Escolar Documentos

Profissional Documentos

Cultura Documentos

Alfa Laval CB60 Cooler

Enviado por

kman548Direitos autorais

Formatos disponíveis

Compartilhar este documento

Compartilhar ou incorporar documento

Você considera este documento útil?

Este conteúdo é inapropriado?

Denunciar este documentoDireitos autorais:

Formatos disponíveis

Alfa Laval CB60 Cooler

Enviado por

kman548Direitos autorais:

Formatos disponíveis

.

CB60 / CBH60

Brazed Plate Heat Exchanger

General information

Alfa Laval introduced its first brazed plate heat exchanger

(BHE) in 1977 and has since continuously developed and

optimized its performance and reliability.

Brazing the stainless steel plates together eliminates the need

for gaskets and thick frame plates. The brazing material seals

and holds the plates together at the contact points ensuring

optimal heat transfer efficiency and pressure resistance. The

plate design guarantees the longest possible life.

The design options of the brazed heat exchanger are

extensive. Different plate patterns are available for various

duties and performance specifications. You can choose a

standard configuration BHE, or a unit designed according to

your own specific needs. The choice is entirely yours.

Typical applications

- HVAC heating/cooling

- Refrigerant applications

- Industrial cooling/heating

- Oil cooling

Working principles

The heating surface consists of thin corrugated metal plates

stacked on top of each other. Channels are formed between

. plates and corner ports are arranged so that the two media

the

flow through alternate channels, usually in countercurrent flow

for the most efficient heat transfer process.

Examples of connections

Standard design

The plate pack is covered by cover plates. Connections are

located in the front or rear cover plate. To improve the heat

transfer design, the channel plates are corrugated.

Particulars required for quotation

To enable Alfa Lavals representative to make a specific

quotation, specify the following particulars in your enquiry:

- Required flow rates or heat load

- Temperature program

- Physical properties of liquids in question

- Desired working pressure

- Maximum permitted pressure drop

External

threaded

Internal

threaeded

Soldering

* More connections are available on request.

Welding

CB60 and CBH60 - PED approval pressure/temperature graph*

Standard data

Min. working temperature

Max. working temperature

Min. working pressure

Max. working pressure

Volume per channel, litres (ga)

Max. particle size mm (inch)

Max. flowrate* m3/h (gpm)

Min. nbr of plates

Max. nbr of plates

* Water at 5 m/s (16.4 ft/s) (connection velocity)

see graph

see graph

vacuum

see graph

0.10 (0.027)

1 (0.04)

14.5 (63.7)

4

150

Standard materials

CB60 and CBH60 - UL approval pressure/temperature graph*

Cover plates

Connections

Plates

Brazing filler

Stainless steel

Stainless steel

Stainless steel

Copper

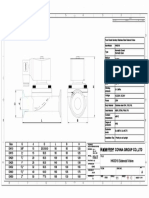

Standard dimensions and weight*

A measure mm

A measure inch

Weight** kg

Weight** lb

=

=

=

=

13 + (2.35 * n) (+/-1.5 %)

0.51 + (0.09 * n) (+/-1.5 %)

2.1 + (0.18 * n)

4.63 + (0.4 * n)

(n = number of plates)

* Excluding connections

CB60 / CBH60 - KHK and KRA approval pressure/temperature graph*

Standard dimensions

mm (inch)

113 (4.45)

S1

S3

S2

466 (18.34)

S4

CB60 / CBH60 - CRN approval pressure/temperature graph*

527 (20.8)

50 (1.97)

.

For exact values please contact your local Alfa Laval representative

PCT00095EN 1203

How to contact Alfa Laval

Up-to-date AlfaLaval contact details for

all countries are always available on our

website on www.alfalaval.com

Alfa Laval reserves the right to change specifications without prior notification.

Você também pode gostar

- Hydraulic and Compressible Flow TurbomachinesDocumento146 páginasHydraulic and Compressible Flow TurbomachinesPaul Healy100% (3)

- Heating Systems Troubleshooting & Repair: Maintenance Tips and Forensic ObservationsNo EverandHeating Systems Troubleshooting & Repair: Maintenance Tips and Forensic ObservationsAinda não há avaliações

- ViFlow Funke GB PDFDocumento8 páginasViFlow Funke GB PDFukalAinda não há avaliações

- Brazed Aluminium Plate Fin Heat Exchangers-Construction, Uses Advantages in Cryogenic Refrigeration SystemsDocumento31 páginasBrazed Aluminium Plate Fin Heat Exchangers-Construction, Uses Advantages in Cryogenic Refrigeration SystemsHitesh Panchal100% (1)

- Applied Process Design for Chemical and Petrochemical Plants: Volume 1No EverandApplied Process Design for Chemical and Petrochemical Plants: Volume 1Nota: 3.5 de 5 estrelas3.5/5 (3)

- HP300 GA and Dimensional Drawings MM1472950 - 0Documento10 páginasHP300 GA and Dimensional Drawings MM1472950 - 0Thiago PaivaAinda não há avaliações

- Scania Technical Data - Issue-13Documento51 páginasScania Technical Data - Issue-13kman548Ainda não há avaliações

- De Walt 1450 - 1250 Radial Arm Saw Assembly InstructionsDocumento6 páginasDe Walt 1450 - 1250 Radial Arm Saw Assembly Instructionsloach71100% (1)

- All-in-One Manual of Industrial Piping Practice and MaintenanceNo EverandAll-in-One Manual of Industrial Piping Practice and MaintenanceNota: 5 de 5 estrelas5/5 (1)

- t20 Semi Welded Gasketed Plate Heat ExchangerDocumento2 páginast20 Semi Welded Gasketed Plate Heat ExchangerEmersonAinda não há avaliações

- Air Cooled Heat Exchangers - GEA BrochureDocumento16 páginasAir Cooled Heat Exchangers - GEA BrochurenorthstarleoAinda não há avaliações

- Flowserve PompeDocumento76 páginasFlowserve Pompemariasofiarossi50% (2)

- Bolt Tightening e PDFDocumento15 páginasBolt Tightening e PDFdromaki0% (1)

- CHEVRON Shell and Tube Exchanger Component Design ConsiderationsDocumento42 páginasCHEVRON Shell and Tube Exchanger Component Design Considerationsbabak mir80% (5)

- Hot Tap CalculationDocumento20 páginasHot Tap Calculationsurekha_ahireAinda não há avaliações

- Alfa Laval PHE For REFDocumento4 páginasAlfa Laval PHE For REFNiraj ReginaldAinda não há avaliações

- eBroc-Shell and Tube Heat Exchangers Model Series and Customer Oriented Solutions, FunkeDocumento18 páginaseBroc-Shell and Tube Heat Exchangers Model Series and Customer Oriented Solutions, FunkeMoly69xAinda não há avaliações

- PD Sheet - M3, M6, M10, M15 Series Plate Heat Exchanger - enDocumento8 páginasPD Sheet - M3, M6, M10, M15 Series Plate Heat Exchanger - enJulio Alberto Guerrero EnriquezAinda não há avaliações

- Heat Exchanger Equipment Field Manual: Common Operating Problems and Practical SolutionsNo EverandHeat Exchanger Equipment Field Manual: Common Operating Problems and Practical SolutionsNota: 4 de 5 estrelas4/5 (6)

- Browning Form - 8972E - 2012 PDFDocumento180 páginasBrowning Form - 8972E - 2012 PDFkman548Ainda não há avaliações

- Design of Plate & Frame HEXsDocumento7 páginasDesign of Plate & Frame HEXsChem.EnggAinda não há avaliações

- Heat Exchanger Selection Webinar PDFDocumento47 páginasHeat Exchanger Selection Webinar PDFAzar DeenAinda não há avaliações

- Twin Disc Marine Product GuideDocumento41 páginasTwin Disc Marine Product Guidekman548Ainda não há avaliações

- ABC 200 Heat ExchangerDocumento200 páginasABC 200 Heat Exchanger전상문100% (2)

- Alfa Laval Gasketed Heat Exchangers PDFDocumento14 páginasAlfa Laval Gasketed Heat Exchangers PDFIkhwanul HujiatnaAinda não há avaliações

- Heat ExchangersDocumento14 páginasHeat ExchangersPrateek JainAinda não há avaliações

- Alignment Coupling Operation Manual Tyre-FlexDocumento37 páginasAlignment Coupling Operation Manual Tyre-Flexer_sanjaypatelAinda não há avaliações

- CB16Documento2 páginasCB16fredyAinda não há avaliações

- Cb14 77 2Documento2 páginasCb14 77 2LudimillaFreitasAinda não há avaliações

- Plate Heat Exchanger: Applications Standard DesignDocumento2 páginasPlate Heat Exchanger: Applications Standard DesignNikhil BhatiaAinda não há avaliações

- T20 PDFDocumento2 páginasT20 PDFtrof_twdAinda não há avaliações

- Basco Type ESDocumento8 páginasBasco Type ESkawag51241Ainda não há avaliações

- m10 BWDocumento2 páginasm10 BWMiguel CallataAinda não há avaliações

- File39014 0 MK15BWDocumento2 páginasFile39014 0 MK15BWMarielena ChunabAinda não há avaliações

- Basco - Type - Es-Heat Exchangers BrochureDocumento8 páginasBasco - Type - Es-Heat Exchangers BrochureMarco Andrés Guevara LunaAinda não há avaliações

- Alfa Laval TS6: Gasketed Plate-And-Frame Heat ExchangerDocumento2 páginasAlfa Laval TS6: Gasketed Plate-And-Frame Heat ExchangerMichael GallegoAinda não há avaliações

- Phe M10Documento2 páginasPhe M10sumit11235Ainda não há avaliações

- Alfa Laval Heat ExchangersDocumento2 páginasAlfa Laval Heat Exchangersghera_gheraAinda não há avaliações

- American Industrial Liquid Cooled Oil Heat ExchangerDocumento12 páginasAmerican Industrial Liquid Cooled Oil Heat ExchangerAlejandro AguirreAinda não há avaliações

- Funke Shell Tube He eDocumento24 páginasFunke Shell Tube He eSubrata DasAinda não há avaliações

- TL35 Plate Heat ExchangerDocumento2 páginasTL35 Plate Heat ExchangerPueykia AndyAinda não há avaliações

- Plate Heat Exchanger: ApplicationsDocumento2 páginasPlate Heat Exchanger: ApplicationsGoce VasilevskiAinda não há avaliações

- Shell & Tube Heat ExchangersDocumento16 páginasShell & Tube Heat ExchangersShawala AzharAinda não há avaliações

- Schmidt Bretten SIGMAWIGDocumento6 páginasSchmidt Bretten SIGMAWIGUroš ČampragAinda não há avaliações

- Aq4 Ahri Certified Plate Heat Exchanger PDFDocumento2 páginasAq4 Ahri Certified Plate Heat Exchanger PDFmarko absAinda não há avaliações

- Trocador de Calor TS6 Da Alfa Laval.Documento2 páginasTrocador de Calor TS6 Da Alfa Laval.Adriano PantarotoAinda não há avaliações

- Sanitary Dual Tube Coil: High Efficiency Tube-In-Tube Heat ExchangerDocumento2 páginasSanitary Dual Tube Coil: High Efficiency Tube-In-Tube Heat ExchangerparsmessengerAinda não há avaliações

- CP LeftletDocumento4 páginasCP LeftletSiang LingAinda não há avaliações

- 438d8b4c-9d3a-4e95-be60-0b3a7dd96f1eDocumento4 páginas438d8b4c-9d3a-4e95-be60-0b3a7dd96f1eCristian Jhair PerezAinda não há avaliações

- Brazed Plate Heat Exchangers: A Product Catalogue For Comfort HeatingDocumento16 páginasBrazed Plate Heat Exchangers: A Product Catalogue For Comfort HeatingPROGRESS FLUID REXROTH BOSCH100% (1)

- Alfa Laval TL3: Gasketed Plate-And-Frame Heat ExchangerDocumento2 páginasAlfa Laval TL3: Gasketed Plate-And-Frame Heat ExchangerDONGTA123Ainda não há avaliações

- M15 PDFDocumento2 páginasM15 PDFkinjalpatel12345Ainda não há avaliações

- MK15-BW: Semi-Welded Plate Heat ExchangerDocumento2 páginasMK15-BW: Semi-Welded Plate Heat ExchangerAli NorouziAinda não há avaliações

- High Performance Thermal Solutions Heat-Pipes & Engineering Systems For Power ElectronicsDocumento12 páginasHigh Performance Thermal Solutions Heat-Pipes & Engineering Systems For Power ElectronicscivicbladeAinda não há avaliações

- Cbe enDocumento14 páginasCbe enStefanAinda não há avaliações

- Exchanger Piping Design Filetype PDFDocumento2 páginasExchanger Piping Design Filetype PDFChristinaAinda não há avaliações

- Mechanical Design and Design CriteriaDocumento32 páginasMechanical Design and Design CriteriaGhost RileyAinda não há avaliações

- Shell-And-Tube Heat Exchangers: Standard Series and Customer Oriented SolutionsDocumento24 páginasShell-And-Tube Heat Exchangers: Standard Series and Customer Oriented SolutionsZewdu TsegayeAinda não há avaliações

- AH AV CatalogDocumento16 páginasAH AV CatalognomurapreAinda não há avaliações

- Gestra Steam Trap - Thermostatic Steam Trap BK 29: Class Rating: ANSI 900 Available SizesDocumento2 páginasGestra Steam Trap - Thermostatic Steam Trap BK 29: Class Rating: ANSI 900 Available SizesdcarunchioAinda não há avaliações

- Heating Centre CatalogDocumento157 páginasHeating Centre Catalogwaynepowell21Ainda não há avaliações

- FlatPlate Hydronic HeatExchanger UsaDocumento28 páginasFlatPlate Hydronic HeatExchanger Usasas999333100% (1)

- Brazed Plate Heat ExchangersDocumento6 páginasBrazed Plate Heat ExchangersDhanielAinda não há avaliações

- 01 - Chemetics Gas-Gas Heat Exchanger InfoSheetDocumento2 páginas01 - Chemetics Gas-Gas Heat Exchanger InfoSheetWeb LogueandoAinda não há avaliações

- Na Gea Biofuels Mag Ad UsaDocumento2 páginasNa Gea Biofuels Mag Ad UsaTharakeshAinda não há avaliações

- Plate Fin Heat Ex ChangersDocumento16 páginasPlate Fin Heat Ex Changerscapricorno4694Ainda não há avaliações

- Mini Non-Taco Cat (Rev 10-1-14)Documento8 páginasMini Non-Taco Cat (Rev 10-1-14)api-282678113Ainda não há avaliações

- Fundamentals of Industrial Heat Exchangers: Selection, Design, Construction, and OperationNo EverandFundamentals of Industrial Heat Exchangers: Selection, Design, Construction, and OperationAinda não há avaliações

- Axiomatix TDAX184000 - J1939 RTD ScannerDocumento7 páginasAxiomatix TDAX184000 - J1939 RTD Scannerkman548Ainda não há avaliações

- Divingboards 011314Documento1 páginaDivingboards 011314kman548Ainda não há avaliações

- TR-16204 J1939 Temp-Sensor SS r3Documento1 páginaTR-16204 J1939 Temp-Sensor SS r3kman548Ainda não há avaliações

- Olympian G175LG4 12.9LDocumento6 páginasOlympian G175LG4 12.9Lkman548Ainda não há avaliações

- Commercial Boardsplusstands 1022Documento8 páginasCommercial Boardsplusstands 1022kman548Ainda não há avaliações

- Engine Performance Curve: Rating: Application:MarineDocumento4 páginasEngine Performance Curve: Rating: Application:Marinekman548Ainda não há avaliações

- En 8 260 100 F68GDocumento5 páginasEn 8 260 100 F68Gkman548Ainda não há avaliações

- Engine Performance Curve: Rating: Application:MarineDocumento4 páginasEngine Performance Curve: Rating: Application:Marinekman548Ainda não há avaliações

- Engine Performance Curve: Rating: Application:MarineDocumento4 páginasEngine Performance Curve: Rating: Application:Marinekman548Ainda não há avaliações

- Olympian G60F1 G75F1 Spec SheetDocumento6 páginasOlympian G60F1 G75F1 Spec Sheetkman548Ainda não há avaliações

- SL280UHV-Furnace-Users Manual-11-2010Documento7 páginasSL280UHV-Furnace-Users Manual-11-2010kman548Ainda não há avaliações

- Engine Performance Curve: Rating: Application:MarineDocumento4 páginasEngine Performance Curve: Rating: Application:Marinekman548Ainda não há avaliações

- LEHM20671-00 - C4.4 Electronic Data SheetDocumento3 páginasLEHM20671-00 - C4.4 Electronic Data Sheetkman548Ainda não há avaliações

- Engine Performance Curve: Rating: Application:MarineDocumento4 páginasEngine Performance Curve: Rating: Application:Marinekman548Ainda não há avaliações

- Engine Performance Curve: Rating: Application:MarineDocumento4 páginasEngine Performance Curve: Rating: Application:Marinekman548Ainda não há avaliações

- Powertech 9.0L Engine Engine Performance Curve: 60 HZ - 298Hp (222Kw) at 1800 RPMDocumento4 páginasPowertech 9.0L Engine Engine Performance Curve: 60 HZ - 298Hp (222Kw) at 1800 RPMkman548Ainda não há avaliações

- Engine Performance Curve: Rating: Application:MarineDocumento4 páginasEngine Performance Curve: Rating: Application:Marinekman548Ainda não há avaliações

- Engine Performance Curve: Rating: Application:MarineDocumento4 páginasEngine Performance Curve: Rating: Application:Marinekman548Ainda não há avaliações

- Engine Performance Curve: Rating: Application:MarineDocumento4 páginasEngine Performance Curve: Rating: Application:Marinekman548Ainda não há avaliações

- Engine Performance Curve: Rating: Application:MarineDocumento4 páginasEngine Performance Curve: Rating: Application:Marinekman548Ainda não há avaliações

- AG09 - 5 - Marine CoolingDocumento20 páginasAG09 - 5 - Marine Coolingkman548Ainda não há avaliações

- G3512H - EM3858 - Pump Curves (Imperial)Documento2 páginasG3512H - EM3858 - Pump Curves (Imperial)kman548Ainda não há avaliações

- Cummins Inc.: Engine Model: X15-M Data Sheet: Date: General Engine Data Metric (U.S. Customary) 12-Feb-21 D15-MX-01Documento2 páginasCummins Inc.: Engine Model: X15-M Data Sheet: Date: General Engine Data Metric (U.S. Customary) 12-Feb-21 D15-MX-01kman548Ainda não há avaliações

- Mini Tek PDFDocumento6 páginasMini Tek PDFkman548Ainda não há avaliações

- FR11675 X15M 500 at 1800Documento3 páginasFR11675 X15M 500 at 1800kman548Ainda não há avaliações

- Warning: Assembly, Installation, Care, Maintenance and Use InstructionsDocumento20 páginasWarning: Assembly, Installation, Care, Maintenance and Use Instructionskman548Ainda não há avaliações

- UENR2648 - Electrical SchematicDocumento2 páginasUENR2648 - Electrical Schematickman548Ainda não há avaliações

- Hidraulic Hammers Yekn0343Documento12 páginasHidraulic Hammers Yekn0343Andy DellepianeAinda não há avaliações

- Strength of Material Chapter 3Documento22 páginasStrength of Material Chapter 3naserunnAinda não há avaliações

- Encapsulated Submersible Motors 4" Product Information and ServiceDocumento48 páginasEncapsulated Submersible Motors 4" Product Information and ServiceMartín RománAinda não há avaliações

- GB E4313 - AWS A5.1 E6013 Welding Rods - Carbon Steel ElectrodeDocumento2 páginasGB E4313 - AWS A5.1 E6013 Welding Rods - Carbon Steel ElectrodeArfanAli100% (1)

- WORKSHOP MANUAL Aprilia MA - MY 50 Usa PDFDocumento54 páginasWORKSHOP MANUAL Aprilia MA - MY 50 Usa PDFwiyasatamaAinda não há avaliações

- CP - Original Lubricants PDFDocumento4 páginasCP - Original Lubricants PDFJan HendriksAinda não há avaliações

- BS 864-2 Capillary and Compression Tube Fittings of Copper and Copper AlloyDocumento24 páginasBS 864-2 Capillary and Compression Tube Fittings of Copper and Copper AlloyJames AlejoAinda não há avaliações

- The Griffith Relation - A Historical Review: by Dietrich Munz and Theo FettDocumento28 páginasThe Griffith Relation - A Historical Review: by Dietrich Munz and Theo FettV.v. TaguisAinda não há avaliações

- Force & Laws of Motion Numericals SolutionDocumento10 páginasForce & Laws of Motion Numericals SolutionViji GowriAinda não há avaliações

- Rule Bki V Rules For Materials 2009Documento249 páginasRule Bki V Rules For Materials 2009Saadi AlimAinda não há avaliações

- s5113 Mm39 F.O Supply UnitDocumento408 páginass5113 Mm39 F.O Supply UnitJorge AguilarAinda não há avaliações

- Seleção SALA 1 Ou 2Documento10 páginasSeleção SALA 1 Ou 2Gustavo RomeroAinda não há avaliações

- COVNA HK0018 Series Sanitary Solenoid Valve SpecificationDocumento1 páginaCOVNA HK0018 Series Sanitary Solenoid Valve Specificationemosquerasaurus saurusAinda não há avaliações

- Valves S&S B Series 8-Inch Globe: Instruction ManualDocumento12 páginasValves S&S B Series 8-Inch Globe: Instruction ManualpedroAinda não há avaliações

- Blackmer Parts List PUMP MODELS: SGL1.25A, SGRL1.25A, SGL1.5ADocumento2 páginasBlackmer Parts List PUMP MODELS: SGL1.25A, SGRL1.25A, SGL1.5AJackAinda não há avaliações

- Butt Heat Fusion Polyethylene (PE) Plastic Fittings For Polyethylene (PE) Plastic Pipe and TubingDocumento6 páginasButt Heat Fusion Polyethylene (PE) Plastic Fittings For Polyethylene (PE) Plastic Pipe and TubingHernando Andrés Ramírez GilAinda não há avaliações

- Hardox 500 PDFDocumento2 páginasHardox 500 PDFMustafa Mahmoud ElsayedAinda não há avaliações

- Chemistry 231 Tutorial Session # 5: The Following Questions Will Be Answered On The Tutorial SessionDocumento8 páginasChemistry 231 Tutorial Session # 5: The Following Questions Will Be Answered On The Tutorial SessionFiqkyAkbarAinda não há avaliações

- Ropar ItemInventoryItemWiseList 10-02-2024Documento2 páginasRopar ItemInventoryItemWiseList 10-02-2024lahotishreyanshAinda não há avaliações

- Toyota/Lexus: Boost Valve Kit 3 Oversized Lockup Control Valve Kit 1Documento1 páginaToyota/Lexus: Boost Valve Kit 3 Oversized Lockup Control Valve Kit 1Aays thAinda não há avaliações

- Practical Aspects of Finite Element SimulationDocumento11 páginasPractical Aspects of Finite Element SimulationChandrashekar HiremathAinda não há avaliações

- Em7281-0 Chassis FaultsDocumento5 páginasEm7281-0 Chassis FaultsJose ZorrillaAinda não há avaliações

- Vapro Pressure and Heat Heat of VaporazationDocumento5 páginasVapro Pressure and Heat Heat of VaporazationStephen Rey CaldeaAinda não há avaliações

- Engine Perfomance Job Sheet 10Documento2 páginasEngine Perfomance Job Sheet 10Christian Villa GuerraAinda não há avaliações