Escolar Documentos

Profissional Documentos

Cultura Documentos

Coatings PDF

Enviado por

Gabriel Valdés AlonzoDescrição original:

Título original

Direitos autorais

Formatos disponíveis

Compartilhar este documento

Compartilhar ou incorporar documento

Você considera este documento útil?

Este conteúdo é inapropriado?

Denunciar este documentoDireitos autorais:

Formatos disponíveis

Coatings PDF

Enviado por

Gabriel Valdés AlonzoDireitos autorais:

Formatos disponíveis

Analysis of Stresses in Ti(C,N) Coatings Deposited on

WC-Co Hardmetal Cutting Tools Under Thermal Cycling

G. Valds1, C. Espinoza1, R.S. Coelho2, H. Pinto3, J. Garcia4 and E. Ramos-Moore1,*

1 Instituto de Fsica, Pontificia Universidad Catlica de Chile, Santiago, Chile.

2 Depto. de Materiais, SENAI - CIMATEC, Brazil.

3 Universidade de So Paulo, Sao Paulo, Brazil.

4 Sandvik Machining Solutions, R&D Materials & Processes, Stockholm, Sweden.

* evramos@fis.puc.cl

ABSTRACT

We analyzed the residual and thermal stresses of Ti(C,N) coatings deposited

on WC-Co cutting tools during several thermal cycles in order to reproduce

working conditions. The stress analyses were performed in-situ by energy

dispersive X-ray diffraction using a white synchrotron beam and the stresses

were determined using the sin2 method. The obtained results can support the

design of coated tools with improved properties at interrupted cutting

operations by understanding the role of thermal cycling on the stresses and

subsequent generation of cracks in Ti(C,N) coatings.

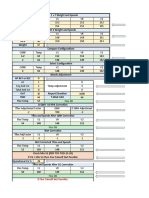

Sin2 distributions (figure 3.b) are linearly fitted to calculate the in-plane stress.

Every plane has a stress associated with the penetration of the X-rays (). As

presented in figure 3.c.

EXPERIMENTAL METHODS

Sample description. Cemented carbide cutting tool (WC-Co) coated with

hard layers of Ti(C,N) and Al2O3 (Figure 1) fabricated by chemical vapor

deposition (CVD) techniques.

Figure 1. Schematic diagram of hard coating multilayer

deposited on cutting tools by CVD techniques .

X-ray Diffraction (XRD) Analysis. Synchrotron diffraction experiments

were performed by Energy-Dispersive (ED) XRD at the material science

beam line EDDI located in the BESSY storage ring of the Helmholtz-Zentrum

Berlin, Germany.

Figure 3: a) ED-XRD spectrum. b) Sin2 distributions. c)

Stresses over thermal cycles.

Experimental data shows a strong stress gradient in the Ti(C,N) layer which

increases over thermal cycles, with an increasing tension at the Ti(C,N)-WC

interface and sight decrease at the Ti(C,N)-Al2O3 interface, with stress at the

layer center being almost constant. During heating, this stress gradient is also

evidenced and seems to increase with several thermal cycles.

Figure 2. Experimental setup of measurements at the

EDDI beam line in BESSY Synchrotron.

Energy-dispersive diffraction relies upon a polychromatic X-ray beam, which

allows for the acquisition of complete energy resolved diffraction spectra. In

the spectrum, each diffraction line () stems from a certain energy ()

level, which can in turn be related to the interplanar lattice distance () via

Braggs law (Equation 1). The sin2 method consisted in varying the angle

and obtaining the in-plane stress () as presented in Equation 2, where 0 is

the stress-free lattice parameter and 1 and 2 /2 are the diffraction

elastic constant of the analyzed layer.

0

0

0.6199

1

sin []

1

2

2 sin

2

(1)

21

CONCLUSIONS

Residual tensions tend to increase with thermal cycles, which makes the

sample prone to cracking after repeated use in working conditions. Strong

stress gradients appear in the middle Ti(C,N) layer produced by differences in

thermal expansion coefficients of the different layer materials, being bigger in

Ti(C,N)-WC interface than in Ti(C,N)-Al2O3 interface. Under this conditions,

common weight-averaged estimations are not a valid approximations of

stresses of interlayer coatings.

ACKNOWLEDGEMENTS

(2)

RESULTS AND ANALYSIS

Experimental data are resumed in Figure 3. As an example, Figure 3.a shows a

spectrum obtained by ED-XRD at a fixed angle . After determining the

intensity peaks associated with the Ti(C,N) layer, the energies of different

angles are converted to lattice distances with Equation 1.

This work was carried out in the framework of the BESSY proposal 2012-1-110859. E. RamosMoore thanks the financial support from the Project FONDECYT 11121630, Chile. H. Pinto

acknowledges the fundingof FAPESP(Process 2010/11391-2).

REFERENCES

E. Ramos Moore et al. AdvancedMaterials Research996,848854,(2014).

Ch. Genzelet al. Nuclear Instruments and Methods in Physics ResearchA578,2333,(2007).

I. C. Noyanet al. CriticalRev in SolidState & Mat Sci 20, 125177,(1995).

Você também pode gostar

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeNo EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeNota: 4 de 5 estrelas4/5 (5784)

- The Yellow House: A Memoir (2019 National Book Award Winner)No EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Nota: 4 de 5 estrelas4/5 (98)

- Never Split the Difference: Negotiating As If Your Life Depended On ItNo EverandNever Split the Difference: Negotiating As If Your Life Depended On ItNota: 4.5 de 5 estrelas4.5/5 (838)

- The Emperor of All Maladies: A Biography of CancerNo EverandThe Emperor of All Maladies: A Biography of CancerNota: 4.5 de 5 estrelas4.5/5 (271)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceNo EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceNota: 4 de 5 estrelas4/5 (890)

- The Little Book of Hygge: Danish Secrets to Happy LivingNo EverandThe Little Book of Hygge: Danish Secrets to Happy LivingNota: 3.5 de 5 estrelas3.5/5 (399)

- Team of Rivals: The Political Genius of Abraham LincolnNo EverandTeam of Rivals: The Political Genius of Abraham LincolnNota: 4.5 de 5 estrelas4.5/5 (234)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaNo EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaNota: 4.5 de 5 estrelas4.5/5 (265)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryNo EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryNota: 3.5 de 5 estrelas3.5/5 (231)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureNo EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureNota: 4.5 de 5 estrelas4.5/5 (474)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersNo EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersNota: 4.5 de 5 estrelas4.5/5 (344)

- The Unwinding: An Inner History of the New AmericaNo EverandThe Unwinding: An Inner History of the New AmericaNota: 4 de 5 estrelas4/5 (45)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyNo EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyNota: 3.5 de 5 estrelas3.5/5 (2219)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreNo EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreNota: 4 de 5 estrelas4/5 (1090)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)No EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Nota: 4.5 de 5 estrelas4.5/5 (119)

- PSP StompFilter Operation ManualDocumento26 páginasPSP StompFilter Operation ManualMoving BackwardsAinda não há avaliações

- 1 Crisp Projects: Erode Salem Madurai Trichy Kochi Bengaluru CoimbatoreDocumento20 páginas1 Crisp Projects: Erode Salem Madurai Trichy Kochi Bengaluru CoimbatoreKathir VelAinda não há avaliações

- McMurdo SART S4 v1 A4 06-13-2019Documento2 páginasMcMurdo SART S4 v1 A4 06-13-2019Felipe OliveiraAinda não há avaliações

- Public Speaking RulesDocumento12 páginasPublic Speaking RulesAnonymous 0ejRGUpmo1Ainda não há avaliações

- Telescopic sight basics and reticle typesDocumento18 páginasTelescopic sight basics and reticle typesKoala LumpurAinda não há avaliações

- Organizational Change & Development - VIL2021 - 22Documento3 páginasOrganizational Change & Development - VIL2021 - 22Rahul TRIPATHIAinda não há avaliações

- Onward Journey Ticket Details E Ticket Advance ReservationDocumento1 páginaOnward Journey Ticket Details E Ticket Advance ReservationAnonymous yorzHjDBdAinda não há avaliações

- Design TheoryDocumento2 páginasDesign Theoryhamidreza mohseniAinda não há avaliações

- Quantitative Metallography Lab Report: Grain Size and Carbon Volume FractionDocumento14 páginasQuantitative Metallography Lab Report: Grain Size and Carbon Volume FractionMhd. Didi Endah PranataAinda não há avaliações

- PGSuperDocumento71 páginasPGSuperVietanh PhungAinda não há avaliações

- Standard 2Documento10 páginasStandard 2Bridget GumboAinda não há avaliações

- Quiz 2 ReviewDocumento17 páginasQuiz 2 ReviewabubakkarAinda não há avaliações

- Murat Kenedy: Bu Içerik Tarafından HazırlanmıştırDocumento2 páginasMurat Kenedy: Bu Içerik Tarafından HazırlanmıştırChatorg. orgAinda não há avaliações

- Example4 FatigueTools WS01-SNDocumento23 páginasExample4 FatigueTools WS01-SNJosé Luciano Cerqueira CesarAinda não há avaliações

- Unit 1 Question AnswerDocumento5 páginasUnit 1 Question AnswerSubhankar BiswalAinda não há avaliações

- Ch05 - Deformation - HamrockDocumento14 páginasCh05 - Deformation - HamrockMuhammad Mansor BurhanAinda não há avaliações

- PCH (R-407C) SeriesDocumento53 páginasPCH (R-407C) SeriesAyman MufarehAinda não há avaliações

- Mapping of Significant Natural Resources: Category: Bodies of WaterDocumento3 páginasMapping of Significant Natural Resources: Category: Bodies of WaterDei HernandezAinda não há avaliações

- Hybrid Electric Bike ResearchDocumento31 páginasHybrid Electric Bike Researchmerlinson1100% (5)

- CH 07Documento40 páginasCH 07Ambreen31Ainda não há avaliações

- Chapter 3Documento12 páginasChapter 3Raymond LeoAinda não há avaliações

- Work Instruction For Coil Taping Process of EE14 (1&4 Pin)Documento6 páginasWork Instruction For Coil Taping Process of EE14 (1&4 Pin)k.mehaboob bashaAinda não há avaliações

- A320 Flex CalculationDocumento10 páginasA320 Flex CalculationMansour TaoualiAinda não há avaliações

- Eco 201Documento23 páginasEco 201Tâm TítAinda não há avaliações

- Paper 2 Answer SPMDocumento12 páginasPaper 2 Answer SPMSylarkAinda não há avaliações

- Oxford Exam Trainer: Oetmintaunit PDFDocumento2 páginasOxford Exam Trainer: Oetmintaunit PDFКатерина ПетрушевськаAinda não há avaliações

- Mastercam 8.1 Beta 4: New Verification Engine in Beta 4! Sub-Programs Post ChangesDocumento48 páginasMastercam 8.1 Beta 4: New Verification Engine in Beta 4! Sub-Programs Post ChangesSaul Saldana LoyaAinda não há avaliações

- Cylindrical Plug Gage DesignsDocumento3 páginasCylindrical Plug Gage DesignskkphadnisAinda não há avaliações

- Assignment 5: Building More Complex Tasks: 1 BackgroundDocumento3 páginasAssignment 5: Building More Complex Tasks: 1 Backgroundt_hoffmannAinda não há avaliações

- Electrical Design Analysis: 3 Storey Commercial BuildingDocumento6 páginasElectrical Design Analysis: 3 Storey Commercial Buildingcjay ganir0% (1)