Escolar Documentos

Profissional Documentos

Cultura Documentos

DS200 Installation Guide

Enviado por

Arokiaraj RajDireitos autorais

Formatos disponíveis

Compartilhar este documento

Compartilhar ou incorporar documento

Você considera este documento útil?

Este conteúdo é inapropriado?

Denunciar este documentoDireitos autorais:

Formatos disponíveis

DS200 Installation Guide

Enviado por

Arokiaraj RajDireitos autorais:

Formatos disponíveis

CONTENTS

I. SETTING UP THE SYSTEM ........................................................................................... 1

I.1.THE WALL TYPE DS200 SYSTEM INSTALLATION .............................................................. 1

I.1.A. PREPARATION ...............................................................................................................................1

I.1.B. APPLICATION ................................................................................................................................1

I.1.C. GROUNDING ..................................................................................................................................4

I.1.D. BATTERY CONNECTION................................................................................................................5

I.2.THE CABINET-TYPE DS200 SYSTEM INSTALLATION ........................................................ 5

I.2.A. PREPARATION ...............................................................................................................................5

I.2.B. APPLICATION ................................................................................................................................6

I.2.C. INSTALLATION OF SYSTEMS WITH FOUR OR MORE RACKS .....................................................8

I.2.C.1. CONNECTIONS IN THE MAIN RACK, TO WHICH THE CPU200 CARD HAS BEEN ATTACHED:........... 9

I.2.C.1.1. ATTACHING THE CC EXTRA CARD ONTO THE CPU200 CARD: ..........................................................................9

I.2.C.1.2. INTEGRATION OF THE C MASTER CARD TO THE MAIN RACK:........................................................................10

I.2.C.1.3. CONNECTING THE BPLSPS-FCX CABLE:.........................................................................................................11

I.2.C.2. CONNECTIONS ON THE FOURTH RACK: .............................................................................................12

I.2.C.2.1. INTEGRATION OF THE C SLAVE CARD TO THE MAIN RACK ............................................................................12

I.2.C.2.2. ATTACHING THE CC ENABLE CARD TO THE MAIN RACK: ..............................................................................12

I.2.C.2.3. CONNECTING THE BPLSPS-FCX CABLE:.........................................................................................................12

I.2.D. GROUNDING ................................................................................................................................12

I.2.E. BATTERY CONNECTION ..............................................................................................................14

I.3.INSTALLING POWER SUPPLIES IN THE SYSTEM............................................................ 16

I.3.A. SPS200 AC/DC POWER SUPPLY .................................................................................................16

I.3.B. SPS248 DC/DC POWER SUPPLY ................................................................................................16

I.4.INTEGRATING MODULES TO THE SYSTEM...................................................................... 16

I.4.A.CPU200, REDUNDANT CPU200 & DS200 CPUKON CARDS.......................................................16

I.4.A.1. THE LAN ADAPTOR CARD:....................................................................................................................17

I.4.B. THE UTIL200 UTILITY MODULE ..................................................................................................18

I.4.B.1. nstallng the conference chp on UTIL200...........................................................................................18

I.4.C. CON2/CON3 LINE CONNECTION CARDS...................................................................................19

I.4.D. INSTALLING EXPANSION MODULES .........................................................................................21

I.4.D.1. ATTACHING EX200 MODULES: .............................................................................................................21

I.4.D.2. CABLING OF EX200 MODULES: ............................................................................................................22

I.4.D.2.1. EX200 (0/16) ANALOG EXTENSION MODULE:...................................................................................................22

I.4.D.2.2. EX200 (8/0) ANALOG LINE MODULE: ................................................................................................................23

I.4.D.2.3. EX200 (0/8S0) ISDN BRI EXTENSION MODULE: ...............................................................................................23

I.4.D.2.4. EX200 (1S2/0) ISDN PRI MODULE: ....................................................................................................................24

I.4.D.2.5. EX200 (1R2/0) R2 DIGITAL LINE MODULE: .......................................................................................................24

I.4.D.2.6. EX200 (0/8U) DIGITAL EXTENSION MODULE:...................................................................................................25

I.4.D.2.7. EX200 (0/16U) DIGITAL EXTENSION MODULE:.................................................................................................25

I.4.D.2.8. EX200 (8 T0/S0) ISDN BRI LINE/EXTENSION MODULE: ...................................................................................26

I.4.D.2.9. EX200 (0/8LB) LOCAL BATTERY EXTENSION MODULE:...................................................................................27

I.4.D.2.10. EX200 (4E&M/0) E&M LINE MODULE: ............................................................................................................27

I.4.E. JUMPER SETTINGS ON THE EX200 (8T0/S0)

MODULE........................................................28

I.4.F. JUMPER SETTINGS ON THE EX200 (4E&M/0)

MODULE ......................................................29

I.4.G. INSTALLATION OF THE EVM200L MODULE ..............................................................................31

I.5. THE FINAL PREPARATIONS............................................................................................ 31

II. PUTTING THE SYSTEM ON LINE............................................................................... 33

II.1. SINGLE-RACK, WALL-TYPE SYSTEM............................................................................. 33

II.2. TWO-RACK WALL-TYPE SYSTEM................................................................................... 33

II.3. CABINET-TYPE SYSTEM................................................................................................. 33

II.4. TWO-CABINET SYSTEM.................................................................................................. 34

III. TESTING THE SYSTEM AND TROUBLESHOOTING BASIC PROBLEMS .................. 36

DS200 Installation Guide

I. SETTING UP THE SYSTEM

The DS200 system can be set up in two different structures, namely as wall type and cabinet

type.

I.1.THE WALL TYPE DS200 SYSTEM INSTALLATION

If the DS200 system consists of one or two racks at most, then it can be mounted as wall

type. As for the systems with three or more racks, they definitely have to be mounted as

cabinet type.

I.1.A. PREPARATION

The following requirements should be fulfilled prior to the installation of the exchange:

1- The wall on which the DS200 exchange will be mounted should be firm enough to carry

the weight and it should have a smooth surface.

2- The exchange should be installed in places that are not exposed to direct sunlight, that

are not humid, but that are ventilated, well lit, with an environmental temperature of 045oC. It should not be exposed to effects of dust, vibration, oil and water.

3- Devices that generate high frequency waves (such as welding machines, office equipment

such as computers and telex machines, air conditioners, TV sets) should not be in the

same room if possible, and they should be at least 3 meters away from the exchange,

otherwise.

4- The mains supply should be reserved for the exchange only. The power supply of the

system should be uninterrupted and, if possible, the system should be powered from an

independent and well-grounded source from which no other device is powered.

POWER SUPPLY THAT IS INTERRUPTED FREQUENTLY MAY AFFECT

NORMAL OPERATION OF THE SYSTEM!

5- The spot where the exchange is to be mounted should be at a distance to the main

distribution frame (MDF), so that the MDF can be reached through three-meter line

connection cables. While the distance is being determined, the flexibility of the cables

and the way they will be fixed to the wall should also be considered.

6- A location that can be reached easily should be chosen, considering the installation work

and later maintenance work.

7- Place requirement for the batteries should be considered, as well.

THE AIR VENTS AT THE TOP AND BOTTOM OF THE EXCHANGE MUST

NOT BE BLOCKED BY ANY MEANS. PREVENTING VENTILATION MAY DAMAGE

THE EXCHANGE!

I.1.B. APPLICATION

1- Plot a location that complies with the requirements indicated in the Preparation step

above.

2- By making use of the installation template that comes with the racks, mark the locations

for the wall mount bars carefully that are to be used for hanging the racks on the wall.

V003. 25.06.2002

B-1

DS200 Installation Guide

The lower hole of the wall mount bars should be approximately 130 cm. above the floor. It

is essential to check whether the height of both holes are the same, in order to make

sure the exchange is parallel to the floor.

3- If there are two DS200 racks to be installed, then the lower hole of the wall mount bars,

for the first rack to be installed (That will be the lower rack.), should be 100 cm. above

the floor.

4- Drill the lower wall mount bar hole of the second rack 140 cm. above the floor, vertically

on the same line with the first one. When the installation is over, there will be a 10-cm

gap between the two racks.

Figure 1

5- Drive the anchor plugs into the holes, whose locations have already been checked, and

then screw the wall mount bars. Note that the right and the left side of the wall mount

bars differ. The screws must be fixed enough to burry their heads completely into the

wall.

6- After removing the front cover of the exchange by unscrewing the Allen screws, remove

the bottom cover by sliding it to the front.

7- While removing the bottom cover, watch out for the grounding cables that are between

the cover and the main frame, so that they will not break off. Remove the cables from the

covers together with their tags and keep them safe from any damage during the

installation.

8- Slide the SPS200 to the front and remove it, after loosening its screws. (This is just for

facilitating the installation and not obligatory.)

V003. 25.06.2002

B-2

DS200 Installation Guide

9- Hold the exchange so that the wall mount bar holes at the back of the exchange

correspond to the wall mount bar holders, then push the exchange towards the wall, so

that the holders would carry it. Make sure the holders of both wall mount bars have been

inserted into the holes, and then lower the exchange cautiously. The exchange is fixed 5

mm. below. If it is still not fixed, even though it has been lowered for about one

centimeter, that indicates the holders do not carry it. In that case, try to hang the

exchange once again. In order to make sure that the exchange has been fixed, gently

shake it to check whether the wall mount bars really carry it.

10- In case it is necessary to displace the exchange, just lift it upwards cautiously and pull it

out.

IT IS ESSENTIAL TO MOUNT AND DISMOUNT THE WALL MOUNT BARS

SIMULTANEOUSLY; OR THEY MAY GET DISTORTED.

11- If the second rack will be installed, then remove the top cover of the lower rack and the

bottom cover of the upper rack, in order to attach the cables that will connect the racks

to each other (Caution is needed for the grounding cables, as explained in the seventh

step.) The BPL200 main boards are connected to each other by the BPL200-FC and

BPLSPS-FC connection cables that come with the shipped hardware of the auxiliary rack.

There are three such cables. Two BPL200-FC's (34-pin flat cable) are used for connecting

the BPL200 backplanes and the single BPLSPS-FC (5-wire cable) is used for combining

BPL200-SPS backplanes.

1. BPL200-FC connections

V003. 25.06.2002

2. BPLSPS-FC connection

B-3

DS200 Installation Guide

a) BPL200-AUX

d) BPL200-SPS

b) BPL200-FC

e) BPLSPS-FC

c) BPL200-MAIN

f) BPL200-SPS

Figure 2

12- Replace the covers by coinciding the cables with the corresponding cable slots that are at

the back of the covers.

13- If SPS200 has been removed in order to facilitate the installation, then replace it as will

be explained in detail later.

14- Connect the 230 VAC cable to the corresponding input on SPS200. Before plugging the

other end of the cable in, check the position of the on/off switches and whether the fuses

are defective. The mains on/off switch must be off. Keep in mind that the battery on/off

switch must be set to on after the mains supply is on and it must be set to off before

the power is shut off. (Putting the System on Line is described in Section II.)

Two 2A T-type fuses that are necessary for 230 VAC are in the drawer-type compartment

next to the 230 VAC input.

I.1.C. GROUNDING

Grounding is required for protecting the DS200 exchange from lightning and other sources of

high voltage that may affect through lines or peripheral devices. The 230 VAC power cable of

the exchange has grounding feature, so there is no need for an extra grounding if the

electrical installation of the building has sound grounding.

Although special tools are required for measuring the sufficiency of grounding of the electric

installation of the building precisely, voltages between Neuter-Phase and Neuter-Ground

can be measured for getting a rough idea. The Neuter-Phase voltage should be 180-260 VAC

and the Neuter-Ground voltage should be 1-2 VAC. Those values must be consistent.

Possible voltage leakage in grounding installation may damage your exchange, just like all

other devices that require grounding.

ADDITIONAL GROUNDING MUST BE PROVIDED, IF SOUNDNESS OF

THE GROUNDING OF THE ELECTRIC SYSTEM CANNOT BE GUARANTEED.

Water installation of the building can be used for grounding, provided that the pipes are of

metal and no insulation material has been used at junctions.

Indeed, the most secure grounding method is inserting a copper rod that is 1.5 cm in

diameter with 1.5 m of length, or inserting a copper plate with 1 m2 of area to the ground and

connecting it to the exchange through a copper grounding cable. The cable should be

fastened tightly to the rod or to the plate and precautions should be taken against corrosion.

The cable coming from the grounding plate or grounding installation must be connected to

the ground connection point of the exchange.

If the second rack is to be installed as well, then the ground connection points of the two

racks must be connected to each other tightly with the ground connection cable that comes

with the auxiliary rack.

THE GROUND CONNECTIONS OF THE LOWER AND UPPER COVERS OF

THE EXCHANGE MUST DEFINITELY BE DONE AGAIN WHEN THE COVERS ARE

REMOVED AND THEN REPLACED.

V003. 25.06.2002

B-4

DS200 Installation Guide

A- DS200 Main Rack

B- DS200 Auxiliary Rack

C- The grounding cable

D- The copper grounding plate or rod

Figure 3

I.1.D. BATTERY CONNECTION

Since power failure will impede your exchange to fulfill its normal functions, a battery must

be connected to it, if there is such a possibility. Battery connection is made after SPS200 has

been fixed. The battery switch must be 0 during the connection. There are two clips on

SPS200 for the battery connection. (See The Technical Reference GuideFigure 13). It is

strictly recommended that a 48V 24Ah dry battery group (12V, 24Ah X 4) should be connected

to those clips. The red end must be connected to the + pole of the battery group, and the

black end to the - pole. In order to make the connection, press the springed latch of the

clips, insert the corresponding end of the battery cable into the hole in front, deep enough so

that no naked portion of the cable is left outside, and then release the latch.

Battery connection is provided only for the SPS200 of the main rack, in two-rack systems.

There is no battery connection for the second SPS200.

REVERSE BATTERY CONNECTION MAY DAMAGE YOUR EXCHANGE!

I.2.THE CABINET-TYPE DS200 SYSTEM

INSTALLATION

I.2.A. PREPARATION

The following requirements should be fulfilled prior to the installation of the exchange:

1- The DS200 exchange cabinet should be installed in places that are not exposed to direct

sunlight, that are not humid, but that are ventilated, well lit, with an environmental

temperature of 0-45oC.

2- It should not be exposed to the effects of dust, vibration, oil and water.

V003. 25.06.2002

B-5

DS200 Installation Guide

3- Devices that generate high frequency waves (such as welding machines, office equipment

such as computers and telex machines, air conditioners, TV sets) should not be in the

same room if possible, and they should be at least 3 meters away from the exchange,

otherwise.

4- The mains supply should be reserved for the exchange only. The power supply of the

system should be uninterrupted and, if possible, the system should be powered from a

well-grounded source from which no other device is powered.

FREQUENT POWER FAILURES MAY AFFECT NORMAL OPERATION OF

THE SYSTEM!

5- The spot where the exchange is to be mounted should be chosen considering its position

relative to the main distribution frame (MDF) and length of the cables. The installation

work and later maintenance work should also be considered, so that the covers can be

removed and replaced easily.

6- Since the installation connections will be made at the back of the cabinet, the position of

the cabinet should be arranged accordingly. The lighting at the back has been placed for

facilitating the work.

I.2.B. APPLICATION

1- Take the cabinet to a location as defined in the preparation step.

2- Lock the wheels by pressing the latches so that the exchange will not move.

3- Remove the front cover and the rack stopper screws that prevent the racks to slide.

Figure 4

4- Remove the back and side covers, after unlocking them, by lifting them for approximately

10 cm in a manner so that their paint is not scratched.

5- While removing the covers, watch out for the grounding cables that are between the main

frame and the covers so that they do not break off. Detach the cables, together with their

tags, from the covers and keep them so as to make sure they would not get damaged

during the placement of the exchange into the cabinet.

6- Push the main rack and auxiliary racks one by one until the holes of the removed

stopping screws appear. Then replace the stopping screws so that the racks would not

slide along the slots.

V003. 25.06.2002

B-6

DS200 Installation Guide

Figure 5

7- Open the cable panels from rear in order to facilitate the access.

8- In order to connect the main rack and the auxiliary racks, as well as to make inter-rack

ground connection: First, use the BPL200-FC and BPLSPS-FC connection cables that

come with the auxiliary rack. There are three such cables. Two BPL200-FC's (34-pin flat

cable) are used for connecting the BPL200 backplanes and BPLSPS-FC (5-wire cable) is

used for connecting BPL200-SPS backplanes. In order to connect the backplanes:

a) Primarily, attach one end of each BPL200-FC to the BPL200-MAIN backplane of the

main rack that has been placed to the bottom.

b) Extend the free ends of the BPL200-FC cables to the second rack through the cable

holes corresponding to the upper panel at the back of the first rack and the lower

panel at the back of the second rack. Attach the ends of those two cables to the

BPL200-AUX backplane connector. The cables should be parallel to each other.

Repeat the same procedure to connect the second rack to the third, later. See Figure

2.

V003. 25.06.2002

B-7

DS200 Installation Guide

9) Each rack comes as the power card-backplane connection has been made as factory

default. There are special cables that are used for this purpose. In case it is necessary,

those cables can be detached and the two cards can be separated or they can be

combined again, with those cables.

10) Then, you are supposed to make the power connection among the racks. In order to

connect the BPL200-SPS backplanes:

a) For the connection of the BPL200-SPS backplanes of the first and second racks, first

attach the BPLSPS-FC (5-wire cable) to the inter-rack SPS connector that is on the

BPL200-SPS backplane of the first rack.

b) Then, extend the free end of the cable through the holes of the metal plates that are

at the back of the first and the second racks and then attach it to the inter-rack SPS

connector that is on the BPL200-SPS backplane of the second rack. Repeat the same

procedure for the connection between the second and the third racks. See Figure 2.

11) Attach the 230 VAC cable to the connector on the SPS200. First, make sure that the on/off

switches are off and the fuses are free from any defect. Then, attach the other end of the

cable to one of the plugs next to the mains switch that is at the lower front section of the

cabinet, by extending it through the back of the cabinet.

Two 2A T-type fuses that are necessary for 230 VAC are in the drawer-type compartment

next to the 230 VAC input.

VENTS OVER THE CABINET FANS MUST NOT BE COVERED BY ANY

MEANS DURING OPERATION OF THE SYSTEM. CERTAINLY CHECK

WHETHER THE FANS WORK PROPERLY, AT THE TEMPERATURES OVER

20C.

CAUTION!

The rules that must be obeyed strictly while powering the system on and off are stated as a

special chapter at the end of this guide.

When the system consists of three or more racks, if it is powered on and off by the battery

switches, then those switches are damaged in time, due to the electric arcs. In order to

prevent this situation, a delayed main battery breaker (10 Ampere 250 V Main breaker) is

included in the system. Control of the electricity provided to the racks from the battery is

maintained by this breaker. Detailed information about this is in Chapter II of this guide.

I.2.C. INSTALLATION

MORE RACKS

OF

SYSTEMS

WITH

FOUR

OR

Installation of the DS200 system in configurations with four, five or six racks is indeed a step

that follows the cabinet-type installation of the system.

Except the case of the four-rack cabinet that has been designed for the four-rack systems,

since installation cannot be realized with one cabinet for the systems with more than three

racks, first installation of two cabinets are realized so as to distribute the necessary quantity

of racks to those two cabinets.

The crucial point while installing the two cabinets is that they should be located side by side

and they should not be displaced during and after the installation.

THE CABLES PROVIDING THE CONNECTION BETWEEN THE CABINETS

MAY BE DAMAGED IN CASE OF A DISPLACEMENT.

V003. 25.06.2002

B-8

DS200 Installation Guide

The four-rack cabinet is used, if a system has four racks. In this case, since the entire racks

will fit into that cabinet, single-cabinet installation will suffice. The rack that will fit into the

uppermost rack slot of the cabinet will be of the main rack structure, too, like the first rack.

In two-cabinet systems, the first racks (lowermost) will be main rack and the others will be

auxiliary racks. However, there is CPU200 card only in a single cabinets main rack.

Likewise, there is DS200 CPUKON card in only a single main rack.

The first and the fourth racks are of the main rack structure and the connection between

these two racks is provided with some additional cards and cables. The list of those cards

and cables are below:

1) CC Extra card

2) C Master card

3) C Slave card

4) CC Enable card

5) Two BPL200-FC

6) Five PCM carrier cable

7) BPLSPS-FCX cable

In order to facilitate the connection of the two cabinets, you need to remove the SPS248

power units, UTIL200, DS200 CPUKON and CPU200 cards (redundant CPU200, too, if there is

any.)

I.2.C.1. CONNECTIONS IN THE MAIN RACK, TO WHICH THE

CPU200 CARD HAS BEEN ATTACHED:

I.2.C.1.1. ATTACHING THE CC EXTRA CARD ONTO THE CPU200 CARD:

Attach the card to the 20-pin connector with the code CON402, in a manner as it coincides

with the lower back corner of the CPU200 card that has been indicated with white lines,

through the female connector that is on the CC Extra card.

V003. 25.06.2002

B-9

DS200 Installation Guide

Figure 6

If there will be a redundant CPU200 card in the system, then you should attach another CC

Extra card onto that redundant CPU200 card, too.

I.2.C.1.2. INTEGRATION OF THE C MASTER CARD TO THE MAIN RACK:

The C Master card must be attached to the main rack on which there is CPU200. Structure of

this card is suitable for attaching it to the plastic card slots of DS200 and its size is the same

as that of the CPU200 card. However, there is no 64-pin male connector at the back of the

card for the backplane connection. Instead, it is connected by a BPL200-FC to the inter-rack

connector that is at the lower section on the BPL200 backplane of the main rack, at the same

level with the CPU200.

If, on the other hand, there will not be a redundant CPU200 card in the DS200 system, then

the C Master card is attached to the slot that is reserved for the redundant CPU200 card.

Connect the cables before completely fixing the card in the slot.

The procedure for this:

1) Connect one end of the BPL200-FC to the inter-rack connector that is at the lower edge

of the BPL200-MAIN backplane of the main rack.

2) Connect the other end of the BPL200-FC to the similar connector that is on the C Master

card.

3) Connect the PCM carrier cables to the five RJ45 connectors that are on the C Master

card. The connection order of those cables is essentially important because those cables

will be connected to the second rack in the same order.

V003. 25.06.2002

B-10

DS200 Installation Guide

1- BPL200-FC

4- C Master card

2- PCM cable connectors (RJ45)

5- BPL200-Main

3- PCM carrier cables (The order is important.)

Figure 7

After making the entire cable connections, push the card into the slot completely and make

sure the fixing latches that are on the plastic front cover have been fully fixed on the metal

casing.

If there will be redundant CPU200 card in the system, then you may install the C Master card

in the second general-purpose slot that is on the main rack. (Keep in mind that there must

be an extension card in the first general-purpose slot.) The cable connections are the same

as above.

Then, attach the DS200 CPUKON, UTIL200, CPU200 and redundant CPU200 (if there is any) of

the main rack to their corresponding slots, as will be described in later sections.

I.2.C.1.3. CONNECTING THE BPLSPS-FCX CABLE:

The BPLSPS-FCX cable is structurally the same as the BPLSPS-FC cable, yet it is longer.

Connect one end of that cable to the SPS connector that is at the lower section of the

BPLSPS backplane.

Attach the SPS248 Power Unit to its corresponding slot, as will be described in later

sections.

Finally, extend the free ends of the PCM carrier cables and the BPLSPS-FCX cable out of the

cabinet through the cable channels that are at the lower back of the cabinet. Then, insert

those cables into the second cabinet through the similar opening as that of the first one, and

extend them to the front part of the main rack.

V003. 25.06.2002

B-11

DS200 Installation Guide

I.2.C.2. CONNECTIONS ON THE FOURTH RACK:

The procedure is similar to that for the first rack.

I.2.C.2.1. INTEGRATION OF THE C SLAVE CARD TO THE MAIN RACK

Structure of the C Slave card is the same as that of the C Master card, which is on the first

rack . Besides, the connections are exactly the same.

Since there will not be any CPU200 and redundant CPU200 cards in the second cabinet, you

can place the C Slave card into the redundant CPU200 card slot that is on the main rack of

the second cabinet. You are supposed to connect the corresponding cables before

completely fixing the card in the slot.

The procedure for this:

1) Connect one end of the BPL200-FC to the inter-rack connector that is at the lower edge

of the BPL200-MAIN backplane of the main rack.

2) Connect the other end of the BPL200-FC to the similar connector that is on the C Slave

card.

3) Connect the PCM carrier cables to the five RJ45 connectors that are on the C Slave card.

The connection order of those cables is essentially important because those cables will

be connected to the C Slave card in the same order as they have been connected to the C

Master card in the first cabinet. (See Figure 7)

INCORRECT CONNECTION ORDER OF THE PCM CARRIER CABLES

WOULD PRECLUDE THE OPERATION OF THE SYSTEM.

After making the entire cable connections, push the card into the slot completely and make

sure the fixing latches that are on the plastic front cover have been fully fixed on the metal

casing.

I.2.C.2.2. ATTACHING THE CC ENABLE CARD TO THE MAIN RACK:

The CC Enable card has a structure, which makes it possible to be attached to the BPL200MAIN backplane, thanks to the 64-pin male connector that is located at the back of it.

Attach the CC Enable card to the slot reserved for CPU200 on the main rack.

Then, you should attach the UTIL200 card of the main rack to its corresponding slot.

I.2.C.2.3. CONNECTING THE BPLSPS-FCX CABLE:

Connect free end of the BPLSPS-FCX cable, whose connection with the first cabinet has

already been provided, to the SPS connector that is at the lower section of the BPLSPS

backplane.

Attach the SPS248 Power Unit to its corresponding slot, as will be described in later

sections.

The operation of connecting two cabinets to each other will have been completed after

applying the steps above.

I.2.D. GROUNDING

Grounding is essential for protecting the DS200 Exchange from the effects of lightning or

other sources of high voltage that might affect over lines or peripheral devices.

V003. 25.06.2002

B-12

DS200 Installation Guide

Although special tools are required for measuring the sufficiency of grounding of the electric

installation of the building precisely, voltages between Neuter-Phase and Neuter-Ground

can be measured for getting a rough idea.

The Neuter-Phase voltage should be 180-260 VAC and the Neuter-Ground voltage should be

1-2 VAC. Those values must be consistent. Possible voltage leakage in grounding installation

may damage your exchange, just like all other devices that require grounding.

Water installation of the building can be used for grounding, provided that the pipes are of

metal and no insulation material has been used at junctions. Indeed, the most secure

grounding method is inserting a copper rod that is 1.5 cm in diameter with 1.5 m of length, or

inserting a copper plate with 1 m2 of area to the ground and connecting it to the exchange

through a copper grounding cable. The cable should be fastened tightly to the rod or to the

plate and precautions should be taken against corrosion.

The cable coming from the grounding plate or grounding system must be connected to the

ground connection point of the exchange.

The DS200 Exchange and auxiliary racks are connected to each other tightly at the ground

connection points with the ground connection cable that comes with the shipped hardware.

A- DS200 Main Rack

B- DS200 Auxiliary rack

C- The grounding cable

D- The copper grounding plate or rod

Figure 8

ADDITIONAL GROUNDING MUST BE PROVIDED, IF SOUNDNESS OF

THE GROUNDING OF THE ELECTRIC SYSTEM CANNOT BE GUARANTEED.

For providing the internal inter-rack grounding, first connect the grounding cable and the

grounding screw of the first rack, which is under the rack. Then, connect the grounding

screw that is under the first rack and the grounding screw of the second rack. Repeat the

same operation for the third rack. Afterwards, connect the cabinet grounding screw and the

external grounding system that has been installed for the cabinet, in order to provide

grounding for the entire cabinet.

For the two-cabinet structure, the grounding points of both cabinets must be the same.

V003. 25.06.2002

B-13

DS200 Installation Guide

I.2.E. BATTERY CONNECTION

!

SINCE ANY POWER FAILURE WILL DISRUPT THE EXCHANGE TO

PERFORM ITS NORMAL FUNCTIONS, YOU SHOULD CONNECT BATTERY TO

THE SYSTEM, IF THERE IS SUCH A POSSIBILITY.

!

THE BATTERY BREAKER MUST BE OFF DURING THE CONNECTION

PROCESS.

The system uses dry batteries. The batteries are placed at the bottom of the DS200 cabinet.

The compartment has been designed as large enough to include 38 Ah, dry-type batteries.

The dimensions of the cabinet bottom are about 60x78 cm. The capacity of that space is at

most12 batteries of 24 Ah (width: 17.5 cm, length: 16.6 cm, height: 12.5 cm) or of 38 Ah

(width: 16.5 cm, length: 19.7 cm, height: 17.0 cm). A three-rack system requires at least 4

batteries and there is room in the cabinet for 8 or 12 batteries, as needed.

Placing the batteries close to the back cover facilitates connecting them, as well as their

maintenance.

In order to connect the batteries:

First, connect the batteries that are in the compartment under the exchange serially to each

other. Then, connect the battery output through main breaker to the battery input of the main

rack, which is the lowermost rack. Attach the battery output to the connection clips on the

SPS200 (See the Technical Reference GuideFigure 13), in the manner as the red end being

the + pole, and the black end being the - pole. No battery connection is required for the

other SPSs.

REVERSE BATTERY CONNECTION MAY DAMAGE YOUR EXCHANGE.

In order to complete the connection, press the spring latch of the clips and insert the

corresponding end of the battery cable into the hole in front, deep enough so that no naked

portion of the cable is left outside and then release the latch.

Since the batteries are connected to the 48 VDC-output of the SPS200 in parallel, completely

exhausted batteries may affect normal operation of the system. In that case, you should

charge them from an external source and then re-connect them to the system.

NORMAL OPERATION OF SYSTEMS WITH BATTERIES WOULD BE

AFFECTED BY FAILURES OF 230 VAC MAINS SUPPLY DURING NIGHT TIME

AND HOLIDAYS.

THE SYSTEM AUTOMATICALLY SHUTS DOWN IF THE BATTERY

VOLTAGE DROPS BELOW 34 VDC DURING PROLONGED POWER FAILURES AND

THE BATTERIES DO NOT SWITCH ON UNTIL THE BATTERY VOLTAGE LEVEL

EXCEEDS 46 VDC.

V003. 25.06.2002

B-14

DS200 Installation Guide

1. 230 VAC cable

4. BPL200-FC

2. BPLSPS-FC

5. Grounding screw

3. Grounding wire

6. Battery connection cables

7. Main grounding cable

Figure 9

V003. 25.06.2002

B-15

DS200 Installation Guide

I.3.

INST

I.3.A. SPS200 AC/DC POWER SUPPLY

The SPS200 AC/DC Power Supply, which includes the SPS200CR Power Card, has been

placed in a metal casing.

In order to fix SPS200 in the rack, place the metal rails properly, which are on the power

chassis, in the metal slots that are on rightmost side of the rack. (See the Technical

Reference GuideFigure3). Then, push the SPS200 into the rack until it is firmly fixed to the

connector that is on the BPLSPS-Backplane, which is behind the power rack. Afterwards,

drive the SPS200 fixing screw that is in the upper front part of the rack. (See the Technical

Reference GuideFigure 4).

In case you need to take the SPS200 out of rack, switch the battery and mains off,

respectively, by the ON/OFF switches on the SPS200 module. (See The Technical Reference

GuideFigure 13). Detach the 230 V cable and battery connection cables (if there is any.)

Then, pull the power rack out after loosening the fixing screw that is on the upper front part

of the system rack.

I.3.B. SPS248 DC/DC POWER SUPPLY

SPS248 DC/DC Power Supply, which includes the SPS248CR Power Card and ring

transformer, has been mounted in a metal casing.

Attaching the SPS248 is very similar to that of the SPS200. It is attached to the slot on the

left-hand side of the SPS200. (See The Technical Reference GuideFigure 4).

CAUTION! IN MULTI-RACK DS200 SYSTEMS, THE INTER-RACK

!

POWER CONNECTIONS MUST HAVE BEEN COMPLETED PRIOR TO PLACEMENT

OF SPS248 MODULES.

I.4.

INTEG

In this section, integration of the CPU200, DS200 CPUKON, UTIL200 UTILITY and Expansion

Modules to the system, together with CON2/CON3 Line Connection Cards, have been

explained.

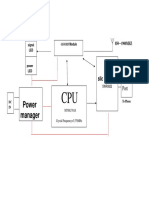

I.4.A.CPU200, REDUNDANT CPU200 & DS200 CPUKON

CARDS

The CPU200 Central Processing Module has been fixed in the corresponding slot, as being

connected to the BPL200-MAIN backplane in the rack. (See The Technical Reference

GuideFigure 11). The DS200 CPUKON Connection Card has been situated in the leftmost

slot of the main rack, as connected to the CPU200 card via the DS200 CPU-FC flat cable. The

DS200 CPUKON card has not been connected to the BPL200-MAIN backplane.

Install the CPU200, DS200 CPUKON and DS200 CPU-FC modules in the main rack as

described below:

1- Make sure that the UTIL200 module of the first rack has not been installed.

V003. 25.06.2002

B-16

DS200 Installation Guide

2- Connect the cables of the accessories to the connectors on the DS200 CPUKON. In order

to do this, extend the cables through the cable hole that is in the lower front rack and

attach them to the corresponding connectors on the DS200 CPUKON card. Then take the

free end of the cable out of the rack by extending it along underneath the rack through

the corresponding path within the cable channel that has been fixed on the back cover.

3- Install DS200 CPUKON card together with DS200 CPU-FC cable. First, attach the DS200

CPU-FC cable to the connector on the DS200 CPUKON card. Then, insert the DS200

CPUKON card so as its back corners fit the channel of the plastic card slot. Afterwards,

extend the free end of the DS200 CPU-FC cable along underneath the UTIL200 connector

on the backplane. As for the final step, when the card is completely placed, fix the DS200

CPUKON card by the fixing latches on the plastic card holder. See the figure below for

the correct usage of the plastic fixing latches.

Figure 10

4- In order to install the CPU200 module, place the back corners of the module into the

channel of the plastic card slot and push it towards the rack. Before you set the module

completely, connect the DS200 CPU-FC cable to CPU200. Then, push the CPU200 module

inside, so as it tightly fits on its corresponding connector on the BPL200-Backplane.

When the module has been completely set, fix it by using fixing latches on the front cover

of the card. (See The Technical Reference GuideFigure 24). See Figure 10 for the

correct usage of the plastic fixing latches.

In case it is necessary to take CPU200 out of the rack, press the card fixing latches on the

front cover of CPU200 toward the tag on the holder and then pull the module cautiously until

DS200 CPU-FC appears. As for the final step, detach DS200 CPU-FC from CPU200 and then

take it out of the rack.

In case it is necessary to take DS200 CPUKON out of the rack, press the card fixing latches

on the front cover of the card toward the tag on the holder and then pull the module

cautiously until DS200 CPU-FC appears. Afterwards, detach DS200 CPU-FC from DS200

CPUKON and take it out of the rack.

If a redundant CPU200 is needed in the system, then install that card in the special slot at the

right-hand side of CPU200, which is reserved for it by following the same installation steps

as for CPU200. Its connection to DS200 CPUKON card is provided by DS200 CPU-FC.

DO NOT EVER REMOVE THE CPU200 CARD DURING THE OPERATION

OF THE EXCHANGE.

I.4.A.1. THE LAN ADAPTOR CARD:

V003. 25.06.2002

B-17

DS200 Installation Guide

The LAN Adaptor card has been designed to be attached to two female sockets, each with 5

pins, which are on the CPUKON card. There are pins on the solder side of the card

corresponding to the female sockets on CPUKON. While the RJ45 socket on the LAN Adaptor

card is facing out of the CPUKON card, attach the pins to the sockets. In addition to that, fix

the LAN Adaptor card to the CPUKON card through lead card holders.

In the figure below the LAN Adaptor card is illustrated as it has been attached onto CPUKON.

Figure 11

After you have attached the LAN Adaptor card onto the DS200 CPUKON card, adjust the

jumpers on the CPUKON card according to the proper configuration. The table below shows

states of the jumpers:

Jumper

State

1, 2

ON

3, 4

OFF

1, 2

OFF

3, 4

ON

Selected output

RS232

LAN Adaptor

After the installation of the card is over, make the network connection through a one-to-one

cable with RJ45 connectors on both sides.

I.4.B. THE UTIL200 UTILITY MODULE

The UTIL200 Utility Module has been set on the related plastic card slot in the rack. (See The

Technical Reference GuideFigure 11 and Figure 12). The UTIL200 module is situated

between the CPU200 and DS200 CPUKON cards in the main rack. The DS200 CPU-FC cable

passes through the back of the UTIL200 module. On the other hand, it is installed in the

leftmost slot in the auxiliary racks.

In order to set UTIL200 into the rack, insert the module so as its back corners fits the plastic

card slot. Then, you should push it towards the inside of the rack so as the connector at the

back of it would fully fit its correspondent on BPL200-MAIN or BPL200-AUX (While you are

attaching the one that is on the main rack, be careful so that the DS200 CPU FC cable

remains behind the card.) When the module has been completely set, fix it by using latches

on the plastic card holder. (See Figure 10).

In case it is necessary to take UTIL200 out of the rack, press the card fixing latches on the

front cover of the card toward the sticker on the holder and then take the module out of the

rack.

I.4.B.1. INSTALLING THE CONFERENCE CHIP ON UTIL200

V003. 25.06.2002

B-18

DS200 Installation Guide

If the chip enabling conferencing with up to 16 participants, which is offered optionally is to

be utilized within the system, then insert this into the socket that is reserved for it on the

UTIL200 card of the first rack. While inserting the chip into the socket, make sure positioning

of the chip is correct.

In case there is an optional conference chip in the system, since this chip needs 32 PCM

channel in order to be functional, you must leave the last two general-purpose slots (The two

general-purpose slots on the rightmost edge of the rack) of the first rack vacant.

WHILE INSERTING THE CONFERENCE CHIP INTO THE UTIL200

CARD, LEAVE THE TWO GENERAL-PURPOSE SLOTS VACANT, WHICH ARE AT

THE RIGHTMOST SIDE ON THE BACKPLANE.

I.4.C. CON2/CON3 LINE CONNECTION CARDS

The CON2 and CON3 line connection cards constitute the connection among telephones,

lines and the extension and line cards of the system. High voltage protection circuits, the

line-busy LED, grounding pins and line connection connectors are all situated on the line

connection cards.

There are four female RJ45 connectors on the CON2 card. The MDF cable with 16 pairs,

which is called CBL-16, is for CON2. The male RJ45s at one end of the CBL-16 cable are

attached to the corresponding female connectors on CON2. Cable pairs at the other end of

the CBL-16 cable should be attached to the related sections on the MDF.

There are two female RJ45 connectors on the CON3 card. The MDF cable with 8 pairs, which

is called CBL-8, is for CON3. The male RJ45s at one end of the CBL-8 cable are attached to

the corresponding female connectors on CON3. Cable pairs at the other end of the CBL-8

cable should be attached to the related sections on the MDF.

The CON2 and CON3 cards are attached to the related expansion card on the side with circuit

elements. Two 20-pin connectors on the component side of the CON2 and CON3 cards are

attached to the corresponding connectors on the component side of the expansion card.

You should connect the cables CBL-8 and CBL-16 correctly in order to experience no

problems while removing the expansion modules from the exchange and replacing them

back. Proper connection of those cables is shown in Figure 12.

It would be proper to extend the cables that go to the line connection connectors alongside

the expansion card connection connector (20-pin, white connector) in order to reduce the

space they occupy. Fixing line connection cables tightly to the expansion card by cable tie so

as their thin sides would touch the card, would provide for a trouble-free installation.

V003. 25.06.2002

B-19

DS200 Installation Guide

1. Ground contact spring

4. Line status LED

7. CBL-8 line cable

2. Line connection connector (RJ45)

5. Card status LED

8. CBL-16 line cable

3. EX200B connection connector

6. Cable tie

Figure 12

While attaching the line connection card to the expansion card, be careful about fully

inserting the connection connectors and fully fitting the line connection card into the clicks

on sides of the plastic cover. Cards that are not completely fitted cause friction with the

cards nearby, as well as they cause the LEDs on the front face not to be seen from outside,

for they would not fit.

The connectors on the line connection cards have been included only to provide for easy

replacement of the card without detaching the cabling, in case protection circuitry on the

card is damaged. While replacing the card, do not detach the cables from that connector. In

order to achieve this, during the first connection, insert the expansion module to its

corresponding place by sliding it in the slot while the cable is still loosely hanging, however,

leave it 6-7 cm before the point it is completely fixed. Then, fix the line connection cable to

the back surface of the exchange while the expansion module is in this position.

V003. 25.06.2002

B-20

DS200 Installation Guide

1. CON2 / CON3 connection card

6. Ground contact spring of rack

2. Ground contact spring of

connection card

7. CBL-8 / CBL-16 line cable

3. EX200B line card

8. Card removing latch

4. Card slot

9. Card fixing click

5. Bottom front section of rack

10. Front card cover

Figure 13

I.4.D. INSTALLING EXPANSION MODULES

This section explains integrations of the entire EX200 extension, line and network connection

modules to the system.

I.4.D.1. ATTACHING EX200 MODULES:

EX200 modules fundamentally consist of the electronic card and the card cover that

maintains connection to chassis. Figure 24 in the Technical Reference Guide shows

fundamental characteristics of a card and a card cover.

There are two points to consider while establishing the configuration of the system:

1) An extension card must be installed in the first general-purpose slot of the first rack.

2) If EX200 (1S2/0) or EX200 (1R2/0) module or modules are to be installed in the system,

then the ones that are to be utilized for data or video transmission must be installed in

the first rack, into the card slots with even numbers. On the other hand, the modules that

are to be utilized for voice transmission can be installed into the even-numbered slots of

any rack.

THE EX200 (1S2/0) OR EX200 (1R2/0) MODULES THAT ARE TO BE

UTILIZED FOR DATA OR VIDEO TRANSMISSION IN THE SYSTEM MUST BE

INSTALLED IN THE FIRST RACK OF THE EXCHANGE.

After considering criteria such as the system configuration, traffic rate (distribution of

extension and line connections to the racks), begin with installing the modules in their

corresponding slots.

Hold the module upright and make sure the corners in the rear fit lower and upper

plastic slot, then push it forward in the slot slowly and cautiously.

V003. 25.06.2002

B-21

DS200 Installation Guide

After more than half of the module has been inserted into the slot, arrange any

cable that is connected to the module.

You need to push a little bit harder so that the connector for backplane connection

fits, which is at the back of the expansion card.

Finally, push the module by gently pressing the latches upward / downward, which

are at the top and bottom of the card cover to fit it to its place.

Check if the card fixing clicks that are over the card cover latches have fit to the

holes on the chassis. Card latches that have not fit appear as in Figure 10.

Before the expansion module contacts with the backplane while it is being pushed into its

slot, the pins that are on and under the connection card provides grounding for the cards by

applying pressure on the ground contact spring. (See Figure 13).

In case it would be necessary to remove the modules following the first installation:

Pull the module by pressing the latches at the top and bottom of the card cover to

disconnect it from the backplane.

Pull the module until the line connection card gets out of the exchange. Be careful

about the cable that has been fixed under the exchange, so that it would not forced

too much by being pulled.

At this point, remove the line connection card from the expansion card and set it

free as connected to the line connection cable. Then do whatever would be

necessary by pulling the module out.

Repeat the steps above in reverse order in order to replace the card. While removing and

replacing the module, pay attention to the facts that line connection cable has been tightly

attached to the chassis, the expansion card and the connection cards are completely in

contact, and the card cover moves in a straight line parallel to slot.

MOVE THE MODULES IN A STRAIGHT LINE WHILE INSERTING OR

REMOVING, WITHOUT TILTING THEM TOWARDS RIGHT-LEFT OR IN

UPWARD-DOWNWARD DIRECTION.

See Figure 10 for the appearance of a card latch that has not fit.

I.4.D.2. CABLING OF EX200 MODULES:

After you have installed the expansion modules in the corresponding slots in the rack,

establish line or extension connections by making use of the cable pairs at the free ends of

CBL-8 or CBL-16 cables, which have properly been taken out of the rack. The following

tables present cabling information related to those connections on module basis.

I.4.D.2.1. EX200 (0/16) ANALOG EXTENSION MODULE:

Pairs in the CBL-16 cable and connected extensions are given in the table below.

V003. 25.06.2002

Pair No

Color & Signal of Pair

Extension No

White (A) Blue (B)

1st Extension

White (A) Orange (B)

2nd Extension

White (A) Green (B)

3rd Extension

White (A) Brown (B)

4th Extension

White (A) Gray (B)

5th Extension

B-22

DS200 Installation Guide

6

Red (A) Blue (B)

6th Extension

Red (A) Orange (B)

7th Extension

Red (A) Green (B)

8th Extension

Red (A) Brown (B)

9th Extension

10

Red (A) Gray (B)

10th Extension

11

Black (A) Blue (B)

11th Extension

12

Black (A) Orange (B)

12th Extension

13

Black (A) Green (B)

13th Extension

14

Black (A) Brown (B)

14th Extension

15

Black (A) Gray (B)

15th Extension

16

Yellow (A) Blue (B)

16th Extension

The order of A and B wires are not important for the connection of the cable mentioned

above to the extension phone.

I.4.D.2.2. EX200 (8/0) ANALOG LINE MODULE:

Pairs in the CBL-8 cable and connected lines are given in the table below.

Pair No

Color & Signal of Pair

Line No

White (A) Blue (B)

1st Line

White (A) Orange (B)

2nd Line

White (A) Green (B)

3rd Line

White (A) Brown (B)

4th Line

White (A) Gray (B)

5th Line

Red (A) Blue (B)

6th Line

Red (A) Orange (B)

7th Line

Red (A) Green (B)

8th Line

The order of A and B wires are not important for the connection of the cable mentioned

above to the lines. The line circuitry automatically detects polarity and takes action

accordingly.

I.4.D.2.3. EX200 (0/8S0) ISDN BRI EXTENSION MODULE:

Pairs in the CBL-16 cable and connected extensions are given in the table below.

V003. 25.06.2002

Pair No

Color & Signal of Pair

White (R1) - Blue (T1)

White (T2) Orange (R2)

White (R1) Green (T1)

White (T2) Brown (R2)

White (R1) Gray (T1)

Red (T2) Blue (R2)

Red (R1) Orange (T1)

Extension No

1st ISDN Extension

2nd ISDN

Extension

3rd ISDN Extension

4th ISDN Extension

B-23

DS200 Installation Guide

8

Red (T2) Green (R2)

Red (R1) Brown (T1)

10

Red (T2) Gray (R2)

11

Black (R1) Blue (T1)

12

Black (T2) Orange (R2)

13

Black (R1) Green (T1)

14

Black (T2) Brown (R2)

15

Black (R1) Gray (T1)

16

Yellow (T2) Blue (R2)

5th ISDN Extension

6th ISDN Extension

7th ISDN Extension

8th ISDN Extension

For the cable above, order of the four wires that are to be used for connection to ISDN

devices is important.

The signals represented as R are the receiving signals of DS200; on the other hand, the

signals represented as T are the transmitting signals. Pay attention to this order for

cabling.

Pin-signal assignments of cabling for the connection between DS200 and Iris ISDN

telephones are given in the table below:

Signal with

respect to Iris

RJ45 pins of the

Iris side

CBL-16 wires of

the DS200 side

Signal with respect

to DS200

T1

R1

R1

T1

R2

T2

T2

R2

I.4.D.2.4. EX200 (1S2/0) ISDN PRI MODULE:

The assignments required for the PRI ISDN line connections of the EX200B (1S2/0) card are

given in the table below.

Signal

D-type Connector Pin No

RJ45 Pin No

R1

R2

T1

T2

For the cable above, order of the four wires that are to be used for the ISDN connection is

important.

Pin assignments of the cable that comes with the EX200 (1S2/0) module are given with

respect to the RJ45 connectors at both ends, in the table below:

RJ45

Signal

RJ45

R1

R2

T1

T2

I.4.D.2.5. EX200 (1R2/0) R2 DIGITAL LINE MODULE:

V003. 25.06.2002

B-24

DS200 Installation Guide

The assignments required for the line connections of the EX200 (1R2/0) card are given in the

table below.

Signal

D-type Connector Pin No

RJ45 Pin No

R1

R2

T1

T2

For the cable above, order of the four wires that are to be used for the R2 connection is

important.

Pin assignments of the cable that comes with the EX200 (1R2/0) module are given with

respect to the RJ45 connectors at both ends, in the table below:

RJ45

Signal

RJ45

R1

R2

T1

T2

I.4.D.2.6. EX200 (0/8U) DIGITAL EXTENSION MODULE:

Pairs in the CBL-8 cable and connected extensions are given in the table below.

Pair No

Color & Signal of Pair

Extension No

White (A) Blue (B)

1st Extension

White (A) Orange (B)

2nd Extension

White (A) Green (B)

3rd Extension

White (A) Brown (B)

4th Extension

White (A) Gray (B)

5th Extension

Red (A) Blue (B)

6th Extension

Red (A) Orange (B)

7th Extension

Red (A) Green (B)

8th Extension

The order of A and B wires are not important for the connection of the cable mentioned

above to the extension phone.

I.4.D.2.7. EX200 (0/16U) DIGITAL EXTENSION MODULE:

Pairs in the CBL-16 cable and connected extensions are given in the table below.

V003. 25.06.2002

Pair No

Color & Signal of Pair

Extension No

White (A) Blue (B)

1st Extension

White (A) Orange (B)

2nd Extension

White (A) Green (B)

3rd Extension

White (A) Brown (B)

4th Extension

White (A) Gray (B)

5th Extension

Red (A) Blue (B)

6th Extension

Red (A) Orange (B)

7th Extension

B-25

DS200 Installation Guide

8

Red (A) Green (B)

8th Extension

Red (A) Brown (B)

9th Extension

10

Red (A) Gray (B)

10th Extension

11

Black (A) Blue (B)

11th Extension

12

Black (A) Orange (B)

12th Extension

13

Black (A) Green (B)

13th Extension

14

Black (A) Brown (B)

14th Extension

15

Black (A) Gray (B)

15th Extension

16

Yellow (A) Blue (B)

16th Extension

The order of A and B wires are not important for the connection of the cable mentioned

above to the extension phone.

I.4.D.2.8. EX200 (8 T0/S0) ISDN BRI LINE/EXTENSION MODULE:

Pairs in the CBL-16 cable and connected extensions are given in the table below.

Pair No

Color & Signal of Pair

White (R1) - Blue (T1)

White (T2) Orange (R2)

White (R1) Green (T1)

White (T2) Brown (R2)

White (R1) Gray (T1)

Red (T2) Blue (R2)

Red (R1) Orange (T1)

Red (T2) Green (R2)

Red (R1) Brown (T1)

10

Red (T2) Gray (R2)

11

Black (R1) Blue (T1)

12

Black (T2) Orange (R2)

13

Black (R1) Green (T1)

14

Black (T2) Brown (R2)

15

Black (R1) Gray (T1)

16

Yellow (T2) Blue (R2)

Line No

1st ISDN line

2nd ISDN line

3rd ISDN line

4th ISDN line

5th ISDN line

6th ISDN line

7th ISDN line

8th ISDN line

For the cable above, order of the four wires that are to be used for connection to ISDN

devices is important.

The signals represented as R are the receiving signals of DS200; on the other hand, the

signals represented as T are the transmitting signals. Pay attention to this order for

cabling.

Pin-signal assignments of cabling for the connection between DS200 and lines extending out

of NT1 (network terminating device) are given in the table below:

V003. 25.06.2002

B-26

DS200 Installation Guide

Signal with respect

to NT1

RJ45 pins of the

NT1 side

CBL-16 wires of

the DS200 side

Signal with respect

to DS200

T1

R1

R1

T1

R2

T2

T2

R2

I.4.D.2.9. EX200 (0/8LB) LOCAL BATTERY EXTENSION MODULE:

Pairs in the CBL-8 cable and connected extensions are given in the table below.

Pair No

Color & Signal of Pair

Line No

White (A) Blue (B)

1st LB Line

White (A) Orange (B)

2nd LB Line

White (A) Green (B)

3rd LB Line

White (A) Brown (B)

4th LB Line

White (A) Gray (B)

5th LB Line

Red (A) Blue (B)

6th LB Line

Red (A) Orange (B)

7th LB Line

Red (A) Green (B)

8th LB Line

The order of A and B wires are not important for the connection of the cable mentioned

above to the extension phone.

I.4.D.2.10. EX200 (4E&M/0) E&M LINE MODULE:

Pairs in the CBL-16 cable and connected extensions are given in the table below.

V003. 25.06.2002

Pair No

Color & Signal of Pair

White (E) - Blue (SG)

White (M) Orange (SB)

White (T) Green (R)

White (T1) Brown (R1)

White (T1) Gray (R1)

Red (T) Blue (R)

Red (M) Orange (SB)

Red (E) Green (SG)

Red (E) Brown (SG)

10

Red (M) Gray (SB)

11

Black (T) Blue (R)

12

Black (T1) Orange (R1)

13

Black (T1) Green (R1)

14

Black (T) Brown (R)

15

Black (M) Gray (SB)

16

Yellow (E) Blue (SG)

Line No

1st E&M Line

2nd E&M Line

3rd E&M Line

4th E&M Line

B-27

DS200 Installation Guide

Connection orders of both signaling and voice transmission wires for cabling E&M lines are

important.

These wires should be connected by being crossed within their own groups.

Those orders are given in the table below for two correspondent exchanges:

RJ45 wire order on

DS200 side

Wire order on the

Signal

opposite side

SG

SB

SB

SG

R1 (R, if it is 2-wire)

T1 (T, if it is 2-wire)

T1

R1

I.4.E. JUMPER SETTINGS ON THE EX200 (8T0/S0)

MODULE

The ISDN BRI lines of the EX200 (8 T0/S0) module can be configured as either external line or

extension. (The software with the version 1.05 does not support the configuration for

extension.) This setting operation is done trough jumpers that exist within the structure of

each line. The list of those settings are given per line in the table below:

Line Number

1st ISDN BRI line

2nd ISDN BRI line

3rd ISDN BRI line

4th ISDN BRI line

5th ISDN BRI line

6th ISDN BRI line

7th ISDN BRI line

8th ISDN BRI line

Positions of the jumpers for extension settings

K4, K5 pins 1,2 and K6, K7 pins 1,2

K8, K9 pins 1,2 and K10, K11 pins 1,2

K12, K13 pins 1,2 and K14, K15 pins 1,2

K16, K17 pins 1,2 and K18, K19 pins 1,2

K20, K21 pins 1,2 and K22, K23 pins 1,2

K24, K25 pins 1,2 and K26, K27 pins 1,2

K28, K29 pins 1,2 and K30, K31 pins 1,2

K32, K33 pins 1,2 and K34, K35 pins 1,2

Line Number

1st ISDN BRI line

2nd ISDN BRI line

3rd ISDN BRI line

4th ISDN BRI line

5th ISDN BRI line

6th ISDN BRI line

7th ISDN BRI line

8th ISDN BRI line

Positions of the jumpers for line settings

K4, K5 pins 2,3 and K6, K7 pins 2,3

K8, K9 pins 2,3 and K10, K11 pins 2,3

K12, K13 pins 2,3 and K14, K15 pins 2,3

K16, K17 pins 2,3 and K18, K19 pins 2,3

K20, K21 pins 2,3 and K22, K23 pins 2,3

K24, K25 pins 2,3 and K26, K27 pins 2,3

K28, K29 pins 2,3 and K30, K31 pins 2,3

K32, K33 pins 2,3 and K34, K35 pins 2,3

V003. 25.06.2002

B-28

DS200 Installation Guide

I.4.F. JUMPER SETTINGS ON THE EX200 (4E&M/0)

MODULE

Since several different configurations are possible for the E&M module, unlike the others,

some configuration settings must be done on it before it is installed in the system. Those

settings are done through jumpers. A list of jumper settings for different configurations is as

follows:

A) FOR THE SIGNALING CHANNEL CONFIGURATION:

Type 1:

TRUNKING SIDE

E&M channel 1: JP1, JP4, JP17, JP19, JP22

E&M channel 2: JP5, JP8, JP31, JP33, JP36

E&M channel 3: JP9, JP12, JP24, JP26, JP29

E&M channel 4: JP13, JP16, JP38, JP40, JP43

SIGNALING SIDE

E&M channel 1: JP2, JP3, JP19, JP21

E&M channel 2: JP6, JP7, JP33, JP35

E&M channel 3: JP10, JP11, JP26, JP28

E&M channel 4: JP14, JP15, JP40, JP42

Type 2:

TRUNKING SIDE

E&M channel 1: JP1, JP4, JP19, JP20

E&M channel 2: JP5, JP8, JP33, JP34

E&M channel 3: JP9, JP12, JP26, JP27

E&M channel 4: JP13, JP16, JP40, JP41

SIGNALING SIDE

E&M channel 1: JP2, JP3, JP21, JP23

E&M channel 2: JP6, JP7, JP35, JP37

E&M channel 3: JP10, JP11, JP28, JP30

E&M channel 4: JP14, JP15, JP42, JP44

Type 3:

TRUNKING SIDE

E&M channel 1: JP1, JP4, JP17, JP19, JP20

E&M channel 2: JP5, JP8, JP31, JP33, JP34

E&M channel 3: JP9, JP12, JP24, JP26, JP27

E&M channel 4: JP13, JP16, JP38, JP40, JP41

V003. 25.06.2002

B-29

DS200 Installation Guide

SIGNALING SIDE

E&M channel 1: JP2, JP3, JP19, JP21, JP23

E&M channel 2: JP6, JP7, JP33, JP35, JP37

E&M channel 3: JP10, JP11, JP26, JP28, JP30

E&M channel 4: JP14, JP15, JP40, JP42, JP44

Type 4:

TRUNKING SIDE

E&M channel 1: JP1, JP4, JP19, JP20

E&M channel 2: JP5, JP8, JP33, JP34

E&M channel 3: JP9, JP12, JP26, JP27

E&M channel 4: JP13, JP16, JP40, JP41

SIGNALING SIDE

E&M channel 1: JP1, JP4, JP18, JP21

E&M channel 2: JP5 JP8, JP32, JP35

E&M channel 3: JP9, JP12, JP25, JP28

E&M channel 4: JP13, JP16, JP39, JP42

Type 5

TRUNKING SIDE

E&M channel 1: JP1, JP4, JP19, JP21

E&M channel 2: JP5, JP8, JP33, JP35

E&M channel 3: JP9, JP12, JP26, JP28

E&M channel 4: JP13, JP16, JP40, JP42

SIGNALING SIDE

E&M channel 1: JP1, JP4, JP19, JP21

E&M channel 2: JP5 JP8, JP33, JP35

E&M channel 3: JP9, JP12, JP26, JP28

E&M channel 4: JP13, JP16, JP40, JP42

B) FOR SPEECH CHANNEL CONNECTION

Two-wire connection

E&M channel 1: JP45, JP46

E&M channel 2: JP48, JP49

E&M channel 3: JP51, JP52

E&M channel 4: JP54, JP55

Four-wire connection

E&M channel 1: JP47

E&M channel 2: JP50

E&M channel 3: JP53

E&M channel 4: JP56

V003. 25.06.2002

B-30

DS200 Installation Guide

I.4.G. INSTALLATION OF THE EVM200L MODULE

Integration of the EVM200L module to the system is the same as that of the EX200 cards.

However, there are two points that differ from the case for the EX200 modules:

1) No cabling is needed for EVM200L installation,

2) EVM-FL Flash ROM Auto Attendant message module or EVM-DL, DRAM voice mail

module can be installed on the EVM200L module in order to increase the capacity of Auto

Attendant or voice mail.

On the EVM200L card, there are two slots in which the EVM-FL card can be installed and

there are four slots in which the EVM-DL card can be installed. Figure 14 shows locations

of those slots on the card:

Figure 14

The EVM-FL or EVM-DL cards can be installed in the slots reserved for them without respect

to any order.

After the installation of EVM-FL or EVM-DL is over, hold the module upright and make sure

the corners in the rear fit lower and upper plastic slot, then push it forward in the slot slowly

and cautiously. You need to push a little bit harder so that the connector for backplane

connection fits, which is at the back of the EVM200L card. In this final step, push the module

by gently pressing the latches upward / downward, which are at the top and bottom of the

card cover and make sure the module fits completely.

Check if the card fixing clicks that are over the card cover latches have fit to the holes on the

chassis. Card latch that has not fit appears as in Figure 10.

In case it would be necessary to remove the module following the first installation, pull the

module by pressing the latches at the top and bottom of the card cover to disconnect it from

the backplane. Then, pull it until it gets out of the exchange.

I.5. THE FINAL PREPARATIONS

Upon completion of all those operations, connect the computer to the system, to which the

ADMIN200 has been loaded. For this, connect one end of the computer cable, which comes

with DS200, to the RS232 output on the DS200 CPUKON card. As for the other end of the

cable, connect it to the related serial port on the computer.

In addition to that, you need to connect an LT200 (-H) or FT20 Feature Telephone set as the

operator telephone in order to watch the tests closely that would be carried out on the

system. For this, plug the two-pin end of the cable, which comes with DS200 with a two-pin

V003. 25.06.2002

B-31

DS200 Installation Guide

connector at one end and with telephone connection box on the other, into one of the KTS

ports that are on the DS200 CPUKON card. Additionally, connect the first extension of the

first EX200 (0/16) card (blue-white pair) to the red and green ends of the connection box that

is at the other end of that cable.

Details about those connections have been explained in the guides of the related telephones

and in the ADMIN200 guide.

V003. 25.06.2002

B-32

DS200 Installation Guide

II. PUTTING THE SYSTEM ON LINE

After all the cards have been installed, the system is ready to be powered.

The methods for properly powering the system have been listed below for different system

configurations:

II.1. SINGLE-RACK, WALL-TYPE SYSTEM

1) Make sure the entire cables in the rack have been connected properly.

2) Check if the mains and battery switches on the SPS200 module are off.

3) Connect the mains cord to the SPS200 module and then plug it into an outlet of the

premise that has been properly grounded.

4) Connect the batteries (if battery connection is to be made) to the battery connectors

of the SPS200 module.

5) Turn on the mains switch on the SPS200 module.

6) Turn on the battery switch on the SPS200 module.

II.2. TWO-RACK WALL-TYPE SYSTEM

1) Make sure the entire inner-rack and inter-rack connections have been made

properly.

2) Check if the mains and battery switches on the entire SPS200 modules are off.

3) Connect the mains cords to the SPS200 modules and then plug them into an outlet of

the premise that has been properly grounded.

4) Connect the batteries (if battery connection is to be made) to the battery connectors

of the first SPS200 module (Note that no connection shall be made to the second

SPS200 module.)

5) Turn on the mains switches on the SPS200 modules.

6) Turn on the battery switch that is on the SPS200 module to which the batteries have

been connected.

II.3. CABINET-TYPE SYSTEM

1) Make sure the entire inner-rack and inter-rack connections have been made

properly.

2) Check, if the primary mains switch, which is on the control panel of the cabinet, is off.

3) Check, if the primary battery switch, which is on the control panel of the cabinet, is

off.

4) Check if the mains and battery switches on the entire SPS200 modules are off.

V003. 25.06.2002

B-33

DS200 Installation Guide

5) Plug the mains cords of the entire SPS200 modules into the mains outlets that are on

the control panel of the cabinet.

6) Plug the mains cord that comes from the mains outlets on the control panel of the

cabinet into an outlet of the premise that has been properly grounded. Since the

primary mains switch is protected with a fuse of 10 A, the mains outlet of the premise

must be protected with a higher-rate fuse.

7) Connect the batteries (if battery connection is to be made) to the battery connection

points on the cabinet.

8) Make the connection from the primary battery switch to the first of the SPS200

battery connectors (Note that the battery connection is not made to the entire SPS200

modules.)

9) Turn on the entire mains switches on the SPS200 modules, beginning with the

SPS200 module in the first rack.

10) Turn on the battery switch that is on the SPS200 module to which the batteries have

been connected.

11) Turn on the primary mains switch that is on the control panel of the cabinet.

12) Turn on the primary battery switch that is on the control panel of the cabinet.

13) Turn on the two fan switches that are on the control panel of the cabinet. The fans

must be working while the system is in operation.

II.4. TWO-CABINET SYSTEM

1) Make sure the inner-rack, inter-rack and inter-cabinet connections have been made

properly.

2) Check if the primary mains switches that are on the control panels of the cabinets are

off.

3) Check if the primary battery switches that are on the control panels of the cabinets

are off.

4) Check if the mains and battery switches on the entire SPS200 modules are off.

5) Plug the mains cords of the entire SPS200 modules into the mains outlets that are on

the control panels of the cabinets.

6) Plug the mains cords that come from the mains outlets on the control panels of the

cabinets into outlets of the premise that have been properly grounded. Since the

primary mains switch is protected with a fuse of 10 A, the mains outlet of the premise

must be protected with a higher-rate fuse.

7) Connect the batteries (if battery connection is to be made) to the primary battery

connection points on the first cabinet.

8) Make the connection from the battery switch to the first of the SPS200 battery

connectors (Note that the battery connection is not made to the entire SPS200

modules and it is made only for one cabinet.)

9) Turn on the entire mains switches on the SPS200 modules, beginning with the

SPS200 module in the first rack.

10) Turn on the battery switch that is on the SPS200 module to which the batteries have

been connected.

11) Turn on the primary mains switch that is on the control panel of the second cabinet.

V003. 25.06.2002

B-34

DS200 Installation Guide

12) Turn on the primary mains switch that is on the control panel of the first cabinet.

13) Turn on the primary battery switch that is on the control panel of the first cabinet.

14) Turn on the fan switches that are on the control panels of the cabinets. The fans must

be working while the system is in operation.

After being powered, the system carries out a series of automatic tests in order to check the

current configuration. Beginning with the card in the rightmost slot, two LEDs that are on the

front plastic panel of each card start to light in a row. This action begins with the bottom

rack.

After the entire LEDs have begun to light, the message connecting appears on LCD screen

of LT200 (-H) or FT20 feature telephone that is connected to the system. Once that message

disappears, the system is ready to operate.

WARNING

1) In order to turn on and off a cabinet-type system, use the

mains and battery switches that are in front of the cabinet.

2) The correct way of powering the system is

batteries on line after turning the system on.

putting

the

3) The correct way of shutting down the system is putting the