Escolar Documentos

Profissional Documentos

Cultura Documentos

5 Structural System Selector Guide

Enviado por

aomareltayebDireitos autorais

Formatos disponíveis

Compartilhar este documento

Compartilhar ou incorporar documento

Você considera este documento útil?

Este conteúdo é inapropriado?

Denunciar este documentoDireitos autorais:

Formatos disponíveis

5 Structural System Selector Guide

Enviado por

aomareltayebDireitos autorais:

Formatos disponíveis

Structural System Selector Guide

Multi-Story Residential Buildings

Apartments Condominiums Retirement Communities

Hotels and Motels Assisted Living & Extended Care Facilities

Student Housing and Dormitories Military Housing

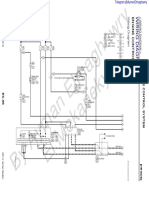

The structural systems considered are listed below and indicate the basic

structure type, floor/roof slab construction and typical span. The chart on the

back is designed to guide you in the selection of a structural system according

to its advantages in the Multi-Story Residential Market:

1.

GIRDER-SLAB SYSTEM: Steel, bay-framed using D-Beam Girder,

supporting 8 precast hollow core slabs. Typical bay size: 20 x 28.

2.

Staggered Truss: Steel, full height trusses (floor to floor) staggered vertically

by floor, placed at demising walls, supporting 8 precast hollow core slabs.

Typical bay size: 70 x 28.

3.

Steel Frame & Joists: Steel, bay-framed using bar joists, supporting metal

deck and CIP concrete slabs. Typical bay size: 25 x 25.

4.

CMU Bearing Wall: Concrete masonry walls (reinforced), placed at demising

walls, supporting 8 precast hollow core slabs. Typical span: 28.

5.

Flat Plate Concrete: Prestressed CIP concrete, bay framed using two way

prestressed 8 CIP concrete slabs. Typical bay size: 25 x 25.

6.

CMU Walls & Joists: Concrete masonry walls (reinforced), placed at demising

walls, using bar joists, supporting metal deck and CIP concrete slabs. Typical

span: 25.

(888) 478-1100

www.girder-slab.com

Limited Coordination of Trades (same crew for entire installation)

Schedule Fast Installation

Bay Framing for Design Flexibility

Limited or No Structural Demising Walls

Mixed Use Spaces Below (parking, retail, office, hospitality, etc.)

Dwelling Unit Layouts Atypical or Not Repetitive

Architectural Features (balconies, bays, saw tooth, irregular, etc.)

Vibration & Sound Control

Structure Tolerances to AISC Standards

Future Vertical or Horizontal Expansion

Limited Quality Control Insp. & Testing Program

Non-Combustible Construction

Economical Seismic & Wind Resistance

Mechanical/Electrical Distribution (horiz. pipe & duct systems)

Mechanical/Electrical Distribution at Demising Walls

Economical Construction Low Rise

Economical Construction Mid Rise

Economical Construction High Rise

Limited Use of Suspended Ceilings

Design Flexibility in Location of Unit Demising Walls

Workmanship (100% Factory Made Materials, Limited Assembly)

Erect Prefabricated Exterior Walls with Superstructure

Future interior partition & space plan modifications

Limited Field Labor (formwork, cast-in-place concrete slabs)

EPA & Energy Efficient (unpainted - recycled steel no waste)

Improved Safety Program

Environmentally Friendly (No on-site waste, debris)

Cost: Initial & Life Cycle

Site Impacts & Staging (storage, labor, scaffolding, etc.)

n

n

n

n

n

n

n

Site Logistics & Locality, Trucking to Site (HC Slabs)

Denotes Advantage

Availability of Labor, Size of Crews

Availability of Materials (limited delivery lead times)

Limited Interior Finishing of Structural Elements

CMU Walls & Joist,

CIP Slabs

Less Risk of Schedule Over-Run due to Winter Conditions

Flat Plate CIP

Concrete

CMU Bearing Wall

& HC Slabs

Staggard Truss

& HC Slabs

Steel Frame & Joist,

CIP Slabs

Girder-Slab System

Low Floor-to-Floor, Low Overall Building Height

Residential Structures

n

n

Denotes Disadvantage

n

n

Você também pode gostar

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeNo EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeNota: 4 de 5 estrelas4/5 (5794)

- Concrete Expansion JointsDocumento80 páginasConcrete Expansion JointsDiana Sekar Sari100% (1)

- The Little Book of Hygge: Danish Secrets to Happy LivingNo EverandThe Little Book of Hygge: Danish Secrets to Happy LivingNota: 3.5 de 5 estrelas3.5/5 (400)

- Who Invented Youngs ModulusDocumento6 páginasWho Invented Youngs ModulusaomareltayebAinda não há avaliações

- Chapter 9 Bearings and Expansion Joints: WSDOT Bridge Design Manual M 23-50.18 Page 9-I June 2018Documento40 páginasChapter 9 Bearings and Expansion Joints: WSDOT Bridge Design Manual M 23-50.18 Page 9-I June 2018aomareltayebAinda não há avaliações

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceNo EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceNota: 4 de 5 estrelas4/5 (895)

- PLN V000000 06 00004 PDFDocumento114 páginasPLN V000000 06 00004 PDFaomareltayebAinda não há avaliações

- The Yellow House: A Memoir (2019 National Book Award Winner)No EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Nota: 4 de 5 estrelas4/5 (98)

- Vibration Analysis ReportDocumento13 páginasVibration Analysis ReportaomareltayebAinda não há avaliações

- The Emperor of All Maladies: A Biography of CancerNo EverandThe Emperor of All Maladies: A Biography of CancerNota: 4.5 de 5 estrelas4.5/5 (271)

- PT EconomicsDocumento53 páginasPT EconomicsaomareltayebAinda não há avaliações

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryNo EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryNota: 3.5 de 5 estrelas3.5/5 (231)

- Optimum Design of Resilient Sliding Isolation SystemDocumento12 páginasOptimum Design of Resilient Sliding Isolation SystemaomareltayebAinda não há avaliações

- Never Split the Difference: Negotiating As If Your Life Depended On ItNo EverandNever Split the Difference: Negotiating As If Your Life Depended On ItNota: 4.5 de 5 estrelas4.5/5 (838)

- 0510 S 15 Ms 43Documento16 páginas0510 S 15 Ms 43aomareltayebAinda não há avaliações

- Soil Structure InteractionDocumento16 páginasSoil Structure InteractionEmad Ahmed Khan67% (3)

- Control of Crack WidthsDocumento55 páginasControl of Crack WidthsMahmood Mufti100% (1)

- Who Invented Youngs ModulusDocumento6 páginasWho Invented Youngs ModulusaomareltayebAinda não há avaliações

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureNo EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureNota: 4.5 de 5 estrelas4.5/5 (474)

- Technology Paper Report CSI 31-03-09Documento98 páginasTechnology Paper Report CSI 31-03-09aomareltayebAinda não há avaliações

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaNo EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaNota: 4.5 de 5 estrelas4.5/5 (266)

- Hollowblockandribbedslabs 130702183359 Phpapp01Documento38 páginasHollowblockandribbedslabs 130702183359 Phpapp01aomareltayebAinda não há avaliações

- The Unwinding: An Inner History of the New AmericaNo EverandThe Unwinding: An Inner History of the New AmericaNota: 4 de 5 estrelas4/5 (45)

- JORDAHL Catalogue Jda PDFDocumento6 páginasJORDAHL Catalogue Jda PDFIoan SosaAinda não há avaliações

- Example Buildings KL Aug 2002Documento25 páginasExample Buildings KL Aug 2002aomareltayebAinda não há avaliações

- Team of Rivals: The Political Genius of Abraham LincolnNo EverandTeam of Rivals: The Political Genius of Abraham LincolnNota: 4.5 de 5 estrelas4.5/5 (234)

- Design of Shear Walls Using ETABS PDFDocumento97 páginasDesign of Shear Walls Using ETABS PDFEmanuelRodriguezElera100% (1)

- Sika FRP Design Program ManualDocumento10 páginasSika FRP Design Program ManualYoshua Yang100% (1)

- Power Virtual Collaboration in Project Management FinalDocumento38 páginasPower Virtual Collaboration in Project Management FinalTerrence GargiuloAinda não há avaliações

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyNo EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyNota: 3.5 de 5 estrelas3.5/5 (2259)

- المرشد في الإسعافات الأولية PDFDocumento75 páginasالمرشد في الإسعافات الأولية PDFbentaharAinda não há avaliações

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreNo EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreNota: 4 de 5 estrelas4/5 (1090)

- Damping and Energy DissipationDocumento14 páginasDamping and Energy DissipationAlex da SilvaAinda não há avaliações

- Damping and Energy DissipationDocumento14 páginasDamping and Energy DissipationAlex da SilvaAinda não há avaliações

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersNo EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersNota: 4.5 de 5 estrelas4.5/5 (344)

- Diaphragm Wall Specifications R 0Documento10 páginasDiaphragm Wall Specifications R 0aomareltayebAinda não há avaliações

- Diaphragm Walls SpecsDocumento8 páginasDiaphragm Walls SpecsaomareltayebAinda não há avaliações

- BurjDocumento39 páginasBurjarjunmurali1993Ainda não há avaliações

- Structure Modelling ChecklistDocumento4 páginasStructure Modelling ChecklistaomareltayebAinda não há avaliações

- Diaphragm Walls SpecsDocumento8 páginasDiaphragm Walls SpecsaomareltayebAinda não há avaliações

- Abacus FoundationsDocumento9 páginasAbacus FoundationsNath GunasekeraAinda não há avaliações

- AbuDhabi LowDocumento1 páginaAbuDhabi LowaomareltayebAinda não há avaliações

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)No EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Nota: 4.5 de 5 estrelas4.5/5 (121)

- 4608 - 160214 - Structural Design Data SheetDocumento9 páginas4608 - 160214 - Structural Design Data SheetaomareltayebAinda não há avaliações

- Risk Register TemplateDocumento1 páginaRisk Register TemplateaomareltayebAinda não há avaliações

- KeyDocumento8 páginasKeyJohnny DonnyAinda não há avaliações

- Object Oriented Programming: Lecture 14: Friend FunctionsDocumento14 páginasObject Oriented Programming: Lecture 14: Friend Functionskhawar abbasiAinda não há avaliações

- Conformance Testing ProcessDocumento37 páginasConformance Testing ProcessvietbkfetAinda não há avaliações

- Quiz WC PDFDocumento3 páginasQuiz WC PDFHarith NawfelAinda não há avaliações

- PGCIL Standard SectionsDocumento692 páginasPGCIL Standard SectionsThamizhAinda não há avaliações

- Academic Texts (Types, Structure, Strategies For Reading) : Miss RonaDocumento21 páginasAcademic Texts (Types, Structure, Strategies For Reading) : Miss RonaRona Mae MagnoAinda não há avaliações

- 06 Engine Control (Sunny 2015)Documento25 páginas06 Engine Control (Sunny 2015)Abd Alkarem SalamhAinda não há avaliações

- NFPA72Documento1 páginaNFPA72aammxxiAinda não há avaliações

- GSM KPI'sDocumento38 páginasGSM KPI'sMorteza MoradiAinda não há avaliações

- R48 3500e Rectifier UM1R483500e PDFDocumento28 páginasR48 3500e Rectifier UM1R483500e PDFHythamMidani100% (1)

- YANMAR 3TNV-4TNV Series Shop ManualDocumento392 páginasYANMAR 3TNV-4TNV Series Shop ManualPHÁT NGUYỄN THẾ91% (22)

- ANSI Device NumbersDocumento4 páginasANSI Device NumbersBharath SaiAinda não há avaliações

- GR 326 Core SpecificationDocumento4 páginasGR 326 Core SpecificationTori0% (3)

- Summative Test in EPP6 ICT 2Documento2 páginasSummative Test in EPP6 ICT 2Lennex Marie Sario0% (1)

- Epsilon 140z DatasheetDocumento2 páginasEpsilon 140z DatasheetRiga RingsAinda não há avaliações

- XML Publisher Report Registration Steps in Oracle AppsDocumento33 páginasXML Publisher Report Registration Steps in Oracle AppsFerasHamdanAinda não há avaliações

- Expert System Design For Fault Diagnosis in Diesel EnginesDocumento10 páginasExpert System Design For Fault Diagnosis in Diesel EnginesevanAinda não há avaliações

- ISO 9001 - 2015-Training MaterialDocumento21 páginasISO 9001 - 2015-Training MaterialP.NAVEENAN0% (1)

- T630 7277035 enUS Om (OPERACIÓN Y MANTENIMIENTO) PDFDocumento246 páginasT630 7277035 enUS Om (OPERACIÓN Y MANTENIMIENTO) PDFRamiro Alexis Garcia LópezAinda não há avaliações

- DEM Theory Attainment SY-A - 2022-23Documento30 páginasDEM Theory Attainment SY-A - 2022-23shital jadhavAinda não há avaliações

- Later Instagram Analytics Strategy Guide PDFDocumento68 páginasLater Instagram Analytics Strategy Guide PDFMuhammad Wisnu WardhanaAinda não há avaliações

- Data Science EssayDocumento2 páginasData Science EssayAbdelhak100% (1)

- Talend For Data Integreation Day - 1 (01-09-2017)Documento9 páginasTalend For Data Integreation Day - 1 (01-09-2017)Anonymous xMYE0TiNBcAinda não há avaliações

- Finaln DocumentDocumento52 páginasFinaln DocumentTemesgenAinda não há avaliações

- Money Lender and Pawn BrokerDocumento53 páginasMoney Lender and Pawn BrokerAkshay polAinda não há avaliações

- Please Refer To The Product Specifications For Details.: Jul-2017/Rev.01Documento4 páginasPlease Refer To The Product Specifications For Details.: Jul-2017/Rev.01HARSHA PAinda não há avaliações

- CSI 2130 Reference Manual - Emerson Process ManagementDocumento360 páginasCSI 2130 Reference Manual - Emerson Process ManagementPeter VerhulstAinda não há avaliações

- Problem Statement: Video Library Management SystemDocumento4 páginasProblem Statement: Video Library Management SystemPritamAinda não há avaliações

- Ra 8792 IRR PDFDocumento40 páginasRa 8792 IRR PDFJohn Lloyd MacuñatAinda não há avaliações

- Senate Commerce's Cybersecurity BillDocumento27 páginasSenate Commerce's Cybersecurity BillBrendan SassoAinda não há avaliações