Escolar Documentos

Profissional Documentos

Cultura Documentos

10 11648 J Ajac 20130103 12

Enviado por

tata_77Título original

Direitos autorais

Formatos disponíveis

Compartilhar este documento

Compartilhar ou incorporar documento

Você considera este documento útil?

Este conteúdo é inapropriado?

Denunciar este documentoDireitos autorais:

Formatos disponíveis

10 11648 J Ajac 20130103 12

Enviado por

tata_77Direitos autorais:

Formatos disponíveis

American Journal of Applied Chemistry

2013; 1(3): 43-48

Published online August 30, 2013 (http://www.sciencepublishinggroup.com/j/ajac)

doi: 10.11648/j.ajac.20130103.12

Performances analysis of the reverse osmosis

desalination plant of brackish water used for irrigation:

Case study

Nada. El Harrak, Fatima. Elazhar, Abdel ali. Zdeg, Nourdine. Zouhri, Maryem. Elazhar,

Azzeddine. Elmidaoui.

Laboratory of Separation Processes, Department of Chemistry, Faculty of Sciences, Ibn Tofail University, Kenitra, Morocco

Email address:

azh80ar@yahoo.fr (F. Elazhar)

To cite this article:

Nada. El Harrak, Fatima. Elazhar, Abdel ali. Zdeg, Nourdine. Zouhri, Maryem. Elazhar, Azzeddine. Elmidaoui.. Performances Analysis

of the Reverse Osmosis Desalination Plant of Brackish Water Used for Irrigation: Case Study. American Journal of Applied Chemistry.

Vol. 1, No. 3, 2013, pp. 43-48. doi: 10.11648/j.ajac.20130103.12

Abstract: Desalinated brackish water is becoming an important water source for agricultural irrigation. In Brackish water

desalination, pretreatment of reverse osmosis is the key step in designing the plants to avoid membrane fouling and scaling.

It is enormously important to carry out a study designed at ensuring the optimization of the pretreatment system for

brackish desalination plant in order to optimize the quality of the water fed through the reverse osmosis membranes, to

guarantee the highest performance and to minimize the number of shutdowns for chemical cleaning. In this paper,

performance evaluation carried out for a brackish water reverse osmosis plant for agricultural application, located in

Dokkala Region in Morocco. This plant showed poor performances after few months of operating and frequent shutdown.

The operating pressure increased significantly and the permeate conductivity decreased surprisingly. To identify the causes

for the poor performance, different investigations were carried out. Thus, the pretreatment scheme was thoroughly

reviewed to find out the causes of anomalies. The problem was resolved by removing chlorination and sodium bisulfate

steps from the pretreatment.

Keywords: Reverse Osmosis, Desalination, Agriculture, Performances, Chemical Pretreatment, Cost

1. Introduction

Desalination is becoming an important source of

drinking and agricultural irrigation water [1,2].

Desalination of brackish groundwater in some countries has

a high potential in increasing the availability of water for

agriculture, such as in Spain 22,4 % of the total desalinated

water is used for agriculture, because it offers a solution to

the problem for long distance water transportation [3,4].

The cost of brackish water (BW) desalination is

considerably lower about 35% comparing with the cost of

seawater (SW) desalination [2,5,6], making it more suitable

for agriculture [3]. In addition, the use of desalinated BW

in agriculture can potentially lead to increasing total

biomass production [7] and also enables shifting from some

types of crops to others, more salt sensitive and often more

profitable [8].

The use of water for agriculture represents 70% of the

global use of water and in developing countries the

consumption of water in the agricultural sector exceeds

80% [9].The volume of desalinated water used for

agricultural irrigation in countries such as Spain, Israel and

the United Arab Emirates has dramatically increased in the

last years [9,10,11].

In Morocco, the percentage of the used water in

agriculture exceeds the 75% [12]. The use of underground

water in agriculture becomes frequently facing to the

dryness of last the last decades. The use of underground

water becomes frequent. This is the case in some regions in

Morocco. However the salinity of much underground water

exceeds the standards for irrigation of many crops and the

use of this water resource without treatment decreases the

yield of agricultural crops.

In this field, the big progress in Morocco in the water

management since the beginning of the last decade is the

use of desalination of brackish water, seawater, and water

reuse for, irrigation, potable water and industrial units.

Today the national desalination production capacity

exceeds 50.000 m3/day. The market of RO desalination

44

Nada. El Harrak et al.: Performances Analysis of the Reverse Osmosis Desalination Plant of

Brackish Water Used for Irrigation: Case Study

was 43% in 2004 and is forecasted to increase up to 61% in

2015 [14,15].

Many studies were carried out on the use of membranes

process to treat the saline waters as sources of water for

irrigation such as reverse osmosis, nanofiltration and

electrodialysis. Table 1 gives the some investigations.

Table 1: Membranes process used for agricultural irrigation

Authors

Membrane process

EL malki et al [12], Goodman et al [16]

Electrodialysis

Soliz et al [17], Shaffer et al [18],

Mrayeda[19]

Mrayeda et al [19], Yan et al [20]

Reverse osmosis

2. Methods and Materials

2.1. Raw Water Characterization

The raw water coming from three wells (located at about

6 Km from the sea) contains 2 g/l of total dissolved solid

predominantly chloride and sodium ions. The feed salinity

varies during the seasons but never exceeds 4 g/l. The

characteristics of raw water are given in table 2.

Table 2: Characteristics of the raw water

Well 1

Well 2

Well 3

Limits for

irrigation

406,25

2,24

144,6

237,24

1136,2

184,47

192,20

200,08

7,07

25

2180

261,73

1,30

131,43

149,99

624,47

174,12

255,64

237,53

7,15

25

1515

338,45

2,53

226,32

242,71

1134,91

197,61

214,16

241,65

7,11

25

2210

<54,116

<391,02

114,95

103,32

155,01

<1000

Nanofiltration

In this study case, Doukkala is a plain stretching from

the Atlantic Ocean south of Oum Er-Rbia River in Morocco,

It is mainly an agricultural region, this activity occupies

about 56,6% of the economy of this region. Doukkala

region has a large capacity of groundwater, but the water

quality is deteriorating due particularly to the saline

intrusion. For this, the reverse osmosis is the used process

to minimize the salinity of the saline water.

In this paper, performances analysis was carried out of

desalination plant by reverse osmosis for irrigation, of a

geranium flower kind, which is sensitive to saline water.

The main objective is to identify the causes for the disorder

of performances of the plant after one year of operation.

For this aim, different investigations were proposed. In

addition, the cost associated with the examined chemicals

pretreatment options was evaluated.

Sodium (Na+), mg/l

Potassium (K+), mg/l

Magnesium (Mg2+), mg/l

Calcium (Ca2+), mg/l

Chlorides (Cl-), mg/l

Sulfates (SO42-), mg/l

Bicarbonate (HCO3-), mg/l

Nitrates (NO3-), mg/l

pH

Temperature, C

TDS, mg/l

2.2. Description of the Reverse Osmosis plant

The proposed design of the reverse osmosis unit is

shown in figure 1.The main treatment unit is composed of:

Pre-treatment post,

Reverse osmosis group,

Post-treatment.

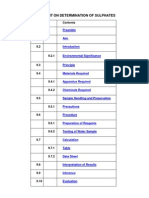

Figure1: Schematic diagram of RO desalination process

Pre-Treatment:

The pre-treatment was designed to improve the raw

water quality, to remove the undesirable materials in raw

water, to provide a final protection and to adapt the pretreated water to the reverse osmosis membranes

requirements [11]. Figure 1 shown the main steps of pretreatment, it includes:

Dosage of 6-9 ppm of Sodium hypochlorite in order

to control the membrane biofouling.

Injection of Sulphuric acid (H2SO4), in order to

regulate the water pH, about 62 ppm of Sodium

American Journal of Applied Chemistry 2013; 1(3): 43-48

Metabisulfit (NaHSO3) (reducing agent) to

neutralize completely the residual active chlorine

[21].

Injection of a commercial scale inhibitor

(antiscalant) with a dosage level at 9 ppm in order

to attenuate the risk of salt precipitations.

The water undergoes a single sand filtration, in

order to remove the solid particles and to protect the

RO membranes from breakthrough particles.

In the last step, a filtration with a cartridge filter is

used for pretreatment sequence to remove particles

larger than 5m [22].

Reverse Osmosis Unit:

Table 3 gives the

desalination plant.

characteristics

of

45

significant difference between all the seasons especially in

the case of well 1 .

As showed in figure 2, in winter 2011 the feed water

TDS was about 1,20 g/l, and gradually increased during the

same year. Comparing with the same season but in 2012,

the TDS of feed water from well 1, was the double value

comparing with 2011. Moreover, there was no difference of

reverse osmosis plant feed water TDS variation from 2011

to 2012, in the case of wells 2 and 3.

Doukkala

Table 3: RO characteristics

Permeate Flow

20 (m3/h)

Concentrate flow

12 (m3/h)

Recovery rate

63 - 65 (%)

High pressure

13 (bar)

Concentrate pressure

Number stage

Number pressure vessel

Number membrane/vessel

(bar)

Figure 2: TDS well 1

Post-Treatment:

The Post-treatment step is limited to use the sodium

hydroxide at level 6-9 ppm, in order to adjust the pH at

value of 7.

2.3. Cleaning of Membrane

The fouling of reverse osmosis elements is unavoidable

with long-term operation. They can be fouled by biological

matter, colloidal particles and mineral scale, element should

be cleaned [20]. The protocol of membrane cleaning

consisted of washing the membrane with several chemical

solutions, it includes two steps:

Step 1: Alkaline solution, extremely effective against

organic compounds.

Step 2: Acid solution, remove metal hydroxides, calcium

carbonate, and other similar scales.

The consequence was the very high frequency of

cleaning, as often as twice per month.

Figure 3: TDS well 2

3. Results and Discussion

Figure 4: TDS well 3

3.1. Performances of Raw Water

Figures 2, 3, and 4 present the daily variations of the

Total Dissolved solids (TDS) collected from the tree RO

feed well, during the year of 2011- 2012.

The results show that the Total Dissolved Solid (TDS)

survey indicates that brackish water used to feed the RO

plant, has a TDS approximately 1,20- 2,20 g/l, with a

3.2. Performances of Reverse Osmosis Plant

To optimize the reverse osmosis plant performances of

brackish water desalination for irrigation. The TDS of

producer water, the permeate flow, and feed pressure were

controlled continuously. Figure 5 (a, b and c) shows the

variation of these parameters versus time.

46

Nada. El Harrak et al.: Performances Analysis of the Reverse Osmosis Desalination Plant of

Brackish Water Used for Irrigation: Case Study

a.

b.

c.

disorder, three actions were undertaken:

Change the fouled membrane by osminics

membranes AG8040F.

Eliminate the chlorination step in pretreatment, to

avoid the oxidation problem.

Eliminate the sodium bisulfate from the

pretreatment step, because it is used for the

reduction of residual chlorine.

Figure 6 (a, b and c) groups together the evolution versus

time of measured parameters such as permeate TDS, feed

pressure and product flow.

The permeate variation

a.

Feed pressure variation

b.

Permeate TDS variation

The Feed pressure variation

The permeate TDS variation

Figure 5: Performances of reverse osmosis plant versus time

The analysis of the results shows that the permeate flow

decreases progressively with the increase of the feed

pressure, and the produced water TDS increases from 70 to

350 mg/l, the increases of the feed pressure was more

significant from 13 to 17 bars.

The first investigation, indicated that it might be a

seriously membranes fooling. For this reason it was

appropriate to establish a cleaning protocol of the

membranes, to remove the fouling aspect. The

disfunctioning noticed was linked to biological activity as

well as the presence of oxidizing agents in raw water.

Furthermore, the use of prechlorination would have caused

an increased oxidizing power of water by adding the

residual chlorine.

In order to overcome the abnormal dysfunction of the

RO plant and to remedy definitely the origin of this

c.

Product flow variation

Figure 6: Performances of reverse osmosis plant versus time

The results show that the evolution of the permeate TDS

have been remained above the required values 75 mg/l,

with a feed pressure of 15 bar as recommended by the

manufacturer of membranes. Also, the variation of the

product flow was improved conforming to the

characteristics of operation of the Doukkala desalination

plant.

American Journal of Applied Chemistry 2013; 1(3): 43-48

3.3. Economic Evaluation

Several factors affect the cost of reverse osmosis

desalination plant [23]. The total cost of the plant consists

of two terms: capital cost and operation/maintenance cost

[24]. The Capital Cost includes all expenditures associated

with the implementation for construction (equipment,

piping, service utilities, etc.), engineering efforts, and

administrative/financing activities.

The Operation and maintenance (O&M) costs consist of

plant operation costs (energy, chemicals, replacement of

consumables, and labor) and maintenance costs for plant

equipment, buildings, and utilities. The O&M costs are

typically expressed as either all operational expenditures

per year (e.g., $/y) or operational costs for desalinated

product water per volume (e.g., $/m3) [25].

In this study case and in terms of the economic point of

view, economical evaluation was done concerning the

chemicals cost. Table 4 gives the cost of chemical

pretreatment. The remove of Sodium hypochlorite and

sodium metabisulfite from pretreatment step, cause the

saving cost of 54 800 $/year in operation unit cost.

Table 4: Cost of chemical pretreatment

Product

Cost $/m3

Cost $/ yr

Sodium hypochlorite- NaCl

0.30

50 274

Sodium Metabisulfit- NaHSO3

0.03

4 570

Antiscalant

0.57

95 297

4. Conclusion

In reverse osmosis desalination technology, the steep of

pretreatment of feed water is very important issue and is the

key of the RO plants operation success. The operations of

the pretreatment phase are more complicated when raw

water quantity and quality changes during seasons. Thus

the designed pretreatment became improper and not enough

to secure RO membrane.

In this paper, the performance evaluation of a brackish

water desalination plant used for irrigation was carried out.

The poor performances of the plant were mainly due to the

risk of membranes damage, by the effect of chlorine

injection. After modification of chemical pretreatment steps

by canceling the chlorine and sodium bisulfate, the plant

showed stable performances. A new control system is

applied in the plant to predict any futures anomalies.

Furthermore, it is also important to investigate the

inuence of this water on the soil and its effects on the crop

yields.

References

[1]

A. Ben-Gal, U. Yermiyahu, S. Cohen, Fertilization and

blending alternatives for irrigation with desalinated water, J.

Environ. Qual. 38 (2009) 529536.

47

[2]

L.F. Greenlee, D.F. Lawler, B.D. Freeman, B. Marrot, P.

Moulin, Reverse osmosis desalination: water sources,

technology, and today's challenges, Water Res. 43 (4) (2009)

23172348.

[3]

J.M. Beltran, S. Koo-Oshima, FAO expert consultation on

water desalination for agricultural applications, Rome (Italy),

FAO Land and Water Discussion Paper, no.5, 2006, 60 pp.

[4]

G.R. Lashkaripour, M. Zivdar, Desalination of brackish

groundwater in Zahedan city in Iran, Desalination 177 (1-3)

(2005) 15.

[5]

P. Glueckstern, M. Priel, E. Kotzer, Blending brackish water

with desalted seawater as an alternative to brackish water

desalination, Desalination 178 (1-3) (2005) 227232.

[6]

Y. Zhou, R.S.J. Tol, Evaluating the costs of desalination and

water transport, Water Resour. Res. 41 (3) (2005) 3003/1

3003/10.

[7]

A. Ghermandi, R. Messalem, Solar-driven desalination with

reverse osmosis: the state of the art, Desalination Water

Treat. 7 (2009) 285296.

[8]

Z. Shimron, Economics of brackish and desalination water

reuse for irrigation, Desalination 98 (13) (1994) 471478

[9]

UNEP 2002, Vital Water Graphics World Resources 200001,People and Ecosystems. The Fraying Web of Life,

WorldResources Institute (ERI), Washington DC, 2000.

[10] A. Saadi, N. Ouazzani, Perspectives of desalination of

brackish water for valorization in arid regions of Morocco.

Desalination 165 (2004) 81)

[11] N. Prihasto, Q. Liu, S. Kim, Pre-treatment strategies for

seawater desalination by reverse osmosis system.

Desalination 249 (2009) 308-316.

[12] S. El malki, R.El Habbani, M. Tahaikt, M.Zeraouli and A.

Elmidaoui, The desalination of salt water destine to

irrigation by electrodialysis and its effects on the

germination, growth and seed yield of wheat (Triticum

durum Desf. Var. Karim). African Journal of Agricultural

Research Vol.2. 041-046 (2007).

[13] A. Elmidaoui, Desalination and wastewater reuse, resources

to be considered, Nato Security through Science Series, E:

Human and Societal Dynamics, 12, IOS Press, 2006, pp.

185187

[14] F. Elazhar, N. El Harrak, A. Zdeg, M.El Amrani, M.Taky, A.

Elmidaoui., Technical and economical comparison of the

nanofiltration and reverse osmosis membranes in the

brackish water desalination, Chemical technology An

Indian Journal 7(2012), pp 29-33.

[15] Hyun-Je Oh, Tae-Mun Hwang, Sangho Lee, A simplified

simulation model of RO systems for seawater desalination.

Desalination 238 (2009) 128139.

[16] B. Nigel, G. Russell, J. Taylor , Z. Xie , Y. Gozukara , A.

Clements, A feasibility study of municipal wastewater

desalination using electrodialysis reversal to provide

recycled water for horticultural irrigation. Desalination 317

(2013) 7783.

[17] D. Soliz, E. P. Glenn, R. Seaman, M. Yoklic, S. G.

Nelson, P. Brown, Water consumption, irrigation efficiency

and nutritional value ofAtriplex lentiformis grown on

48

Nada. El Harrak et al.: Performances Analysis of the Reverse Osmosis Desalination Plant of

Brackish Water Used for Irrigation: Case Study

reverse osmosis brine in a desert irrigation district. Journal

of Agriculture, Ecosystems & Environment 140, (2011)

473483.

[18] L. Shaffer, N.Y. Yip, J. Gilron, M. Elimelech, Seawater

desalination for agriculture by integrated forward and

reverse osmosis: Improved product water quality for

potentially less energy, Journal of Membrane Science 415

416 (2012).

[19] S.M. Mrayed, P. Sanciolob, L. Zou, G. Leslie An

alternative membrane treatment process to produce low-salt

and high-nutrient recycled water suitable for irrigation

purposes. Desalination 274 (2011)144149

[20] Y.A. Le Gouellec, M. Elimelech, Calcium sulfate (gypsum)

scaling in nanofiltration of agricultural drainage water

Journal of Membrane Science 205 (2002) 279291

[21] A. Munoz Elguera, S. O. Prez Bez. Development of the

most adequate pre-treatment for high capacity seawater

desalination plants with open intake. Desalination 184 (2005)

173183.

[22] L. Birnhack, N. Voutchkov, O. Lahav. Desalination, Volume

273, Issue 1, 1 June 2011, Pages 6-22. Fundamental

chemistry and engineering aspects of post-treatment

processes for desalinated waterA review.

[23] F. Elazhar, M.Tahaikt, A.Achatei, F. Elmidaoui, M.Taky, F.

El hannouni,I. Laaziz, S.Jariri, M. El Amrani, A.Elmidaoui.

Economical evaluation of the fluoride removal by

nanofiltration. Desalination 249 (2009) 154-157.

[24] S.A. Avlonitis, Operational water cost and productivity

improvements for small-size RO desalination plants.

Desalination, 142 (2002) 295304.

[25] Young M. Kim , Seung J. Kim , Yong S. Kim , Sangho Lee,

In S. Kim,Joon Ha Kim. Overview of systems engineering

approaches for a large-scale seawater desalination plant with

a reverse osmosis network. Desalination 238 (2009) 312

332.

Você também pode gostar

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryNo EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryNota: 3.5 de 5 estrelas3.5/5 (231)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)No EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Nota: 4.5 de 5 estrelas4.5/5 (119)

- Never Split the Difference: Negotiating As If Your Life Depended On ItNo EverandNever Split the Difference: Negotiating As If Your Life Depended On ItNota: 4.5 de 5 estrelas4.5/5 (838)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaNo EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaNota: 4.5 de 5 estrelas4.5/5 (265)

- The Little Book of Hygge: Danish Secrets to Happy LivingNo EverandThe Little Book of Hygge: Danish Secrets to Happy LivingNota: 3.5 de 5 estrelas3.5/5 (399)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyNo EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyNota: 3.5 de 5 estrelas3.5/5 (2219)

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeNo EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeNota: 4 de 5 estrelas4/5 (5794)

- Team of Rivals: The Political Genius of Abraham LincolnNo EverandTeam of Rivals: The Political Genius of Abraham LincolnNota: 4.5 de 5 estrelas4.5/5 (234)

- The Emperor of All Maladies: A Biography of CancerNo EverandThe Emperor of All Maladies: A Biography of CancerNota: 4.5 de 5 estrelas4.5/5 (271)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreNo EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreNota: 4 de 5 estrelas4/5 (1090)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersNo EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersNota: 4.5 de 5 estrelas4.5/5 (344)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceNo EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceNota: 4 de 5 estrelas4/5 (890)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureNo EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureNota: 4.5 de 5 estrelas4.5/5 (474)

- The Unwinding: An Inner History of the New AmericaNo EverandThe Unwinding: An Inner History of the New AmericaNota: 4 de 5 estrelas4/5 (45)

- The Yellow House: A Memoir (2019 National Book Award Winner)No EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Nota: 4 de 5 estrelas4/5 (98)

- Septic Tank Design Program RASDocumento8 páginasSeptic Tank Design Program RASMagdy BakryAinda não há avaliações

- Module 4 Annex Part 1 MKDocumento95 páginasModule 4 Annex Part 1 MKtata_77Ainda não há avaliações

- Basics For Small Water Systems in Oregon: Storage Tank ChlorinationDocumento2 páginasBasics For Small Water Systems in Oregon: Storage Tank Chlorinationtata_77Ainda não há avaliações

- 3.2 17566 Product Leaflet MBR LowresDocumento2 páginas3.2 17566 Product Leaflet MBR LowresRahul Damodar100% (1)

- EmulsionDocumento8 páginasEmulsiontata_77Ainda não há avaliações

- RO System Quotation 20m3/h 73% RecoveryDocumento6 páginasRO System Quotation 20m3/h 73% Recoverytata_77Ainda não há avaliações

- DesignDocumento3 páginasDesigntata_77Ainda não há avaliações

- Catalogue Absorption Chillers ENG FDocumento80 páginasCatalogue Absorption Chillers ENG FBubai111100% (1)

- Water Quality MicrobiologyDocumento56 páginasWater Quality MicrobiologyEva Pa'e OAinda não há avaliações

- Shock Chloro CalcDocumento2 páginasShock Chloro Calctata_77Ainda não há avaliações

- 03 Lewabrane Manual System Design 03Documento13 páginas03 Lewabrane Manual System Design 03zamijakaAinda não há avaliações

- Lecture 2. Water Quality ParametersDocumento52 páginasLecture 2. Water Quality ParametersAbo-Khaled MohammedAinda não há avaliações

- Microbiology CourseDocumento129 páginasMicrobiology Coursetata_77Ainda não há avaliações

- Microbiology CourseDocumento132 páginasMicrobiology Coursetata_77Ainda não há avaliações

- Homogenizer: Standard Operating ProcedureDocumento1 páginaHomogenizer: Standard Operating ProcedureDermedic phar este0% (1)

- Water Sources and Potential Contamination of Taps and Water SystemsDocumento26 páginasWater Sources and Potential Contamination of Taps and Water Systemstata_77Ainda não há avaliações

- Bromate Prove Ulr en 2016-01-06 HintDocumento3 páginasBromate Prove Ulr en 2016-01-06 Hinttata_77Ainda não há avaliações

- Water Microbiology Quality Assurance ProgramDocumento74 páginasWater Microbiology Quality Assurance Programtata_77Ainda não há avaliações

- EPA WWT Factsheet - Ozone Disinfection 9-1999Documento7 páginasEPA WWT Factsheet - Ozone Disinfection 9-1999kkdaAinda não há avaliações

- 03 Lewabrane Manual System Design 03Documento13 páginas03 Lewabrane Manual System Design 03zamijakaAinda não há avaliações

- Cepacia From Respiratory Secretions of Patients With Cystic Fibrosis. J.Clin - Microbiol. 22 (1) 5-8Documento1 páginaCepacia From Respiratory Secretions of Patients With Cystic Fibrosis. J.Clin - Microbiol. 22 (1) 5-8tata_77Ainda não há avaliações

- Determain SulphateDocumento13 páginasDetermain SulphateNalita Aurelia AuritaAinda não há avaliações

- CH Lori NationDocumento11 páginasCH Lori NationihllhmAinda não há avaliações

- CH Lori NationDocumento11 páginasCH Lori NationihllhmAinda não há avaliações

- Calcium TestDocumento7 páginasCalcium Testtata_77Ainda não há avaliações

- Pseudomona in Hot TubsDocumento2 páginasPseudomona in Hot Tubstata_77Ainda não há avaliações

- Technical Service Bulletin: Procedure For Measuring Silt Density Index (SDI)Documento3 páginasTechnical Service Bulletin: Procedure For Measuring Silt Density Index (SDI)JC PinoAinda não há avaliações

- Permeate Recycle Improves RO PerformanceDocumento8 páginasPermeate Recycle Improves RO Performancetata_77Ainda não há avaliações

- Technical Service Bulletin: Procedure For Measuring Silt Density Index (SDI)Documento3 páginasTechnical Service Bulletin: Procedure For Measuring Silt Density Index (SDI)JC PinoAinda não há avaliações

- وجية جرجس جزء 1Documento207 páginasوجية جرجس جزء 1Anonymous mghI7I7pAinda não há avaliações

- Chemical Additve CalculationDocumento2 páginasChemical Additve Calculationtata_77Ainda não há avaliações

- Biocides For Disinfection and Storage of Hydranautics Membrane ElementsDocumento6 páginasBiocides For Disinfection and Storage of Hydranautics Membrane Elementstata_77Ainda não há avaliações

- Utilities Pugeda Quiz 7Documento1 páginaUtilities Pugeda Quiz 7corazon philAinda não há avaliações

- Unit Operations & Processes in Waste Water TreatmentDocumento16 páginasUnit Operations & Processes in Waste Water Treatmentbefkadu ayalkieAinda não há avaliações

- Ai RWHDocumento22 páginasAi RWHMukharam SaranAinda não há avaliações

- Urban LakesDocumento4 páginasUrban LakesNeha GhatageAinda não há avaliações

- Georgia Water Quality Report 2018-2019Documento130 páginasGeorgia Water Quality Report 2018-2019Ehsanul KabirAinda não há avaliações

- Environmental Awareness Water ConservationDocumento38 páginasEnvironmental Awareness Water ConservationCalvin Kim PeramanAinda não há avaliações

- Ebook Schemes Ministry of Jal Shakti Lyst8874Documento7 páginasEbook Schemes Ministry of Jal Shakti Lyst8874exp expoAinda não há avaliações

- Rainwater HarvestingDocumento8 páginasRainwater HarvestingVenkatesan PAinda não há avaliações

- Dams in UttarakhandDocumento2 páginasDams in UttarakhandARUN RAWATAinda não há avaliações

- Water Supply SystemDocumento52 páginasWater Supply Systemnyagabona goodluckAinda não há avaliações

- Activity 2.3.11 Calculating Property Drainage Answer KeyDocumento8 páginasActivity 2.3.11 Calculating Property Drainage Answer Keyanon_68250875380% (5)

- Determination of background concentrations and water quality in Armenia's Akhuryan River BasinDocumento1 páginaDetermination of background concentrations and water quality in Armenia's Akhuryan River BasindexAinda não há avaliações

- Save Water SpeechDocumento4 páginasSave Water SpeechHari Prakash Shukla0% (1)

- Design of Subsurface Drip Irrigation Base On Soil Hydraulic Conductivity For Horticulture Crop ProductionDocumento12 páginasDesign of Subsurface Drip Irrigation Base On Soil Hydraulic Conductivity For Horticulture Crop ProductionSagitan Putra La KimbiAinda não há avaliações

- How Does Sewerage System Work (Pants)Documento4 páginasHow Does Sewerage System Work (Pants)Christian Kenneth PantonialAinda não há avaliações

- G o 111Documento6 páginasG o 111Srihari PulagamAinda não há avaliações

- Hyderabad Metropolitan Water Supply and Sewerage BoardDocumento1 páginaHyderabad Metropolitan Water Supply and Sewerage BoardKhalid KhanAinda não há avaliações

- VES-2300 Sewage Disposal SystemsDocumento10 páginasVES-2300 Sewage Disposal SystemsDwiadi CahyabudiAinda não há avaliações

- Ukkadam STP, Coimbatore Co-Treatment Case Study: List of TablesDocumento14 páginasUkkadam STP, Coimbatore Co-Treatment Case Study: List of TablesVikram SKAinda não há avaliações

- FloodDocumento6 páginasFloodnazoAinda não há avaliações

- Environmental Law 8th Edition Kubasek Test BankDocumento4 páginasEnvironmental Law 8th Edition Kubasek Test Bankmarcusquyepv100% (36)

- Water Conservation From Wikipedia, The Free Encyclopedia: Manufacturing IrrigationDocumento13 páginasWater Conservation From Wikipedia, The Free Encyclopedia: Manufacturing Irrigationpramod_singhAinda não há avaliações

- WRE 2 SyllabusDocumento3 páginasWRE 2 SyllabusVivek KasarAinda não há avaliações

- Sangli District Is Located in The Southern Parts of The State and Lies Between 160 42Documento11 páginasSangli District Is Located in The Southern Parts of The State and Lies Between 160 42shiv infotechAinda não há avaliações

- Water Resources in The PhilippinesDocumento3 páginasWater Resources in The PhilippinesAllan DeGuzman Dela VegaAinda não há avaliações

- Progress Report On The Waste Water Treatment SectorDocumento3 páginasProgress Report On The Waste Water Treatment SectorIsrael Defense ForcesAinda não há avaliações

- Cabrera 111Documento14 páginasCabrera 111uroskAinda não há avaliações

- Pipe Roughness CoefficientDocumento1 páginaPipe Roughness CoefficientkapsarcAinda não há avaliações