Escolar Documentos

Profissional Documentos

Cultura Documentos

Posi Concrete 01 Eng

Enviado por

bogdi220 notas0% acharam este documento útil (0 voto)

75 visualizações4 páginasPosi Construction, MiTek system, floor solution, wood construction

Direitos autorais

© © All Rights Reserved

Formatos disponíveis

PDF, TXT ou leia online no Scribd

Compartilhar este documento

Compartilhar ou incorporar documento

Você considera este documento útil?

Este conteúdo é inapropriado?

Denunciar este documentoPosi Construction, MiTek system, floor solution, wood construction

Direitos autorais:

© All Rights Reserved

Formatos disponíveis

Baixe no formato PDF, TXT ou leia online no Scribd

0 notas0% acharam este documento útil (0 voto)

75 visualizações4 páginasPosi Concrete 01 Eng

Enviado por

bogdi22Posi Construction, MiTek system, floor solution, wood construction

Direitos autorais:

© All Rights Reserved

Formatos disponíveis

Baixe no formato PDF, TXT ou leia online no Scribd

Você está na página 1de 4

PosiConcrete Structural Hybrid System

Structural

hybrid floor

system

MiTek Industries www.mii.com MiTek Industries

www.mii.com

MiTek Industries

www.mii.com

MiTek industries

PosiConcrete Structural Hybrid System

The basic system:

Posi joists on 600 mm center.

Bearing on bottom cord, resting on

support.

70 mm reenforced concrete floor slab.

Watertight folio to protect casing panel.

14 mm casing panel (OSB, chipborad ).

PS 10

total joist height 338 mm.

+ Top chord 51 mm wide x 76 mm

height. C24 timber.

+ Bottom chord 51mm

x 102 mm

height. C24 timber.

Details on connector:

Metal nail plate connector is pressed in

flange of top chord of Posi joist.

Connector is embeded into 70mm

concrete slab and structural connected.

Concrete caps top connectors and

reenforcement steel by 20mm.

Reenforcement rests on top of connector,

so connector positiones the steel in the

right depth in the concrete. (no spacers

needed)

Connecor sits between the posi webs.

One web space = one concrete

connector.

Structural aspects:

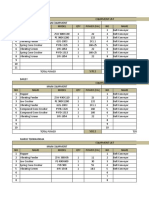

Loads and span distance applied:

Deadload

2kN (solid concrete slab +

flooring etc.) .

Traffic load 2kN (load distribution by

concrete slab in area not respected so

far => higher traffic loads possible).

Free span 6 meters using PS10 (338

mm joist heiht).

All calculations acording to EuroCode ,

DIN 1052:2008 and ETAG for Posi webs.

Conector values acording to M 20 plates

certificates.

MiTek Industries www.mii.com MiTek Industries

www.mii.com

MiTek Industries

www.mii.com

MiTek industries

PosiConcrete Structural Hybrid System

Advantages:

Advantages:

No casing system to be installed to pour

the concrete floor. Saves about 30% of

onsite labor compared to a traditional

concrete floor.

Excellent sound insulation values due to

high weight of the concrete and the

softness of a sandwich component using

different materials.

Outstanding energy saving capabilities

compared to traditional concrete floor,

due to large space between Posi joists

taking up to 300mm insulaton.

Posi-concrete

structural

sandwich

system reduces the weight of the floor by

about 50% compared to full concrete,

but offers about the same shear stiffness

and load carrying capabilities. Beneficial

especialy in seismic areas.

Installation time for

all services is

reduced by about 50% and work can be

started imedeately after installing the

floor. No downtime and delay in the

building process due to casing systems

staying in place for about 20 days.

(Hardening time for concrete)

Due to large free, unsuported span much

more space to move around or storing

building materials in a weather protected

part of the raw building. No studs

blocking ways or rooms.

Individual engineered casing + floor

system. Optimized use of material,

cambered joists to improve deflection.

MiTek Industries www.mii.com MiTek Industries

www.mii.com

Short installation time. No overhad

manual work for installling, or taking

down casing system. All components are

supplied by light crane from top.

Saves all on site time + costs for

cleaning / maintaining the casing system,

for storing the casing system, for

transporting the casing system on site

and off site.

Components can be prefabricated as

light weight floor casettes off site and

quickly topped with heavy concrete on

site. Improves precission and speed

compared to the traditional process.

Structural design software directly

interfacing with production line for Posi

joists. This means that the structural

engineer who does the detailed floor

design will automatically receive all

production data at the same time. Saves

costs + time and helps to avoid mistakes

or misunderstandings on site.

Bill of materials, production times and

quantity take offs are precise and

avaliable at the very beginning of the

building + design process for quoting,

costing, on site scheduling , on site

controll and management.

High speed production of joists. Up to

200 lfm/h => 300 m / h (spacing

600mm).

Precise installation drawings and on site

advises. Avoids mistakes and costly

misunderstandings on site.

MiTek Industries

www.mii.com

MiTek industries

PosiConcrete Structural Hybrid System

Commercial aspects:

Customer groups:

Companies who are renting out casing

systems. Sell consumabel instead of

renting out.

Sawmills who are producing casing

boards and studs. Add a timber related

product which goes into the non timber

building markets.

MiTek customers who are active in roof

trusses only. Adds a second product and

opens a new customer group.

Builders using traditional brick &

concrete. Time saving on site for

following activities.

Steel building companies. (Steel

skeleton). Much lighter floor system for

multi storey office buildings.

Prefab house industry. High quality and

sound dense floor system + extra space

for iservices + time savings installing the

services.

Glue lam and heavy timber building

companies. Much slimer and smaller

system than glue lam + excellent ratio of

weight-span-stability.

Professional casing companies. Add a

consumable casing system which can be

sold on top of the expensive on site

labor. Add value to expensive labor and

shorten on site time because the casing

does not have to be taken down and

removed.

MiTek Industries www.mii.com MiTek Industries

www.mii.com

One PCS connector sells about 2 Posi

web connectors.

1 m floor (600mm spacing) requires in

average about 3,3 PCS connectors and

6,5 Posi web connectors .

=> 2,53 Kg connectors / m

=> 395 m = 1 to connectors.

Each manufacture requires machinrey +

software + service.

Revolution press ~ 180.000,-

Strut runner press ~ 60.000,-

Splicer press

~ 12.000,-

PCS connector requires extra software

which means it could be sold as a

seperate licensed system. Charging a

basic license fee up front, like

franchising.

Using the PCS connector in design jobs

requires engineering skills which are

possibly not existent at all potential

customer groups. This offers aditional

income for MiTek design services and

external design offices.

For external design offices a special

version of software could be sold , like

the RoofCon-TrussCon design office

version. Offering aditional income and

outstanding marketing oportunities for the

PCS system as such. 3rd party external

engineering offices as multipliers to pull

projects from developers and architects.

MiTek Industries

www.mii.com

MiTek industries

Você também pode gostar

- The Yellow House: A Memoir (2019 National Book Award Winner)No EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Nota: 4 de 5 estrelas4/5 (98)

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeNo EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeNota: 4 de 5 estrelas4/5 (5794)

- The Little Book of Hygge: Danish Secrets to Happy LivingNo EverandThe Little Book of Hygge: Danish Secrets to Happy LivingNota: 3.5 de 5 estrelas3.5/5 (400)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureNo EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureNota: 4.5 de 5 estrelas4.5/5 (474)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryNo EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryNota: 3.5 de 5 estrelas3.5/5 (231)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceNo EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceNota: 4 de 5 estrelas4/5 (895)

- Team of Rivals: The Political Genius of Abraham LincolnNo EverandTeam of Rivals: The Political Genius of Abraham LincolnNota: 4.5 de 5 estrelas4.5/5 (234)

- Never Split the Difference: Negotiating As If Your Life Depended On ItNo EverandNever Split the Difference: Negotiating As If Your Life Depended On ItNota: 4.5 de 5 estrelas4.5/5 (838)

- The Emperor of All Maladies: A Biography of CancerNo EverandThe Emperor of All Maladies: A Biography of CancerNota: 4.5 de 5 estrelas4.5/5 (271)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaNo EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaNota: 4.5 de 5 estrelas4.5/5 (266)

- The Unwinding: An Inner History of the New AmericaNo EverandThe Unwinding: An Inner History of the New AmericaNota: 4 de 5 estrelas4/5 (45)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersNo EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersNota: 4.5 de 5 estrelas4.5/5 (345)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyNo EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyNota: 3.5 de 5 estrelas3.5/5 (2259)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreNo EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreNota: 4 de 5 estrelas4/5 (1090)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)No EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Nota: 4.5 de 5 estrelas4.5/5 (121)

- PDVSA Am 211 PRTDocumento10 páginasPDVSA Am 211 PRT75bm73Ainda não há avaliações

- Manual CAEPipeDocumento47 páginasManual CAEPipeClaudio GimenezAinda não há avaliações

- Crusher Equipment ListDocumento12 páginasCrusher Equipment ListTommy AndriAinda não há avaliações

- PCI Standard For Thin BrickDocumento2 páginasPCI Standard For Thin BrickJohn CarpenterAinda não há avaliações

- Anti-Vibration Pads For CNC Machines-EnglishDocumento3 páginasAnti-Vibration Pads For CNC Machines-EnglishDynemech Anti Vibration TechnologyAinda não há avaliações

- Cavitation PaperDocumento6 páginasCavitation PaperTony KadatzAinda não há avaliações

- Work As Senior Electrical Engineer/Maintenance Engineer / Design Engineer / Supervision / Qa-Qc Engineer /mep Engineer & Low Current EngineerDocumento5 páginasWork As Senior Electrical Engineer/Maintenance Engineer / Design Engineer / Supervision / Qa-Qc Engineer /mep Engineer & Low Current Engineerconsultnadeem70Ainda não há avaliações

- February2009-Errata - Hiner Seismic BookDocumento16 páginasFebruary2009-Errata - Hiner Seismic BookfdafaAinda não há avaliações

- LX3 Maintenance Manual TOE-C843-9.25BDocumento152 páginasLX3 Maintenance Manual TOE-C843-9.25Bsunhuynh100% (1)

- Overhead Bridge and Gantry Cranes Overhead Bridge and Gantry CranesDocumento8 páginasOverhead Bridge and Gantry Cranes Overhead Bridge and Gantry CranesSetyo ThreebAinda não há avaliações

- 10 Saes-Q-007..Documento23 páginas10 Saes-Q-007..engr.sulaiman0016Ainda não há avaliações

- Model MS41: 10 Amp DPDT, Hermetically SealedDocumento2 páginasModel MS41: 10 Amp DPDT, Hermetically SealedEndra BudimansyahAinda não há avaliações

- Cyient - Oil and Gas IndustryDocumento8 páginasCyient - Oil and Gas Industrycyient_analyticsAinda não há avaliações

- Alexander Elder Como Se Transformar em Um Operador e Investidor de Sucesso PDFDocumento18 páginasAlexander Elder Como Se Transformar em Um Operador e Investidor de Sucesso PDFGustavo Vasconcellos0% (1)

- M - Sanitary & Plumbing INSPECTION CHECKLISTDocumento1 páginaM - Sanitary & Plumbing INSPECTION CHECKLISTmandelaria0163% (8)

- Lab Manual - EEE18R171Documento86 páginasLab Manual - EEE18R171K.V. PrabhasAinda não há avaliações

- Design Basis TelecommunicationsDocumento36 páginasDesign Basis Telecommunicationsnknfive100% (6)

- The Self-Healing Technologies of Smart Distribution Grid PDFDocumento6 páginasThe Self-Healing Technologies of Smart Distribution Grid PDFedmuarizt7078Ainda não há avaliações

- UntitledDocumento126 páginasUntitledKarthik Raja 23Ainda não há avaliações

- Good Practices For Requirements EngineeringDocumento4 páginasGood Practices For Requirements EngineeringJessicaAinda não há avaliações

- T19101 118Documento18 páginasT19101 118Chintan Raval100% (1)

- Pore Pressure Engineering ServiceDocumento1 páginaPore Pressure Engineering ServicePaunam Rajib SinghaAinda não há avaliações

- NDT Evaluation of Rigid PavementDocumento2 páginasNDT Evaluation of Rigid PavementIJSTEAinda não há avaliações

- Ppop Bab Ii PDFDocumento44 páginasPpop Bab Ii PDFSabrinanur RamadhaniAinda não há avaliações

- Interior Designers List GurgaonDocumento53 páginasInterior Designers List GurgaonKevin HansonAinda não há avaliações

- Avoiding Plagiarism Through ParaphrasingDocumento36 páginasAvoiding Plagiarism Through ParaphrasingJan Iriesh EspinosaAinda não há avaliações

- Micropr NotesDocumento119 páginasMicropr NotesYasyrAinda não há avaliações

- As 62040.2-2008 Uninterruptible Power Systems (UPS) Electromagnetic Compatibility (EMC) RequirementsDocumento8 páginasAs 62040.2-2008 Uninterruptible Power Systems (UPS) Electromagnetic Compatibility (EMC) RequirementsSAI Global - APACAinda não há avaliações

- RoboTek Curriculum Guide (2019)Documento32 páginasRoboTek Curriculum Guide (2019)tonet enteaAinda não há avaliações

- Boq Rogacicabridge EngDocumento19 páginasBoq Rogacicabridge EngYss CastañedaAinda não há avaliações