Escolar Documentos

Profissional Documentos

Cultura Documentos

直饮水设备选型Q1922A - GOCG PDF

Enviado por

Roger YanDescrição original:

Título original

Direitos autorais

Formatos disponíveis

Compartilhar este documento

Compartilhar ou incorporar documento

Você considera este documento útil?

Este conteúdo é inapropriado?

Denunciar este documentoDireitos autorais:

Formatos disponíveis

直饮水设备选型Q1922A - GOCG PDF

Enviado por

Roger YanDireitos autorais:

Formatos disponíveis

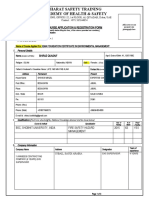

FILTRINE MANUFACTURING COMPANY 15 Kit Street, Keene, NH 03431 USA

DATE

April 18, 2014

ATTN

S.A.I.T.

Dr. Hassan Al-Harthi

PO Box 32912

401 Gulf Center 4rd Floor

Madina Road, Near Al Harithy Hotel

Jeddah 21438 Saudi Arabia

Tel: +966 2 665 6456

Fax: +966 2 661 3369

Email: pcd-jed@saite.com.sa

SUBJECT

QUOTE # 1922A

PROJECT

KKU Male Campus - Abha, Saudi Arabia

MODEL

MC 01 DIV 15A

MC 02

MC 03 DIV 15A

MC 05 DIV 15A

MC 08 DIV 15A

MC 09B

[1] ES-160-RFCA-MOD Chiller/Purifier

[16] Model 103-ALC Recessed Drinking Fountain

[1] ES-160-RFCA-MOD Chiller/Purifier

[18] Model 103-ALC Recessed Drinking Fountain

[1] ES-160-RFCA-MOD Chiller/Purifier

[28] Model 103-ALC Recessed Drinking Fountain

[1] ES-240-RFCA-MOD Chiller/Purifier

[9] Model 103-ALC Recessed Drinking Fountain

[1] ES-240-RFCA-MOD Chiller/Purifier

[23] Model 103-ALC Recessed Drinking Fountain

[1] ES-240-RFCA-MOD Chiller/Purifier

[12] Model 103-ALC Recessed Drinking Fountain

We are pleased to enclose a submittal for the project referenced above.

If you should have any questions, please do not hesitate to contact our office.

Please note that EQUIPMENT IS NOT RELEASED FOR PRODUCTION until the customer approves this submittal.

SUBMITTAL APPROVED ____ YES ____ NO

RELEASED FOR PRODUCTION ____ YES ____ NO

APPROVED BY _________________________________ DATE __________

Please sign and return to Filtrine.

David Hansel, VP

Drinking Water Division

Tel: 603-352-5500 [ext 596]

Fax: 603-352-0330

E-Mail: dhansel@filtrine.com

SUBMITTAL FOR: KKU Male Campus - MC01 DIV 15A

SITE: Abha, Saudi Arabia

QUOTE: 1922A

PLUMBING

CONNECTIONS

CHILLER MODEL .............................................................. ES-160-RFCA-MOD

ELECTRICAL

CONNECTIONS

COOLING CAPACITY

Btu/Hr ................................................................................................................................. 97,000

Outlet Temp ......................................................................................................................... 45F

Ambient Air Temp........................................................................................................ 110F

H

FRONT

LEFT

END

CONDENSER.......................................................................................................... Air Cooled

REFRIGERANT............................................................................................................... R-134a

HEAT DISSIPATION ................................................................................ 126,100 BTU/hr

CFM ..................................................................................................................................... 10,920

DIMENSIONS

90W

56D

70H

Channel Skids: Add 2 to height and 4 to depth

CLEARANCES

Left 24

Front 36

REFRIGERATION SYSTEMS

COMPRESSOR AND CONTROLS

Semi-hermetic compressor with condenser, high/low pressure stat,

solenoid valve, expansion valve, sight glass and dehydrator.

Compressor ............................................................................................ Carrier 06EM450

HP .................................................................................................................................................... 10

Voltage....................................................................................................................... 400/60/3*

Starter........................................................................................................................... Magnetic

Right 36

Rear 12

PLUMBING CONNECTIONS

TYPE

SIZE

Water In

1 FPT

Water Out

1 FPT

Water Return

1 FPT

LOCATION

Left End

Left End

Left End

ELECTRICAL

400/60/3*

* RANGE WHICH IS 380 V +/- 10 % [342 V - 418 V]

COOLING TANK & EVAPORATOR

CONSTRUCTION

Welded all stainless steel shell and immersion coil evaporator.

Tank tested at 250# for 125# working pressure. Supplied with

drain out and insulated with closed-cell thermo-elastomer,

housed in rust proof steel cabinet.

Tank Capacity .............................................................................................................. 160 gal

PUMP

DESCRIPTION

Pump mounted on rubber vibration pads over a stainless steel

condensation tray and supplied with unions and service valves and a

manually adjusted bypass valve. All piping and ttings brass, copper

or bronze and insulated with closed-cell thermoelastomer.

Pump Make ....................................................................................................... MTH C51BC

HP ............................................................................................................................................. 1-1/2

Voltage ..................................................................................................................... 400/60/3*

Starter ......................................................................................................................... Magnetic

Rated Capacity .................................................................................... 20 gpm @ 30 psi

STERILIZER/PURIFIER

STERILIZER MODEL: 200S with UV monitor light and dry contact

PURIFIER MODEL: IL15-PFTM with DPS and dry contact

[2] PF10 Pre-lter [PF10-17-5-SP element]

[3] TM3 Purier [TM3-17-5-CB element]

CORROSION INHIBITOR MODEL: #2 Phosphate Feeder

DRY CONTACTS FOR:

Compressor run

Pump run

Low temperature

CABINET CONSTRUCTION

18 gauge enameled aluminum panels on a welded angle iron frame.

Panels removable without tools for access to all components

OPTIONS

7 day timer

ES-160-RFCA-MOD

[Q1922A]

REVISED 01.29.14

SUBMITTAL FOR: KKU Male Campus - MC 02

SITE: Abha, Saudi Arabia

QUOTE: 1922A

PLUMBING

CONNECTIONS

CHILLER MODEL .............................................................. ES-160-RFCA-MOD

ELECTRICAL

CONNECTIONS

COOLING CAPACITY

Btu/Hr ................................................................................................................................. 97,000

Outlet Temp ......................................................................................................................... 45F

Ambient Air Temp........................................................................................................ 110F

H

FRONT

LEFT

END

CONDENSER.......................................................................................................... Air Cooled

REFRIGERANT............................................................................................................... R-134a

HEAT DISSIPATION ................................................................................ 126,100 BTU/hr

CFM ..................................................................................................................................... 10,920

DIMENSIONS

104W

46D

74H

Channel Skids: Add 2 to height and 4 to depth

CLEARANCES

Left 24

Front 36

REFRIGERATION SYSTEMS

COMPRESSOR AND CONTROLS

Semi-hermetic compressor with condenser, high/low pressure stat,

solenoid valve, expansion valve, sight glass and dehydrator.

Compressor ............................................................................................ Carrier 06EM450

HP .................................................................................................................................................... 10

Voltage....................................................................................................................... 400/60/3*

Starter........................................................................................................................... Magnetic

Right 36

Rear 12

PLUMBING CONNECTIONS

TYPE

SIZE

Water In

1 FPT

Water Out

1 FPT

Water Return

1 FPT

LOCATION

Left End

Left End

Left End

ELECTRICAL

400/60/3*

* RANGE WHICH IS 380 V +/- 10 % [342 V - 418 V]

COOLING TANK & EVAPORATOR

CONSTRUCTION

Welded all stainless steel shell and immersion coil evaporator.

Tank tested at 250# for 125# working pressure. Supplied with

drain out and insulated with closed-cell thermo-elastomer,

housed in rust proof steel cabinet.

Tank Capacity .............................................................................................................. 160 gal

PUMP

DESCRIPTION

Pump mounted on rubber vibration pads over a stainless steel

condensation tray and supplied with unions and service valves and a

manually adjusted bypass valve. All piping and ttings brass, copper

or bronze and insulated with closed-cell thermoelastomer.

Pump Make ....................................................................................................... MTH C51BC

HP ............................................................................................................................................. 1-1/2

Voltage ..................................................................................................................... 400/60/3*

Starter ......................................................................................................................... Magnetic

Rated Capacity .................................................................................... 20 gpm @ 30 psi

STERILIZER/PURIFIER

STERILIZER MODEL: 200S with UV monitor light and dry contact

PURIFIER MODEL: IL15-PFTM with DPS and dry contact

[2] PF10 Pre-lter [PF10-17-5-SP element]

[3] TM3 Purier [TM3-17-5-CB element]

CORROSION INHIBITOR MODEL: #2 Phosphate Feeder

DRY CONTACTS FOR:

Compressor run

Pump run

Low temperature

CABINET CONSTRUCTION

18 gauge enameled aluminum panels on a welded angle iron frame.

Panels removable without tools for access to all components

OPTIONS

7 day timer

ES-160-RFCA-MOD

[Q1922A]

REVISED 01.29.14

SUBMITTAL FOR: KKU Male Campus - MC 03 DIV 15A

SITE: Abha, Saudi Arabia

QUOTE: 1922A

PLUMBING

CONNECTIONS

CHILLER MODEL .............................................................. ES-160-RFCA-MOD

ELECTRICAL

CONNECTIONS

COOLING CAPACITY

Btu/Hr ................................................................................................................................. 47,000

Outlet Temp ......................................................................................................................... 45F

Ambient Air Temp........................................................................................................ 110F

H

FRONT

LEFT

END

CONDENSER.......................................................................................................... Air Cooled

REFRIGERANT............................................................................................................... R-134a

HEAT DISSIPATION ................................................................................... 61,100 BTU/hr

CFM ..................................................................................................................................... 10,920

DIMENSIONS

88W

37D

88H

Channel Skids: Add 2 to height and 4 to depth

CLEARANCES

Left 24

Front 36

REFRIGERATION SYSTEMS

COMPRESSOR AND CONTROLS

Semi-hermetic compressor with condenser, high/low pressure stat,

solenoid valve, expansion valve, sight glass and dehydrator.

Compressor ............................................................................................ Carrier 06DR820

HP ....................................................................................................................................................... 5

Voltage....................................................................................................................... 400/60/3*

Starter........................................................................................................................... Magnetic

Right 36

Rear 12

PLUMBING CONNECTIONS

TYPE

SIZE

Water In

1 FPT

Water Out

1 FPT

Water Return

1 FPT

LOCATION

Left End

Left End

Left End

ELECTRICAL

400/60/3*

* RANGE WHICH IS 380 V +/- 10 % [342 V - 418 V]

COOLING TANK & EVAPORATOR

CONSTRUCTION

Welded all stainless steel shell and immersion coil evaporator.

Tank tested at 250# for 125# working pressure. Supplied with

drain out and insulated with closed-cell thermo-elastomer,

housed in rust proof steel cabinet.

Tank Capacity .............................................................................................................. 160 gal

PUMP

DESCRIPTION

Pump mounted on rubber vibration pads over a stainless steel

condensation tray and supplied with unions and service valves and a

manually adjusted bypass valve. All piping and ttings brass, copper

or bronze and insulated with closed-cell thermoelastomer.

Pump Make ....................................................................................................... MTH C51DE

HP ............................................................................................................................................. 1-1/2

Voltage ..................................................................................................................... 400/60/3*

Starter ......................................................................................................................... Magnetic

Rated Capacity .................................................................................... 30 gpm @ 30 psi

STERILIZER/PURIFIER

STERILIZER MODEL: 200S with UV monitor light and dry contact

PURIFIER MODEL: IL15-PFTM with DPS and dry contact

[2] PF10 Pre-lter [PF10-17-5-SP element]

[3] TM3 Purier [TM3-17-5-CB element]

CORROSION INHIBITOR MODEL: #2 Phosphate Feeder

DRY CONTACTS FOR:

Compressor run

Pump run

Low temperature

CABINET CONSTRUCTION

18 gauge enameled aluminum panels on a welded angle iron frame.

Panels removable without tools for access to all components

OPTIONS

7 day timer

ES-160-RFCA-MOD

[Q1922A]

REVISED 04.17.14

SUBMITTAL FOR: KKU Male Campus - MC 05 DIV 15A

SITE: Abha, Saudi Arabia

QUOTE: 1922A

PLUMBING

CONNECTIONS

CHILLER MODEL .............................................................. ES-240-RFCA-MOD

ELECTRICAL

CONNECTIONS

COOLING CAPACITY

Btu/Hr ................................................................................................................................. 65,000

Outlet Temp ......................................................................................................................... 45F

Ambient Air Temp........................................................................................................ 110F

H

FRONT

LEFT

END

CONDENSER.......................................................................................................... Air Cooled

REFRIGERANT............................................................................................................... R-134a

HEAT DISSIPATION ................................................................................... 84,500 BTU/hr

CFM ........................................................................................................................................ 8,200

DIMENSIONS

90W

56D

75H

Channel Skids: Add 2 to height and 4 to depth

CLEARANCES

Left 36

Front 36

REFRIGERATION SYSTEMS

COMPRESSOR AND CONTROLS

Semi-hermetic compressor with condenser, high/low pressure stat,

solenoid valve, expansion valve, sight glass and dehydrator.

Compressor ....................................................................................... CARRIER 06DR228

HP .............................................................................................................................................. 7-1/2

Voltage....................................................................................................................... 400/60/3*

Starter........................................................................................................................... Magnetic

Right 36

Rear 12

PLUMBING CONNECTIONS

TYPE

SIZE

Water In

1 FPT

Water Out

1 FPT

Water Return

1 FPT

LOCATION

Left End

Left End

Left End

ELECTRICAL

400/60/3*

* RANGE WHICH IS 380 V +/- 10 % [342 V - 418 V]

COOLING TANK & EVAPORATOR

CONSTRUCTION

Welded all stainless steel shell and immersion coil evaporator.

Tank tested at 250# for 125# working pressure. Supplied with

drain out and insulated with closed-cell thermo-elastomer,

housed in rust proof steel cabinet.

Tank Capacity .............................................................................................................. 240 gal

PUMP

DESCRIPTION

Pump mounted on rubber vibration pads over a stainless steel

condensation tray and supplied with unions and service valves and a

manually adjusted bypass valve. All piping and ttings brass, copper

or bronze and insulated with closed-cell thermoelastomer.

Pump Make ....................................................................................................... MTH C51DE

HP ............................................................................................................................................. 1-1/2

Voltage ..................................................................................................................... 400/60/3*

Starter ......................................................................................................................... Magnetic

Rated Capacity .................................................................................... 30 gpm @ 30 psi

STERILIZER/PURIFIER

STERILIZER MODEL: 200S with UV monitor light and dry contact

PURIFIER MODEL: IL15-PFTM with DPS and dry contact

[2] PF10 Pre-lter [PF10-17-5-SP element]

[3] TM3 Purier [TM3-17-5-CB element]

CORROSION INHIBITOR MODEL: #2 Phosphate Feeder

DRY CONTACTS FOR:

Compressor run

Pump run

Low temperature

CABINET CONSTRUCTION

18 gauge enameled aluminum panels on a welded angle iron frame.

Panels removable without tools for access to all components

OPTIONS

7 day timer

ES-240-RFCA-MOD

[Q1922A]

REVISED 04.17.14

SUBMITTAL FOR: KKU Male Campus - MC08 DIV 15A

SITE: Abha, Saudi Arabia

QUOTE: 1922A

PLUMBING

CONNECTIONS

CHILLER MODEL .............................................................. ES-240-RFCA-MOD

ELECTRICAL

CONNECTIONS

COOLING CAPACITY

Btu/Hr .............................................................................................................................. 130,000

Outlet Temp ......................................................................................................................... 45F

Ambient Air Temp........................................................................................................ 110F

H

FRONT

LEFT

END

CONDENSER.......................................................................................................... Air Cooled

REFRIGERANT............................................................................................................... R-134a

HEAT DISSIPATION ................................................................................ 169,000 BTU/hr

CFM ..................................................................................................................................... 16,400

DIMENSIONS

140W

62D

75H

Channel Skids: Add 2 to height and 4 to depth

CLEARANCES

Left 24

Front 36

REFRIGERATION SYSTEMS

COMPRESSOR AND CONTROLS

Semi-hermetic compressor with condenser, high/low pressure stat,

solenoid valve, expansion valve, sight glass and dehydrator.

Compressor ............................................................................................. Carrier 06EA265

HP .................................................................................................................................................... 15

Voltage....................................................................................................................... 400/60/3*

Starter........................................................................................................................... Magnetic

Right 36

Rear 12

PLUMBING CONNECTIONS

TYPE

SIZE

Water In

1 FPT

Water Out

1 FPT

Water Return

1 FPT

LOCATION

Left End

Left End

Left End

ELECTRICAL

400/60/3*

* RANGE WHICH IS 380 V +/- 10 % [342 V - 418 V]

COOLING TANK & EVAPORATOR

CONSTRUCTION

Welded all stainless steel shell and immersion coil evaporator.

Tank tested at 250# for 125# working pressure. Supplied with

drain out and insulated with closed-cell thermo-elastomer,

housed in rust proof steel cabinet.

Tank Capacity .............................................................................................................. 240 gal

PUMP

DESCRIPTION

Pump mounted on rubber vibration pads over a stainless steel

condensation tray and supplied with unions and service valves and a

manually adjusted bypass valve. All piping and ttings brass, copper

or bronze and insulated with closed-cell thermoelastomer.

Pump Make ....................................................................................................... MTH C51DE

HP ............................................................................................................................................. 1-1/2

Voltage ..................................................................................................................... 400/60/3*

Starter ......................................................................................................................... Magnetic

Rated Capacity .................................................................................... 30 gpm @ 30 psi

STERILIZER/PURIFIER

STERILIZER MODEL: 200S with UV monitor light and dry contact

PURIFIER MODEL: IL15-PFTM with DPS and dry contact

[2] PF10 Pre-lter [PF10-17-5-SP element]

[3] TM3 Purier [TM3-17-5-CB element]

CORROSION INHIBITOR MODEL: #2 Phosphate Feeder

DRY CONTACTS FOR:

Compressor run

Pump run

Low temperature

CABINET CONSTRUCTION

18 gauge enameled aluminum panels on a welded angle iron frame.

Panels removable without tools for access to all components

OPTIONS

7 day timer

ES-240-RFCA-MOD

[Q1922A]

REVISED 04.17.14

SUBMITTAL FOR: KKU Male Campus - MC 09B DIV 15A

SITE: Abha, Saudi Arabia

QUOTE: 1922A

PLUMBING

CONNECTIONS

CHILLER MODEL .............................................................. ES-240-RFCA-MOD

ELECTRICAL

CONNECTIONS

COOLING CAPACITY

Btu/Hr ................................................................................................................................. 65,000

Outlet Temp ......................................................................................................................... 45F

Ambient Air Temp........................................................................................................ 110F

H

FRONT

LEFT

END

CONDENSER.......................................................................................................... Air Cooled

REFRIGERANT............................................................................................................... R-134a

HEAT DISSIPATION ................................................................................... 84,500 BTU/hr

CFM ........................................................................................................................................ 8,200

DIMENSIONS

90W

56D

75H

Channel Skids: Add 2 to height and 4 to depth

CLEARANCES

Left 36

Front 36

REFRIGERATION SYSTEMS

COMPRESSOR AND CONTROLS

Semi-hermetic compressor with condenser, high/low pressure stat,

solenoid valve, expansion valve, sight glass and dehydrator.

Compressor ....................................................................................... CARRIER 06DR228

HP .............................................................................................................................................. 7-1/2

Voltage....................................................................................................................... 400/60/3*

Starter........................................................................................................................... Magnetic

Right 36

Rear 12

PLUMBING CONNECTIONS

TYPE

SIZE

Water In

1 FPT

Water Out

1 FPT

Water Return

1 FPT

LOCATION

Left End

Left End

Left End

ELECTRICAL

400/60/3*

* RANGE WHICH IS 380 V +/- 10 % [342 V - 418 V]

COOLING TANK & EVAPORATOR

CONSTRUCTION

Welded all stainless steel shell and immersion coil evaporator.

Tank tested at 250# for 125# working pressure. Supplied with

drain out and insulated with closed-cell thermo-elastomer,

housed in rust proof steel cabinet.

Tank Capacity .............................................................................................................. 240 gal

PUMP

DESCRIPTION

Pump mounted on rubber vibration pads over a stainless steel

condensation tray and supplied with unions and service valves and a

manually adjusted bypass valve. All piping and ttings brass, copper

or bronze and insulated with closed-cell thermoelastomer.

Pump Make ....................................................................................................... MTH C51DE

HP ............................................................................................................................................. 1-1/2

Voltage ..................................................................................................................... 400/60/3*

Starter ......................................................................................................................... Magnetic

Rated Capacity .................................................................................... 30 gpm @ 30 psi

STERILIZER/PURIFIER

STERILIZER MODEL: 200S with UV monitor light and dry contact

PURIFIER MODEL: IL15-PFTM with DPS and dry contact

[2] PF10 Pre-lter [PF10-17-5-SP element]

[3] TM3 Purier [TM3-17-5-CB element]

CORROSION INHIBITOR MODEL: #2 Phosphate Feeder

DRY CONTACTS FOR:

Compressor run

Pump run

Low temperature

CABINET CONSTRUCTION

18 gauge enameled aluminum panels on a welded angle iron frame.

Panels removable without tools for access to all components

OPTIONS

7 day timer

ES-240-RFCA-MOD

[Q1922A]

REVISED 04.01.14

Page C-23

C41 C51 C61 SERIES

Performance Curves

3450 RPM

BHP

C51BC - 1 1/2 HP* (3/4 X 1 X 5)

100

Head-Capacity

1.8

60

1.6

40

1.4

1.2

1.0

60

80

NPSHR

20

NPSHR IN FEET

HEAD IN FEET

BEP

BHP**

20

30

40

U.S. GALLONS PER MINUTE

C51BC - 1 1/2 HP* (3/4 X 1 X 5)

50

2880 RPM

BHP

100

10

80

1.4

1.2

1.0

0.8

0.6

60

60

BEP

40

NPSHR

20

NPSHR IN FEET

HEAD IN FEET

Head-Capacity

C51 SERIES PUMPS

BHP**

10

20

30

40

U.S. GALLONS PER MINUTE

50

*High Service Factor Motor Horsepower Selections - See Standard Motor Guide and/or Motor Price Sheets for more information.

**BHP data valid for 1.0 specific gravity fluids only.

Copyright 2011 MTH Tool Company, Inc.

Dated May 2011

Q1922A

Page C-27

C41 C51 C61 SERIES

Performance Curves

3450 RPM

C51DE - 1 1/2 HP* (1 1/4 X 1 1/2 X 5)

Head-Capacity

HEAD IN FEET

80

1.8

16

1.6

12

1.4

1.2

1.0

80

BEP

60

40

20

100

NPSHR

BHP**

10

20

30

40

50

U.S. GALLONS PER MINUTE

60

70

NPSHR IN FEET

BHP

100

2880 RPM

C51DE - 1 1/2 HP* (1 1/4 X 1 1/2 X 5)

Head-Capacity

60

BEP

40

NPSHR

20

C51 SERIES PUMPS

1.2

12

1.0

0.8

0.6

80

NPSHR IN FEET

HEAD IN FEET

BHP

80

BHP**

10

20

30

40

50

U.S. GALLONS PER MINUTE

*High Service Factor Motor Horsepower Selections - See Standard Motor Guide and/or Motor Price Sheets for more information.

**BHP data valid for 1.0 specic gravity uids only.

Copyright 2008 MTH Tool Company, Inc.

60

70

Q1922A

Dated January 2008

Model 103-ALC

In-Wall Drinking Fountain

FOUNTAIN SPECIFICATIONS

BOTTLE FILLER - OPTION 1

With integral push back lever valve on back of

fountain

FOUNTAIN MATERIAL - 16 gauge

Stainless Steel

Bronze

FINISH

Satin

Mirror

Statuary Bronze

Oil Rubbed Bronze

Powder Coat

BOTTLE FILLER - OPTION 2

With gooseneck with push down lever valve

mounted on fountain deck over bowl

BUBBLER TYPE

Integral PUSH BUTTON valve

Separate SOFT TOUCH button valve

Integral EASY TOUCH lever valve

Separate SIDE MOUNT lever valve

BUBBLER FINISH

Stainless Steel

Bronze

FINISH

Satin

Mirror

Statuary Bronze

Oil Rubbed Bronze

103-ALC DRINKING FOUNTAIN

Illustration

VANDAL-PROOF BUBBLER - OPTION

Tamper-resistant set screw secures

bubbler to fountain

Model 103-ALC DRINKING FOUNTAIN

REFERENCE INFORMATION: Contact Filtrine for quote or submittal

TOP

12

CL

10 DIA

BOWL

WALL OPENING

WITH BOTTLE FILLER

17W x 15D x 33-3/4H

2

1

WALL OPENING

WITHOUT BOTTLE FILLER

17W x 12-1/2D x 33-3/4H

3/16 HOLE FOR

MOUNTING SCREWS

[BY OTHERS]

16

18

RIGHT END

FRONT

LEVER VALVE

BOTTLE FILLER

OPTIONAL

3/8

12

24-3/4

20

GOOSENECK

FILLER

OPTIONAL

CL

3/16 HOLES

FOR MOUNTING

SCREWS

[BY OTHERS]

34-3/4

WATER

BUBBLER

SOFT TOUCH

PUSH BUTTON

OPTIONAL

1-1/4 O.D.

DRAIN

3

ACCESS

PANEL

WATER IN

1/4 O.D.

MARK AVAILABLE

LEAD

FO

53

APPROVED

L I E S WI

19

PRODUCT LINE

LABOR & PARTS

MP

TH

FILTRINE IS ISO 9001-2008 REGISTERED

C AL

FILTRINE Mfg Co 15 Kit St. Keene, NH 03431 USA

800-930-3367 603-352-5500 FAX 603-352-0330

www.filtrine.com drinkingwater@filtrine.com

CO

R NIA AB

103-ALC [EB]

REVISED

Q1922A

07.23.12

F-501 WATER BUBBLER INSTALLATION

ASSEMBLY DIAGRAM & PARTS LIST

8

7

6

REGULATOR

CARTRIDGE

ASSEMBLY

REGULATOR

BODY

F-501BUBBLER

BEFORE INSTALLING YOUR NEW DRINKING FOUNTAIN,

OR REPLACING BUBBLER PARTS

FLUSH THE MAKEUP WATER LINE

10

12

1 Remove hexagon cover, push button, retaining ring and

regulator gasket

2 Insert regulator cartridge into body as shown

and tighten with spanner wrench.

Do not over tighten - 3.5 lb/ft torque max

3 Reverse Step 1

BODY - Chrome plated brass

REGULATOR CARTRIDGE ASSEMBLY

RETAINING RING - Brass

BUTTON - Chrome

HEXAGON COVER - Chrome

SPOUT - Chrome

SCREEN - Stainless Steel

STREAM STRAIGHTNER - Brass

O-RING - Rubber

MOUNTING WASHER - Rubber

SPANNER WRENCH

45.0001

45.0006

45.0008

45.0009

45.0010

SOLD AS UNIT

45.0011

45.0016

45.0017

NOTE

Model F-501 bubbler is "LEAD-FREE" per

manufacturer's NSF listing to ANSI/NSF Standard 61.

1

4

6

7

8

9

10

11

12

14

15

ORDER

PART #

INSTALLING THE REGULATOR

DRWG

PART # PART DESCRIPTION

Adjustments to the stream height should be slight [about 1/8

turn at a time]. If the stream height does not change, check

for ow restrictions elsewhere [i.e.: stop valve not completely

open, loose washer in stop valve, pinched piping, pipe dope or

solder in piping, debris in screen at base of bubbler or spout].

Air in the water can also cause erratic ow. Once the steam

height is satisfactory, the nished hex nut and push button

can be screwed onto the remaining threads of the retaining

ring. Snug the hex nut with a padded wrench.

15

When replacing a ow regulator the line should be ushed

[as outlined above] to ensure proper operation of the new

regulator. After ushing, install the regulator and snug the

retaining ring gently. It should be tightened only enough to

make a water seal. Do not over tighten - 3.5 lb/ft torque max.

Turn the supply stop valve fully on and check for leaks. Push

the button on the regulator and check the stream height.

14

Flow regulators in the bubbler valve can be fouled by debris

and sediment in the water. Before connecting the makeup

water line to the fountain, open the supply line stop valve

enough to give a good rush of water into a bucket. Repeat

several times until the water runs clear. Start with the nearest

fountain and progress one by one to the furthest down the

supply line.

REGULATOR

GASKET

11

F-501 INSTALL [EB]

REVISED

Q1922A

01.29.13

WATER REGULATOR ASSEMBLY

THREADED

ADJUSTER CAP

PLUNGER

CAP

SPRING

HOUSING

CAP

PLUNGER

SPRING

WASHER

REGULATOR

VALVE

LOCK

WASHER

NEOPRENE

GASKET

REGULATOR

HOUSING

TO ASSEMBLE WATER REGULATOR AFTER CLEANING

Align regulator valve inside regulator housing

Place gasket over regulator valve and housing

Place washer and lockwasher over stem of regulator valve

Place housing, plunger spring and plunger over regulator housing

Insert cap spring and screw threaded adjuster cap in place

1

2

3

4

5

F-501 INSTALL [EB]

REVISED

01.29.13

Você também pode gostar

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeNo EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeNota: 4 de 5 estrelas4/5 (5794)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreNo EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreNota: 4 de 5 estrelas4/5 (1090)

- Never Split the Difference: Negotiating As If Your Life Depended On ItNo EverandNever Split the Difference: Negotiating As If Your Life Depended On ItNota: 4.5 de 5 estrelas4.5/5 (838)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceNo EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceNota: 4 de 5 estrelas4/5 (895)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersNo EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersNota: 4.5 de 5 estrelas4.5/5 (345)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureNo EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureNota: 4.5 de 5 estrelas4.5/5 (474)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)No EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Nota: 4.5 de 5 estrelas4.5/5 (121)

- The Emperor of All Maladies: A Biography of CancerNo EverandThe Emperor of All Maladies: A Biography of CancerNota: 4.5 de 5 estrelas4.5/5 (271)

- The Little Book of Hygge: Danish Secrets to Happy LivingNo EverandThe Little Book of Hygge: Danish Secrets to Happy LivingNota: 3.5 de 5 estrelas3.5/5 (400)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyNo EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyNota: 3.5 de 5 estrelas3.5/5 (2259)

- The Yellow House: A Memoir (2019 National Book Award Winner)No EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Nota: 4 de 5 estrelas4/5 (98)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaNo EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaNota: 4.5 de 5 estrelas4.5/5 (266)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryNo EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryNota: 3.5 de 5 estrelas3.5/5 (231)

- Team of Rivals: The Political Genius of Abraham LincolnNo EverandTeam of Rivals: The Political Genius of Abraham LincolnNota: 4.5 de 5 estrelas4.5/5 (234)

- The Unwinding: An Inner History of the New AmericaNo EverandThe Unwinding: An Inner History of the New AmericaNota: 4 de 5 estrelas4/5 (45)

- Methodical Pointing For Work of Students On Practical EmploymentDocumento32 páginasMethodical Pointing For Work of Students On Practical EmploymentVidhu YadavAinda não há avaliações

- 5 Star Hotels in Portugal Leads 1Documento9 páginas5 Star Hotels in Portugal Leads 1Zahed IqbalAinda não há avaliações

- Manufacturing StrategyDocumento31 páginasManufacturing Strategyrajendra1pansare0% (1)

- HILTI Technology Manual PDFDocumento210 páginasHILTI Technology Manual PDFRoger Yan100% (1)

- MINIMUM BIM, 2nd Edition Proposed Revision - NBIMS v3Documento35 páginasMINIMUM BIM, 2nd Edition Proposed Revision - NBIMS v3Roger YanAinda não há avaliações

- Identification and Analysis of Interoperability Gaps Between Nbims/Open Standards and Building Performance Simulation ToolsDocumento25 páginasIdentification and Analysis of Interoperability Gaps Between Nbims/Open Standards and Building Performance Simulation ToolsRoger YanAinda não há avaliações

- Ansi Z21.45-1995 PDFDocumento29 páginasAnsi Z21.45-1995 PDFRoger YanAinda não há avaliações

- HILTI Technology ManualDocumento210 páginasHILTI Technology ManualRoger Yan100% (1)

- Final ExamSOMFinal 2016 FinalDocumento11 páginasFinal ExamSOMFinal 2016 Finalkhalil alhatabAinda não há avaliações

- 3412C EMCP II For PEEC Engines Electrical System: Ac Panel DC PanelDocumento4 páginas3412C EMCP II For PEEC Engines Electrical System: Ac Panel DC PanelFrancisco Wilson Bezerra FranciscoAinda não há avaliações

- Wiley Chapter 11 Depreciation Impairments and DepletionDocumento43 páginasWiley Chapter 11 Depreciation Impairments and Depletion靳雪娇Ainda não há avaliações

- Kaitlyn LabrecqueDocumento15 páginasKaitlyn LabrecqueAmanda SimpsonAinda não há avaliações

- Sweet Biscuits Snack Bars and Fruit Snacks in MexicoDocumento17 páginasSweet Biscuits Snack Bars and Fruit Snacks in MexicoSantiagoAinda não há avaliações

- Address MappingDocumento26 páginasAddress MappingLokesh KumarAinda não há avaliações

- Health Insurance in Switzerland ETHDocumento57 páginasHealth Insurance in Switzerland ETHguzman87Ainda não há avaliações

- Social Media Marketing Advice To Get You StartedmhogmDocumento2 páginasSocial Media Marketing Advice To Get You StartedmhogmSanchezCowan8Ainda não há avaliações

- ATPDraw 5 User Manual UpdatesDocumento51 páginasATPDraw 5 User Manual UpdatesdoniluzAinda não há avaliações

- Gabby Resume1Documento3 páginasGabby Resume1Kidradj GeronAinda não há avaliações

- PFI High Flow Series Single Cartridge Filter Housing For CleaningDocumento2 páginasPFI High Flow Series Single Cartridge Filter Housing For Cleaningbennypartono407Ainda não há avaliações

- Astm E53 98Documento1 páginaAstm E53 98park991018Ainda não há avaliações

- Ludwig Van Beethoven: Für EliseDocumento4 páginasLudwig Van Beethoven: Für Eliseelio torrezAinda não há avaliações

- Manual 40ku6092Documento228 páginasManual 40ku6092Marius Stefan BerindeAinda não há avaliações

- Audit On ERP Implementation UN PWCDocumento28 páginasAudit On ERP Implementation UN PWCSamina InkandellaAinda não há avaliações

- Blade Torrent 110 FPV BNF Basic Sales TrainingDocumento4 páginasBlade Torrent 110 FPV BNF Basic Sales TrainingMarcio PisiAinda não há avaliações

- HealthInsuranceCertificate-Group CPGDHAB303500662021Documento2 páginasHealthInsuranceCertificate-Group CPGDHAB303500662021Ruban JebaduraiAinda não há avaliações

- Powerpoint Presentation: Calcium Sulphate in Cement ManufactureDocumento7 páginasPowerpoint Presentation: Calcium Sulphate in Cement ManufactureDhruv PrajapatiAinda não há avaliações

- BST Candidate Registration FormDocumento3 páginasBST Candidate Registration FormshirazAinda não há avaliações

- 6 V 6 PlexiDocumento8 páginas6 V 6 PlexiFlyinGaitAinda não há avaliações

- Introduction To Motor DrivesDocumento24 páginasIntroduction To Motor Drivessukhbat sodnomdorjAinda não há avaliações

- Extent of The Use of Instructional Materials in The Effective Teaching and Learning of Home Home EconomicsDocumento47 páginasExtent of The Use of Instructional Materials in The Effective Teaching and Learning of Home Home Economicschukwu solomon75% (4)

- Basics: Define The Task of Having Braking System in A VehicleDocumento27 páginasBasics: Define The Task of Having Braking System in A VehiclearupAinda não há avaliações

- Edita's Opertionalization StrategyDocumento13 páginasEdita's Opertionalization StrategyMaryAinda não há avaliações

- Exp. 5 - Terminal Characteristis and Parallel Operation of Single Phase Transformers.Documento7 páginasExp. 5 - Terminal Characteristis and Parallel Operation of Single Phase Transformers.AbhishEk SinghAinda não há avaliações

- Innovations in Land AdministrationDocumento66 páginasInnovations in Land AdministrationSanjawe KbAinda não há avaliações

- Government of West Bengal Finance (Audit) Department: NABANNA', HOWRAH-711102 No. Dated, The 13 May, 2020Documento2 páginasGovernment of West Bengal Finance (Audit) Department: NABANNA', HOWRAH-711102 No. Dated, The 13 May, 2020Satyaki Prasad MaitiAinda não há avaliações