tubes in ChattanoogaJKKAinda não há avaliações

- Steam Tracing CalculationDocumento76 páginasSteam Tracing CalculationChristina Martin63% (8)

- PB02-LPS-001 Low Pressure Steam System: Saudi Arabian Oil CompanyDocumento1 páginaPB02-LPS-001 Low Pressure Steam System: Saudi Arabian Oil CompanyzhangAinda não há avaliações

- Nozzle Calculation - Primary Reformer Stack-R0Documento22 páginasNozzle Calculation - Primary Reformer Stack-R0Aditya Jain100% (1)

- Standard For Closed Feedwater HeatersDocumento80 páginasStandard For Closed Feedwater Heatersrenoyabo100% (2)

- SCR Mean - Metal - Temps For Heat Exchanger TubeDocumento2 páginasSCR Mean - Metal - Temps For Heat Exchanger TubescranderiAinda não há avaliações

- Steam Drum LevelsDocumento11 páginasSteam Drum LevelsAnith kumar Reddy100% (1)

- Terminal Points (TBWES & Toshiba) JSPL, 8 X 660 MWDocumento6 páginasTerminal Points (TBWES & Toshiba) JSPL, 8 X 660 MWpunitg_2Ainda não há avaliações

- Metal TempDocumento101 páginasMetal TempJKKAinda não há avaliações

- Centrifugal Comp Calc Without ImpellerDocumento8 páginasCentrifugal Comp Calc Without Impellersohail1985100% (1)

- Performance NT100M HVDocumento1 páginaPerformance NT100M HVAnonymous 3fTYXaW7WAinda não há avaliações

- Glaxo Vol IDocumento164 páginasGlaxo Vol IPrakash WarrierAinda não há avaliações

- Aircooled Heat Exchanger Process Data SheetDocumento2 páginasAircooled Heat Exchanger Process Data SheetamitkrayAinda não há avaliações

- TEMA Shell Bundle Entrance and Exit AreasDocumento3 páginasTEMA Shell Bundle Entrance and Exit AreasArunkumar MyakalaAinda não há avaliações

- HEI Standards For Air Cooled Condensers - Dave Sanderlin SPIG USADocumento8 páginasHEI Standards For Air Cooled Condensers - Dave Sanderlin SPIG USASyed HafeezAinda não há avaliações

- Tubular Heat Exchanger Rating Sheet: Start o 2 o o 3 2 o 2 oDocumento1 páginaTubular Heat Exchanger Rating Sheet: Start o 2 o o 3 2 o 2 oSIVAAinda não há avaliações

- 235-76-02 Det. & Assembly For Disk Type Orifice & Butt Welded Tube JointsDocumento3 páginas235-76-02 Det. & Assembly For Disk Type Orifice & Butt Welded Tube JointsJKKAinda não há avaliações

- TubesheetDocumento14 páginasTubesheethassnain iqbalAinda não há avaliações

- Dump CondenserDocumento6 páginasDump CondensersakalidhasavasanAinda não há avaliações

- SEL-TBD-O-CA-001 R0 Process Simulation Report SignedDocumento12 páginasSEL-TBD-O-CA-001 R0 Process Simulation Report Signedahmad santosoAinda não há avaliações

- FD Fan Sizing CalculationDocumento3 páginasFD Fan Sizing CalculationkumarananyarupeshAinda não há avaliações

- Vacuum Design DataDocumento354 páginasVacuum Design Datajlcheefei925850% (2)

- Analysis of Air Water Cooled Condenser in Vapour Compression System IJERTV10IS050132Documento6 páginasAnalysis of Air Water Cooled Condenser in Vapour Compression System IJERTV10IS050132Abdulrahman AlnasharAinda não há avaliações

- Dump TubeDocumento4 páginasDump TubeKrishna KumarAinda não há avaliações

- Design Conditions Datasheet: Unit Tag Qty Model No Net Cooling Capacity (Ton.r) Nominal Voltage Refrigerant TypeDocumento2 páginasDesign Conditions Datasheet: Unit Tag Qty Model No Net Cooling Capacity (Ton.r) Nominal Voltage Refrigerant TypeFernando CabreraAinda não há avaliações

- Desuperheater CalculationsDocumento2 páginasDesuperheater CalculationsMuzzamil ShahzadAinda não há avaliações

- Heat ExchangerDocumento53 páginasHeat ExchangerNurulHidayahAinda não há avaliações

- 14 ACC Air Side Performance PDFDocumento24 páginas14 ACC Air Side Performance PDFDSGAinda não há avaliações

- Ibr CalculationsDocumento12 páginasIbr CalculationsGopal RamalingamAinda não há avaliações

- Heat Loss From An Insulated Pipe: ParametersDocumento4 páginasHeat Loss From An Insulated Pipe: ParametersMohan BabuAinda não há avaliações

- 00000-JDS-015 (ERV Manhole) Rev 0Documento10 páginas00000-JDS-015 (ERV Manhole) Rev 0sithulibraAinda não há avaliações

- 1 TPH For 10.54P Boiler IBR Design Calculations - R2-6-2-13Documento21 páginas1 TPH For 10.54P Boiler IBR Design Calculations - R2-6-2-13Vishal KandAinda não há avaliações

- E-03.0) General Static-Mixing Customer Specification QuestionnaireDocumento6 páginasE-03.0) General Static-Mixing Customer Specification QuestionnaireWladimir Antonio Egurrola RomeroAinda não há avaliações

- Water PropertiesDocumento4 páginasWater Propertiesaw_aeAinda não há avaliações

- Data Sheet Massecuite D Heater Rev 0Documento2 páginasData Sheet Massecuite D Heater Rev 0rudiskw456Ainda não há avaliações

- Coal Fired Fluid Bed Boiler: Salient FeaturesDocumento12 páginasCoal Fired Fluid Bed Boiler: Salient FeaturesBangto YibsipAinda não há avaliações

- CWR 36&39Documento1 páginaCWR 36&39atulbhogare7Ainda não há avaliações

- Heat ExchangerDocumento16 páginasHeat Exchangeratulbhogare7100% (1)

- Charge Hand OverDocumento1 páginaCharge Hand Overatulbhogare7Ainda não há avaliações

- Circular No.1508 Dated 03.06.2022Documento1 páginaCircular No.1508 Dated 03.06.2022atulbhogare7Ainda não há avaliações

- 85 27213748 91 27213852 92 Open Open SC Open Open OpenDocumento7 páginas85 27213748 91 27213852 92 Open Open SC Open Open Openatulbhogare7Ainda não há avaliações

- Tripping of Turbine On High Differential PressureDocumento3 páginasTripping of Turbine On High Differential Pressureatulbhogare7Ainda não há avaliações

- Academic CV ExampleDocumento3 páginasAcademic CV Exampleatulbhogare7Ainda não há avaliações

- Awesome Aug. 2017 Premium High Reco CallsDocumento3 páginasAwesome Aug. 2017 Premium High Reco Callsatulbhogare7Ainda não há avaliações

- Standing Orders: Applica BilityDocumento24 páginasStanding Orders: Applica Bilityatulbhogare7Ainda não há avaliações

- PAP-23-4-15 - Project Affecred PeopleDocumento4 páginasPAP-23-4-15 - Project Affecred Peopleatulbhogare7Ainda não há avaliações

- Belt Sway Switch-Nasik R1-Final Sent On 04.01.11Documento4 páginasBelt Sway Switch-Nasik R1-Final Sent On 04.01.11atulbhogare7Ainda não há avaliações

- Procedure For Calibration of Drum Level TramittersDocumento1 páginaProcedure For Calibration of Drum Level Tramittersatulbhogare7Ainda não há avaliações

- RockPhysicsModellingPorousRocksMultiplePoreTypes CriticalPorosity Zhang 2019Documento13 páginasRockPhysicsModellingPorousRocksMultiplePoreTypes CriticalPorosity Zhang 2019Maria Fernanda Landa ElizaldeAinda não há avaliações

- Motion Chp. NumericalsDocumento6 páginasMotion Chp. NumericalsSatwik AroraAinda não há avaliações

- Fca 10Documento2 páginasFca 10nicolas barrera aguileraAinda não há avaliações

- Physical Geography NotesDocumento16 páginasPhysical Geography NotesVernon88% (26)

- Specification CZS100Documento1 páginaSpecification CZS100jackAinda não há avaliações

- Coh FRANC2D Tutorial PCDocumento0 páginaCoh FRANC2D Tutorial PCthegreatest0888Ainda não há avaliações

- Physics 1 Quiz1Documento2 páginasPhysics 1 Quiz1Hai Ha100% (1)

- Letter To Editor On The Effects of Climate Change On The EnvironmentDocumento2 páginasLetter To Editor On The Effects of Climate Change On The EnvironmentKAYANNA LAWRENCEAinda não há avaliações

- Surfadone LP: Specialty SurfactantsDocumento12 páginasSurfadone LP: Specialty SurfactantsSohaib BraziAinda não há avaliações

- Optical Communications4Documento19 páginasOptical Communications4keane1Ainda não há avaliações

- Thermal Stability and Performance Data For Sm-Co 2 17 High-TemperatureDocumento4 páginasThermal Stability and Performance Data For Sm-Co 2 17 High-TemperatureelectronenergyAinda não há avaliações

- Eq Missing Mass CorrectionDocumento6 páginasEq Missing Mass CorrectionTejashri SalunkheAinda não há avaliações

- General Welding Procedures (0679, 7000) (REHS1841-23)Documento73 páginasGeneral Welding Procedures (0679, 7000) (REHS1841-23)Anderson Oliveira SilvaAinda não há avaliações

- Ball Joint Failure DocumentDocumento2 páginasBall Joint Failure DocumentAbeer Darhous100% (1)

- 316 316L Technical Information SheetDocumento5 páginas316 316L Technical Information SheetfejlongAinda não há avaliações

- Microsoft PowerPoint - HVAC FINALDocumento20 páginasMicrosoft PowerPoint - HVAC FINALaravoof84Ainda não há avaliações

- EAPSDocumento7 páginasEAPSAerospace Technical AcademyAinda não há avaliações

- ORLENOIL Folder Przemyslowy en 2014Documento45 páginasORLENOIL Folder Przemyslowy en 2014Handerson PanjaitanAinda não há avaliações

- M.S. Abd-ElhadyDocumento8 páginasM.S. Abd-ElhadyNasser93Ainda não há avaliações

- Rubber Products in Automotive Applications: Standard Classification System ForDocumento53 páginasRubber Products in Automotive Applications: Standard Classification System ForKhimeshAinda não há avaliações

- PHYSICSDocumento36 páginasPHYSICSUnknown userAinda não há avaliações

- EEE 533: Semiconductor Device and Process Simulation: Spring 2001Documento9 páginasEEE 533: Semiconductor Device and Process Simulation: Spring 2001Garima BhatiaAinda não há avaliações

- Activated Carbon FiltrationDocumento0 páginaActivated Carbon FiltrationIrhamAinda não há avaliações

- Vacuum&SemiconDocumento96 páginasVacuum&Semiconcajaro100% (1)

- 2023-24 Exemplar Problems Chemistry Class 11Documento188 páginas2023-24 Exemplar Problems Chemistry Class 11Sai KarthiAinda não há avaliações

- Soil Shear StrengthDocumento89 páginasSoil Shear Strengthmuhd nizamAinda não há avaliações

- What Is The Ozone Layer and Where Is It Located?Documento6 páginasWhat Is The Ozone Layer and Where Is It Located?JoseAinda não há avaliações

- HT - Theory - CH - 5 - Heat Exchanger PDFDocumento41 páginasHT - Theory - CH - 5 - Heat Exchanger PDFAkkiAinda não há avaliações

- Piled Foundations-Design Parte1Documento28 páginasPiled Foundations-Design Parte1Vilma CabreraAinda não há avaliações

- Corrosion On Ships and Countermeasures - Dwidaya KorosindoDocumento6 páginasCorrosion On Ships and Countermeasures - Dwidaya KorosindoMekineAinda não há avaliações