Escolar Documentos

Profissional Documentos

Cultura Documentos

Simulink Modeling For An Electrical Vehicle

Enviado por

Gadam Siva Charan DasDescrição original:

Título original

Direitos autorais

Formatos disponíveis

Compartilhar este documento

Compartilhar ou incorporar documento

Você considera este documento útil?

Este conteúdo é inapropriado?

Denunciar este documentoDireitos autorais:

Formatos disponíveis

Simulink Modeling For An Electrical Vehicle

Enviado por

Gadam Siva Charan DasDireitos autorais:

Formatos disponíveis

GECE553 Real-time Simulator

Electrical and Computer Engineering Department

Gannon University

Yong-Kyu Jung, Ph.D.

Simulink Modeling for an Electrical Vehicle

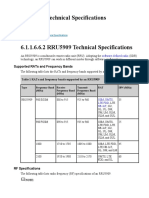

A schematic of the RT-Sim suite shown in Figure 1 (a) has been developed for

evaluation of the RT-Sim. The developed RT-Sim suite is illustrated in Figure 1. Figure

1 (a) is the console client. Figure 1 (b) and (c) are the hardware module and the RT-Sim

respectively. The hardware module consisting of an FPGA and an interface boards is

also shown in Figure 1 (b). The console and the RT-Sim are connected with 100 M bps

socket-based Ethernet. The hardware module for the HIL simulation is connected to the

RT-Sim via the PCI card for 8 analog outputs (i.e., +/- 12 Volts), 3 digital outputs, and

4 digital inputs (5 Volts). The interface board converts LVTTL and/or PCI 33/66 MHz

and AGP-2X single-ended type signals (i.e., 3.3 Volts) received from the FPGA board

to 5 Volts TTL signals vice versa although the FPGA board supports 19 different

standards including LVTTL, LVCMOS2/18, Bus LVDS, and so forth. Two 14-bit

output ADCs with 1.5 M Hz sampling rate are used for analog inputs to the hardware

models programmed in the FPGA. A 12-bit resolution DAC with 6 analog outputs

including a VCC and a ground signals is used for analog outputs to the PCI card.

(a)

(b)

(c)

Figure 1. An Evaluation Setup of the RT-Sim Suite

1.

An Electric Vehicle (EV)

A subsystem of an EV was used for evaluation of the RT-Sim suite. As seen in

Figure 2 (a), the complete Simulink closed-loop model of an EV subsystem was

modeled. The EV subsystem consists of a battery for supplying DC power, a DC motor

for driving, and components for sensing speed of EV and charging level of the battery,

and a control unit for controlling speed and torque of the DC motor. The EV subsystem

includes a 25 horsepower, four quadrant operation wound DC motor. The model is

designed to execute in discrete time with a sampling rate of 5 micro-seconds. The

control unit controls speed of the armature. Inputs of the control unit are the desired

speed, in RPM, and the armature speed, in RPM. Outputs of the control unit are the

speed change and armature current. The control unit controls the armature current and

1

GECE553 Real-time Simulator

Electrical and Computer Engineering Department

Gannon University

Yong-Kyu Jung, Ph.D.

prevents the current from surpassing the rated armature current. Inputs of the control

unit are the armature current, armature speed, speed change, and change in armature

current. The control unit outputs the PWM pulses to set the armature voltage to the

desired voltage to achieve the desired armature speed. The control unit also outputs the

control values used to generate the PWM pulses. The DC motor is connected to a 30

volt battery with a linear load torque. The DC motor subsystem block, illustrated in

Figure 2 (a), contains a DC-DC converter connected to the PWM pulses to provide the

desired armature voltage. The motor inputs are the torque load, PWM pulses, and

battery voltage. The motor outputs are the armature current, armature speed, armature

voltage, and the field voltage.

(a)

(b)

Figure 2. (a) Complete Electric Vehicle Simulink Model and (b) Simulink

Simulation Results

Figure 2 (b) illustrates the simulation results with the reference speed and

engine speed. The results, with a reference speed of 300 RPM, illustrate that the motor

is able to achieve the desired speed within 0.3 seconds with a 10 RPM overshoot. These

results are used as the baseline for the SIL and HIL evaluation of the RT-Sim.

GECE553 Real-time Simulator

Electrical and Computer Engineering Department

Gannon University

Yong-Kyu Jung, Ph.D.

1.1. Speed Controller Design

Figure 3 illustrates the contents of the speed controller. The two inputs of the

speed controller are Motor and Speed. The Motor input is the armature speed feedback

from the DC motor. The Speed input is the reference speed that the motor is to be

running.

The three outputs of the Speed Controller are Ia*(p.u.), N*, and d_N. The

Ia*(p.u.) output is the required armature current per unit request to be processed by the

current controller. The N* output is the rate limited reference speed utilized to ensure

that the motor does not accelerate too quickly. The d_N output is the difference

between the armature speed and the reference speed.

The speed controller is a PI controller which calculates the armature current per

unit to be used by the current controller. The reference speed is rate limited before the

reference speed and armature speed pass through the PI controller. The output of the PI

controller is saturated to ensure that the armature current does not surpass the rated

current of the motor.

Figure 3. Contents of Speed Controller.

1.2. Current Controller Design

Figure 4 illustrates the top-level sub-systems of the current controller, a

regulation switch and current controller. The regulation switch regulates the armature

current request passing through to the current controller. The current controller

contains a PI controller and a PWM cenerator which transmits the PWM pulses to the

IGBT of the DC motor subsystem.

The inputs of the current controller are Motor, Speed, N*, d_N, and Ia*(p.u.)

The motor input is the feedback from the DC motor, the armature current and field

current feedback values are used. The Speed input is the reference speed that the DC

motor is to be running. The N* input is the rate limited version of the reference speed.

The d_N input is the difference between the reference speed and the armature speed.

The Ia*(p.u.) is the requested armature current generated by the speed controller.

3

GECE553 Real-time Simulator

Electrical and Computer Engineering Department

Gannon University

Yong-Kyu Jung, Ph.D.

The outputs of the current controller are Pulses and Ctrl. The Pulses output is

the multiplexed values of the PWM generator fed to the IGBT of the DC Motor

subsystem. The Ctrl output is a bus creator that is used for debugging purposes during

the simulation.

Figure 4. Subsystems of Current Controller.

1.3.

Regulation Switch Design

Figure 5 illustrates the contents of the regulation switch, which regulates the

armature current request going into the current controller. The inputs of the regulation

switch subsystem are d_i, If, T*, N*, d_N, and Ia*(p.u.). The d_i input is the current

feedback from the current controller. The input is the field current feedback from the

DC motor. The T* input is the reference speed that the motor should go. The d_N input

is the difference between the armature and reference speeds. The Ia*(p.u.) input is the

generated armature current output generated by the speed controller.

The outputs of the regulation switch subsystem are Ia*(p.u.), d, and Ref. The

Ia*(p.u.) output is the regularized armature current feeding into the current controller.

The d output is the multiplication value of the current feedback and the field current,

used for debugging purposes. The Ref. output is the reference speed, used for

debugging purposes.

GECE553 Real-time Simulator

Electrical and Computer Engineering Department

Gannon University

Yong-Kyu Jung, Ph.D.

Figure 5. Content of Regulation Switch.

1.4.

Current Controller Design

Figure 6 illustrates the design of the current controller. The current controller

subsystem utilizes a PI controller and a PWM generator which outputs PWM pulses

into the DC motor subsystem. The inputs of the current controller are Ia and Ia*(p.u.).

The Ia input is the armature current feedback from the DC motor. The Ia*(p.u.) input is

the requested armature current which is output by the speed controller.

The current controller subsystem outputs are PWM_Ref, Pulses, SawTooth,

DCycles, Ia*, and d_i. The PWM_Ref output is the Vcontrol output of the PI controller.

The Pulses output is the PWM output, which is comprised of four multiplexed values

with PWMs 1 and 4 having the same value and PWMs 2 and 3 having the same value.

The SawTooth output is the saw tooth generator value and is used for debugging

purposes. The DCycles output is the duty cycle used by each of the four PWMs. The Ia*

output is the converted Ia*(p.u.) value, which is the speed controller output. The d_i

output is the difference between the armature current and the current output by the

speed controller.

GECE553 Real-time Simulator

Electrical and Computer Engineering Department

Gannon University

Yong-Kyu Jung, Ph.D.

Figure 6. Content of Current Controller.

1.5.

Current PI Controller Design

Figure 7 illustrates the content of the PI controller of the current controller

subsystem. The inputs of the PI controller are Ia and Iref. The Ia input is the armature

current feedback from the DC motor. The Iref input is the reference armature currrent

generated by the speed controller.

The PI controller subsystem has one output, Ec. The Ec output is equivalent to

Vcontrol and indicates the equivalent voltage that should be supplied to the DC motor

to generate the appropriate armature current.

Figure 7. Content of Current PI Controller.

1.6.

PWM Subsystem Design

Figure 8 (a) illustrates the content of the PWM generator of the current

controller subsystem. The input of the PWM subsystem is Ref, which is the equivalent

voltage level that the subsystem should output to the DC motor. The outputs of the

PWM subsystem are Pulses and SawTooth. The Pulses output is the multiplexed values

GECE553 Real-time Simulator

Electrical and Computer Engineering Department

Gannon University

Yong-Kyu Jung, Ph.D.

of the Ref input compared to the value of the sawtooth generator. The SawTooth output

is the saw tooth generator value that is used to determine the Pulses output.

Figure 8 (b) illustrates the content of the Sawtooth Generator subsystem of the

PWM subsystem. The Sawtooth Generator subsystem has no inputs and one output,

Out. The Out output is the value of the saw tooth generator that is to be compared with

the Ref. input.

(a)

(b)

Figure 8. Content of (a) PWM Subsystem, (b) Sawtooth Generator, (c) Duty Cycle

1.7. DC Motor Subsystem Design

Figure 9 illustrates the contents of the DC motor subsystem. The motor

subsystem contains two traditional inputs, TL and Pulses. The TL input is the torque

load that is applied to the DC motor. The Pulses input is the four PWM pulses that are

fed into the IGBT subsystem to provide the current voltage level to the DC motor. The

motor subsystem also contains two power system inputs, Va+ and Va-. The Va+ and

7

GECE553 Real-time Simulator

Electrical and Computer Engineering Department

Gannon University

Yong-Kyu Jung, Ph.D.

Va- inputs are connected to the battery and provide the IGBT with the voltage level to

be regulated.

The DC motor subsystem provides three outputs, Motor, Wm, and If. The

Motor output provides the speed and controllers with feedback values corresponding

with the current state of the motor. The Wm outputs the armature speed in radians per

seconds.

(a)

Figure 9. (a) Content of DC Motor Subsystem and (b) Moter Creator.

Você também pode gostar

- Implement Four-Quadrant Chopper DC Drive - Simulink - MathWorks IndiaDocumento9 páginasImplement Four-Quadrant Chopper DC Drive - Simulink - MathWorks IndiaAbhilash PatelAinda não há avaliações

- H09344550 PDFDocumento6 páginasH09344550 PDFkavyaAinda não há avaliações

- Simulation work on Fractional Order PIλ Control Strategy for speed control of DC motor based on stability boundary locus methodDocumento7 páginasSimulation work on Fractional Order PIλ Control Strategy for speed control of DC motor based on stability boundary locus methodseventhsensegroupAinda não há avaliações

- Simulation & Controlling of Brushless DC Motor Using PI/Fuzzy HybridDocumento4 páginasSimulation & Controlling of Brushless DC Motor Using PI/Fuzzy Hybridsunil kumarAinda não há avaliações

- PID Practical PDFDocumento18 páginasPID Practical PDFJose Luis HurtadoAinda não há avaliações

- DESIGNING THE PROPORTIONAL (P) AND PROPORTIONAL-INTEGRAL (PI) CONTROLLERS Control SystemDocumento7 páginasDESIGNING THE PROPORTIONAL (P) AND PROPORTIONAL-INTEGRAL (PI) CONTROLLERS Control SystemjayxcellAinda não há avaliações

- Indirect Vector Control of Induction MotorDocumento5 páginasIndirect Vector Control of Induction MotorCharlotte ReynoldsAinda não há avaliações

- Design and Implementation of PID Controller For Motor Position ControlDocumento5 páginasDesign and Implementation of PID Controller For Motor Position ControlOwais Ahmad KhanAinda não há avaliações

- Co-Simulation of BLDC Motor Commutation by Using MDocumento7 páginasCo-Simulation of BLDC Motor Commutation by Using Mahurtado017Ainda não há avaliações

- Design and Implementation of IGBT Based Single Phase AC Drive Using PIC 18F452Documento4 páginasDesign and Implementation of IGBT Based Single Phase AC Drive Using PIC 18F452lajosmol100% (1)

- PID Controller For A Two Quadrant Chopper Fed DC Motor DriveDocumento5 páginasPID Controller For A Two Quadrant Chopper Fed DC Motor DriveSalman HabibAinda não há avaliações

- Ijetae 0812 25 PDFDocumento10 páginasIjetae 0812 25 PDFvishiwizardAinda não há avaliações

- Topic 6 and 7 - DC and AC DrivesDocumento26 páginasTopic 6 and 7 - DC and AC DrivesAvinesh ChandAinda não há avaliações

- Speed Control DC Motor Under Varying Load Using Phase-Locked Loop SystemDocumento5 páginasSpeed Control DC Motor Under Varying Load Using Phase-Locked Loop SystemAwdhesh SawhneyAinda não há avaliações

- Hybrid Electric VehicleDocumento11 páginasHybrid Electric VehicleOnur ATASEVENAinda não há avaliações

- PID Speed Control of DC Motor Using MicrocontrollerDocumento7 páginasPID Speed Control of DC Motor Using MicrocontrollerGias NawariAinda não há avaliações

- DSP Based Real Time Implementation of AC-DC-AC Converter Using SPWM TechniqueDocumento18 páginasDSP Based Real Time Implementation of AC-DC-AC Converter Using SPWM Techniquebalamurugan041992Ainda não há avaliações

- Advanced Three Phase PWM Inverter Control Using MicrocontrollerDocumento8 páginasAdvanced Three Phase PWM Inverter Control Using MicrocontrollerAbdur Rehman TayyabAinda não há avaliações

- Harmonics and Torque Ripple Reduction of Brushless DC Motor (BLDCM) Using Cascaded H-Bridge Multilevel InverterDocumento4 páginasHarmonics and Torque Ripple Reduction of Brushless DC Motor (BLDCM) Using Cascaded H-Bridge Multilevel InverterNirmalaNeeruAinda não há avaliações

- Design of PLC-based PI Controller For TH PDFDocumento5 páginasDesign of PLC-based PI Controller For TH PDFRamesh SahniAinda não há avaliações

- DC Motor Speed Control System - ED4400BDocumento14 páginasDC Motor Speed Control System - ED4400BDanang Pradika Purnomo100% (1)

- Syllignakis J. Et AlDocumento14 páginasSyllignakis J. Et Alali ghalibAinda não há avaliações

- Speed Control of Single Phase Induction Motor Using AC Chopper by Asymmetrical PWM TechniqueDocumento6 páginasSpeed Control of Single Phase Induction Motor Using AC Chopper by Asymmetrical PWM TechniqueGRD Journals100% (2)

- 00718a - Brush-DC Servomotor Implementation Using PIC17C756ADocumento33 páginas00718a - Brush-DC Servomotor Implementation Using PIC17C756AadisaksAinda não há avaliações

- DC Motor PI ControllerDocumento6 páginasDC Motor PI ControllerPooja MaathAinda não há avaliações

- Design of Antiwindup AVR For Synchronous Generator Using Matlab SimulationDocumento9 páginasDesign of Antiwindup AVR For Synchronous Generator Using Matlab SimulationusefiAinda não há avaliações

- Design and Construction of Single Phase Pure Sine Wave Inverter For Photo Voltaic ApplicationDocumento4 páginasDesign and Construction of Single Phase Pure Sine Wave Inverter For Photo Voltaic ApplicationRafid Haider ShantonuAinda não há avaliações

- P. F Correction Control of 3-Ф Induction Motor Drive through PWM Current Controlled TechniqueDocumento6 páginasP. F Correction Control of 3-Ф Induction Motor Drive through PWM Current Controlled TechniqueDivya ShriAinda não há avaliações

- MATLABSimulink, Stepper Motor, Vector ControlDocumento5 páginasMATLABSimulink, Stepper Motor, Vector ControlDobai SzilardAinda não há avaliações

- Speed Control of DC Motor Using Pid Controller BasedDocumento16 páginasSpeed Control of DC Motor Using Pid Controller Basedayesha amjadAinda não há avaliações

- Matlab-Simulink Controller DesignDocumento4 páginasMatlab-Simulink Controller DesignMohamed SomaiAinda não há avaliações

- GTO RectifierDocumento13 páginasGTO RectifierBijay PoudelAinda não há avaliações

- Embedded Four Switch Three Phase Inverter Fed Induction Motor DriveDocumento6 páginasEmbedded Four Switch Three Phase Inverter Fed Induction Motor DriveTJPRC PublicationsAinda não há avaliações

- DC Link Approach To Variable-Speed, Sensorless,: Induction Motor DriveDocumento5 páginasDC Link Approach To Variable-Speed, Sensorless,: Induction Motor DrivesamirmansourAinda não há avaliações

- Speed Control of Brushless DC Motor Using Fuzzy Logic ControllerDocumento9 páginasSpeed Control of Brushless DC Motor Using Fuzzy Logic ControllerIOSRjournalAinda não há avaliações

- Ijert Ijert: Control of Three Phase BLDC Motor Using Fuzzy Logic ControllerDocumento5 páginasIjert Ijert: Control of Three Phase BLDC Motor Using Fuzzy Logic ControllergbksnAinda não há avaliações

- Performance of A 4-Switch, 3-Phase Inverter Fed Induction Motor (IM) Drive SystemDocumento5 páginasPerformance of A 4-Switch, 3-Phase Inverter Fed Induction Motor (IM) Drive SystemInternational Journal of Application or Innovation in Engineering & ManagementAinda não há avaliações

- An Overview of PLC Based Control Panel System For External Plunge Grinding Machine and CNC MachineDocumento3 páginasAn Overview of PLC Based Control Panel System For External Plunge Grinding Machine and CNC MachineIJMERAinda não há avaliações

- Four-Quadrant Single-Phase Rectifier DC DriveDocumento14 páginasFour-Quadrant Single-Phase Rectifier DC DriveBivolaru AndreiAinda não há avaliações

- Advanced Control System Lab PDFDocumento15 páginasAdvanced Control System Lab PDFarpitg2208Ainda não há avaliações

- Automation of Rotogravure Printing MachineDocumento12 páginasAutomation of Rotogravure Printing MachineshraddhaAinda não há avaliações

- Tuning A PID Controller For A Digital Excitation Control SystemDocumento8 páginasTuning A PID Controller For A Digital Excitation Control SystemSharat Chandra KeswarAinda não há avaliações

- Simulation DC Motor Speed Control System by Using PID ControllerDocumento6 páginasSimulation DC Motor Speed Control System by Using PID ControllerEditor IJTSRDAinda não há avaliações

- Ac 2011-1439: Fuzzy Logic-Based PMDC Motor Controller - An Undergraduate Student ProjectDocumento13 páginasAc 2011-1439: Fuzzy Logic-Based PMDC Motor Controller - An Undergraduate Student ProjectFlorin CiudinAinda não há avaliações

- EnhancDocumento7 páginasEnhancsofAinda não há avaliações

- Position Control of An AC Servo Motor Using VHDL & Fpga: Kariyappa B. S., Hariprasad S. A., and R. NagarajDocumento4 páginasPosition Control of An AC Servo Motor Using VHDL & Fpga: Kariyappa B. S., Hariprasad S. A., and R. NagarajBalu ViswanathAinda não há avaliações

- N EOM Project Report: Fuzzy-Pid ControllerDocumento35 páginasN EOM Project Report: Fuzzy-Pid ControllerAnime XAinda não há avaliações

- 1 SMDocumento7 páginas1 SMaswardi8756Ainda não há avaliações

- Paris, FranceICSTEM (2019)Documento6 páginasParis, FranceICSTEM (2019)Dr. D. V. KamathAinda não há avaliações

- Three-Phase Induction Motor Drive by FPGADocumento6 páginasThree-Phase Induction Motor Drive by FPGAmani_kumar_16100% (2)

- Final Report Acs 12Documento36 páginasFinal Report Acs 12Abhishek SinghAinda não há avaliações

- Ijert Ijert: Microcontroller Controlled BLDC Drive For Electric Vehicle Raju Yanamshetti, Juhi Nishat AnsariDocumento4 páginasIjert Ijert: Microcontroller Controlled BLDC Drive For Electric Vehicle Raju Yanamshetti, Juhi Nishat AnsariAvinash Babu KmAinda não há avaliações

- Controlling 3-Phase AC Induction Motors Using PIC18F4431Documento24 páginasControlling 3-Phase AC Induction Motors Using PIC18F4431sanct1Ainda não há avaliações

- (P1) Modul DC Motor Speed Control SystemDocumento13 páginas(P1) Modul DC Motor Speed Control SystemTito Bambang Priambodo - 6726Ainda não há avaliações

- DSP-Based Experimental Rig With The Doubly-Fed Induction Generator ForDocumento12 páginasDSP-Based Experimental Rig With The Doubly-Fed Induction Generator Fordebasis250Ainda não há avaliações

- Experimental Setup For Ac Motor Speed Control by Using PLC: Journal of Scientific PerspectivesDocumento12 páginasExperimental Setup For Ac Motor Speed Control by Using PLC: Journal of Scientific PerspectivesMounir BelalaAinda não há avaliações

- Variable Speed AC Drives with Inverter Output FiltersNo EverandVariable Speed AC Drives with Inverter Output FiltersAinda não há avaliações

- Simulation of Some Power System, Control System and Power Electronics Case Studies Using Matlab and PowerWorld SimulatorNo EverandSimulation of Some Power System, Control System and Power Electronics Case Studies Using Matlab and PowerWorld SimulatorAinda não há avaliações

- Power Systems-On-Chip: Practical Aspects of DesignNo EverandPower Systems-On-Chip: Practical Aspects of DesignBruno AllardAinda não há avaliações

- Power System Transient Analysis: Theory and Practice using Simulation Programs (ATP-EMTP)No EverandPower System Transient Analysis: Theory and Practice using Simulation Programs (ATP-EMTP)Ainda não há avaliações

- An-ION-1-1100 Introduction To The CANopen ProtocolDocumento9 páginasAn-ION-1-1100 Introduction To The CANopen ProtocolGadam Siva Charan DasAinda não há avaliações

- LLF Series: Vertical Fast Lift Float SwitchesDocumento1 páginaLLF Series: Vertical Fast Lift Float SwitchesGadam Siva Charan DasAinda não há avaliações

- Jawaharlal Technological University Ananthapur, AnanthapuramuDocumento2 páginasJawaharlal Technological University Ananthapur, AnanthapuramuGadam Siva Charan DasAinda não há avaliações

- Circuit BreakerDocumento10 páginasCircuit BreakerGadam Siva Charan DasAinda não há avaliações

- 5 - Control System TrainerDocumento50 páginas5 - Control System TrainerGadam Siva Charan DasAinda não há avaliações

- Flight Inspection of GAST D Approach and Taxi Guidance Systems - v1Documento10 páginasFlight Inspection of GAST D Approach and Taxi Guidance Systems - v1Olivier LaylyAinda não há avaliações

- Newton First Law of MotionDocumento6 páginasNewton First Law of MotionKin ChristineAinda não há avaliações

- GPS 2Documento6 páginasGPS 2Arnold Alexander GarzonAinda não há avaliações

- When Bad Things Happen To Good MissilesDocumento9 páginasWhen Bad Things Happen To Good Missilesmykingboody2156Ainda não há avaliações

- 支持允許多個 Vlan 的 Trunk 接口。: Techtalk/Td-P/58419Documento6 páginas支持允許多個 Vlan 的 Trunk 接口。: Techtalk/Td-P/58419000-924680Ainda não há avaliações

- LYNQ 2020 Installation GuideDocumento16 páginasLYNQ 2020 Installation GuideasdfsadfasdfAinda não há avaliações

- RRU5909 Technical SpecificationsDocumento7 páginasRRU5909 Technical SpecificationsDmitry059100% (1)

- Topic 4Documento23 páginasTopic 4Joe HanAinda não há avaliações

- Selection of Antifriction BearingsDocumento22 páginasSelection of Antifriction BearingsSunil MandoreAinda não há avaliações

- Drive Shafts For Steel Production/ Industrial EquipmentDocumento36 páginasDrive Shafts For Steel Production/ Industrial EquipmentEdna Odette Melo UscangaAinda não há avaliações

- What Is Not Said: Metaphor and The Deflationary Account: Chris GenovesiDocumento13 páginasWhat Is Not Said: Metaphor and The Deflationary Account: Chris GenovesimiprofesorjaviAinda não há avaliações

- Boiler Efficiency R K JainDocumento28 páginasBoiler Efficiency R K JainPriyesh KumarAinda não há avaliações

- MPMC Unit 2Documento31 páginasMPMC Unit 2nikitaAinda não há avaliações

- CADCAM PortfolioDocumento5 páginasCADCAM PortfolioGuhan MAinda não há avaliações

- UNIT - 3: Fast-Fourier-Transform (FFT) Algorithms: Dr. Manjunatha. PDocumento100 páginasUNIT - 3: Fast-Fourier-Transform (FFT) Algorithms: Dr. Manjunatha. PMVRajeshMaliyeckalAinda não há avaliações

- FMF-01-10-911-302 - 100 GPM - 60 HZ Electric Motor DriveDocumento1 páginaFMF-01-10-911-302 - 100 GPM - 60 HZ Electric Motor DriveMarkAinda não há avaliações

- 1 Seam 2 LM FinalDocumento84 páginas1 Seam 2 LM FinalTrestan TenegraAinda não há avaliações

- Re - (Repeater-Builder) Midland Vehicular Repeater InfoDocumento3 páginasRe - (Repeater-Builder) Midland Vehicular Repeater InfobbarinkAinda não há avaliações

- 3107 Enthusiast Score Advanced Paper-2 (E+H) JADocumento56 páginas3107 Enthusiast Score Advanced Paper-2 (E+H) JAsonu goyalAinda não há avaliações

- Latex ProjectDocumento3 páginasLatex ProjectPrincess MiroAinda não há avaliações

- 01 Process CapabilityDocumento33 páginas01 Process CapabilitySrinivasagam Venkataramanan100% (1)

- Package Changepoint': R Topics DocumentedDocumento28 páginasPackage Changepoint': R Topics Documentedivan estevesAinda não há avaliações

- The Effects of GeoGebra Software On Pre-Service Mathematics Teachers' Attitudes and Views Toward Proof and ProvingDocumento22 páginasThe Effects of GeoGebra Software On Pre-Service Mathematics Teachers' Attitudes and Views Toward Proof and ProvingLidra Ety Syahfitri Harahap lidraety.2022Ainda não há avaliações

- Inductive Sensor For Temperature Measurement in Induction Heating Applications PDFDocumento8 páginasInductive Sensor For Temperature Measurement in Induction Heating Applications PDFNjabulo XoloAinda não há avaliações

- Oracle Ebs InstallationDocumento22 páginasOracle Ebs InstallationMr. JalilAinda não há avaliações

- BS 131-7-1998Documento21 páginasBS 131-7-1998Germán VSAinda não há avaliações

- SDH To EthernetDocumento23 páginasSDH To Ethernetpulkit_khAinda não há avaliações

- DISTANCE MEASUREMENT - Problem Solving With Theory and Objective Type QuestionsDocumento40 páginasDISTANCE MEASUREMENT - Problem Solving With Theory and Objective Type QuestionsSakuntala Uteebrirova100% (2)

- An Experimental and Statistical Study of Olfactory PreferencesDocumento7 páginasAn Experimental and Statistical Study of Olfactory Preferencesjungseong parkAinda não há avaliações

- BLM 343 Course BookDocumento966 páginasBLM 343 Course Bookarda1940Ainda não há avaliações