Escolar Documentos

Profissional Documentos

Cultura Documentos

Stainless Steel - Grade 321 (UNS S32100)

Enviado por

mp87_ingDescrição original:

Direitos autorais

Formatos disponíveis

Compartilhar este documento

Compartilhar ou incorporar documento

Você considera este documento útil?

Este conteúdo é inapropriado?

Denunciar este documentoDireitos autorais:

Formatos disponíveis

Stainless Steel - Grade 321 (UNS S32100)

Enviado por

mp87_ingDireitos autorais:

Formatos disponíveis

Stainless Steel - Grade 321 (UNS S32100)

Stainless Steel - Grade 321 (UNS S32100)

Chemical Formula

Fe, <0.08% C, 17-19% Cr, 9-12% Ni, <2% Mn, <1% Si, 0.3-0.7% Ti, <0.045% P, <0.03% S

Topics Covered

Background

Key Properties

Composition

Mechanical Properties

Physical Properties

Grade Specification Comparison

Possible Alternative Grades

Corrosion Resistance

Heat Resistance

Heat Treatment

Welding

Applications

Background

Grades 321 and 347 are the basic austenitic 18/8 steel (Grade 304) stabilised by Titanium (321) or Niobium

(347) additions. These grades are used because they are not sensitive to intergranular corrosion after heating

within the carbide precipitation range of 425-850C. Grade 321 is the grade of choice for applications in the

temperature range of up to about 900C, combining high strength, resistance to scaling and phase stability with

resistance to subsequent aqueous corrosion.

Grade 321H is a modification of 321 with a higher carbon content, to provide improved high temperature

strength.

A limitation with 321 is that titanium does not transfer well across a high temperature arc, so is not

recommended as a welding consumable. In this case grade 347 is preferred - the niobium performs the same

carbide stabilisation task but can be transferred across a welding arc. Grade 347 is therefore the standard

consumable for welding 321. Grade 347 is only occasionally used as parent plate material.

Like other austenitic grades, 321 and 347 have excellent forming and welding characteristics, are readily brake or

roll formed and have outstanding welding characteristics. Post-weld annealing is not required. They also have

excellent toughness, even down to cryogenic temperatures. Grade 321 does not polish well, so is not

recommended for decorative applications.

Grade 304L is more readily available in most product forms, and so is generally used in preference to 321 if the

requirement is simply for resistance to intergranular corrosion after welding. However 304L has lower hot

strength than 321 and so is not the best choice if the requirement is resistance to an operating environment over

about 500C.

Key Properties

These properties are specified for flat rolled product (plate, sheet and coil) in ASTM A240/A240M. Similar but not

necessarily identical properties are specified for other products such as pipe and bar in their respective

specifications.

Composition

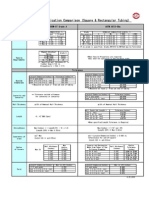

Typical compositional ranges for grade 321 stainless steels are given in table 1.

Table 1. Composition ranges for 321 grade stainless steel

Saved from URL: http://www.azom.com/article.aspx?ArticleID=967

/4

Stainless Steel - Grade 321 (UNS S32100)

Grade

C

min.

Mn

Si

Cr

Mo

Ni

17.0

321

2.00

0.75

0.045

0.030

0.10

0.08

19.0

12.0

min.

0.04

17.0

9.0

2.00

max

0.75

0.045

0.030

0.10

0.08

2.00

0.75

0.045

0.70

Ti=4(C+N)

min.

347

Ti=5(C+N)

max

321H

19.0

12.0

17.0

9.0

0.030

0.70

Nb=10(C+N)

max

Other

9.0

19.0

13.0

1.0

Mechanical Properties

Typical mechanical properties for grade 321 stainless steels are given in table 2.

Table 2. Mechanical properties of 321 grade stainless steel

Grade

Tensile

Yield Strength

Strength (MPa)

0.2% Proof

min

(MPa) min

Elongation (% in

50mm) min

Hardness

Rockwell B (HR

Brinell (HB)

B) max

max

321

515

205

40

95

217

321H

515

205

40

95

217

347

515

205

40

92

201

321H also has a requirement for a grain size of ASTM No 7 or coarser.

Physical Properties

Typical physical properties for annealed grade 321 stainless steels are given in table 3.

Table 3. Physical properties of 321 grade stainless steel in the annealed condition

Grade

321

Density

3

(kg/m )

8027

Elastic

Mean Coefficient of Thermal

Expansion (mm/m/C)

Modulus

(GPa)

193

0-100C 0-315C 0-538C

16.6

17.2

18.6

Thermal

Conductivity

(W/m.K)

at

at

100C 500C

16.1

22.2

Specific

Heat

0-100 C

(J/kg.K)

500

Electrical

Resistivity

(nW.m)

720

Grade Specification Comparison

Approximate grade comparisons for 321 stainless steels are given in table 4.

Table 4. Grade specifications for 321 grade stainless steel

Old British

Grade

UNS No

321

S32100

321S31

321H

S32109

321S51

347

S34700

347S31

BS

Euronorm

En

Swedish SS

Japanese JIS

X6CrNiTi18-10

2337

SUS 321

1.4878

X10CrNiTi18-10

SUS 321H

1.4550

X6CrNiNb18-10

2338

SUS 347

No

Name

1.4541

58G

58B,

58C

These comparisons are approximate only. The list is intended as a comparison of functionally similar materials not

as a schedule of contractual equivalents. If exact equivalents are needed original specifications must be consulted.

Possible Alternative Grades

Possible alternative grades to grade 321 stainless steels are given in table 5.

Table 5. Possible alternative grades to 321 grade stainless steel

Saved from URL: http://www.azom.com/article.aspx?ArticleID=967

/4

Stainless Steel - Grade 321 (UNS S32100)

Grade

304L

3CR12

304H

310

S30815

(253MA)

Why it might be chosen instead of 321

The requirement is for resistance to intergranular corrosion, not for

high temperature strength

Only mild "high temperature" environment is present up to about

600C.

Only mild "high temperature" environment is present up to about

800C.

The temperature of the operating environment is up to about

1100C - too high for 321 or 321H.

The temperature of the operating environment is up to about

1150C- too high for 321 or 321H.

Corrosion Resistance

Equivalent to Grade 304 in the annealed condition, and superior if a weldment in these grades has not been

post-weld annealed or if the application involves service in the 425-900C range. Subject to pitting and crevice

corrosion in warm chloride environments, and to stress corrosion cracking above about 60C. Considered

resistant to potable water with up to about 200mg/L chlorides at ambient temperatures, reducing to about

150mg/L at 60C.

Heat Resistance

Good oxidation resistance in intermittent service to 900C and in continuous service to 925C. These grades

perform well in the 425-900C range, and particularly where subsequent aqueous corrosive conditions are

present. 321H has higher hot strength, and is particularly suitable for high temperature structural applications.

Heat Treatment

Solution Treatment (Annealing) - heat to 950-1120C and cool rapidly for maximum corrosion resistance.

Stabilising - heat to 870-900C for 1 hour per 25mm of thickness and air cool. Stabilisation is recommended for

most severe service conditions (above 425C) and particularly for material annealed at the upper side of the

annealing temperature range.

Stress Relief - Heat to 700C for 1 to 2 hours and air cool.

These grades cannot be hardened by thermal treatment.

Welding

Excellent weldability by all standard fusion methods, both with and without filler metals. AS 1554.6 pre-qualifies

welding of 321 and 347 with Grade 347 rods or electrodes; high silicon version of 347 is also pre-qualified for

welding of 321.

Applications

Typical applications include:

Aircraft exhaust manifolds

Expansion joints

Bellows

Furnace parts

Heating element tubing

Saved from URL: http://www.azom.com/article.aspx?ArticleID=967

/4

Stainless Steel - Grade 321 (UNS S32100)

Heat Exchangers

Woven or welded screens for high temperature mineral processing

Spiral Welded tube for burner pipes and flues

Source: Atlas Steels Australia

For more information on this source please visit Atlas Steels Australia

Date Added: Oct 23, 2001 | Updated: Apr 8, 2013

Saved from URL: http://www.azom.com/article.aspx?ArticleID=967

/4

Você também pode gostar

- Stainless Steel Grade AISI 321Documento2 páginasStainless Steel Grade AISI 321Mitul RawatAinda não há avaliações

- A276A276M-15 Stainless Steel Bars and ShapesDocumento8 páginasA276A276M-15 Stainless Steel Bars and Shapesgsb2Ainda não há avaliações

- Asme B18.2.6 2003Documento11 páginasAsme B18.2.6 2003Jesse ChenAinda não há avaliações

- 6061 Aluminum Sheet SuppliersDocumento7 páginas6061 Aluminum Sheet Supplierssanghvi overseas incAinda não há avaliações

- A 29 - A 29M - 16Documento17 páginasA 29 - A 29M - 16Isabel Christina Gonzalez MoralesAinda não há avaliações

- Specification For Stainless Steel Bars and Shapes For Use in Boilers and Other Pressure VesselsDocumento9 páginasSpecification For Stainless Steel Bars and Shapes For Use in Boilers and Other Pressure VesselsExcel Hydro Pneumatics (INDIA) EHPIAinda não há avaliações

- A176 PDFDocumento2 páginasA176 PDFmahmoud hanafiAinda não há avaliações

- About Stainless Steel PropertiesDocumento8 páginasAbout Stainless Steel Propertiesprajash007Ainda não há avaliações

- Astm A 278 - A 278M - 01 (2015)Documento4 páginasAstm A 278 - A 278M - 01 (2015)Nguyễn Như ThếAinda não há avaliações

- AISI Steel Code TablesDocumento12 páginasAISI Steel Code TablesWahyu DiAinda não há avaliações

- Lvsuysl Blikr DH Iysv) Píjsa RFKK Ifùk K¡ Fof'Kf"V: HKKJRH EkudDocumento17 páginasLvsuysl Blikr DH Iysv) Píjsa RFKK Ifùk K¡ Fof'Kf"V: HKKJRH EkudshamrajjAinda não há avaliações

- Voestalpine Heavy Plate TTD DUROSTAT E 10042015Documento16 páginasVoestalpine Heavy Plate TTD DUROSTAT E 10042015Ella Byla SaraAinda não há avaliações

- ASME SA240 304 (S30400) Stainless Steel Plate - A516Gr70 - S355J2 - SA516GR70 - A516 Grade 70 - SA516 Grade 70 - A572GR50 Steel Plate PDFDocumento7 páginasASME SA240 304 (S30400) Stainless Steel Plate - A516Gr70 - S355J2 - SA516GR70 - A516 Grade 70 - SA516 Grade 70 - A572GR50 Steel Plate PDFJA KAinda não há avaliações

- SIGA CT1 Est Manual Instalacion SH IngenieriaDocumento3 páginasSIGA CT1 Est Manual Instalacion SH IngenieriaedgarAinda não há avaliações

- As MeDocumento235 páginasAs Meshashi_uitAinda não há avaliações

- AstmDocumento25 páginasAstmcasperxxxAinda não há avaliações

- Enovia VPLM VPM NavigatorDocumento11 páginasEnovia VPLM VPM NavigatorAsker Ali TPAinda não há avaliações

- A 488A 488M 01 Welding Qualifications of Procedures and Personnel PDFDocumento16 páginasA 488A 488M 01 Welding Qualifications of Procedures and Personnel PDFshakeelahmadjsrAinda não há avaliações

- General Requirements For Steel Sheet, Metallic-Coated by The Hot-Dip ProcessDocumento9 páginasGeneral Requirements For Steel Sheet, Metallic-Coated by The Hot-Dip ProcessCarlos Ramirez BaltazarAinda não há avaliações

- Astm A1008 CRC Crs PDFDocumento9 páginasAstm A1008 CRC Crs PDFArul Edwin VijayAinda não há avaliações

- Is 513 Amendment-1Documento2 páginasIs 513 Amendment-1sanjeev00747488Ainda não há avaliações

- A493 00 PDFDocumento3 páginasA493 00 PDFJohano AraújoAinda não há avaliações

- Scope Aluminum 6061 Catalogue enDocumento4 páginasScope Aluminum 6061 Catalogue ensav33Ainda não há avaliações

- A270 PDFDocumento5 páginasA270 PDFHansSarmientoAinda não há avaliações

- Astm A 336 .03Documento8 páginasAstm A 336 .03FrengkiAinda não há avaliações

- A500 Vs A513Documento2 páginasA500 Vs A513Angelo CubillosAinda não há avaliações

- SAE 8620H Chemical Composition, SAE 8620H Mechanical Properties, SAE 8620H Heat TreatmentDocumento2 páginasSAE 8620H Chemical Composition, SAE 8620H Mechanical Properties, SAE 8620H Heat TreatmentAnush Swaminathan100% (1)

- Tata Steel - YMPRESS S500MC - Data SheetDocumento2 páginasTata Steel - YMPRESS S500MC - Data SheetpnagarajjAinda não há avaliações

- Aisi 1008Documento2 páginasAisi 1008GANESH GAinda não há avaliações

- High-Strength Low-Alloy Structural Steel Plate With Low Carbon and Restricted Sulfur For Improved Weldability, Formability, and ToughnessDocumento3 páginasHigh-Strength Low-Alloy Structural Steel Plate With Low Carbon and Restricted Sulfur For Improved Weldability, Formability, and ToughnessMarcelo BarretosAinda não há avaliações

- Astm A500.1978 PDFDocumento8 páginasAstm A500.1978 PDFpradellesAinda não há avaliações

- B432Documento6 páginasB432Cesar Augusto Vinasco MartinezAinda não há avaliações

- Is 1501 Part 1Documento114 páginasIs 1501 Part 1Mohit DhimaanAinda não há avaliações

- Astm-A270 PipeDocumento6 páginasAstm-A270 PipeMiguel David Celis QuinteroAinda não há avaliações

- Stainless Steel Grade 304 (UNS S30400)Documento4 páginasStainless Steel Grade 304 (UNS S30400)105034412Ainda não há avaliações

- 440C 1Documento4 páginas440C 1svk1234Ainda não há avaliações

- En 573-3-2009Documento36 páginasEn 573-3-2009akifAinda não há avaliações

- Astm A27 (2010) PDFDocumento4 páginasAstm A27 (2010) PDFStuar TencioAinda não há avaliações

- MSRR 6522Documento7 páginasMSRR 6522pradellesAinda não há avaliações

- QQ N 290aDocumento17 páginasQQ N 290aBryan MartinezAinda não há avaliações

- Stainless Steel 321Documento2 páginasStainless Steel 321Fadhil Azhar Abdul RahmanAinda não há avaliações

- A867-03 (2013) Standard Specification For Iron-Silicon Relay SteelsDocumento4 páginasA867-03 (2013) Standard Specification For Iron-Silicon Relay SteelsdcardonasterAinda não há avaliações

- Steel, Sheet and Strip, High-Strength, Low-Alloy, Hot-Rolled and Cold-Rolled, With Improved Atmospheric Corrosion ResistanceDocumento4 páginasSteel, Sheet and Strip, High-Strength, Low-Alloy, Hot-Rolled and Cold-Rolled, With Improved Atmospheric Corrosion ResistancePham Huu Loc Ho100% (1)

- Astm A659-18Documento3 páginasAstm A659-18Ryan ZhangAinda não há avaliações

- Din 1.4003Documento2 páginasDin 1.4003Dhaniel100% (1)

- Astm A106 1999Documento13 páginasAstm A106 1999Rolando CastilloAinda não há avaliações

- A299 A299m (2001) Standard Specification For Pressure Vessel Plates, Carbon Steel, Manganese-Si PDFDocumento2 páginasA299 A299m (2001) Standard Specification For Pressure Vessel Plates, Carbon Steel, Manganese-Si PDFGagan SinghAinda não há avaliações

- Aisi 4135Documento4 páginasAisi 4135saurabhsubhuAinda não há avaliações

- A 299 - A 299M - 09 (2014) PDFDocumento2 páginasA 299 - A 299M - 09 (2014) PDFأسامة وحيد الدين رمضانAinda não há avaliações

- B729Documento3 páginasB729LambertWayneAinda não há avaliações

- ASTM A985 Investment CastingDocumento12 páginasASTM A985 Investment CastingBobNobbitsAinda não há avaliações

- A276a276m 2023Documento8 páginasA276a276m 20237620383tlAinda não há avaliações

- Sa 193Documento18 páginasSa 193Haridev MoorthyAinda não há avaliações

- Surface Vehicle Standard: Rev. JUN1998Documento45 páginasSurface Vehicle Standard: Rev. JUN1998Sandeep Goud ChatlaAinda não há avaliações

- 219-Asme-Sec-Ii-B-Sb-211 Alu AlloyDocumento14 páginas219-Asme-Sec-Ii-B-Sb-211 Alu AlloyGRIPHOLD Engineering ServicesAinda não há avaliações

- BS 2S 98Documento8 páginasBS 2S 98Lokesh NarasimhaiahAinda não há avaliações

- Specification For Seamless Medium-Carbon Steel Boiler and Superheater TubesDocumento4 páginasSpecification For Seamless Medium-Carbon Steel Boiler and Superheater TubesMauricio Esteban Fernandez RamirezAinda não há avaliações

- Shallow Crack Fracture Mechanics Toughness Tests and Applications: First International ConferenceNo EverandShallow Crack Fracture Mechanics Toughness Tests and Applications: First International ConferenceAinda não há avaliações

- Stainless Steel Grade 316L Properties Fabrication and Applications (UNS S31603)Documento6 páginasStainless Steel Grade 316L Properties Fabrication and Applications (UNS S31603)ganmosesAinda não há avaliações

- Ball Pen in 4 Colours With Medium Point: Main FeaturesDocumento1 páginaBall Pen in 4 Colours With Medium Point: Main Featuresmp87_ingAinda não há avaliações

- Using The Power Law Model To Quantify Shear Thinning Behavior On A Rotational RheometerDocumento7 páginasUsing The Power Law Model To Quantify Shear Thinning Behavior On A Rotational Rheometermp87_ingAinda não há avaliações

- Leaded Nickel SilverDocumento1 páginaLeaded Nickel Silvermp87_ingAinda não há avaliações

- LDM CuNi7Zn39Pb3Mn2 MSDSDocumento4 páginasLDM CuNi7Zn39Pb3Mn2 MSDSmp87_ingAinda não há avaliações

- CDA Benzotriazole Corrosion Inhibitor For Copper Alloys PDFDocumento10 páginasCDA Benzotriazole Corrosion Inhibitor For Copper Alloys PDFmp87_ingAinda não há avaliações

- SANDVIK Understanding Cemented Carbide PDFDocumento20 páginasSANDVIK Understanding Cemented Carbide PDFmp87_ingAinda não há avaliações

- JIS G4805:1999 High Carbon Chromium Bearing SteelsDocumento34 páginasJIS G4805:1999 High Carbon Chromium Bearing Steelsmp87_ingAinda não há avaliações

- Fatigue, Static Tensile Strength and Stress Corrosion of Aircraft Materials and StructuresDocumento232 páginasFatigue, Static Tensile Strength and Stress Corrosion of Aircraft Materials and Structuresmp87_ing100% (1)

- Alloy CarbidesDocumento2 páginasAlloy Carbidesmp87_ing100% (1)

- Strategies For Eliminating DecarburizationDocumento3 páginasStrategies For Eliminating Decarburizationmp87_ingAinda não há avaliações

- Understanding Magnesium Heat TreatmentDocumento2 páginasUnderstanding Magnesium Heat Treatmentmp87_ingAinda não há avaliações

- Revealing Prior-Austenite Grain Boundaries in Heat-Treated SteelsDocumento5 páginasRevealing Prior-Austenite Grain Boundaries in Heat-Treated Steelsmp87_ingAinda não há avaliações

- Interpreting Carburized Case DepthsDocumento4 páginasInterpreting Carburized Case Depthsmp87_ingAinda não há avaliações

- Wall Colmonoy Surfacing Alloys Selector ChartDocumento3 páginasWall Colmonoy Surfacing Alloys Selector Chartmp87_ingAinda não há avaliações

- A Chrome Alternative For Corrosive EnvironmentsDocumento3 páginasA Chrome Alternative For Corrosive Environmentsmp87_ingAinda não há avaliações

- Vacuum Oil Quenching: Applications and Unique PropertiesDocumento4 páginasVacuum Oil Quenching: Applications and Unique Propertiesmp87_ingAinda não há avaliações

- GMAW - Complete GuideDocumento1 páginaGMAW - Complete GuideVijay OfficialAinda não há avaliações

- Internship Report - HRM - Central Railway Workshop, Mysore - Final To PrintDocumento68 páginasInternship Report - HRM - Central Railway Workshop, Mysore - Final To PrintshashankAinda não há avaliações

- Big Blue Miller 700Documento98 páginasBig Blue Miller 700Juan Eduardo JeRico100% (1)

- Orinoco Installation ManualDocumento238 páginasOrinoco Installation ManualZoroastro Mo100% (1)

- ZINC METAL SPRAY COMPLETE With Applications KB 629Documento1 páginaZINC METAL SPRAY COMPLETE With Applications KB 629kolanarendrababuAinda não há avaliações

- ASME I Part PMB Requirements For Miniature BoilersDocumento2 páginasASME I Part PMB Requirements For Miniature BoilersAmanda Ariesta ApriliaAinda não há avaliações

- Distortion in Weld JointDocumento54 páginasDistortion in Weld JointDiVik BhargAva100% (1)

- Introduction Spark TestDocumento1 páginaIntroduction Spark TestKarl CastroAinda não há avaliações

- KF-Puls EN V6Documento22 páginasKF-Puls EN V6Diego MondragonAinda não há avaliações

- Work Permit FormatDocumento12 páginasWork Permit FormatAejaz Mujawar0% (1)

- Safe Operating Procedures SOP 19 - Electric Arc Welder - Small Welding JobsDocumento2 páginasSafe Operating Procedures SOP 19 - Electric Arc Welder - Small Welding JobsACCELOR HRAinda não há avaliações

- PUB145Documento133 páginasPUB145Eithne FajardoAinda não há avaliações

- Stainless Steel Welding by Weld RealityDocumento50 páginasStainless Steel Welding by Weld RealitylightwinterdayAinda não há avaliações

- Macha ResumeDocumento3 páginasMacha Resumemagi magiAinda não há avaliações

- Asme Sec 9Documento12 páginasAsme Sec 9ckkashyap0007Ainda não há avaliações

- Submerged Arc WeldingDocumento4 páginasSubmerged Arc WeldingshifaAinda não há avaliações

- Phase IV Welder Module 1.1Documento23 páginasPhase IV Welder Module 1.1Magdi SiamAinda não há avaliações

- 2009 11 Brouwer UreaKnowHow - Com Stainless Steels in Urea PlantsDocumento11 páginas2009 11 Brouwer UreaKnowHow - Com Stainless Steels in Urea Plantsrj13103100% (1)

- BCSA Guide To The CE Marking of Structural SteelworkITADocumento73 páginasBCSA Guide To The CE Marking of Structural SteelworkITAdavidemolAinda não há avaliações

- 650-680 Rev 4 - Hydrostatic Test ExemptionsDocumento3 páginas650-680 Rev 4 - Hydrostatic Test ExemptionsAnonymous 6S9tcbhAinda não há avaliações

- Lj-Ts Series Horizontal ScreensDocumento8 páginasLj-Ts Series Horizontal ScreensLuis Vallecillo100% (1)

- Inspection Report of Rail Installation and Welding For WBXDocumento2 páginasInspection Report of Rail Installation and Welding For WBXabdel mohamedAinda não há avaliações

- Strenx 700MC D e 2017-04-20Documento2 páginasStrenx 700MC D e 2017-04-20Amandeep SinghAinda não há avaliações

- Haz CC enDocumento48 páginasHaz CC enMuthana JalladAinda não há avaliações

- VRTEX 360 Lincoln ElectricDocumento65 páginasVRTEX 360 Lincoln ElectricLuis FelipeAinda não há avaliações

- TCVN 3146-1986Documento10 páginasTCVN 3146-1986thangha83Ainda não há avaliações

- Dual Shield 7100 Ultra - KoreaDocumento1 páginaDual Shield 7100 Ultra - KoreaHansBrüningAguilarAinda não há avaliações

- KM Welding FundamentalsDocumento42 páginasKM Welding FundamentalsJignesh GunasegerenAinda não há avaliações

- Production GATE AcademyDocumento76 páginasProduction GATE AcademyKavin KabilanAinda não há avaliações

- General Installation Practices: Section EDocumento26 páginasGeneral Installation Practices: Section EMohsen ArabifardAinda não há avaliações